Your Ultimate Guide to Sourcing Ac Electric Motors

Introduction: Navigating the Global Market for ac electric motors

Electric motors are the driving force behind countless industrial applications, playing a pivotal role in sectors such as manufacturing, agriculture, and logistics. Among these, AC electric motors stand out for their robustness and versatility, powering everything from conveyor belts in Brazil’s logistics hubs to water treatment facilities in Nigeria. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding the intricacies of sourcing AC motors is not just beneficial; it’s essential for ensuring operational efficiency and competitiveness.

This comprehensive guide serves as an invaluable resource for navigating the complexities of the global market for AC electric motors. It delves into various motor types and materials, providing insights on manufacturing processes and quality control standards that are critical for long-term performance and reliability. Buyers will find structured frameworks for selecting and qualifying suppliers, alongside strategies for effective cost management and risk mitigation.

Additionally, the guide addresses common challenges and questions faced by procurement leaders, enabling them to make informed sourcing decisions that align with regional requirements and operational goals. By equipping buyers with the knowledge to evaluate their options critically, this guide empowers organizations to enhance productivity and achieve sustainable growth in diverse markets.

Understanding ac electric motors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AC Induction Motor | Simple, robust design; operates on AC power; squirrel cage or wound rotor types | Pumps, compressors, conveyors, fans | Reliable, widely available; less efficient at variable speeds |

| Synchronous Motor | Rotor speed synchronized with supply frequency; precise speed regulation | Process plants, mills, power factor correction | High efficiency, precise speed; complex start-up, higher cost |

| Brushless AC Motor | Electronic commutation; high efficiency; low maintenance | HVAC systems, electric vehicles, medical equipment | Long lifespan, compact; higher upfront cost, requires electronic control |

| Servo Motor | Precise position/speed control; closed-loop feedback | Robotics, CNC machines, high-precision automation | Exceptional accuracy; more expensive, complex commissioning |

| Gear Motor | Integrated gearbox with motor for torque adaptation | Packaging, materials handling, agitators | Simplifies system design; gearbox wear, modest efficiency loss |

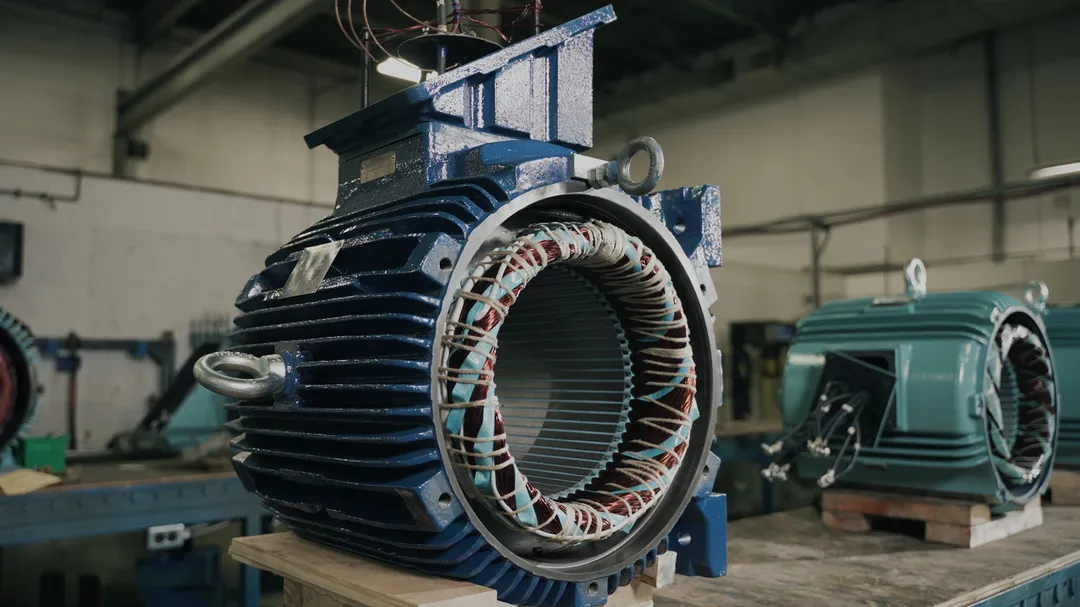

AC Induction Motor

AC induction motors are widely recognized for their durability and adaptability, making them ideal for various industrial applications such as pumps and conveyors. They operate efficiently across different voltage levels, which is particularly beneficial in regions like Africa and South America where electrical supply can be inconsistent. When purchasing, B2B buyers should ensure compatibility with local electrical standards and consider the availability of spare parts and service support, as these factors can significantly impact operational reliability.

