Discover the Top 30 Perforated Plastic Manufacturers

Are you tired of sifting through endless lists of perforated plastic manufacturers, only to find they don’t meet your needs? Choosing the right supplier can feel overwhelming, especially with so many options out there. But what if you could easily find the top factories that deliver quality, reliability, and value? Selecting the right partner can save you time, money, and headaches down the line. In this article, we’ve compiled a comprehensive list of the top 30 perforated plastic manufacturers.

Discover who stands out in quality and service, and why they’re the best fit for your projects. Ready to streamline your search? Let’s dive in and find the perfect supplier for your needs!

Top 30 Perforated Plastic Manufacturers

Mcmaster – Perforated Plastic Sheet Solutions

Domain: mcmaster.com

Registered: 1994 ( 31 years )

Introduction: Perforated plastic sheets available in various materials and thicknesses.

Direct Metals – Custom Perforated Plastic Products

Domain: directmetals.com

Registered: 1998 ( 27 years )

Introduction: Perforated plastic products designed for various applications, offering customization in hole size, pattern, and thickness.

U.S. Plastic – Polypropylene Perforated Sheeting

Domain: usplastic.com

Registered: 1996 ( 29 years )

Introduction: Polypropylene perforated sheeting offered by U.S. Plastic Corp.

Ametco – Custom Perforated Plastic Solutions

Domain: ametco.com

Registered: 1996 ( 29 years )

Introduction: Perforated plastic is available in stock sheets or can be custom perforated to meet your needs. Polypropylene perforated plastic comes in a variety of colors and PVC perforated comes in dark grey (type 1 – class1).

Grainger – Plastic Perforated Sheets Solutions

Domain: grainger.com

Registered: 1994 ( 31 years )

Introduction: Plastic perforated sheets available in various materials and sizes for diverse applications.

McNICHOLS – Perforated Plastic Solutions

Domain: mcnichols.com

Registered: 1996 ( 29 years )

Introduction: McNICHOLS® Perforated Plastic Round, PLASTIPERF™ 1640, made from Polypropylene, 16 Gauge (.0598″ Thick), featuring 1/8″ Round holes on 3/16″ Staggered Centers with 40% Open Area.

Brown-Campbell – Perforated Plastic Solutions

Domain: brown-campbell.com

Registered: 1996 ( 29 years )

Introduction: Perforated plastic products offered by Brown-Campbell Company, a specialty steel manufacturer and fabricator since 1952.

Professional Plastics – Polypropylene Perforated Sheets & Rolls

Domain: professionalplastics.com

Registered: 1997 ( 28 years )

Introduction: Polypropylene perforated sheets and rolls.

Ferguson Perforating – Perforated Plastic Sheets

Domain: fergusonperf.com

Registered: 1997 ( 28 years )

Introduction: Ferguson Perforating offers perforated plastic sheets as part of their range of perforated materials.

Harrison Plastic – Perforated Polypropylene and PVC Sheets

Domain: harrisonplastic.com

Registered: 2005 ( 20 years )

Introduction: Harrison offers 4′ x 8′ sheets of 1/16″, 1/8″, 3/16″ and 1/4″ Polypropylene and PVC perforated sheet with various hole diameters and patterns.

Sourcify China – Perforated Plastic Products

Domain: sourcifychina.com

Registered: 2023 ( 2 years )

Introduction: Perforated plastic products offered by Sourcify China, suitable for various applications.

Mscdirect – Industrial Supply Solutions

Perforated Metals – Plastic Perforated Sheets Solutions

Domain: perforated-metals.com

Registered: 2001 ( 24 years )

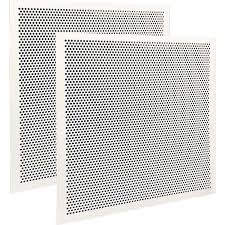

Introduction: Plastic perforated sheets are made from several types of plastics chosen according to the application. They are primarily designed for controlling air streams and airflow, directing air to maintain even and uniform temperatures.

