Your Ultimate Guide to Sourcing Fractional Horsepower

Introduction: Navigating the Global Market for fractional horsepower electric motors

Navigating the global market for fractional horsepower electric motors is essential for businesses seeking efficient and reliable solutions in today’s competitive landscape. These motors, which operate at less than one horsepower, play a pivotal role in a variety of applications, from household appliances to industrial machinery. Their compact size and energy efficiency make them indispensable in sectors that require precision and reliability, such as robotics, HVAC systems, and medical devices.

This comprehensive guide delves into the myriad types of fractional horsepower electric motors, including AC and DC variants, stepper motors, and servo motors. It covers critical aspects such as materials, manufacturing quality control, supplier selection, pricing strategies, and market trends. Each section is designed to empower international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, with the knowledge necessary for informed sourcing decisions.

Understanding the nuances of fractional horsepower motors is crucial for optimizing operational performance and cost-effectiveness. As the demand for innovative and efficient technologies continues to rise, this guide serves as a valuable resource, equipping you with actionable insights to navigate the complexities of the market. By leveraging this information, you can enhance your procurement strategies and ensure that your organization remains competitive in an evolving global marketplace.

Understanding fractional horsepower electric motors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AC Induction Motors | Robust, low maintenance, operates on AC current | HVAC systems, fans, pumps | Pros: Reliable, cost-effective. Cons: Limited speed control. |

| DC Permanent Magnet Motors | High efficiency, responsive, uses permanent magnets | Robotics, small appliances, automotive | Pros: Precise control, compact design. Cons: Higher initial cost. |

| Stepper Motors | Divides rotation into discrete steps, high accuracy | CNC machinery, 3D printers | Pros: Excellent precision, minimal vibration. Cons: Complexity in control systems. |

| Servo Motors | Feedback mechanisms for precise control | Automation systems, robotics, conveyors | Pros: High performance, adaptable. Cons: Can be expensive, requires careful integration. |

| Brushless DC Motors | No brushes, high efficiency, low maintenance | Electric vehicles, drones, cooling fans | Pros: Long lifespan, quiet operation. Cons: More complex electronics. |

AC Induction Motors

AC induction motors are widely recognized for their robustness and reliability. They operate on alternating current and are commonly used in HVAC systems, fans, and pumps. Their key advantages include low maintenance and cost-effectiveness, making them an ideal choice for businesses looking for dependable performance in industrial applications. However, buyers should consider their limited speed control options, which may not suit all applications.

DC Permanent Magnet Motors

These motors utilize permanent magnets to create a magnetic field, resulting in high efficiency and responsiveness. They are particularly favored in robotics and small appliances due to their compact size and ability to provide precise control. When purchasing, B2B buyers should weigh the benefits of precise performance against the potentially higher initial costs associated with these motors.

Stepper Motors

Stepper motors are designed for applications requiring high accuracy, such as CNC machinery and 3D printers. By dividing a full rotation into discrete steps, they offer excellent control over position and speed, making them suitable for precision-driven industries. However, the complexity of control systems can be a drawback, requiring additional investment in technology and training for effective utilization.

Servo Motors

Servo motors are equipped with feedback mechanisms that allow for precise control of angular or linear positioning. They are widely used in automation systems, robotics, and conveyor systems. The adaptability and high performance of servo motors make them an attractive option for B2B buyers. However, potential purchasers should be aware of the higher costs and the need for careful integration into existing systems.

Brushless DC Motors

Known for their efficiency and longevity, brushless DC motors operate without brushes, which minimizes wear and maintenance needs. They are commonly used in modern applications such as electric vehicles and drones. B2B buyers should appreciate the long lifespan and quiet operation of these motors, but they must also consider the complexity of the electronics involved, which can increase initial setup costs.

