Master Sourcing Strategies for Toroid Inductor Procurement

Introduction: Navigating the Global Market for toroid inductor

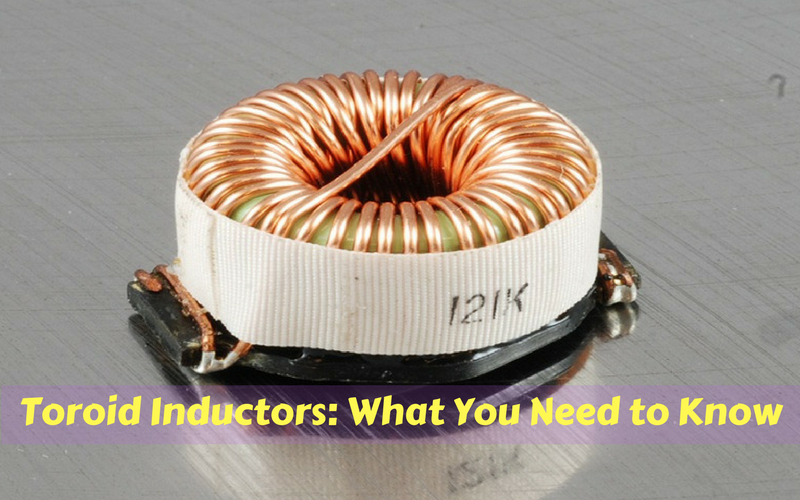

In today’s rapidly evolving electronics landscape, toroid inductors are crucial components that offer exceptional efficiency and performance across various applications. Their unique doughnut-shaped design not only minimizes electromagnetic interference (EMI) but also enhances energy storage capabilities, making them indispensable in sectors such as telecommunications, automotive electronics, and consumer devices. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of toroid inductors is essential for making informed purchasing decisions.

This comprehensive guide delves into the diverse types of toroid inductors, the materials used in their construction, and the manufacturing and quality control processes that ensure reliability. It also highlights key suppliers and provides insights into cost structures, market trends, and potential challenges in sourcing. Furthermore, the guide addresses frequently asked questions, equipping buyers with the knowledge needed to navigate the complexities of the global market.

By leveraging this resource, B2B buyers can empower themselves with actionable insights that facilitate better sourcing strategies, optimize component selection, and ultimately enhance the performance of their electronic products. Whether you are in Egypt, Colombia, or elsewhere, this guide serves as a valuable tool to navigate the intricate landscape of toroid inductors, ensuring that your procurement decisions are both strategic and informed.

Understanding toroid inductor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ferrite Toroidal Inductor | Made from ferrite materials; high inductance; low losses at high frequencies | Power supplies, RF applications | Pros: High efficiency, compact design. Cons: Sensitive to heat, limited current capacity. |

| Iron Powder Toroidal Inductor | Composed of iron powder; better for high current applications | Audio equipment, DC-DC converters | Pros: Handles high currents well. Cons: Larger size, higher core losses at high frequencies. |

| Air Core Toroidal Inductor | No magnetic core; uses air as a medium; low inductance values | High-frequency applications, RF circuits | Pros: Low distortion, high linearity. Cons: Larger and less efficient for low frequencies. |

| Multi-Layer Toroidal Inductor | Features multiple layers of windings; compact design; higher inductance | Telecommunications, compact devices | Pros: Space-saving, higher inductance. Cons: More complex manufacturing, potentially higher cost. |

| Custom Toroidal Inductor | Tailored specifications for specific applications; can vary in materials and design | Specialized industrial applications | Pros: Optimized performance for specific needs. Cons: Longer lead times, potentially higher costs. |

Ferrite Toroidal Inductor

Ferrite toroidal inductors are constructed from ferrite materials, offering high inductance and low losses, especially at high frequencies. They are ideal for applications in power supplies and RF equipment, where efficiency is crucial. For B2B buyers, the compact design and efficiency are significant advantages; however, they can be sensitive to heat and may have limited current capacity, necessitating careful thermal management in application designs.

Iron Powder Toroidal Inductor

Iron powder toroidal inductors are designed for high current applications and are commonly used in audio equipment and DC-DC converters. These inductors excel in handling high currents, making them suitable for demanding environments. Buyers should note that while they can manage higher currents, they tend to be larger and may exhibit higher core losses at elevated frequencies, impacting overall efficiency.