Cnc Perforating – Custom Plastic Perforated Products

Domain: cnc-perforating.com

Registered: 2021 ( 4 years )

Introduction: Mao Ou Plastic Perforating Co., Ltd. specializes in manufacturing various types of perforated plastic products, including sheets, panels, and specialized items like drainage pads and filters.

Clark Perforating – Precision Perforated Plastic Panels

Domain: clarkperforating.com

Registered: 2009 ( 16 years )

Introduction: Clark Perforating offers precision perforated plastic panels and sheets, including polypropylene, PVC, and HDPE.

K-Mac Plastics – Perforated PVC Sheet Solutions

Domain: k-mac-plastics.com

Registered: 2001 ( 24 years )

Introduction: K-Mac Plastics offers a variety of perforated PVC sheets in different thicknesses, sizes, and hole patterns, suitable for various applications.

Theplasticshop – Perforated Polypropylene Sheets

Domain: theplasticshop.co.uk

Registered: 2004 ( 21 years )

Introduction: Perforated Polypropylene Sheet available for online purchase, 3mm thick.

Accurate Perforating – Custom Perforated Plastic Solutions

Domain: accurateperforating.com

Registered: 1997 ( 28 years )

Introduction: Perforated plastic materials for various applications, offering customization in hole size, pattern, and thickness.

RKS Plastics – Perforated Poly Sheeting Solutions

Domain: rksplastics.com

Registered: 2004 ( 21 years )

Introduction: Perforated Poly Sheeting on Roll offered by RKS Plastics Inc.

Sumitspiral – HDPE & PP Perforated Sheets

Domain: sumitspiral.com

Registered: 2021 ( 4 years )

Introduction: SU****MIT offers HDPE and PP perforated sheet with various hole diameters and patterns. The perforated plastic sheet is commonly used for acid resistant applications such as strainers and drains.

ToolsPH – Perforated Sheets for Custom Applications

Polypak Plastics – Perforated Sheeting Solutions

Domain: polypakplastics.com

Registered: 2001 ( 24 years )

Introduction: Perforated Sheeting on a Roll is a type of poly sheeting that is designed for various applications, providing convenience and efficiency in usage.

Uspackagingandwrapping – Perforated Plastic Wrap Solutions

Domain: uspackagingandwrapping.com

Registered: 2011 ( 14 years )

Introduction: Perforated all-purpose plastic wrap designed for various packaging needs.

Veritas Systems – Perforated Plastic Sheets & Profiles

Domain: veritassystems.in

Registered: 2024 ( 1 years )

Introduction: Perforated plastic sheets and profiles for tank building, including square tubes, U-profiles, and welding rods.

Burckhardt – Custom Perforating Machines for Plastics

Domain: burckhardt.com

Registered: 1997 ( 28 years )

Introduction: Burckhardt is a leading producer of machines for perforating plastics and PVC, offering customizable perforating machines and tools for various applications.

Fabco Plastics – Perforated Sheets and PVDF Solutions

Domain: fabcoplastics.com

Registered: 1997 ( 28 years )

Introduction: Fabco Plastics offers a variety of perforated sheets suitable for different applications, including PVDF sheets.

Ysplastics – Custom Perforated Plastic Sheets

Domain: ysplastics.com

Registered: 2017 ( 8 years )

Introduction: Perforated plastic sheets available in various materials and colors, customizable perforation shapes and specifications.

Webstaurantstore – Bread Storage Solutions

Domain: webstaurantstore.com

Registered: 2003 ( 22 years )

Introduction: Plastic bread bag with micro-perforations, ideal for storing and displaying bread products.

Rainfloirrigation – Perforated Plastic Mulch Solutions

Domain: rainfloirrigation.com

Registered: 2008 ( 17 years )

Introduction: Perforated plastic mulch designed for agricultural applications to enhance crop growth and soil health.

