Your Ultimate Guide to Sourcing 316 Stainless Stell

Introduction: Navigating the Global Market for 316 stainless stell

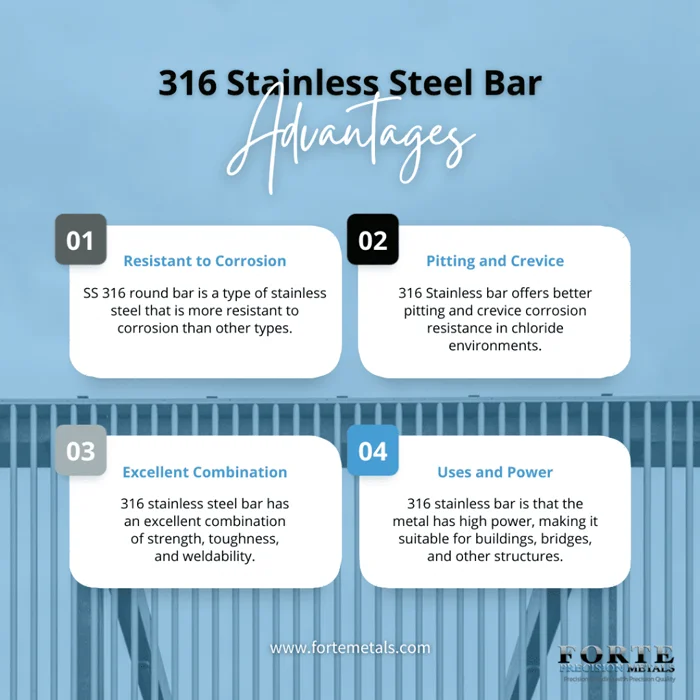

In the fast-paced world of international trade, 316 stainless steel stands out as a critical material for industries demanding high performance and durability. Renowned for its exceptional corrosion resistance, particularly in chloride-rich environments, this alloy is indispensable in sectors such as marine engineering, chemical processing, and pharmaceuticals. For B2B buyers across Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and the UAE—understanding the nuances of 316 stainless steel is essential for making informed procurement decisions.

Illustrative Image (Source: Google Search)

This comprehensive guide delves into the various types of 316 stainless steel, exploring its unique properties, sourcing strategies, and manufacturing processes. It addresses quality control standards, supplier evaluation criteria, and the cost dynamics that influence purchasing decisions. Additionally, the guide provides insights into regional market trends and practical FAQs to help buyers navigate the complexities of stainless steel sourcing.

By equipping international B2B buyers with actionable intelligence, this guide empowers you to choose the right materials for your projects, ensuring compliance with local regulations and enhancing operational efficiency. With an informed approach to sourcing 316 stainless steel, you can mitigate risks, optimize costs, and ultimately strengthen your position within the global supply chain.

Understanding 316 stainless stell Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 316 (Standard) | Contains 16% chromium, 10% nickel, and 2% molybdenum; excellent corrosion resistance | Marine hardware, chemical processing, food and pharmaceutical industries | Superior resistance to chlorides; higher cost than 304 but worth it for harsh environments |