Key Industrial Applications of fractional horsepower electric motors

| Industry/Sector | Specific Application of fractional horsepower electric motors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC Systems | Used in air conditioning units and ventilation fans | Enhances energy efficiency and reduces operational costs | Consider energy efficiency ratings and noise levels |

| Robotics | Powering robotic arms and automated assembly lines | Increases precision and productivity | Evaluate torque requirements and feedback mechanisms |

| Medical Devices | Driving pumps in infusion systems and diagnostic equipment | Ensures reliability and precision in critical applications | Look for compliance with medical standards and safety certifications |

| Home Appliances | Operating small appliances like blenders and vacuum cleaners | Improves user experience and energy consumption | Focus on compact design and power ratings |

| Automotive | Used in window lifts and seat adjusters | Enhances functionality and comfort in vehicles | Assess durability and environmental resistance |

HVAC Systems

Fractional horsepower electric motors are pivotal in HVAC systems, powering air conditioning units and ventilation fans. Their design allows for efficient airflow management, which is crucial in maintaining optimal indoor environments. For international buyers, especially in regions with varying climates, sourcing motors that meet specific energy efficiency standards can lead to significant cost savings in energy consumption. Additionally, understanding local regulations regarding noise levels is vital to ensure compliance and customer satisfaction.

Robotics

In the robotics sector, fractional horsepower motors are integral to driving robotic arms and automated assembly lines. Their ability to provide precise control and responsiveness enhances productivity and accuracy in manufacturing processes. Buyers should consider the torque requirements and the type of feedback mechanisms necessary for their applications. Additionally, sourcing motors that can withstand varying operational conditions is crucial for maintaining reliability in diverse environments, particularly in developing regions.

Illustrative Image (Source: Google Search)

Medical Devices

Fractional horsepower motors are essential in medical devices, particularly in driving pumps for infusion systems and diagnostic equipment. These motors must operate reliably to ensure patient safety and accurate dosing. International buyers in the medical field need to prioritize sourcing motors that comply with stringent medical standards and safety certifications. Additionally, understanding the specific operational requirements, such as power ratings and noise levels, is critical for successful integration into medical applications.

Home Appliances

In the home appliance industry, fractional horsepower motors are commonly used to operate small devices like blenders and vacuum cleaners. The efficiency and compact design of these motors contribute to a better user experience and reduced energy consumption. For B2B buyers, focusing on the power ratings and durability of the motors is essential to ensure they meet consumer expectations. Additionally, understanding local market trends can help in selecting motors that align with consumer preferences for energy-efficient appliances.

Automotive

Fractional horsepower motors play a significant role in automotive applications, such as powering window lifts and seat adjusters. These motors enhance vehicle functionality and comfort, making them vital components in modern automobiles. Buyers should assess the durability and environmental resistance of these motors, particularly in regions with extreme weather conditions. Furthermore, understanding the latest automotive trends can guide sourcing decisions, ensuring compatibility with emerging vehicle technologies.

Related Video: Ultimate Beginners Guide to Using Electric Motors for Makers and DIY Projects; #068

Strategic Material Selection Guide for fractional horsepower electric motors

When selecting materials for fractional horsepower electric motors, it is essential to consider their properties, performance implications, and suitability for specific applications. Below are analyses of four common materials used in the construction of these motors, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Aluminum

Key Properties:

Aluminum is lightweight, has excellent thermal conductivity, and offers good corrosion resistance. It typically performs well under a temperature range of -50°C to 150°C, making it suitable for various environments.

Pros & Cons:

Aluminum’s low weight facilitates easier handling and installation, while its resistance to corrosion enhances durability. However, it has a lower tensile strength compared to steel, which may limit its use in high-stress applications. Additionally, aluminum can be more expensive than some other materials, which could impact overall project costs.

Impact on Application:

Aluminum is particularly effective in applications where weight savings are crucial, such as in portable devices. Its thermal properties help maintain motor efficiency, especially in environments with fluctuating temperatures.

Considerations for International Buyers:

Buyers should ensure compliance with relevant standards such as ASTM B221 for aluminum extrusions. In regions like Europe, adherence to RoHS directives is also essential to avoid hazardous substances.