Air Core Toroidal Inductor

Air core toroidal inductors utilize air as the medium, resulting in low inductance values. They are particularly suited for high-frequency applications, such as RF circuits, due to their minimal distortion and high linearity. While they provide excellent performance in specific applications, their larger size and reduced efficiency at low frequencies may limit their use in compact electronic designs.

Multi-Layer Toroidal Inductor

Multi-layer toroidal inductors feature several layers of windings, allowing for a compact design with higher inductance values. This type is prevalent in telecommunications and compact electronic devices, where space optimization is critical. Buyers can benefit from their space-saving features, but the complexity of manufacturing may lead to higher costs and longer lead times, necessitating strategic sourcing considerations.

Custom Toroidal Inductor

Custom toroidal inductors are designed to meet specific application requirements, allowing for variations in materials, design, and specifications. They are particularly beneficial for specialized industrial applications where standard inductors may not suffice. While they offer optimized performance tailored to unique needs, buyers should prepare for potentially longer lead times and higher costs, making them suitable for projects with specific performance criteria.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of toroid inductor

| Industry/Sector | Specific Application of toroid inductor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Signal processing in telecom equipment | Reduces electromagnetic interference (EMI) for clearer signals | Compliance with international standards and reliability testing |

| Automotive Electronics | Power management in electric vehicles (EVs) | Enhances efficiency and reliability of power systems | Customization for high current applications and environmental conditions |

| Consumer Electronics | Power supply units for compact devices | Provides compact design with high inductance values | Sourcing from manufacturers with stringent quality controls |

| Industrial Automation | Motor drive applications in automation systems | Improves energy efficiency and reduces noise | Availability of specific inductance ratings and core materials |

| Renewable Energy | Energy storage systems in solar inverters | Maximizes energy conversion efficiency | Consideration of temperature stability and long-term performance |

Telecommunications

In the telecommunications sector, toroidal inductors are crucial for signal processing in various equipment, such as routers and base stations. Their design minimizes electromagnetic interference (EMI), which is vital for maintaining signal integrity and improving communication quality. B2B buyers should ensure that the suppliers can meet international standards for electromagnetic compatibility and provide reliable testing results to guarantee product performance.

Automotive Electronics

Toroidal inductors play a significant role in power management systems within electric vehicles (EVs). They contribute to efficient energy conversion, which is essential for the overall performance and reliability of EVs. Buyers in this sector must seek out suppliers capable of customizing inductors to handle high current applications and varying environmental conditions, ensuring the inductors can withstand the rigors of automotive use.

Consumer Electronics

In consumer electronics, toroidal inductors are commonly used in power supply units for compact devices such as smartphones and tablets. Their compact design allows manufacturers to create smaller, more efficient products without sacrificing performance. International buyers should prioritize sourcing from manufacturers that adhere to stringent quality controls to ensure product reliability and longevity, especially given the competitive nature of the consumer electronics market.

Industrial Automation

For industrial automation, toroidal inductors are integral to motor drive applications, enhancing energy efficiency while minimizing noise. These inductors help control the power supplied to motors, ensuring smooth operation in automated systems. Buyers should focus on sourcing inductors with specific inductance ratings and core materials that meet their operational requirements, as these factors significantly impact the overall efficiency of automation systems.

Renewable Energy

In the renewable energy sector, toroidal inductors are utilized in energy storage systems, particularly within solar inverters. Their ability to maximize energy conversion efficiency is critical for the performance of solar power systems. B2B buyers in this industry need to consider the temperature stability and long-term performance of the inductors, as these attributes are vital for ensuring reliable operation in various environmental conditions.

Related Video: TOROID

Strategic Material Selection Guide for toroid inductor

When selecting materials for toroidal inductors, international B2B buyers must consider several factors that affect performance, cost, and application suitability. Below is an analysis of four common materials used in the manufacturing of toroidal inductors, highlighting their key properties, advantages, disadvantages, and specific considerations for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

1. Ferrite

Key Properties: Ferrite materials exhibit high magnetic permeability and low electrical conductivity, which minimizes eddy current losses. They are effective in high-frequency applications, typically rated for temperatures up to 130°C.