Illustrative Image (Source: Google Search)

Synchronous Motor

Synchronous motors are characterized by their ability to maintain a constant speed that is synchronized with the frequency of the supply current. They are particularly suited for applications requiring precise speed control, such as in process plants and power factor correction. However, buyers must evaluate the complexity of their start-up procedures and the associated costs. Investing in synchronous motors can lead to long-term efficiency gains, but it’s essential to weigh these benefits against potential installation challenges and maintenance needs.

Brushless AC Motor

Brushless AC motors are designed for high efficiency and minimal maintenance due to their electronic commutation system. This makes them an excellent choice for applications like HVAC systems and electric vehicles, where space and energy efficiency are crucial. For B2B buyers, the higher upfront costs are often offset by reduced operational expenses over time. Key considerations include ensuring that local technicians are adept at handling the electronic controls and that supply chains can reliably source compatible components.

Servo Motor

Servo motors provide unparalleled precision in position and speed control, making them indispensable in robotics and CNC machinery. Their closed-loop feedback systems ensure high accuracy, which is essential for applications requiring meticulous performance. However, B2B buyers should be prepared for the higher costs associated with these motors and the complexity involved in their installation and commissioning. Understanding the specific application requirements and the necessary control systems is critical when considering servo motors for procurement.

Gear Motor

Gear motors combine a motor with an integrated gearbox, allowing for effective torque and speed adaptation. They are commonly used in packaging and materials handling industries. The primary advantage of gear motors is their ability to simplify system design, which can lead to lower installation costs. However, buyers should be mindful of potential gearbox wear and the modest efficiency loss that may occur over time. Ensuring that the selected gear motor is well-suited for the intended application is vital for maintaining operational efficiency.

Related Video: Types of AC Motor – Different Types of Motors – Electric Motor Types

Key Industrial Applications of ac electric motors

| Industry/Sector | Specific Application of ac electric motors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Enhances efficiency and throughput in production | Ensure compatibility with local voltage and frequency |

| Agriculture | Irrigation Pumps | Reliable water supply for crop irrigation | Check for durability in harsh environments |

| Water Treatment | Water Pumps | Efficient movement of water for treatment processes | Assess availability of spare parts and service |

| HVAC Systems | Fans and Compressors | Maintains optimal climate control in buildings | Look for energy efficiency ratings |

| Mining | Ventilation Systems | Ensures safety and air quality in underground mines | Evaluate motor robustness and maintenance support |

Manufacturing: Conveyor Systems

In the manufacturing sector, AC electric motors are pivotal in powering conveyor systems that move materials and products through various stages of production. These motors enhance operational efficiency and throughput, allowing for a streamlined workflow. Buyers in this sector must ensure that the motors are compatible with local voltage and frequency standards to avoid operational disruptions. Additionally, understanding the motor’s load capacity is crucial for maintaining productivity.

Agriculture: Irrigation Pumps

AC electric motors are widely used in agricultural irrigation pumps, providing a reliable water supply essential for crop growth. These motors enable efficient water distribution, crucial for maximizing yields in regions with variable climates. International buyers should focus on the motor’s durability, as agricultural environments can be challenging, often exposing equipment to moisture and dust. Sourcing motors that can withstand these conditions is vital for long-term operational success.

Water Treatment: Water Pumps

In water treatment facilities, AC electric motors drive water pumps, ensuring the efficient movement of water through treatment processes. These motors are critical for maintaining consistent water quality and supply, especially in regions facing water scarcity. Buyers should assess the availability of spare parts and after-sales service when selecting suppliers, as prompt support is essential for minimizing downtime in critical applications.