2. Steel

Key Properties:

Steel is known for its high tensile strength and durability. It can withstand high temperatures (up to 300°C) and has excellent wear resistance, making it ideal for demanding applications.

Pros & Cons:

The primary advantage of steel is its robustness, which provides longevity and reliability in high-stress environments. However, it is heavier than aluminum, which may not be suitable for all applications. Additionally, steel is prone to corrosion unless adequately treated, which can increase maintenance costs.

Impact on Application:

Steel is commonly used in motors that require high torque and durability, such as in industrial machinery. Its strength allows for consistent performance under heavy loads.

Considerations for International Buyers:

Buyers should be aware of standards such as ASTM A36 for structural steel. In regions like South America and Africa, local sourcing of steel may also affect costs and availability.

3. Composite Materials

Key Properties:

Composite materials, often made from a combination of plastic and fiberglass, offer lightweight properties and good insulation. They can withstand moderate temperatures (up to 120°C) and are resistant to corrosion.

Pros & Cons:

The lightweight nature of composites makes them ideal for applications where minimizing weight is critical. They also provide good electrical insulation. However, composites may not have the same mechanical strength as metals, limiting their use in high-load applications. Additionally, they can be more costly to manufacture.

Impact on Application:

Composites are particularly beneficial in applications where electromagnetic interference (EMI) needs to be minimized, such as in sensitive electronic devices.

Considerations for International Buyers:

Buyers should verify that composite materials meet specific industry standards, such as ASTM D638 for tensile properties. Understanding local regulations regarding material safety and environmental impact is also crucial.

4. Copper

Key Properties:

Copper is an excellent conductor of electricity and heat, with a high melting point (approximately 1,085°C). It is also resistant to corrosion, especially when coated.

Pros & Cons:

Copper’s superior conductivity enhances motor efficiency and performance. However, it is relatively expensive compared to other materials, which can impact the overall cost of the motor. Additionally, copper is heavier, which may not be suitable for all applications.

Impact on Application:

Copper is often used in windings and connections within fractional horsepower motors, where efficient energy transfer is critical. Its thermal properties help dissipate heat, improving motor longevity.

Considerations for International Buyers:

Compliance with standards such as ASTM B170 for copper wire is essential. Buyers should also consider the impact of fluctuating copper prices on their procurement strategies.

| Material | Typical Use Case for fractional horsepower electric motors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight applications, portable devices | Excellent thermal conductivity | Lower tensile strength | Medium |

| Steel | Industrial machinery, high-torque applications | High durability and strength | Prone to corrosion | Medium |

| Composite Materials | Sensitive electronic devices, EMI shielding | Lightweight and good insulation | Limited mechanical strength | High |

| Copper | Motor windings, electrical connections | Superior electrical conductivity | Higher cost and weight | High |

In-depth Look: Manufacturing Processes and Quality Assurance for fractional horsepower electric motors

The manufacturing process for fractional horsepower electric motors involves several critical stages, each essential for ensuring the quality and reliability of the final product. Understanding these processes can help B2B buyers make informed decisions when selecting suppliers, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