Pros & Cons: Ferrite cores are lightweight and can be produced at a relatively low cost. However, they are brittle and can be challenging to manufacture into complex shapes. Their performance can degrade at higher temperatures, limiting their use in some environments.

Impact on Application: Ferrite is particularly suitable for applications requiring low noise and high efficiency, such as in power supplies and RF applications. However, they are less effective in high-power applications due to saturation effects.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN, especially in regions with stringent electronic component regulations. The availability of ferrite materials can vary, so sourcing from reliable manufacturers is crucial.

2. Iron Powder

Key Properties: Iron powder cores provide good magnetic properties with a higher saturation flux density than ferrite. They can operate effectively in temperatures up to 150°C and are often used in applications requiring high inductance.

Pros & Cons: The primary advantage of iron powder is its robustness and ability to handle higher power levels. However, they can be more expensive than ferrite and may require more complex manufacturing processes.

Impact on Application: Iron powder cores are ideal for applications involving power electronics and energy storage systems, where high inductance is critical. Their performance in high-frequency applications may not be as effective as ferrite.

Considerations for International Buyers: Buyers should be aware of the varying quality of iron powder materials available globally. Compliance with local and international standards is essential, particularly in Europe and the Middle East, where regulations are stringent.

3. Laminated Steel

Key Properties: Laminated steel cores consist of thin sheets of steel insulated from each other, which reduces eddy current losses. They are typically rated for high temperatures, making them suitable for various applications.

Pros & Cons: Laminated steel is durable and can handle high current loads effectively. However, they are heavier and bulkier than other materials, which may not be suitable for compact applications.

Impact on Application: This material is commonly used in transformers and inductors in industrial applications where size is less of a concern but power handling is critical.

Considerations for International Buyers: Buyers in regions like South America and Africa should consider the availability of laminated steel and its compliance with local manufacturing standards. Cost considerations are also important, as laminated steel can be more expensive than ferrite or iron powder.

4. Powdered Iron

Key Properties: Powdered iron cores are made from iron particles that are compacted and sintered, offering good magnetic performance with lower losses than solid iron cores. They typically operate effectively at temperatures up to 120°C.

Pros & Cons: They provide a good balance between cost and performance, making them versatile for various applications. However, their performance can be limited at very high frequencies, and they may not be as durable as laminated steel.

Impact on Application: Powdered iron is suitable for applications in audio equipment and low-frequency power supplies where moderate inductance and efficiency are required.

Considerations for International Buyers: Buyers should evaluate the sourcing and quality of powdered iron materials, especially in regions with fluctuating supply chains. Compliance with international standards is also crucial for ensuring product reliability.

Summary Table

| Material | Typical Use Case for toroid inductor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Ferrite | Power supplies, RF applications | Lightweight, low cost | Brittle, limited high-temperature use | Low |

| Iron Powder | Power electronics, energy storage | High inductance, robust | More expensive, complex manufacturing | Medium |

| Laminated Steel | Industrial transformers | Durable, handles high loads | Heavier, bulkier | High |

| Powdered Iron | Audio equipment, low-frequency supplies | Good balance of cost and performance | Limited high-frequency performance | Medium |

This guide provides a strategic overview for B2B buyers to make informed decisions about material selection for toroidal inductors, considering both performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for toroid inductor

Manufacturing Processes for Toroid Inductors

The manufacturing of toroid inductors involves a series of meticulous steps that ensure both performance and reliability. Understanding these processes can help international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, make informed purchasing decisions.

1. Material Preparation

The first stage in the manufacturing process focuses on selecting and preparing the right materials. Toroid inductors are typically made from magnetic materials such as ferrite, iron powder, or powdered iron.

Illustrative Image (Source: Google Search)

- Selection of Core Material: The choice of core material significantly affects the inductor’s performance characteristics, including inductance value, saturation flux density, and temperature stability.

- Wire Selection: Insulated copper wire is commonly used for winding, chosen based on current carrying capacity and resistance.

2. Forming

Once materials are prepared, the next step is forming the core and winding the wire.