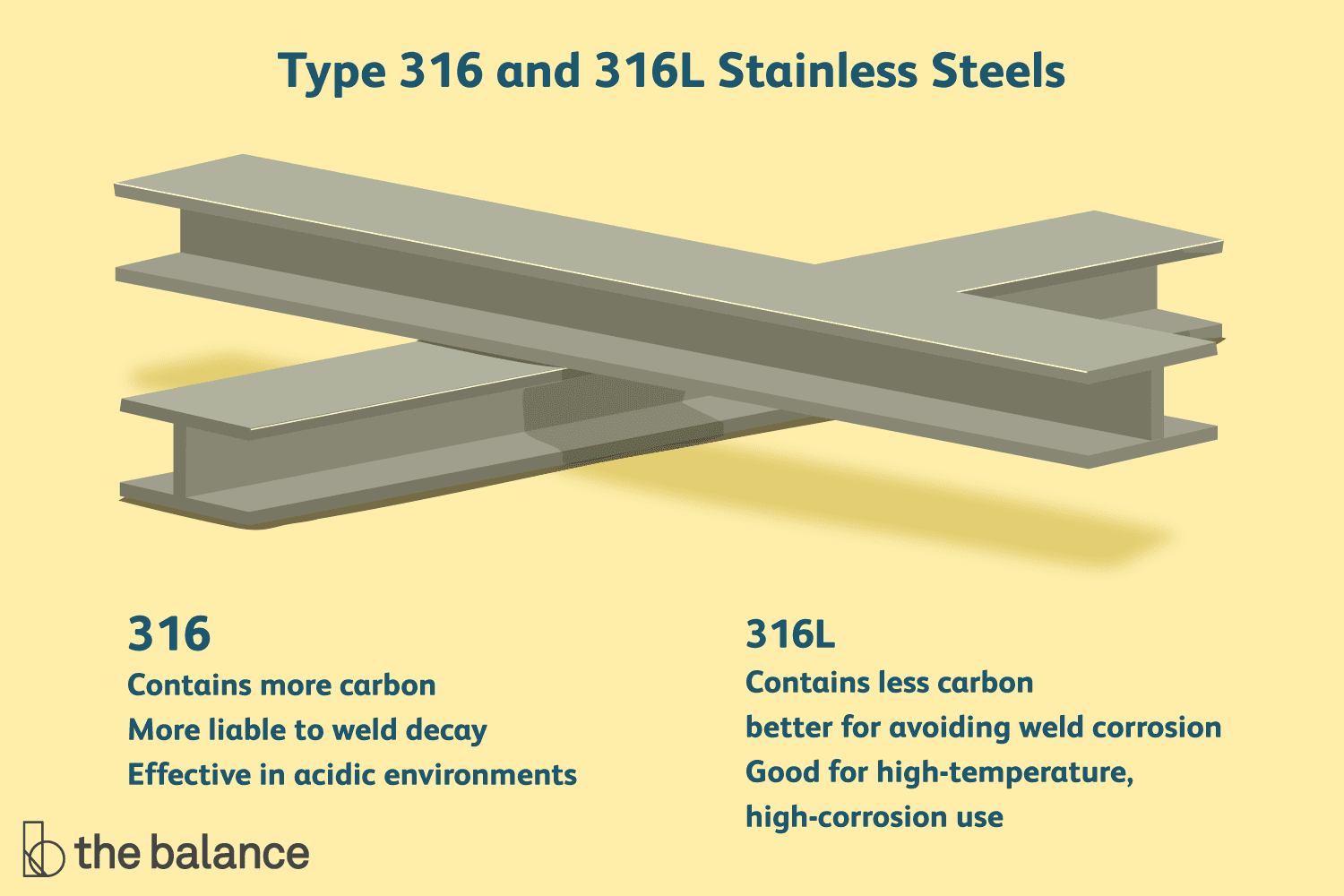

| 316L (Low Carbon) | Lower carbon content enhances weldability and reduces risk of corrosion after welding | Pharmaceutical equipment, chemical tanks, marine applications | Excellent post-weld corrosion resistance; slightly lower strength but minimizes weld decay |

| 316Ti (Titanium Stabilized) | Addition of titanium improves high-temperature stability and resistance to intergranular corrosion | High-temperature applications, chemical processing | Enhanced performance in high-stress environments; more expensive due to titanium content |

| 316H (High Carbon) | Higher carbon content for increased strength at elevated temperatures | Heat exchangers, industrial boilers | Greater strength in high-temperature settings; higher risk of sensitization without proper treatment |

| 316N (Nitrogen Enhanced) | Incorporates nitrogen for improved strength and corrosion resistance | Aerospace, marine, and chemical processing | Offers enhanced mechanical properties; may be more costly and less available than standard grades |

316 (Standard)

The standard 316 stainless steel is known for its robust composition, which includes molybdenum, enhancing its resistance to pitting and corrosion in chloride environments. This makes it ideal for marine hardware, chemical processing, and food and pharmaceutical applications. B2B buyers should consider this grade when durability against harsh chemicals and environmental conditions is essential. While it comes at a higher price point than 304, the long-term savings in maintenance and replacement costs make it a wise investment.

316L (Low Carbon)

316L is specifically designed for applications requiring extensive welding, as its lower carbon content minimizes the risk of intergranular corrosion. This variant is particularly beneficial for the pharmaceutical industry, marine applications, and chemical tanks. B2B purchasers should prioritize 316L when welding is a significant part of the fabrication process, as it ensures better performance and longevity of the welded joints, ultimately leading to reduced downtime and maintenance costs.

316Ti (Titanium Stabilized)

316Ti stainless steel incorporates titanium to enhance its high-temperature stability and resistance to intergranular corrosion. This makes it suitable for demanding environments, such as chemical processing and high-temperature applications. Buyers should consider 316Ti when operating conditions involve elevated temperatures or potential exposure to corrosive elements, as its properties significantly reduce the risk of failure. However, its higher cost compared to standard grades may require careful budget consideration.