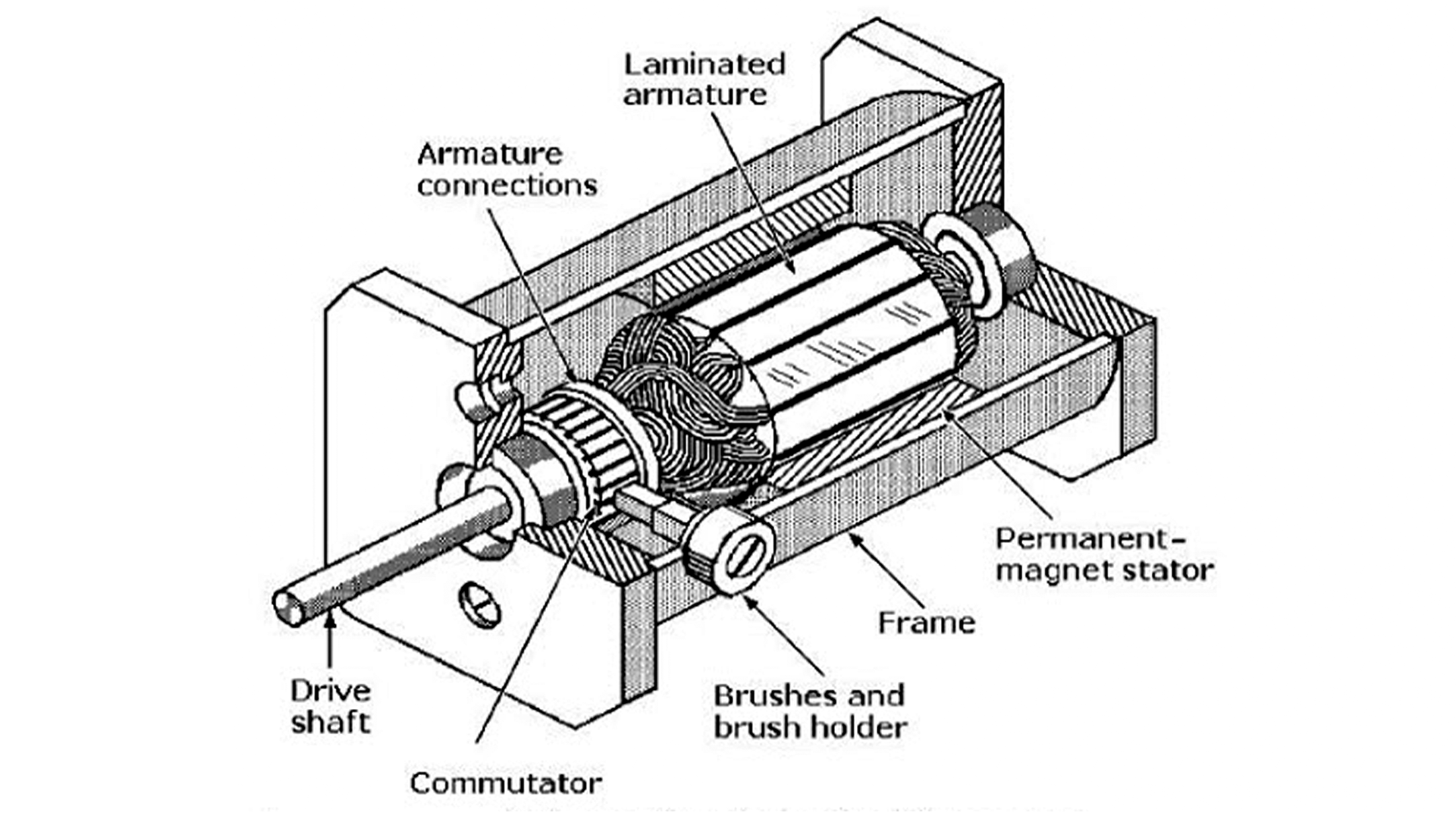

Illustrative Image (Source: Google Search)

Manufacturing Processes

Material Preparation

The first stage in manufacturing fractional horsepower motors is material preparation. This involves sourcing high-quality raw materials such as copper for windings, steel for stator and rotor components, and insulation materials. Suppliers often prioritize materials that meet international standards to ensure durability and performance. B2B buyers should inquire about the sourcing practices and certifications of materials, as these can significantly influence the motor’s overall quality.

Forming

Once materials are prepared, the next step is forming. This includes processes such as:

- Stamping: Used to create the stator and rotor laminations, which are critical for reducing energy losses.

- Winding: Copper wires are wound into coils for the stator and rotor. The precision in this step affects the motor’s efficiency and performance.

- Machining: Components are machined to precise dimensions to ensure a proper fit during assembly.

These forming techniques are often automated to enhance accuracy and reduce production time. Buyers should assess suppliers’ capabilities in automation and the technology employed in these processes.