- Core Shaping: The magnetic core is shaped into a toroidal (doughnut) form using precise machining or molding techniques. This shape is critical as it helps in containing the magnetic field and reducing electromagnetic interference (EMI).

- Winding Process: The insulated wire is wound around the toroidal core using automated winding machines. The winding technique, including the number of turns and the tension applied, must be consistent to ensure uniform inductance.

3. Assembly

After forming, the assembly stage involves combining the wound core with other components, if necessary.

- Connecting Leads: The ends of the wire are connected to external terminals, which may involve soldering or crimping techniques. Care must be taken to ensure strong, reliable connections that can withstand thermal and mechanical stress.

- Integration with Other Components: In some cases, toroidal inductors are integrated into larger assemblies or circuits, requiring careful handling to avoid damage.

4. Finishing

The final stage of manufacturing involves finishing processes that enhance the inductor’s durability and performance.

- Coating: A protective coating may be applied to prevent corrosion and environmental damage. This is particularly important for inductors used in harsh conditions.

- Labeling and Packaging: Proper labeling with specifications, including inductance value and current rating, is essential for traceability. Packaging must protect the inductors during transportation and storage.

Quality Assurance Processes

Quality assurance (QA) is critical in the manufacturing of toroidal inductors to ensure they meet international standards and customer expectations.

International Standards

B2B buyers should look for manufacturers that adhere to recognized quality standards, such as:

- ISO 9001: This standard outlines requirements for a quality management system, ensuring consistent product quality and customer satisfaction.

- CE Marking: This indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

Industry-Specific Standards

Certain industries may have additional requirements, such as:

- API Standards: For inductors used in the oil and gas industry, adherence to API standards ensures they can withstand harsh operational conditions.

- RoHS Compliance: Ensures that products are free from hazardous substances, essential for electronics manufacturers.

Quality Control Checkpoints

Quality control (QC) processes typically include several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Regular checks during the manufacturing process to monitor adherence to specifications, including dimensional checks and material quality.

- Final Quality Control (FQC): A comprehensive inspection before packaging, including electrical testing and performance verification.

Common Testing Methods

B2B buyers should be aware of the testing methods used to verify the quality of toroid inductors, including:

- Inductance Measurement: Using LCR meters to ensure the inductance falls within the specified range.

- Temperature Rise Tests: Evaluating performance under load conditions to ensure the inductor does not overheat.

- Dielectric Strength Tests: Ensuring the insulation between windings and the core is sufficient to prevent short circuits.

Verifying Supplier Quality Control

When sourcing toroidal inductors, B2B buyers can take several steps to verify the quality control measures of potential suppliers:

- Supplier Audits: Conducting on-site audits to evaluate the manufacturing processes and quality assurance practices.

- Requesting Quality Reports: Ask for documentation related to quality checks, including IQC, IPQC, and FQC results.

- Third-Party Inspections: Engaging independent inspection agencies to assess product quality before shipment, providing an additional layer of assurance.

QC and Certification Nuances for International Buyers

International buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control and certification:

- Regulatory Compliance: Different regions may have varying requirements for product certifications. Understanding these can help avoid compliance issues.

- Cultural and Language Barriers: Communication with suppliers may be impacted by language differences. Ensure that all specifications and quality expectations are clearly documented and understood.

- Logistics and Supply Chain Considerations: Be aware of how international logistics can affect product quality. Factors such as transportation conditions and storage practices can impact the final product.

By understanding the manufacturing processes and quality assurance measures associated with toroidal inductors, B2B buyers can make informed decisions that align with their quality expectations and operational needs.

Related Video: Inspection and Quality control in Manufacturing

Comprehensive Cost and Pricing Analysis for toroid inductor Sourcing

Cost Structure of Toroid Inductor Sourcing

When sourcing toroidal inductors, understanding the cost structure is essential for B2B buyers. The overall cost is influenced by several components:

-

Materials: The primary materials used in toroidal inductors include ferrite, iron powder, and copper wire. Fluctuations in the prices of these raw materials can significantly impact the final cost. For instance, a rise in copper prices can lead to higher production costs.

-

Labor: Labor costs vary by region and can affect the pricing of inductors. Countries with higher labor costs may see increased manufacturing prices. Buyers should consider suppliers in regions with competitive labor costs without compromising quality.