316H (High Carbon)

The high-carbon variant, 316H, is engineered for applications that require increased strength at elevated temperatures, such as heat exchangers and industrial boilers. While it offers excellent mechanical properties, B2B buyers must be cautious of sensitization risks if not treated properly. This grade is ideal for sectors where high strength is critical, but buyers should ensure they have the necessary processing capabilities to mitigate potential corrosion issues.

316N (Nitrogen Enhanced)

316N stainless steel introduces nitrogen into its composition to enhance strength and corrosion resistance. This variant is particularly advantageous in aerospace and chemical processing applications where both mechanical strength and durability are essential. B2B buyers should weigh the benefits of its superior properties against its potentially higher cost and availability issues. Its performance in extreme conditions makes it a valuable option for specialized applications, ensuring long-term reliability.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of 316 stainless stell

| Industry/Sector | Specific Application of 316 Stainless Steel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine | Boat fittings, hardware, and hull components | Exceptional resistance to saltwater corrosion, enhancing durability and reducing maintenance costs | Verify certifications for marine-grade materials; assess local suppliers for availability and compliance with marine standards. |

| Chemical Processing | Reactors, storage tanks, and piping systems | Ensures safety and integrity in handling corrosive substances, minimizing risk of leaks and contamination | Consider suppliers with experience in chemical-grade materials; ensure compliance with regional regulations. |

| Pharmaceutical Manufacturing | Equipment for drug production and storage | Guarantees sterility and corrosion resistance, essential for maintaining product quality and safety | Source from suppliers that meet FDA and GMP standards; evaluate the traceability of materials used. |

| Food and Beverage | Processing equipment and storage solutions | Maintains hygiene and prevents contamination, critical for food safety and compliance with health regulations | Look for certifications like NSF; prioritize suppliers with a reputation in food-grade stainless steel. |

| Oil and Gas | Pipeline systems and offshore drilling equipment | Provides reliability and durability in harsh environments, reducing downtime and maintenance costs | Engage with suppliers familiar with offshore and high-pressure applications; assess the impact of local environmental conditions on material performance. |

Marine Applications

In the marine industry, 316 stainless steel is widely utilized for boat fittings, hardware, and hull components. Its superior resistance to saltwater corrosion ensures that vessels remain operational longer, with reduced maintenance costs. International B2B buyers, particularly from coastal regions in Africa and Europe, should prioritize sourcing from suppliers who can provide marine-grade certifications, guaranteeing the material’s suitability for harsh marine environments.

Chemical Processing

In chemical processing, 316 stainless steel is essential for constructing reactors, storage tanks, and piping systems. Its ability to withstand corrosive chemicals protects against leaks and contamination, ensuring safety and compliance with industry regulations. Buyers in the Middle East and South America should seek suppliers experienced in chemical-grade materials, focusing on those who adhere to stringent local safety standards to mitigate risks in their operations.

Pharmaceutical Manufacturing

The pharmaceutical sector relies heavily on 316 stainless steel for equipment used in drug production and storage. Its corrosion resistance and ease of sterilization help maintain product quality and safety, which are critical in this highly regulated industry. B2B buyers in Europe and the Middle East must source from suppliers that comply with FDA and GMP standards, ensuring traceability and quality assurance in their supply chains.

Food and Beverage

In the food and beverage industry, 316 stainless steel is employed for processing equipment and storage solutions. Its hygienic properties prevent contamination, which is crucial for adhering to health regulations. Buyers from Africa and South America should prioritize suppliers with NSF certifications, ensuring that the materials meet strict food safety standards, thereby safeguarding public health and brand integrity.

Oil and Gas

In the oil and gas sector, 316 stainless steel is utilized for pipeline systems and offshore drilling equipment. Its durability and resistance to harsh environmental conditions reduce downtime and maintenance costs, making it a reliable choice for high-stress applications. International buyers should engage with suppliers familiar with the specific demands of offshore and high-pressure operations, assessing the material’s performance under local environmental conditions.

Related Video: What Is the Difference Between 304 and 316 Stainless Steel? | Technical Tuesday

Strategic Material Selection Guide for 316 stainless stell

When selecting materials for applications involving 316 stainless steel, it is essential to consider various alloying elements and their properties. Here are some common materials that complement or serve as alternatives to 316 stainless steel, analyzed from a B2B perspective.