Assembly

The assembly stage combines all the individual components into a complete motor. Key steps include:

- Placement of Windings: Proper alignment and securing of the windings to avoid electromagnetic interference.

- Integration of Components: The rotor is inserted into the stator, and bearings are added to facilitate smooth rotation.

- Electrical Connections: Ensuring correct wiring and connectivity is vital for motor functionality.

Quality during assembly is critical as it directly impacts the motor’s performance. Buyers should verify that suppliers have standardized assembly protocols to maintain consistency.

Finishing

The final stage involves various finishing processes that enhance the motor’s durability and aesthetics. These may include:

- Coating: Application of protective coatings to prevent corrosion and wear.

- Testing: Conducting functional tests to ensure the motor operates as specified.

Finishing not only contributes to the visual appeal of the motor but also its longevity in different operating environments.

Quality Assurance

Quality assurance is integral to the manufacturing process of fractional horsepower motors, ensuring that products meet both regulatory and performance standards.

International Standards

B2B buyers should be aware of relevant international standards such as:

- ISO 9001: A standard that outlines requirements for quality management systems, ensuring consistent product quality and customer satisfaction.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: Especially relevant for motors used in the oil and gas industry, ensuring performance and safety.

Understanding these standards can help buyers assess the credibility and reliability of suppliers.

QC Checkpoints

Quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing to identify any defects or deviations from specifications.

- Final Quality Control (FQC): Comprehensive testing of the finished product to ensure it meets all performance criteria.

These checkpoints help catch potential issues early, ensuring only high-quality motors reach the market.

Common Testing Methods

Various testing methods are employed to verify motor performance, including:

- Electrical Testing: Measures resistance, inductance, and insulation resistance to ensure electrical integrity.

- Thermal Testing: Assesses the motor’s ability to operate under different temperature conditions.

- Vibration Testing: Evaluates the motor’s operational smoothness and potential for wear.

B2B buyers should inquire about the specific testing methods employed by suppliers to ensure comprehensive quality checks.

Verifying Supplier QC

To ensure that suppliers maintain high-quality standards, B2B buyers can take several steps:

- Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes and quality control practices of suppliers.

- Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s performance history and adherence to standards.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality practices.

Buyers should also consider the nuances of quality certification in different regions. For instance, European standards may differ from those in Africa or South America. Understanding these differences can aid in selecting suppliers that align with specific market requirements.

Conclusion

The manufacturing processes and quality assurance protocols for fractional horsepower electric motors are fundamental to ensuring product reliability and performance. By understanding these processes, B2B buyers from Africa, South America, the Middle East, and Europe can make informed decisions, ultimately leading to successful procurement and long-term partnerships. Investing time in evaluating suppliers’ manufacturing capabilities and quality assurance practices will pay dividends in the form of high-quality, efficient motors tailored to meet specific application needs.

Related Video: How to Make Electric MOTOR in Factory | Amazing Electrical Motors Manufacturing Process

Comprehensive Cost and Pricing Analysis for fractional horsepower electric motors Sourcing

Understanding the cost structure and pricing dynamics of fractional horsepower electric motors is crucial for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Below is a comprehensive analysis that outlines the key cost components, price influencers, and actionable buyer tips.

Cost Components

-

Materials: The cost of raw materials—such as copper for windings, steel for the motor casing, and magnets for permanent magnet motors—represents a significant portion of the overall cost. The price of these materials can fluctuate based on market demand and geopolitical factors, impacting sourcing strategies.

-

Labor: Labor costs vary by region and are influenced by local wage rates and skill availability. In areas with higher labor costs, such as parts of Europe, manufacturers may pass these costs onto buyers, impacting the final price.

-

Manufacturing Overhead: This includes costs related to facility operation, utilities, and maintenance of machinery. Efficient manufacturing processes can help minimize these overhead costs, but they must be factored into the pricing.