-

Manufacturing Overhead: This encompasses the costs associated with production facilities, utilities, and maintenance. Efficient manufacturing processes can lower overhead, making it crucial to evaluate suppliers based on their operational efficiency.

-

Tooling: Initial tooling costs are necessary for custom designs or high-volume production runs. Buyers should be aware that these costs are amortized over the production volume, which can affect pricing for small orders.

-

Quality Control (QC): Stringent QC processes ensure reliability and performance. Suppliers that invest in robust QC measures might charge higher prices, but this often translates to better product quality and fewer failures.

-

Logistics: Transportation and shipping costs must be factored into the total price. The choice of shipping method (air vs. sea) and the distance from the supplier can significantly influence logistics costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. This margin varies by supplier and can be negotiated based on order volume.

Price Influencers in Toroid Inductor Sourcing

Several factors can influence the pricing of toroidal inductors:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes generally lead to lower per-unit costs due to economies of scale. Buyers should negotiate terms that allow for bulk purchasing.

-

Specifications/Customization: Custom designs or specific performance requirements can lead to increased costs. Clearly defining specifications before sourcing can help avoid unexpected expenses.

-

Materials and Quality Certifications: Higher quality materials and certifications (like ISO or RoHS compliance) can increase costs but provide assurance of product reliability. Buyers should weigh the benefits of quality against budget constraints.

-

Supplier Factors: A supplier’s reputation, experience, and manufacturing capabilities can affect pricing. Established suppliers may charge more but offer superior reliability and support.

-

Incoterms: Understanding shipping terms (such as FOB, CIF, etc.) is crucial for calculating total costs. These terms define who is responsible for shipping, insurance, and tariffs, impacting the overall pricing strategy.

Buyer Tips for Cost-Efficiency

To navigate the complexities of toroidal inductor sourcing effectively, consider the following actionable strategies:

-

Negotiate: Engage in discussions about pricing and terms with suppliers. Leverage your order volume to negotiate better rates or payment terms.

-

Focus on Total Cost of Ownership (TCO): Evaluate the TCO, which includes initial costs, shipping, potential failure rates, and replacement costs. A slightly higher upfront cost may result in lower long-term expenses.

-

Understand Regional Pricing Nuances: For international buyers, be aware of regional market conditions. For example, sourcing from suppliers in countries like Egypt or Colombia may offer cost advantages due to lower labor rates but could come with trade-offs in logistics or lead times.

-

Request Samples: Before committing to large orders, request samples to assess quality. This helps mitigate risks associated with bulk purchases.

-

Stay Informed on Market Trends: Keep abreast of changes in material prices and manufacturing technologies that could impact costs. This knowledge can inform better sourcing decisions.

Disclaimer

Prices for toroidal inductors can fluctuate based on market conditions, supplier negotiations, and specific project requirements. The insights provided here are indicative and should be validated with suppliers to ensure accuracy in quotes and procurement strategies.

Spotlight on Potential toroid inductor Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘toroid inductor’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for toroid inductor

Key Technical Properties of Toroid Inductors

Understanding the technical specifications of toroid inductors is crucial for B2B buyers, particularly when evaluating components for specific applications. Below are essential properties that influence performance and suitability:

-

Material Grade: The core material, typically ferrite or iron powder, significantly affects the inductor’s efficiency and frequency response. Ferrite cores are preferred for high-frequency applications due to their low losses, while powdered iron cores are better for high current applications. Selecting the right material is vital for optimizing performance in your specific application.

-

Inductance Value: Measured in henries (H), this value indicates the inductor’s ability to store energy in a magnetic field. B2B buyers should choose inductors with inductance values that match their circuit requirements, as this directly impacts the efficiency and stability of the electronic system.

-

DC Resistance (DCR): This specification refers to the resistance of the wire winding within the inductor. A lower DCR results in reduced power losses and heat generation, which is critical for maintaining performance in high-load applications. Buyers must consider this property to ensure reliable operation and longevity of the component.

-

Tolerance: This indicates the permissible deviation from the specified inductance value, typically expressed as a percentage. A tighter tolerance ensures more consistent performance across multiple units, which is crucial in precision applications. Buyers should specify tolerances that align with their quality requirements.