1. 304 Stainless Steel

Key Properties:

304 stainless steel contains 18% chromium and 8% nickel, providing good corrosion resistance in a variety of environments. However, it is less effective in chloride-rich settings compared to 316.

Pros & Cons:

304 is cost-effective and widely available, making it suitable for general applications. Its lower cost is a significant advantage for projects with budget constraints. However, it is more susceptible to pitting and crevice corrosion, particularly in marine environments, which can lead to higher maintenance costs over time.

Impact on Application:

304 is typically used in food processing, construction, and automotive applications. Its performance may be compromised in coastal areas or industries where exposure to chlorides is frequent.

Considerations for International Buyers:

Buyers in regions like Europe and the Middle East must ensure compliance with local standards such as ASTM and DIN, particularly in food and beverage applications where hygiene is critical.

2. Duplex Stainless Steel (e.g., 2205)

Key Properties:

Duplex stainless steel combines austenitic and ferritic structures, offering higher strength and improved resistance to stress corrosion cracking. It typically contains around 22% chromium, 5% nickel, and 3% molybdenum.

Pros & Cons:

Duplex stainless steel is stronger than 316, allowing for thinner sections and reduced weight in applications. However, it is more expensive and can be more challenging to weld, requiring specialized techniques.

Impact on Application:

Ideal for oil and gas, chemical processing, and marine environments, duplex stainless steel can handle high-pressure applications better than 316. Its high strength-to-weight ratio makes it suitable for applications where weight reduction is essential.

Considerations for International Buyers:

When sourcing duplex stainless steel, buyers should be aware of the specific welding requirements and ensure that suppliers meet international standards, particularly in regions with stringent quality control measures.

3. Nickel Alloys (e.g., Inconel 625)

Key Properties:

Nickel alloys like Inconel 625 exhibit exceptional resistance to high temperatures and corrosive environments, particularly in acidic conditions. They are often used in extreme environments where 316 would fail.

Pros & Cons:

These alloys are highly durable and maintain their strength at elevated temperatures. However, they come at a significantly higher cost and can be more complex to machine and fabricate.

Impact on Application:

Nickel alloys are often used in aerospace, chemical processing, and marine applications where exposure to harsh environments is common. Their superior performance justifies the higher investment in critical applications.

Considerations for International Buyers:

Buyers must consider the availability of nickel alloys in their region and the associated costs. Compliance with international standards for aerospace and chemical applications is also crucial.

4. Titanium Alloys

Key Properties:

Titanium alloys are known for their excellent strength-to-weight ratio and outstanding corrosion resistance, particularly in chloride environments. They are significantly lighter than stainless steel.

Pros & Cons:

While titanium offers exceptional performance, it is considerably more expensive than 316 stainless steel and can be challenging to weld and machine. This limits its use to high-performance applications.

Impact on Application:

Titanium is ideal for aerospace, marine, and medical applications where weight and corrosion resistance are critical. Its use can lead to longer-lasting components with lower maintenance needs.

Considerations for International Buyers:

Buyers must evaluate the cost-benefit ratio of using titanium in their applications and ensure that their suppliers can meet stringent quality and compliance standards.

Summary Table

| Material | Typical Use Case for 316 stainless steel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 304 Stainless Steel | Food processing, construction, automotive | Cost-effective and widely available | Less resistant to chlorides | Low |

| Duplex Stainless Steel | Oil and gas, chemical processing, marine | Higher strength and corrosion resistance | More expensive and complex to weld | High |

| Nickel Alloys | Aerospace, chemical processing, marine | Exceptional high-temperature resistance | High cost and machining complexity | High |

| Titanium Alloys | Aerospace, marine, medical | Excellent strength-to-weight ratio | Very high cost and difficult to machine | High |

This guide provides a comprehensive overview of materials relevant to 316 stainless steel, enabling international B2B buyers to make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 316 stainless stell

The manufacturing processes and quality assurance for 316 stainless steel are critical components in ensuring that the final products meet the stringent demands of various industries. Understanding these processes can empower B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, to make informed purchasing decisions.

Manufacturing Processes for 316 Stainless Steel

The production of 316 stainless steel involves several key stages, each requiring precision and adherence to quality standards. Here’s an overview of the typical manufacturing steps:

1. Material Preparation

The first step in manufacturing 316 stainless steel is the preparation of raw materials. This includes:

- Sourcing: The primary materials include iron ore, chromium, nickel, and molybdenum. B2B buyers should consider suppliers who can provide these materials sustainably and reliably.

