Master the Art of Sourcing Agitator Tanks for Optimal

Introduction: Navigating the Global Market for agitator tank

Navigating the global market for agitator tanks is essential for industries that rely on efficient mixing, blending, and chemical reactions. These tanks serve as the backbone of production processes across various sectors, including food and beverage, pharmaceuticals, and chemicals. Their role extends beyond mere mixing; they ensure product consistency, quality, and safety, ultimately influencing operational efficiency and profitability.

This comprehensive guide is designed to empower international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe, including key markets like France and the UAE. It will delve into the various types of agitator tanks, helping you understand which is best suited for your specific applications. Additionally, we will explore the materials used in construction, manufacturing and quality control standards, and the cost factors associated with purchasing and maintaining these critical assets.

Moreover, this guide will provide insights into market trends and reliable suppliers, ensuring that you are well-equipped to make informed sourcing decisions. Common questions and answers will also be addressed, aiding you in navigating the complexities of the agitator tank market. By leveraging the information presented, you can strategically enhance your operational capabilities and drive your business towards greater success in a competitive landscape.

Understanding agitator tank Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Paddle Agitator | Simple design with flat blades for low viscosity | Food & beverage, water treatment | Pros: Cost-effective, easy to clean. Cons: Limited to low-viscosity materials. |

| Turbine Agitator | High-speed rotation, multiple blades | Chemical processing, pharmaceuticals | Pros: Effective for medium to high viscosity, versatile. Cons: Higher energy consumption. |

| High-Efficiency Impeller | Specialized design for gas dispersion or emulsification | Cosmetics, specialty chemicals | Pros: Excellent mixing efficiency, handles complex tasks. Cons: More expensive, requires precise installation. |

| Anchor Agitator | Fixed anchor with flexible blades | Paints, adhesives, and high-viscosity products | Pros: Ideal for viscous materials, gentle mixing. Cons: Limited to specific applications, may require larger tanks. |

| Magnetic Agitator | Utilizes magnetic fields for stirring | Laboratory settings, small-scale production | Pros: Minimal contamination, low maintenance. Cons: Limited capacity, not suitable for large-scale operations. |

Paddle Agitator

Paddle agitators are characterized by their flat blades that effectively mix low-viscosity liquids. They are commonly employed in industries such as food and beverage processing and water treatment. When considering a paddle agitator, buyers should focus on the material compatibility, ease of cleaning, and overall maintenance costs. While they are cost-effective and straightforward to operate, their functionality is limited to less viscous materials, which could restrict their application in more complex mixing scenarios.

Turbine Agitator

Turbine agitators feature a high-speed rotational mechanism with multiple blades, making them suitable for medium to high-viscosity fluids. They are widely used in chemical processing and pharmaceutical manufacturing. When selecting a turbine agitator, buyers should evaluate the agitator’s energy efficiency, as they can consume more power than simpler designs. Despite their higher operational costs, turbine agitators offer versatility and robust mixing capabilities, making them a worthy investment for operations requiring thorough blending.

High-Efficiency Impeller

High-efficiency impellers are designed for demanding mixing tasks, such as gas dispersion and emulsification, often utilized in the cosmetics and specialty chemicals sectors. These agitators provide exceptional mixing efficiency and can handle complex materials. Buyers should consider the installation requirements and potential costs associated with maintenance, as these systems can be more expensive than traditional agitators. The investment pays off in terms of performance and quality of the final product, particularly in applications where consistency is critical.

Anchor Agitator

Anchor agitators are equipped with a fixed anchor and flexible blades, making them ideal for mixing high-viscosity materials like paints and adhesives. They are particularly effective for gentle mixing processes. When purchasing an anchor agitator, buyers should assess the tank size and the specific viscosity of the materials they will be working with. Although they provide excellent mixing for specific applications, their use is somewhat limited, and they may necessitate larger tanks to accommodate their operation.