-

Tooling: The initial investment in specialized tools and equipment for producing specific motor designs can be substantial. For custom orders, these costs may be amortized over larger production runs, affecting the unit price.

-

Quality Control (QC): Implementing stringent quality control measures ensures that motors meet performance and safety standards. While this adds to production costs, it is essential for maintaining product reliability, especially in critical applications.

-

Logistics: Transportation costs, including shipping and handling, significantly influence the total cost. International buyers should be aware of potential tariffs and duties that can add to logistics expenses.

-

Margin: The manufacturer’s profit margin varies by supplier and can be influenced by brand reputation, market competition, and customer relationships. Understanding typical margins in the industry can help buyers negotiate better deals.

Price Influencers

-

Volume/MOQ: Larger order volumes often lead to lower per-unit costs due to economies of scale. Buyers should consider negotiating minimum order quantities (MOQ) to achieve better pricing.

-

Specifications/Customization: Custom specifications, such as unique dimensions or performance features, can increase costs. Buyers should clearly communicate their needs to avoid unnecessary expenses.

-

Materials: The choice of materials impacts both performance and cost. Higher-quality materials may lead to a higher upfront price but can reduce long-term maintenance and replacement costs.

-

Quality/Certifications: Motors that meet international standards and certifications (e.g., ISO, CE) may carry a premium price. However, these certifications can provide assurance of reliability and performance.

-

Supplier Factors: The supplier’s location, reputation, and service capabilities can influence pricing. Local suppliers may offer lower shipping costs, while established brands may command higher prices due to perceived quality.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. Terms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can affect pricing and risk allocation.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing structures, volume discounts, and flexible payment terms. Building a good relationship can lead to better deals.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes initial purchase price, operational costs, maintenance, and lifespan. A higher initial investment may yield lower lifetime costs.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, motors sourced from Asia may be cheaper but could incur higher shipping costs compared to European suppliers.

-

Market Research: Conduct thorough research on multiple suppliers to compare prices and offerings. Utilize platforms that provide insights into market trends and supplier performance.

-

Local Regulations: Ensure compliance with local regulations and standards when importing motors. Non-compliance can result in additional costs or penalties.

Disclaimer

Prices for fractional horsepower electric motors can vary widely based on multiple factors, including market conditions and specific buyer requirements. This analysis serves as a guideline; actual pricing should be confirmed directly with suppliers.

Spotlight on Potential fractional horsepower electric motors Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘fractional horsepower electric motors’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for fractional horsepower electric motors

Understanding the technical properties and trade terminology associated with fractional horsepower electric motors is crucial for B2B buyers, particularly in diverse markets across Africa, South America, the Middle East, and Europe. This knowledge not only facilitates informed purchasing decisions but also enhances the negotiation process with manufacturers and suppliers.

Key Technical Properties

-

Power Rating (HP and Watts)

– Definition: The power output of the motor, typically measured in horsepower (HP) or watts. Fractional horsepower motors operate at less than 1 HP (746 watts).

– Importance: Selecting the correct power rating is essential for ensuring that the motor meets the specific operational demands of the application, whether it’s for HVAC systems or robotics. -

Torque (Starting and Running)

– Definition: Torque refers to the rotational force the motor can generate. Starting torque is the force available when the motor begins to rotate, while running torque is the force during normal operation.

– Importance: Understanding torque specifications is vital for applications requiring high precision and control, such as in automated machinery or delicate instruments. -

Efficiency Rating

– Definition: This measures how effectively the motor converts electrical energy into mechanical energy, typically expressed as a percentage.

– Importance: Higher efficiency ratings lead to lower operational costs and reduced energy consumption, which is crucial for businesses looking to improve their bottom line and sustainability profile. -

Duty Cycle

– Definition: This indicates the motor’s operational pattern, defining how long the motor can run versus how long it should rest. Common duty cycles include continuous, intermittent, and short-term.

– Importance: Knowing the duty cycle helps ensure that the motor can handle the intended application without overheating or failing, which is particularly important in industrial settings. -

Material Grade

– Definition: The materials used in the motor’s construction, including types of metals and insulation.