- Melting: The raw materials are melted in an electric arc furnace (EAF). This method allows for precise control of temperature and composition.

- Refining: The molten steel is refined to remove impurities, ensuring the desired chemical composition is achieved.

2. Forming

Once the steel is prepared, the next stage is forming, which involves shaping the material into the desired forms. Key techniques include:

- Casting: The molten steel is poured into molds to create slabs, billets, or other shapes. Continuous casting is often used for higher efficiency.

- Rolling: The cast material is then rolled into sheets, plates, or coils. Hot rolling is typically employed to achieve the desired thickness and surface finish.

- Cold Working: For certain applications, cold working processes (e.g., cold rolling, drawing) are used to enhance mechanical properties and achieve tighter tolerances.

3. Assembly

For products that require multiple components, assembly is an essential phase:

- Welding: Techniques such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding are used to join parts. The low carbon variant, 316L, is often preferred for its superior weldability.

- Machining: Precision machining is employed to achieve final dimensions and surface finishes. This includes processes like turning, milling, and grinding.

4. Finishing

Finishing processes enhance the appearance and performance of the stainless steel:

- Pickling and Passivation: These chemical treatments remove surface oxides and enhance corrosion resistance. They are particularly important for 316 stainless steel due to its applications in corrosive environments.

- Surface Treatments: Various treatments, such as polishing or coating, can be applied to improve aesthetic appeal and further protect against corrosion.

Quality Assurance in Manufacturing

Quality assurance (QA) is vital in the production of 316 stainless steel, ensuring that the material meets international and industry-specific standards. Here’s how QA is typically structured:

International Standards

B2B buyers should be aware of the following key standards that govern the quality of stainless steel production:

- ISO 9001: This is the international standard for quality management systems. Compliance indicates that the manufacturer has processes in place to ensure consistent quality.

- CE Marking: Particularly relevant for products sold in the European market, CE marking demonstrates that the product meets EU safety, health, and environmental protection standards.

- API Standards: For industries such as oil and gas, compliance with API standards (American Petroleum Institute) ensures that the materials are suitable for high-pressure and high-temperature applications.

Quality Control Checkpoints

Quality control (QC) is implemented at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards. This step is crucial for maintaining the integrity of the final product.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor processes and detect any deviations from established standards.

- Final Quality Control (FQC): Once production is complete, finished products undergo rigorous testing and inspection to verify that they meet all specifications.

Common Testing Methods

Several testing methods are employed to ensure the quality of 316 stainless steel:

- Chemical Analysis: Spectrometry is used to verify the chemical composition of the steel, ensuring it meets the required standards.

- Mechanical Testing: Tensile strength, hardness, and impact tests assess the material’s mechanical properties.

- Corrosion Testing: Tests such as salt spray and pitting resistance tests evaluate how well the stainless steel will perform in corrosive environments.

Verifying Supplier Quality Control

For international B2B buyers, verifying the quality control measures of suppliers is essential. Here are some actionable insights:

- Supplier Audits: Conducting audits of suppliers’ facilities can provide insight into their quality management systems and manufacturing processes.

- Quality Reports: Requesting detailed quality reports that outline testing results, compliance with standards, and any certifications can help assess supplier reliability.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of product quality before shipment. This is particularly important for high-stakes industries such as aerospace and pharmaceuticals.

QC and Certification Nuances for International Buyers

B2B buyers from diverse regions must navigate various certification requirements. Here are some considerations:

- Regional Regulations: Understand local regulations and standards that may affect the use of 316 stainless steel in your industry. For instance, the EU has stringent regulations regarding materials used in food and medical applications.

- Certifications: Look for suppliers who can provide specific certifications (e.g., EN 10204 3.1, which confirms that the materials meet specified requirements) to ensure compliance with international standards.

- Cultural Considerations: Be aware that quality expectations can vary by region. For example, buyers in Europe may have different demands regarding traceability and sustainability compared to those in Africa or South America.

By understanding the manufacturing processes and quality assurance mechanisms for 316 stainless steel, international B2B buyers can make informed decisions, ensuring that the materials they procure meet their operational needs and compliance requirements. This knowledge not only helps in selecting the right suppliers but also in negotiating better terms and ensuring long-term project success.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for 316 stainless stell Sourcing

When sourcing 316 stainless steel, international B2B buyers must navigate a complex cost structure that encompasses various components. Understanding these components and the factors that influence pricing is crucial for making informed procurement decisions.