Home Depot – Drainage Solutions

Domain: homedepot.com

Registered: 1992 ( 33 years )

Introduction: Advanced Drainage Systems 12 in. x 20 ft. HDPE ASTM N12 Dual Wall Pipe

Category Information

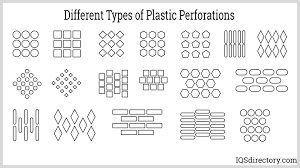

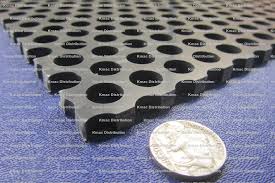

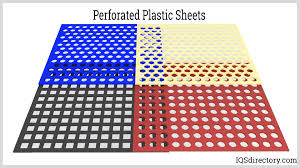

Perforated plastic refers to plastic materials that have been punctured with a series of holes or openings, creating a pattern that enhances their functionality. This category encompasses various types of plastics, including polyethylene, polypropylene, and PVC, which can be customized in terms of hole size, spacing, and overall design. The perforation process can serve multiple purposes, such as improving ventilation, allowing drainage, and reducing weight while maintaining structural integrity.

The significance of perforated plastic spans numerous industries, including construction, automotive, packaging, and consumer goods. In construction, for instance, perforated plastic panels are used for aesthetic applications and as effective barriers for air and water flow. In packaging, perforated films allow for better product visibility and freshness by enabling air circulation. Overall, perforated plastic plays a crucial role in enhancing the performance and efficiency of various products and applications across sectors.

Application Information

Perforated plastic products are widely utilized across various industries due to their lightweight, durable, and versatile nature. One significant application area is in the construction and architecture sector, where perforated panels are used for aesthetic facades, sound dampening, and ventilation in buildings. These panels not only enhance visual appeal but also improve airflow and acoustics. Another key area is in packaging, particularly for food and consumer goods.

Perforated plastic films and containers allow for breathability, which is crucial for preserving freshness in perishable items. Additionally, perforated plastics are common in automotive and aerospace industries, where they are used for lightweight components that require ventilation without compromising structural integrity. Overall, the versatility of perforated plastics makes them essential in many modern applications, from design to functionality.

Production Process Information

The production of perforated plastic products typically involves several key stages. First, the process begins with selecting the right type of plastic material, such as polypropylene or polyethylene, which is chosen based on the desired strength and flexibility. The plastic is then heated and formed into sheets or rolls. Next, the perforation stage takes place, where holes are created in the plastic using specialized machinery.

This can involve techniques like laser cutting or mechanical punching, depending on the size and pattern of the holes required. After perforation, the plastic is often trimmed or finished to ensure it meets specific dimensions and quality standards. Finally, the products are packaged and prepared for distribution. Quality control is a crucial consideration throughout the process, ensuring that the final products are durable and meet the needs of customers, whether for industrial, commercial, or personal use.

Related Video

Frequently Asked Questions (FAQs)

What should I look for in a perforated plastic manufacturer?

When choosing a perforated plastic manufacturer, consider their experience, production capabilities, and quality control processes. Look for a supplier that offers customization options, has positive customer reviews, and can provide samples. It’s also important to check their lead times and whether they can accommodate your specific order quantities.

How can I verify the quality of a factory’s products?

To verify product quality, request samples before placing a large order. Check for certifications like ISO or ASTM that indicate adherence to industry standards. You can also ask for references from other clients and inspect their production processes through factory visits or virtual tours if possible.

What is the typical lead time for orders from perforated plastic manufacturers?

Lead times can vary significantly based on the manufacturer and order size, but typically range from 2 to 6 weeks. It’s best to communicate your timeline upfront and inquire about their production schedule to ensure they can meet your deadlines.

Are there minimum order quantities (MOQs) for perforated plastic products?

Yes, many manufacturers have minimum order quantities, which can range from a few hundred to several thousand units. Be sure to ask about MOQs during your initial discussions, as this will help you determine if a factory is a good fit for your needs.

How can I ensure competitive pricing when choosing a supplier?

To ensure competitive pricing, compare quotes from multiple manufacturers and consider factors like material costs and production efficiency. Don’t hesitate to negotiate terms, and be clear about your budget. Sometimes, building a long-term relationship can also lead to better pricing and terms over time.