HVAC Systems: Fans and Compressors

AC electric motors are integral to HVAC systems, powering fans and compressors that maintain optimal climate control in residential and commercial buildings. These motors contribute to energy efficiency and operational reliability, which are increasingly important in today’s energy-conscious market. Buyers should prioritize energy efficiency ratings when sourcing these motors, as they can significantly affect long-term operational costs.

Mining: Ventilation Systems

In the mining industry, AC electric motors are essential for driving ventilation systems that ensure safety and air quality in underground operations. These motors provide the necessary airflow to dilute harmful gases and maintain a breathable atmosphere for workers. When sourcing motors for this application, buyers must evaluate the robustness of the motors, as they need to withstand harsh mining conditions and require reliable maintenance support to minimize risks and ensure worker safety.

Related Video: How Electric Motors Work – 3 phase AC induction motors ac motor

Strategic Material Selection Guide for ac electric motors

When selecting materials for AC electric motors, international B2B buyers must consider various factors that influence performance, durability, and cost-effectiveness. Here, we analyze four common materials used in the construction of AC electric motors: Copper, Aluminum, Steel, and Insulation Materials. Each material has unique properties and implications for different applications, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

Copper

Key Properties: Copper is known for its excellent electrical conductivity, thermal conductivity, and resistance to corrosion. It can operate effectively at high temperatures and under varying pressure conditions, making it suitable for demanding environments.

Pros & Cons: The primary advantage of copper is its superior conductivity, which enhances motor efficiency and reduces energy losses. However, copper is relatively expensive compared to alternatives like aluminum, and its manufacturing process can be more complex due to the need for precise handling to avoid oxidation.

Impact on Application: Copper is ideal for applications requiring high efficiency and reliability, such as in precision machinery and high-performance electric vehicles. Its compatibility with various media and environments makes it a preferred choice in many industrial settings.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM B170 for copper wire and consider local sourcing options to mitigate costs. In regions like Nigeria and Egypt, where copper theft can be an issue, securing supply chains is crucial.

Aluminum

Key Properties: Aluminum is lightweight, has good electrical conductivity (though less than copper), and offers excellent corrosion resistance. It can withstand moderate temperatures and pressures.

Pros & Cons: The main advantage of aluminum is its lower cost and lighter weight, which can reduce shipping and handling expenses. However, it has lower conductivity than copper, which may lead to increased energy losses in high-performance applications.

Impact on Application: Aluminum is commonly used in applications where weight is a critical factor, such as in aerospace and automotive industries. Its corrosion resistance makes it suitable for environments with high humidity or exposure to chemicals.

Considerations for International Buyers: Buyers should be aware of the different grades of aluminum and their compliance with standards like ASTM B221. In South America, where mining and processing capabilities vary, sourcing quality aluminum can be a challenge.

Steel

Key Properties: Steel is known for its strength, durability, and ability to withstand high temperatures and pressures. It is often used in the structural components of motors.

Pros & Cons: The durability of steel makes it an excellent choice for heavy-duty applications, but it is heavier than copper and aluminum, which can affect overall motor weight and efficiency. Additionally, steel can be prone to corrosion if not properly treated.

Impact on Application: Steel is widely used in industrial applications, particularly in environments where motors are exposed to mechanical stress and high load conditions. Its robustness makes it suitable for pumps, conveyors, and other heavy machinery.

Considerations for International Buyers: Buyers should consider the corrosion resistance of steel (e.g., stainless steel vs. carbon steel) and ensure compliance with relevant standards such as DIN EN 10025. In regions like the Middle East, where humidity can be high, selecting the right type of steel is critical.

Insulation Materials

Key Properties: Insulation materials, often made from polymers or ceramics, are crucial for protecting electrical components from heat and electrical faults. They must withstand high temperatures and provide excellent dielectric strength.

Pros & Cons: High-quality insulation materials improve motor reliability and safety, but they can add to manufacturing complexity and costs. The choice of insulation can also affect the motor’s operational lifespan.

Impact on Application: Insulation is vital in applications where motors are exposed to extreme temperatures or harsh environments, such as in mining or chemical processing.