Cost Components

-

Materials: The primary cost driver for 316 stainless steel is the raw materials used in its production, specifically nickel, chromium, and molybdenum. Prices for these metals fluctuate based on global supply and demand dynamics. For instance, nickel prices can be influenced by mining output from countries like Indonesia and the Philippines, while chromium is primarily sourced from South Africa.

-

Labor: Labor costs vary significantly depending on the region. Countries with higher wages may see increased labor costs in manufacturing, impacting overall pricing. Buyers should consider sourcing from regions where labor costs are more competitive, particularly when engaging with suppliers in Africa or South America.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and other operational expenses. Efficient production processes can help mitigate overhead costs, leading to more competitive pricing.

-

Tooling: The cost of tooling is an important factor, especially for customized orders. Initial setup costs can be substantial, but they are amortized over larger production runs, making high-volume orders more cost-effective per unit.

-

Quality Control (QC): Ensuring product quality can add to the cost. Rigorous QC processes are essential, particularly for industries such as pharmaceuticals and marine applications, where compliance with international standards is critical.

-

Logistics: Shipping and handling costs can significantly affect the final price, especially for international transactions. Factors such as distance, shipping method, and tariffs can influence logistics costs. Buyers should consider the most efficient shipping routes and methods to minimize these expenses.

-

Margin: Supplier profit margins can vary widely based on market competition and the supplier’s position within the supply chain. Understanding the typical margins in different regions can help buyers negotiate better pricing.

Price Influencers

-

Volume/MOQ: The volume of the order, or Minimum Order Quantity (MOQ), plays a crucial role in pricing. Larger orders often lead to bulk pricing discounts, which can significantly reduce the per-unit cost.

-

Specifications/Customization: Customization requirements such as specific dimensions, finishes, or additional certifications can drive up costs. Buyers should clearly define their specifications to avoid unexpected charges.

-

Quality/Certifications: Products that meet specific quality standards or certifications (e.g., ISO, ASTM) may come at a premium. However, investing in certified materials can lead to long-term savings by reducing failure rates and maintenance costs.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their track record of quality and service, while newer suppliers might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect pricing by determining who bears the costs and risks during shipping. For example, Ex Works (EXW) pricing may be lower, but buyers must consider additional logistics costs.

Buyer Tips

-

Negotiation: Effective negotiation can yield better pricing. Building long-term relationships with suppliers can also lead to more favorable terms and conditions.

-

Cost-Efficiency: Consider total cost of ownership (TCO) rather than just the initial purchase price. This includes maintenance, operational costs, and potential savings from reduced downtime.

-

Pricing Nuances: Be aware of regional pricing differences. For example, suppliers in Europe may have higher costs due to stricter regulations, while suppliers in Africa may offer competitive pricing due to lower labor costs.

-

Market Trends: Stay informed about market trends affecting raw material prices. This knowledge can provide leverage during negotiations and help anticipate future price changes.

Disclaimer

Prices for 316 stainless steel can vary widely based on market conditions, specifications, and supplier factors. The information provided is indicative and should be validated through direct inquiries with suppliers.

Spotlight on Potential 316 stainless stell Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘316 stainless stell’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for 316 stainless stell

Key Technical Properties of 316 Stainless Steel

Understanding the critical specifications of 316 stainless steel is essential for B2B buyers to ensure they select the right material for their projects. Here are the key properties that define this grade:

-

Material Grade:

316 stainless steel is classified under the AISI (American Iron and Steel Institute) system as austenitic stainless steel. Its composition includes approximately 16% chromium, 10% nickel, and 2% molybdenum. The presence of molybdenum significantly enhances its resistance to pitting and crevice corrosion, particularly in chloride environments, making it ideal for marine and chemical applications. -

Tensile Strength:

The tensile strength of 316 stainless steel typically ranges from 70,000 to 90,000 psi (pounds per square inch). This property is crucial for applications requiring durability under stress, such as construction and marine fittings. Buyers should consider tensile strength when evaluating the suitability of materials for high-load applications. -

Yield Strength:

Yield strength measures the maximum stress that a material can withstand without permanent deformation. For 316 stainless steel, the yield strength is around 30,000 psi. This characteristic is vital for B2B buyers in industries like oil and gas, where materials must maintain integrity under high pressure. -

Corrosion Resistance:

One of the standout features of 316 stainless steel is its superior corrosion resistance, particularly against chlorides and acidic environments. This property is fundamental for industries such as pharmaceuticals and food processing, where material integrity is critical to safety and compliance. -

Weldability:

316 stainless steel exhibits good weldability, especially in its low-carbon variant (316L), which minimizes the risk of intergranular corrosion during welding. This aspect is particularly important for B2B buyers involved in manufacturing and fabrication processes, as it affects the ease of assembly and long-term durability of welded structures. -

Thermal Conductivity:

Although stainless steel is not known for high thermal conductivity, 316 provides adequate performance for applications involving heat exchange. Understanding thermal properties can help buyers select appropriate materials for specific environmental conditions.