– Importance: Material selection affects durability, performance, and maintenance needs. For example, high-grade steel may offer better performance in high-stress applications.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships is essential for buyers looking to source reliable components that fit specific machinery or systems. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ helps buyers plan their purchasing strategy and manage inventory costs, especially in regions where bulk buying can lead to significant savings. -

RFQ (Request for Quote)

– Definition: A document issued by a buyer to solicit price quotations from suppliers.

– Relevance: An RFQ is a critical tool for B2B buyers to compare prices, terms, and conditions from multiple suppliers, ensuring competitive sourcing. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of sellers and buyers in international transactions.

– Relevance: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks associated with importing fractional horsepower motors. -

NEMA (National Electrical Manufacturers Association) Rating

– Definition: A classification system for electric motors, indicating their design, performance, and suitability for specific environments.

– Relevance: NEMA ratings help buyers select motors that meet regulatory standards and operational conditions, especially in varying climates and industries.

By understanding these technical specifications and trade terminologies, B2B buyers can make more informed decisions, negotiate effectively, and ultimately enhance the performance and efficiency of their operations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the fractional horsepower electric motors Sector

Market Overview & Key Trends

The fractional horsepower electric motors market is experiencing dynamic growth driven by several global factors. The increasing demand for energy-efficient solutions across various sectors, including HVAC, robotics, and consumer electronics, is propelling this market forward. In particular, the push for automation in manufacturing and the rise of smart technologies are influencing purchasing decisions among B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

Emerging trends in sourcing indicate a shift towards integrated supply chain solutions that prioritize flexibility and rapid delivery. B2B buyers are increasingly seeking suppliers that can provide customized solutions tailored to specific operational needs. Additionally, advancements in digital technologies, such as IoT and AI, are facilitating better monitoring and management of motor performance, leading to enhanced efficiency and reduced downtime.

Market dynamics are also shaped by the transition towards renewable energy sources, which has led to an uptick in the use of fractional horsepower motors in green technologies. For international buyers, understanding regional market conditions and aligning with suppliers that emphasize technological innovation and responsiveness is crucial for maintaining competitive advantage. The ongoing global supply chain disruptions necessitate a focus on reliable partnerships that can ensure consistent product availability.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the fractional horsepower electric motors sector. The environmental impact of production processes, including energy consumption and waste generation, is prompting B2B buyers to prioritize manufacturers that demonstrate commitment to sustainable practices. Ethical sourcing is not merely a trend but a necessity, as stakeholders increasingly demand transparency in supply chains.

Buyers should look for suppliers that utilize eco-friendly materials and manufacturing processes. Certifications such as ISO 14001 (Environmental Management) and adherence to REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) guidelines can serve as indicators of a supplier’s commitment to sustainability. Additionally, the use of recyclable materials in the production of fractional horsepower motors can significantly reduce environmental footprints.

Investing in sustainable technologies not only enhances corporate responsibility but also opens avenues for cost savings through energy-efficient solutions. As global regulations on emissions tighten, aligning with suppliers focused on sustainability can help businesses mitigate risks associated with non-compliance and enhance their market reputation.

Brief Evolution/History

The evolution of fractional horsepower electric motors traces back to the early 19th century, coinciding with the advent of electric power. Initially, these motors were primarily used in simple applications due to their compact size and ease of integration. Over the decades, advancements in materials and technology have led to significant improvements in performance and efficiency.

Today, fractional horsepower motors are ubiquitous, powering everything from household appliances to complex industrial machinery. The introduction of brushless and servo motors has expanded the range of applications, enabling precise control and enhanced efficiency. For B2B buyers, understanding this historical context is essential in recognizing the technological advancements that define today’s offerings and the potential for future innovations in the sector.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of fractional horsepower electric motors

-

What factors should I consider when vetting suppliers of fractional horsepower electric motors?