-

Temperature Coefficient: This property defines how the inductance value changes with temperature fluctuations. A low temperature coefficient is essential for applications exposed to varying thermal conditions, ensuring stable performance. Understanding this property helps buyers select inductors that will function reliably in their operational environments.

-

Saturation Current: This is the maximum current the inductor can handle before the core material saturates, leading to a significant drop in inductance. Knowing the saturation current is vital for preventing circuit failures, particularly in power supply applications where high currents are common.

Common Trade Terminology

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are key terms related to the procurement of toroid inductors:

-

OEM (Original Equipment Manufacturer): Refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers establish reliable supply chains and ensure product compatibility.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budget planning and inventory management, especially for international buyers looking to optimize shipping and storage costs.

-

RFQ (Request for Quotation): A formal document soliciting price quotes from suppliers for specific products. An RFQ is crucial for buyers to assess pricing and terms, enabling informed purchasing decisions. Providing detailed specifications in an RFQ can lead to more accurate and competitive quotes.

-

Incoterms (International Commercial Terms): These are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers. Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities during international transactions.

-

Lead Time: The time taken from placing an order to delivery. Understanding lead times is critical for project planning and ensuring timely availability of components. Buyers should communicate their project timelines clearly to suppliers.

-

Testing Standards: These are the criteria and procedures used to evaluate the performance and safety of inductors. Awareness of relevant testing standards is essential for ensuring compliance and reliability in applications, particularly in regulated industries.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, leading to improved outcomes in their procurement processes and project implementations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the toroid inductor Sector

Market Overview & Key Trends

The global toroid inductor market is on a growth trajectory, driven by the increasing demand for compact, high-performance electronic components across various industries. Key factors propelling this growth include the rising adoption of power electronics, particularly in sectors like telecommunications, automotive, and consumer electronics. For international B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for informed sourcing decisions.

Emerging trends include a shift towards miniaturization, where manufacturers prioritize smaller, lighter components that do not compromise on efficiency. This trend is particularly relevant for the automotive sector, where innovations like electric vehicles and advanced driver-assistance systems require highly efficient and compact inductors. Additionally, there is a growing demand for application-specific designs tailored to unique operational needs, which presents opportunities for buyers seeking customized solutions.

Market dynamics are also influenced by fluctuations in raw material costs and supply chain disruptions. B2B buyers should be aware of these factors, as they can impact pricing and availability. Furthermore, the push towards enhanced quality and reliability standards means that buyers must prioritize suppliers who adhere to strict manufacturing processes and offer robust product testing. As the market evolves, maintaining a strategic approach to sourcing will be essential for capitalizing on growth opportunities.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical focus in the toroid inductor sector, driven by increasing regulatory pressures and consumer demand for environmentally responsible products. The production of toroid inductors involves materials that can have significant environmental impacts, particularly if not sourced responsibly. International B2B buyers are encouraged to engage with suppliers who prioritize ethical sourcing practices, ensuring that materials are obtained in a manner that minimizes ecological harm.

Incorporating ‘green’ certifications and using sustainable materials not only aligns with environmental goals but also enhances brand reputation and consumer trust. Buyers should look for suppliers who can demonstrate compliance with international environmental standards, such as ISO 14001, and who utilize recyclable or low-impact materials in their products.

Additionally, investing in suppliers who engage in sustainable manufacturing practices—such as reducing waste and energy consumption—can lead to long-term cost savings and supply chain resilience. As companies increasingly prioritize sustainability, those who align their procurement strategies with these values will likely gain a competitive edge in the market.

Brief Evolution/History

The concept of toroidal inductors has evolved significantly since their inception. Initially developed in the mid-20th century, these components have undergone substantial advancements in design and manufacturing techniques. Early toroid inductors were primarily utilized in radio frequency applications, but their benefits—such as reduced electromagnetic interference and improved efficiency—have led to broader adoption across various sectors, including power supplies and automotive electronics.

Today, innovations in materials science and manufacturing processes continue to enhance the performance characteristics of toroidal inductors, making them indispensable in modern electronic applications. For B2B buyers, understanding this evolution not only provides context for current market dynamics but also highlights the potential for future developments in this vital component sector.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of toroid inductor

-

What factors should I consider when vetting a supplier for toroid inductors?