Common Trade Terminology

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B environment. Below are some essential terms related to the procurement of 316 stainless steel:

-

OEM (Original Equipment Manufacturer):

This term refers to companies that manufacture products or components that are used in another company’s end product. For buyers, understanding who the OEM is can influence quality assurance and warranty considerations. -

MOQ (Minimum Order Quantity):

MOQ represents the smallest number of units a supplier is willing to sell. Buyers should be aware of MOQs to plan their purchases effectively and avoid excess inventory costs. -

RFQ (Request for Quotation):

An RFQ is a document sent to suppliers requesting pricing and terms for specific quantities of products. It is an essential step in the procurement process, allowing buyers to compare offers and negotiate better terms. -

Incoterms (International Commercial Terms):

These are standardized trade terms used in international contracts that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is vital for B2B buyers to manage logistics effectively and mitigate risks in cross-border transactions. -

Lead Time:

This refers to the amount of time from placing an order to receiving it. For B2B buyers, knowing the lead time is essential for project planning and ensuring timely delivery of materials. -

Certification:

This term relates to the documentation that verifies a product meets specific standards and regulations. Buyers should prioritize suppliers who provide relevant certifications for 316 stainless steel to ensure compliance with industry standards and enhance product reliability.

Illustrative Image (Source: Google Search)

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that enhance project success and operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 316 stainless stell Sector

Market Overview & Key Trends

The global market for 316 stainless steel is primarily driven by increasing demand in industries such as marine, chemical processing, and pharmaceuticals. As urbanization progresses in regions like Africa and South America, the need for durable construction materials is escalating. Moreover, the Middle East’s expanding industrial sector, particularly in oil and gas, further fuels the demand for corrosion-resistant materials.

Emerging B2B technologies are reshaping sourcing trends. Digital platforms for procurement are becoming popular, allowing buyers to access real-time pricing, inventory levels, and supplier capabilities. This shift is particularly beneficial for international buyers from Europe and the Middle East, as it enhances the transparency and efficiency of the sourcing process. Additionally, advanced data analytics and AI are helping companies forecast demand more accurately and optimize supply chain operations.

Another notable trend is the growing emphasis on local sourcing. In regions like Africa and South America, buyers are increasingly prioritizing suppliers that can provide shorter lead times and lower shipping costs. This shift not only reduces carbon footprints but also supports local economies. Overall, international B2B buyers must remain agile and informed about these trends to make strategic sourcing decisions in the 316 stainless steel market.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a central pillar in the sourcing of 316 stainless steel, driven by both regulatory pressures and consumer expectations. The production of stainless steel has a significant environmental impact, particularly in terms of energy consumption and raw material extraction. Therefore, buyers are increasingly looking for suppliers that demonstrate a commitment to reducing their carbon footprint through sustainable practices.

Ethical sourcing is equally important, as it ensures that materials are procured in a manner that respects human rights and promotes fair labor practices. Certifications such as ISO 14001 for environmental management systems and ISO 45001 for occupational health and safety are critical for suppliers aiming to demonstrate their commitment to sustainability and ethical practices.

Furthermore, the use of recycled materials in producing 316 stainless steel is gaining traction. Buyers can enhance their sustainability profiles by opting for suppliers that utilize scrap metal and other recycled materials in their production processes. This not only reduces the environmental impact but also helps in meeting the growing demand for ‘green’ certifications from end-users, particularly in Europe and other environmentally conscious markets.

Brief Evolution/History

The development of 316 stainless steel can be traced back to the mid-20th century when it was formulated to withstand the corrosive effects of chloride environments, particularly in marine applications. Its unique composition, which includes molybdenum, was a significant advancement over its predecessor, 304 stainless steel, which struggled in highly corrosive conditions. Over the decades, 316 has become a standard material in various industries, including pharmaceuticals, food processing, and construction, due to its durability and resistance to corrosion.