Magnetic Agitator

Magnetic agitators utilize magnetic fields to create stirring motion, making them suitable for laboratory settings and small-scale production. They are advantageous for minimizing contamination and require low maintenance. However, buyers must be aware of their limited capacity, as they are not designed for large-scale operations. When considering a magnetic agitator, it is crucial to evaluate the specific application requirements and whether the benefits of reduced contamination outweigh the limitations in capacity.

Related Video: Operating An Industrial Tank Agitator Near Critical Speed

Key Industrial Applications of agitator tank

| Industry/Sector | Specific Application of Agitator Tank | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Mixing ingredients for sauces and dressings | Ensures product consistency and flavor uniformity | Focus on hygiene standards, ease of cleaning, and material safety |

| Pharmaceuticals | Formulating and mixing active pharmaceutical ingredients | Guarantees precise mixing, reducing contamination risks | Compliance with regulatory standards and precision in mixing |

| Chemical Manufacturing | Blending chemicals for reactions | Enhances reaction efficiency and product quality | Material compatibility and resistance to corrosive substances |

| Cosmetics and Personal Care | Emulsifying creams and lotions | Achieves stable formulations and improved texture | Consideration for batch size and scalability |

| Water Treatment | Mixing chemicals for water purification | Increases effectiveness of purification processes | Evaluate tank size and agitator type based on water volume |

Food and Beverage

In the food and beverage industry, agitator tanks are essential for mixing ingredients such as sauces, dressings, and beverages. These tanks ensure that ingredients are uniformly blended, which is critical for flavor consistency and quality control. Buyers in this sector should prioritize hygiene standards, as well as the ease of cleaning the tanks to comply with food safety regulations. Material safety is also a key consideration to avoid contamination.

Pharmaceuticals

Agitator tanks play a pivotal role in the pharmaceutical sector, where they are used for the formulation and mixing of active pharmaceutical ingredients (APIs). The precision of mixing in these tanks is crucial to avoid contamination and ensure the efficacy of the final product. International buyers need to ensure that the tanks meet stringent regulatory standards and provide accurate mixing capabilities to support their production processes.

Chemical Manufacturing

In chemical manufacturing, agitator tanks are used for blending various chemicals to facilitate reactions. These tanks improve the efficiency of chemical processes, leading to higher product quality and reduced production times. Buyers should consider the compatibility of the tank materials with the chemicals being mixed, as well as the resistance to corrosive substances, to ensure longevity and safety in operations.

Cosmetics and Personal Care

Agitator tanks are utilized in the cosmetics and personal care industry to emulsify creams and lotions, achieving stable formulations. This application is vital for ensuring that products have the desired texture and consistency. Buyers should evaluate batch sizes and scalability options, as well as the specific agitator types that will best suit their formulation needs.

Water Treatment

In water treatment facilities, agitator tanks are employed for mixing chemicals used in purification processes. These tanks enhance the effectiveness of chemical treatments by ensuring thorough mixing, which is crucial for achieving clean and safe water. When sourcing agitator tanks for this application, buyers should assess the size of the tanks and the type of agitators needed based on the volume of water being treated, ensuring optimal performance.

Related Video: Jacketed Mixing Tank with agitator, Industrial Stirrer

Strategic Material Selection Guide for agitator tank

When selecting the appropriate material for an agitator tank, it is essential to consider the unique properties and performance characteristics of each material. Below, we analyze four common materials used in the construction of agitator tanks: stainless steel, carbon steel, glass-lined steel, and polyethylene. Each material has distinct advantages and disadvantages that can significantly impact operational efficiency and product quality.

Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand both high temperatures and pressures. It is often rated for use in environments with temperatures up to 500°F (260°C) and pressures exceeding 150 psi, depending on the grade.

Pros & Cons:

The durability of stainless steel makes it suitable for a wide range of applications, particularly in the food and pharmaceutical industries where hygiene is paramount. However, it is more expensive than other materials, and its manufacturing complexity can lead to higher initial costs.