Considerations for International Buyers: Buyers should ensure that insulation materials meet international standards such as IEC 60085 for thermal insulation. In Europe, compliance with RoHS (Restriction of Hazardous Substances) is also essential.

Summary Table

| Material | Typical Use Case for ac electric motors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-performance applications | Superior electrical conductivity | Higher cost, complex manufacturing | High |

| Aluminum | Lightweight applications | Lower cost, lightweight | Lower conductivity, energy losses | Medium |

| Steel | Heavy-duty industrial applications | Durability and strength | Heavier, prone to corrosion | Medium |

| Insulation Materials | Extreme temperature environments | Improves reliability and safety | Adds complexity and cost | Medium |

In conclusion, understanding the properties and implications of different materials is essential for B2B buyers in the AC electric motor market. By considering the specific needs of their applications and local conditions, buyers can make informed decisions that enhance operational efficiency and reliability.

In-depth Look: Manufacturing Processes and Quality Assurance for ac electric motors

Electric motors, particularly AC electric motors, are pivotal in various industries, and understanding their manufacturing processes and quality assurance protocols is essential for B2B buyers. This section provides a detailed overview of typical manufacturing stages and quality control measures, tailored for international buyers, particularly those operating in Africa, South America, the Middle East, and Europe.

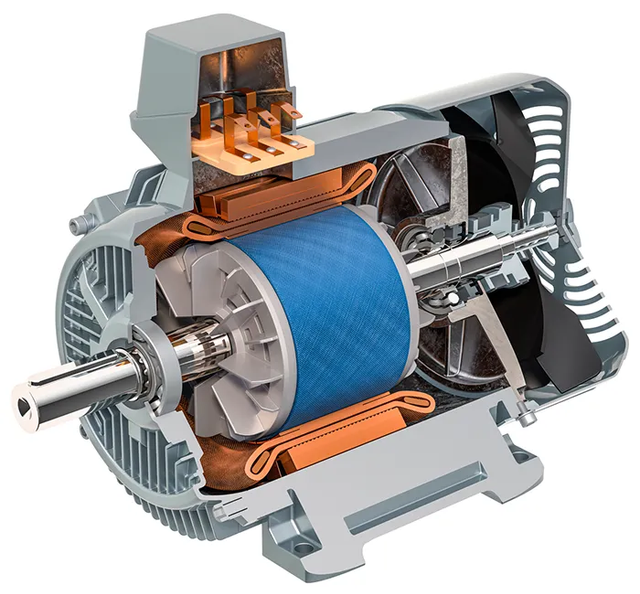

Manufacturing Processes for AC Electric Motors

The manufacturing of AC electric motors involves several critical stages, each contributing to the overall performance and reliability of the final product. Here’s a breakdown of the main stages:

1. Material Preparation

The first step in the manufacturing process involves sourcing and preparing raw materials. Key materials include:

- Copper: Used for windings due to its excellent conductivity.

- Steel: Essential for the motor’s core and housing, providing structural integrity.

- Insulation Materials: Such as varnishes and resins, which are crucial for electrical safety and performance.

Before production, materials undergo rigorous inspection to ensure they meet specified standards. This includes checking for impurities, dimensions, and mechanical properties.

2. Forming

In this stage, the prepared materials are shaped into their required forms. Techniques include:

- Stamping: Sheets of steel are stamped into the desired shapes for the stator and rotor cores.

- Winding: Copper wire is wound around the stator slots to form the motor’s coils. This process is critical, as the winding technique directly affects the motor’s efficiency and performance.

Precision is key in this stage, as any deviation can lead to performance issues.

3. Assembly

Once the components are formed, they are assembled into a complete motor. Key steps include:

- Rotor and Stator Assembly: The rotor is fitted into the stator, and the end shields are attached.

- Electrical Connections: The windings are connected to the terminal box, ensuring that all electrical connections are secure and compliant with safety standards.

Effective assembly is crucial for ensuring that the motor operates smoothly and reliably.

4. Finishing

The final stage involves finishing processes that enhance the motor’s durability and performance. This includes:

- Painting and Coating: Protective coatings are applied to prevent corrosion and wear.