When vetting suppliers, assess their industry experience, production capabilities, and product range. Request references or case studies from previous clients, especially those in your region. Evaluate their certifications (ISO, CE, etc.) to ensure compliance with international standards. Additionally, consider their financial stability, which can impact long-term partnership reliability. A supplier’s responsiveness to inquiries can also indicate their customer service level. -

Can I customize fractional horsepower electric motors to meet specific requirements?

Many manufacturers offer customization options for fractional horsepower motors, including modifications in voltage, speed, and mounting configurations. Before proceeding, clearly define your requirements and check if the supplier has the capability to meet them. Discuss potential design changes, such as specific torque outputs or environmental considerations. Be prepared for longer lead times and possibly higher costs associated with custom orders. -

What are the typical minimum order quantities (MOQ) and lead times for fractional horsepower motors?

MOQs can vary significantly based on the supplier and the motor type. For standard motors, MOQs may range from 10 to 100 units, while custom orders might require larger quantities. Lead times can also differ, typically ranging from 4 to 12 weeks depending on production capacity, customization requirements, and shipping logistics. Always clarify these details upfront to avoid surprises during the ordering process. -

What payment terms should I expect when sourcing fractional horsepower motors internationally?

Payment terms can vary widely among suppliers, but common practices include advance payments, letters of credit, or payment upon delivery. It’s advisable to negotiate terms that align with your financial strategy while ensuring the supplier’s confidence in your commitment. Be aware of the currency exchange rates and any additional bank fees associated with international transactions, as these can impact overall costs. -

How can I ensure quality assurance and certifications for fractional horsepower motors?

Request detailed documentation of quality assurance processes from your supplier, including test reports and certifications. Reputable suppliers should comply with international standards such as ISO 9001 for quality management. Consider asking for samples to evaluate performance before making bulk purchases. Establishing a quality control agreement can also provide added security and ensure that products meet your specifications. -

What logistics considerations should I keep in mind when importing fractional horsepower motors?

When importing motors, factor in shipping methods, customs duties, and potential delays. Determine whether to use air or sea freight based on your urgency and budget. Collaborate with a logistics provider familiar with your region’s import regulations to streamline the process. Ensure that your supplier provides all necessary documentation, including bills of lading and customs clearance paperwork, to avoid complications at the border. -

How should I handle disputes with suppliers during the procurement process?

To manage disputes effectively, establish clear communication channels and document all agreements in writing. If issues arise, approach the supplier with a calm and constructive mindset, focusing on finding a resolution. If necessary, refer to the terms outlined in your contract regarding dispute resolution procedures. Consider involving third-party mediation if a resolution cannot be reached amicably. -

What common applications should I consider when selecting fractional horsepower motors?

Fractional horsepower motors are versatile and can be used in various applications, including HVAC systems, robotics, medical devices, and consumer electronics. Assess the specific requirements of your application, such as power, speed, and torque needs, to determine the suitable motor type. Understanding the end-use will help you select a motor that not only meets performance criteria but also aligns with energy efficiency and operational longevity goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for fractional horsepower electric motors

In conclusion, fractional horsepower electric motors represent a vital component in various industries, offering efficiency, precision, and adaptability. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, strategic sourcing of these motors is essential to align with the specific needs of your applications. Understanding the diverse types—such as AC induction, DC permanent magnet, stepper, servo, universal, and brushless motors—enables businesses to select the right motor that optimizes performance while reducing costs.

Key takeaways include:

– Prioritize the evaluation of application-specific factors, including efficiency, torque, and noise levels.

– Leverage the versatility of fractional horsepower motors to enhance product innovation and meet market demands.

– Establish relationships with reliable suppliers to ensure quality and sustainability in sourcing practices.

Looking ahead, as the global demand for compact and efficient technologies continues to rise, investing in fractional horsepower electric motors will be crucial for maintaining competitive advantage. Take action now to explore partnerships with leading manufacturers and suppliers to secure the best solutions for your operational needs, ensuring that your business is well-positioned for future growth and innovation.