As international trade expanded, the sourcing of 316 stainless steel evolved, with countries like China and India emerging as major producers. This evolution has allowed B2B buyers across diverse regions—including Africa, South America, the Middle East, and Europe—to access high-quality materials that meet stringent industrial standards, ultimately shaping the global supply chain dynamics in the stainless steel sector.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of 316 stainless stell

-

What criteria should I use to vet suppliers of 316 stainless steel?

When vetting suppliers, consider their industry reputation, certifications (such as ISO 9001), and experience in exporting to your region. Check for references from previous clients and evaluate their product quality through samples. Understand their production capacity and whether they can meet your specific needs, including technical specifications and customization options. Additionally, assess their financial stability to ensure they can fulfill large orders and support ongoing supply needs. -

Can I request custom specifications for 316 stainless steel products?

Yes, many suppliers offer customization options for 316 stainless steel products. When requesting custom specifications, provide detailed requirements including dimensions, tolerances, and any specific coatings or treatments needed. Ensure that the supplier has the capability to meet these specifications and ask for previous examples of customized work. This will help ensure that your project requirements are met without compromising on quality. -

What are the typical minimum order quantities (MOQ) and lead times for 316 stainless steel?

MOQs for 316 stainless steel can vary widely depending on the supplier and product type, typically ranging from 500 kg to several tons. Lead times also depend on the order size and supplier capabilities, generally ranging from 4 to 12 weeks. When negotiating, communicate your project timelines clearly to the supplier. It’s advisable to confirm these details in writing to prevent any misunderstandings later. -

How do I ensure quality assurance and certifications for my 316 stainless steel orders?

Request relevant quality assurance certifications from suppliers, such as ASTM or EN standards, to ensure compliance with international quality benchmarks. Ask for mill test reports (MTRs) that detail the chemical and mechanical properties of the steel. Conduct periodic audits or inspections, either personally or through a third-party service, especially for large orders. This helps verify that the products meet your specifications and quality expectations. -

What payment terms are commonly accepted for international orders of 316 stainless steel?

Payment terms can vary by supplier and may include options like advance payment, letter of credit, or payment upon delivery. For international transactions, using a letter of credit can provide security for both parties, ensuring that payment is released only after compliance with agreed terms. Discuss payment terms during initial negotiations and ensure they align with your financial processes to avoid cash flow issues. -

What logistics considerations should I keep in mind when sourcing 316 stainless steel?

When sourcing internationally, consider shipping methods, costs, and import duties that may apply. Ensure that the supplier has experience in exporting to your region and can provide necessary shipping documentation, such as bills of lading and customs declarations. Plan for potential delays in transit and customs clearance, and consider purchasing insurance for high-value shipments to mitigate risks. -

How can I handle disputes with suppliers regarding 316 stainless steel orders?

To manage disputes effectively, maintain clear communication with your supplier throughout the order process. Document all agreements, specifications, and correspondences to have a record in case of disagreements. If issues arise, approach the supplier for resolution first; if unresolved, refer to the terms outlined in your contract regarding dispute resolution. Consider mediation or arbitration as a way to settle disputes without resorting to litigation. -

What are the common applications for 316 stainless steel in my industry?

316 stainless steel is widely used in industries such as marine, chemical processing, and pharmaceuticals due to its superior corrosion resistance. In the marine sector, it is ideal for boat fittings and coastal structures. In chemical processing, it’s used for tanks and piping that handle corrosive substances. Understanding the specific applications relevant to your industry will help you justify the investment in 316 stainless steel and ensure compliance with industry standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 316 stainless stell

The strategic sourcing of 316 stainless steel is a pivotal decision for international B2B buyers operating across diverse regions such as Africa, South America, the Middle East, and Europe. Understanding the superior properties of 316, especially its enhanced corrosion resistance and durability, allows businesses to ensure the longevity and reliability of their applications, particularly in challenging environments like marine or chemical processing sectors.

Key takeaways for buyers include recognizing the balance between upfront costs and long-term savings, as investing in 316 stainless steel can significantly reduce maintenance and replacement expenses over time. Moreover, sourcing from reputable suppliers with robust quality assurance processes is essential to ensure compliance with local and international standards.

As global supply chains continue to evolve, strategic sourcing will remain critical. By prioritizing high-quality materials like 316 stainless steel, businesses can not only enhance operational efficiency but also reinforce their competitive edge in the marketplace.

Looking ahead, now is the time to reassess your sourcing strategies. Engage with suppliers who understand the unique challenges of your region and can provide tailored solutions. Embrace the opportunity to optimize your procurement processes to drive sustainability and profitability in your projects.