- Balancing: The rotor is dynamically balanced to minimize vibrations during operation.

Finishing processes are essential for enhancing the longevity of the motor and ensuring compliance with industry standards.

Quality Assurance Protocols

Quality assurance is critical in ensuring that AC electric motors meet the high standards expected by B2B buyers. Here are the main components of quality assurance:

International Standards

B2B buyers should look for manufacturers that adhere to international quality standards, such as:

- ISO 9001: This standard ensures that manufacturers maintain consistent quality management systems.

- CE Marking: Indicates compliance with European safety, health, and environmental protection standards.

- API Standards: Particularly relevant for motors used in the oil and gas industries.

These certifications provide a level of assurance regarding the quality and reliability of the motors.

Quality Control Checkpoints

Quality control is typically implemented at various stages of production, including:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product before shipment.

These checkpoints help ensure that any defects are identified and rectified early in the production process.

Common Testing Methods

B2B buyers should be aware of the common testing methods used to validate the quality of AC electric motors, including:

- Electrical Testing: Verification of electrical performance, insulation resistance, and short circuit tests.

- Mechanical Testing: Assessing vibration levels, noise output, and thermal performance.

- Durability Testing: Simulating operational conditions to ensure long-term reliability.

Such tests help ensure that the motors will perform reliably in their intended applications.

Verifying Supplier Quality Control

To ensure that suppliers adhere to stringent quality control measures, B2B buyers can implement several strategies:

- Supplier Audits: Conducting regular audits of suppliers’ manufacturing facilities to assess compliance with quality standards.

- Requesting Quality Reports: Buyers should ask for detailed quality assurance reports, including results from IQC, IPQC, and FQC.

- Third-party Inspections: Engaging independent inspection agencies to verify the quality of the motors before shipment can provide additional assurance.

These measures are vital for mitigating risks associated with sourcing from international suppliers.

Navigating Quality Control Nuances for International Buyers

For international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, understanding local nuances in quality control is crucial. Here are some considerations:

- Regulatory Compliance: Different regions may have unique regulatory requirements. Buyers must ensure that the motors comply with local electrical standards and safety regulations.

- Spare Parts Availability: Assessing the availability of spare parts and service support in the buyer’s region is essential for ensuring long-term operational efficiency.

- Cultural Considerations: Communication styles and business practices may vary significantly across regions. Building strong relationships with suppliers can facilitate smoother negotiations and improve quality assurance.

By paying attention to these factors, B2B buyers can enhance their procurement strategies and ensure they source high-quality AC electric motors that meet their operational needs.

In conclusion, the manufacturing processes and quality assurance protocols for AC electric motors are integral to ensuring reliability and performance. By understanding these processes and implementing robust supplier evaluation strategies, international buyers can secure high-quality products that drive operational success.

Related Video: How to Make Electric MOTOR in Factory | Amazing Electrical Motors Manufacturing Process

Comprehensive Cost and Pricing Analysis for ac electric motors Sourcing

When sourcing AC electric motors, understanding the comprehensive cost structure and pricing nuances is crucial for B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis covers essential cost components, price influencers, and actionable tips for effective procurement.

Cost Components

-

Materials: The cost of raw materials, including copper, steel, and aluminum, plays a significant role in the overall pricing of AC electric motors. Prices for these materials can fluctuate based on market demand and geopolitical factors. Buyers should monitor these trends to anticipate potential cost changes.

-

Labor: Labor costs vary significantly across regions and can impact the pricing of electric motors. Skilled labor is essential for high-quality manufacturing, particularly in countries with stringent quality control measures. Understanding local wage standards can help buyers assess the labor component in the total cost.

-

Manufacturing Overhead: This includes costs related to utilities, maintenance, and factory operations. Efficient manufacturing processes can reduce overhead costs, which may be reflected in the pricing. Buyers should inquire about the supplier’s operational efficiency as it can influence pricing.

-

Tooling: The initial investment in tooling can be significant, especially for custom motor specifications. Buyers should consider whether the supplier has the necessary tooling to meet their needs without incurring excessive setup costs.