When vetting a supplier for toroid inductors, consider their manufacturing capabilities, certifications (such as ISO 9001), and experience in your specific industry. Request samples to evaluate product quality and performance. Additionally, assess their ability to provide technical support and customization options, as well as their financial stability and reputation in the market. It’s beneficial to review customer testimonials and case studies that demonstrate their reliability and service quality. -

Can toroid inductors be customized to meet specific application requirements?

Yes, many manufacturers offer customization for toroid inductors. This may include adjustments in inductance values, core materials, and winding configurations to fit specific electrical characteristics or environmental conditions. When discussing customization, provide detailed specifications and performance requirements. Ensure that the supplier has a robust design and testing process to validate the customized inductors against your needs. -

What are typical minimum order quantities (MOQs) and lead times for toroid inductors?

Minimum order quantities for toroid inductors can vary widely depending on the supplier and the complexity of the product. Generally, MOQs can range from a few hundred to several thousand units. Lead times typically range from 4 to 12 weeks, depending on the supplier’s production capacity and order backlog. It’s essential to discuss these aspects upfront and establish clear timelines to align with your project schedules. -

What payment terms are commonly offered by suppliers of toroid inductors?

Payment terms can differ based on the supplier’s policies and your business relationship. Common terms include upfront payments, partial payments upon order confirmation, and balance upon delivery. For international transactions, consider using letters of credit or escrow services to mitigate risks. Negotiate terms that provide both parties with assurance, and clarify any currency exchange considerations if dealing with cross-border payments. -

How do I ensure quality assurance and certifications for toroid inductors?

To ensure quality assurance, request documentation of the supplier’s quality management systems and any relevant certifications (e.g., RoHS, CE, UL). Inquire about their testing procedures, including in-house testing and third-party validation. Establish quality control measures, such as pre-shipment inspections or acceptance sampling, to verify that the products meet your specifications before they are shipped. -

What logistics considerations should I keep in mind when importing toroid inductors?

Logistics considerations include shipping methods, costs, and delivery timelines. Evaluate whether air freight or sea freight is more suitable based on urgency and budget. Understand the customs regulations in your country and ensure that the supplier provides all necessary documentation, such as certificates of origin and commercial invoices. Also, consider the potential for delays in logistics and plan for contingencies. -

How can disputes with suppliers be effectively managed?

To effectively manage disputes, establish clear contracts that outline terms of service, delivery expectations, and quality requirements. Implement regular communication channels to address issues as they arise. In case of a dispute, document all correspondence and agreements. Consider mediation or arbitration as a resolution method, as these can be less adversarial and more cost-effective than litigation.

Illustrative Image (Source: Google Search)

- What are the best practices for maintaining ongoing supplier relationships?

Maintaining strong supplier relationships involves regular communication, providing feedback, and collaborating on improvements. Schedule periodic reviews to assess performance against agreed metrics and discuss future needs. Building trust through transparency and consistency in orders can lead to better pricing and priority service. Additionally, consider exploring joint ventures or co-development opportunities to enhance mutual growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for toroid inductor

In conclusion, the strategic sourcing of toroid inductors presents significant opportunities for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. The growing demand for compact, high-performance electronic components in sectors such as telecommunications, automotive, and industrial automation underscores the importance of establishing reliable supplier relationships.

Key takeaways for effective sourcing include:

- Customization: Seek suppliers who offer tailored solutions to meet specific application needs, enhancing efficiency and performance.

- Quality Assurance: Prioritize manufacturers with rigorous quality standards and testing processes to ensure product reliability and longevity.

- Market Awareness: Stay informed about global supply chain dynamics, as fluctuations in raw material costs and geopolitical factors can impact pricing and availability.

By adopting a proactive approach to sourcing, businesses can mitigate risks associated with supply chain disruptions and secure competitive advantages. As technology continues to evolve, the demand for innovative and efficient components like toroid inductors will only increase.

Now is the time for B2B buyers to engage with leading manufacturers and explore potential partnerships that align with their strategic goals. Embrace this opportunity to enhance your product offerings and drive success in your markets.