Illustrative Image (Source: Google Search)

-

Quality Control (QC): Robust quality control measures ensure that the motors meet required standards, impacting both cost and reliability. Suppliers that maintain high QC standards may charge a premium, but this often results in lower total costs due to reduced failure rates and maintenance needs.

-

Logistics: Transportation and shipping costs can vary widely depending on the supplier’s location and the buyer’s destination. Incoterms, which define the responsibilities of buyers and sellers in shipping, can significantly influence overall logistics costs.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the market landscape can help buyers gauge what constitutes a reasonable margin.

Price Influencers

-

Volume/MOQ: Purchasing in larger volumes often leads to lower per-unit costs due to economies of scale. Buyers should consider their current and future needs when negotiating minimum order quantities (MOQs).

-

Specifications/Customization: Custom motors designed for specific applications may incur additional costs. Buyers should clearly define their requirements to minimize unnecessary modifications and associated costs.

-

Quality/Certifications: Motors that meet international quality standards (e.g., ISO certifications) may be priced higher but offer greater reliability. Buyers should weigh the benefits of certified products against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a track record of quality and service may command higher prices, but they often provide better support and warranty options.

-

Incoterms: Understanding the terms of shipping and delivery (e.g., FOB, CIF) is vital for calculating total costs. Different Incoterms can significantly affect the final price due to variations in responsibility for shipping and insurance.

Buyer Tips

-

Negotiate Wisely: Effective negotiation involves being clear about your requirements and flexible with terms. Aim for a win-win outcome that considers both price and quality.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes initial costs, maintenance, energy consumption, and potential downtime. Sometimes, a higher upfront cost can lead to lower long-term expenses.

-

Understand Pricing Nuances: Be aware of regional differences in pricing and availability. For instance, sourcing from local suppliers may reduce logistics costs but could limit options compared to international suppliers.

-

Disclaimer on Prices: Always remember that pricing can fluctuate based on market conditions, so it is advisable to request quotes and confirm costs during the procurement process.

In conclusion, a thorough understanding of the cost structure and pricing dynamics for AC electric motors will enable B2B buyers to make informed decisions, ultimately leading to enhanced operational efficiency and cost savings.

Spotlight on Potential ac electric motors Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘ac electric motors’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ac electric motors

When sourcing AC electric motors, understanding the essential technical properties and trade terminology is crucial for making informed purchasing decisions. Here, we outline key specifications and common industry terms that every B2B buyer should be familiar with.

Key Technical Properties of AC Electric Motors

-

Material Grade

– Definition: Refers to the type of materials used in the motor’s construction, including copper for windings and various grades of steel for the stator and rotor.

– Importance: The choice of materials affects durability, efficiency, and overall performance. High-grade materials can lead to lower energy losses and longer lifespan, which are critical for reducing operational costs. -

Efficiency Rating

– Definition: This measures how effectively an electric motor converts electrical energy into mechanical energy, often expressed as a percentage.

– Importance: Higher efficiency ratings indicate lower energy consumption, which is vital for cost control and sustainability. For businesses in regions with high energy costs, such as Europe, selecting efficient motors can lead to substantial savings. -

Torque

– Definition: Torque refers to the rotational force produced by the motor, typically measured in Newton-meters (Nm).

– Importance: Understanding the torque requirement for specific applications ensures that the motor can handle the load without overheating or failing. In industries like manufacturing, this is crucial for maintaining productivity. -

Speed (RPM)

– Definition: Speed, measured in revolutions per minute (RPM), indicates how fast the motor’s rotor spins.

– Importance: Different applications require different speeds. Knowing the required RPM helps buyers select a motor that meets operational needs without necessitating costly gear reductions. -

Insulation Class

– Definition: This classifies the thermal limits of motor insulation materials, often categorized as Class A, B, F, or H.

– Importance: Selecting the appropriate insulation class ensures that the motor can operate effectively under the expected temperature conditions, reducing the risk of overheating and extending service life. -

Tolerance

– Definition: Tolerance refers to the permissible limit or limits of variation in a physical dimension or measured value.

– Importance: Precise tolerances are essential for ensuring compatibility with other mechanical systems. Inaccurate tolerances can lead to inefficiencies and failures, impacting productivity.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM products ensures that buyers select components that meet original specifications, which is crucial for warranty compliance and performance. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their procurement strategies and manage inventory levels effectively, especially in regions where storage might be limited. -

RFQ (Request for Quotation)

– Definition: A formal process in which a buyer requests pricing and terms from suppliers for specific products.

– Importance: Issuing an RFQ allows buyers to compare offers from multiple suppliers, ensuring competitive pricing and favorable terms. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of sellers and buyers for the delivery of goods under sales contracts.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risk management, and cost allocation, which is particularly important in international transactions. -

Lead Time

– Definition: The time taken from placing an order until it is delivered.

– Importance: Understanding lead times is crucial for planning and ensuring that projects remain on schedule, particularly in industries with tight deadlines. -

After-sales Support

– Definition: Services provided after the purchase of a product, including installation, maintenance, and repair.

– Importance: Strong after-sales support is essential for minimizing downtime and ensuring that any issues are resolved promptly, which is vital for maintaining operational efficiency.

By familiarizing yourself with these technical properties and trade terms, you can enhance your procurement strategy for AC electric motors, ensuring a better alignment with your operational needs and market conditions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ac electric motors Sector

Market Overview & Key Trends

The AC electric motors market is experiencing robust growth fueled by several global drivers. The push for industrial automation, energy efficiency, and the growing adoption of renewable energy sources are shaping the landscape. In regions like Africa and South America, where industrialization is rapidly advancing, the demand for reliable, efficient AC motors is surging. For international B2B buyers, understanding the regional specificities—such as voltage compatibility and local supply chains—becomes crucial in making informed purchasing decisions.

Emerging trends in sourcing include the integration of smart technology into electric motors. Innovations like IoT-enabled motors provide real-time monitoring, predictive maintenance, and enhanced energy efficiency, which can be particularly advantageous for industries in Europe and the Middle East. Additionally, the shift towards online procurement platforms is transforming how buyers engage with suppliers. This trend offers access to a broader range of manufacturers and facilitates price comparisons, enhancing transparency and competition.

Market dynamics are also influenced by fluctuating raw material prices and geopolitical factors. Buyers need to be aware of supply chain disruptions that can arise from economic sanctions or trade disputes. Establishing relationships with multiple suppliers can mitigate risks associated with single-source dependency and ensure continuity in operations.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a central concern in the sourcing of AC electric motors. The environmental impact of manufacturing processes, from raw material extraction to production, necessitates a focus on ethical sourcing. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint and minimizing waste. This includes evaluating the lifecycle of products and ensuring that end-of-life disposal aligns with sustainable practices.

Ethical supply chains are not just a regulatory necessity but also a market differentiator. Buyers should look for suppliers with certifications such as ISO 14001, which signifies adherence to environmental management standards. Furthermore, sourcing materials that are recyclable or have lower environmental impacts, like certified green components, can enhance a company’s sustainability profile.

The importance of transparency in supply chains cannot be overstated. Implementing traceability systems allows buyers to verify the sustainability claims of suppliers, ensuring that their procurement practices support broader environmental goals. Engaging with suppliers that prioritize social responsibility and fair labor practices can also strengthen brand reputation and foster customer loyalty.

Brief Evolution/History

The evolution of AC electric motors dates back to the late 19th century when pioneers like Nikola Tesla developed the principles that underpin their operation. Initially utilized in industrial applications, these motors have significantly advanced, benefiting from technological innovations that enhance efficiency and reliability. The introduction of variable frequency drives (VFDs) in the 1980s marked a pivotal moment, enabling precise control of motor speed and torque, which has become essential in modern manufacturing processes.

As industries continue to evolve, the focus on energy efficiency and sustainability has driven further innovations in AC motor design and application. Today, AC motors are integral to a wide range of sectors, from manufacturing and agriculture to renewable energy systems. Understanding this historical context allows B2B buyers to appreciate the technological advancements that inform current sourcing strategies and product offerings.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of ac electric motors

-

How can I effectively vet suppliers for AC electric motors?

Vetting suppliers requires a systematic approach. Start by checking their business credentials and industry certifications, such as ISO 9001, which indicates quality management systems. Look for reviews and testimonials from other customers, particularly those in your region. Conducting site visits, if feasible, can provide insights into their manufacturing processes and quality controls. Additionally, request references and assess their responsiveness to inquiries, as good communication is crucial for long-term partnerships. -

What customization options are typically available for AC electric motors?

Many suppliers offer customization options to meet specific operational needs. Common customizations include modifications to voltage ratings, horsepower, frame size, and mounting configurations. Additionally, you can request features like variable frequency drives (VFDs) for speed control or specific insulation types for harsh environments. When discussing customization, ensure that you clearly communicate your requirements and confirm that the supplier can meet your specifications without significantly extending lead times. -

What are the typical minimum order quantities (MOQ) and lead times for AC electric motors?

Minimum order quantities can vary widely depending on the supplier and the specific motor type. Generally, MOQs range from one unit for standard products to several hundred for custom configurations. Lead times can also differ; standard motors may ship within a few weeks, while custom orders could take several months. It’s essential to discuss these aspects upfront during negotiations to ensure that they align with your project timelines and budget. -

What quality assurance certifications should I look for when sourcing AC electric motors?

Key quality assurance certifications to consider include ISO 9001 for quality management systems and CE marking for compliance with European safety standards. Additionally, look for UL or IEC certifications, especially for motors intended for specific applications or industries. Request documentation proving these certifications, and inquire about the supplier’s quality control processes, such as testing protocols and warranties, to ensure product reliability and performance. -

How do I handle logistics when sourcing AC electric motors internationally?

Logistics involve multiple factors, including shipping methods, customs clearance, and delivery timelines. Choose a shipping method that balances cost and speed, such as sea freight for bulk orders or air freight for urgent needs. Ensure that you understand the customs regulations of your country, as this can affect delivery times. Collaborating with a logistics partner familiar with international shipping can streamline the process and help avoid delays or additional costs. -

What should I do if I encounter a dispute with my supplier?

In the event of a dispute, start by reviewing your contract and the terms agreed upon, such as delivery timelines and product specifications. Communicate your concerns directly with the supplier to seek a resolution. If informal discussions do not yield results, consider mediation or arbitration as outlined in your contract. It’s advisable to maintain a professional tone throughout the process, as preserving the relationship may be beneficial for future transactions. -

What are the common challenges faced in international procurement of AC electric motors?

Common challenges include fluctuating currency exchange rates, varying regulatory standards, and differing lead times due to geographical distances. Additionally, language barriers can complicate communication and negotiations. To mitigate these issues, conduct thorough market research and consider working with local agents who understand regional nuances. Establishing clear contracts and maintaining open communication with suppliers can also help address potential misunderstandings.

- How can I ensure the after-sales support is adequate for my AC electric motors?

To ensure adequate after-sales support, inquire about the supplier’s service policies, including warranty periods and the availability of spare parts. Ask if they provide technical support, maintenance services, or training for your staff. It’s also beneficial to establish a clear communication channel for addressing any issues that arise post-purchase. Consider suppliers with a local presence or those who can offer timely support, as this can significantly reduce downtime in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ac electric motors

Effective strategic sourcing of AC electric motors is pivotal for B2B buyers across various industries, especially in regions like Africa, South America, the Middle East, and Europe. By clearly defining procurement needs, researching reliable suppliers, and evaluating their capabilities, organizations can not only secure high-quality products but also foster long-term partnerships that enhance operational efficiency.

Key takeaways include the importance of understanding local electrical standards, evaluating supplier manufacturing processes, and ensuring access to after-sales support. Buyers should prioritize quality and service over mere price competition, recognizing that the right motor can significantly impact productivity and reduce downtime.

Looking ahead, the global landscape for electric motors continues to evolve, driven by advancements in technology and increasing demand for energy-efficient solutions. International B2B buyers are encouraged to stay informed on market trends and emerging technologies in electric motors. By investing in strategic sourcing practices, companies can position themselves for success and build resilience in an ever-changing marketplace. Embrace the opportunity to enhance your operations today—reassess your sourcing strategies and connect with suppliers who align with your business goals.