Impact on Application:

Stainless steel is compatible with a variety of media, including corrosive chemicals and high-viscosity liquids, making it a versatile choice. Its smooth surface also facilitates easy cleaning, which is crucial for maintaining product integrity.

Considerations for International Buyers:

Buyers should ensure compliance with relevant standards such as ASTM A240 or DIN EN 10088 for stainless steel. In regions like the UAE and Europe, certifications for food-grade materials are often required.

Carbon Steel

Key Properties:

Carbon steel offers good strength and is generally more cost-effective than stainless steel. However, it has lower corrosion resistance, making it less suitable for aggressive chemicals.

Pros & Cons:

While carbon steel is durable and relatively inexpensive, it requires protective coatings or linings to prevent rust and corrosion. This adds to maintenance costs over time.

Impact on Application:

Carbon steel is best suited for mixing non-corrosive materials. Its use in applications involving aggressive media can lead to premature failure, necessitating careful consideration of the media compatibility.

Considerations for International Buyers:

Buyers should be aware of the need for coatings that comply with local regulations. In Europe, for example, compliance with standards like EN 10025 is critical to ensure material quality.

Glass-Lined Steel

Key Properties:

Glass-lined steel combines the strength of steel with the inert properties of glass. It offers excellent corrosion resistance and can handle temperatures up to 450°F (232°C).

Pros & Cons:

The primary advantage of glass-lined tanks is their ability to resist chemical attack, making them ideal for aggressive media. However, they can be fragile and susceptible to chipping, which may lead to costly repairs.

Impact on Application:

These tanks are particularly effective in the chemical and pharmaceutical industries, where purity and resistance to contamination are crucial. The glass lining ensures that no metallic ions leach into the product.

Considerations for International Buyers:

Buyers should check for compliance with standards such as ASTM C-550 for glass-lined equipment. In regions like Africa and South America, the availability of skilled technicians for repairs may also be a consideration.

Polyethylene

Key Properties:

Polyethylene is a lightweight, corrosion-resistant plastic that is suitable for a range of applications. It can typically withstand temperatures up to 180°F (82°C) and is resistant to many chemicals.

Pros & Cons:

The low cost and ease of fabrication make polyethylene an attractive option for many industries. However, its lower temperature and pressure ratings compared to metals limit its applications.

Impact on Application:

Polyethylene is well-suited for mixing non-corrosive liquids and is often used in water treatment and agricultural applications. However, it is not suitable for high-temperature processes.

Considerations for International Buyers:

When sourcing polyethylene tanks, buyers should consider compliance with standards such as FDA regulations for food contact materials. In regions with high UV exposure, UV stabilizers may be necessary to prolong tank life.

Summary Table

| Material | Typical Use Case for agitator tank | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and pharmaceutical mixing | Excellent corrosion resistance and durability | Higher initial cost | High |

| Carbon Steel | Non-corrosive liquid mixing | Cost-effective and strong | Requires protective coatings | Medium |

| Glass-Lined Steel | Chemical and pharmaceutical applications | Superior chemical resistance | Fragile and prone to chipping | High |

| Polyethylene | Water treatment and agricultural applications | Lightweight and corrosion-resistant | Limited temperature and pressure ratings | Low |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, ensuring informed decisions that align with operational needs and compliance requirements across diverse regions.

In-depth Look: Manufacturing Processes and Quality Assurance for agitator tank

Agitator tanks are critical components in many industrial processes, requiring a robust manufacturing process and stringent quality assurance to ensure they meet operational demands. Understanding these aspects can significantly aid international B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe. Below, we delve into the typical manufacturing processes involved in creating agitator tanks and the quality assurance measures that should be in place.

Manufacturing Processes for Agitator Tanks

The manufacturing of agitator tanks generally follows a structured approach, encompassing several key stages:

1. Material Preparation

Before any fabrication begins, the selection of materials is crucial. Common materials used in the construction of agitator tanks include stainless steel, carbon steel, and various alloys, depending on the application and the substances being mixed.

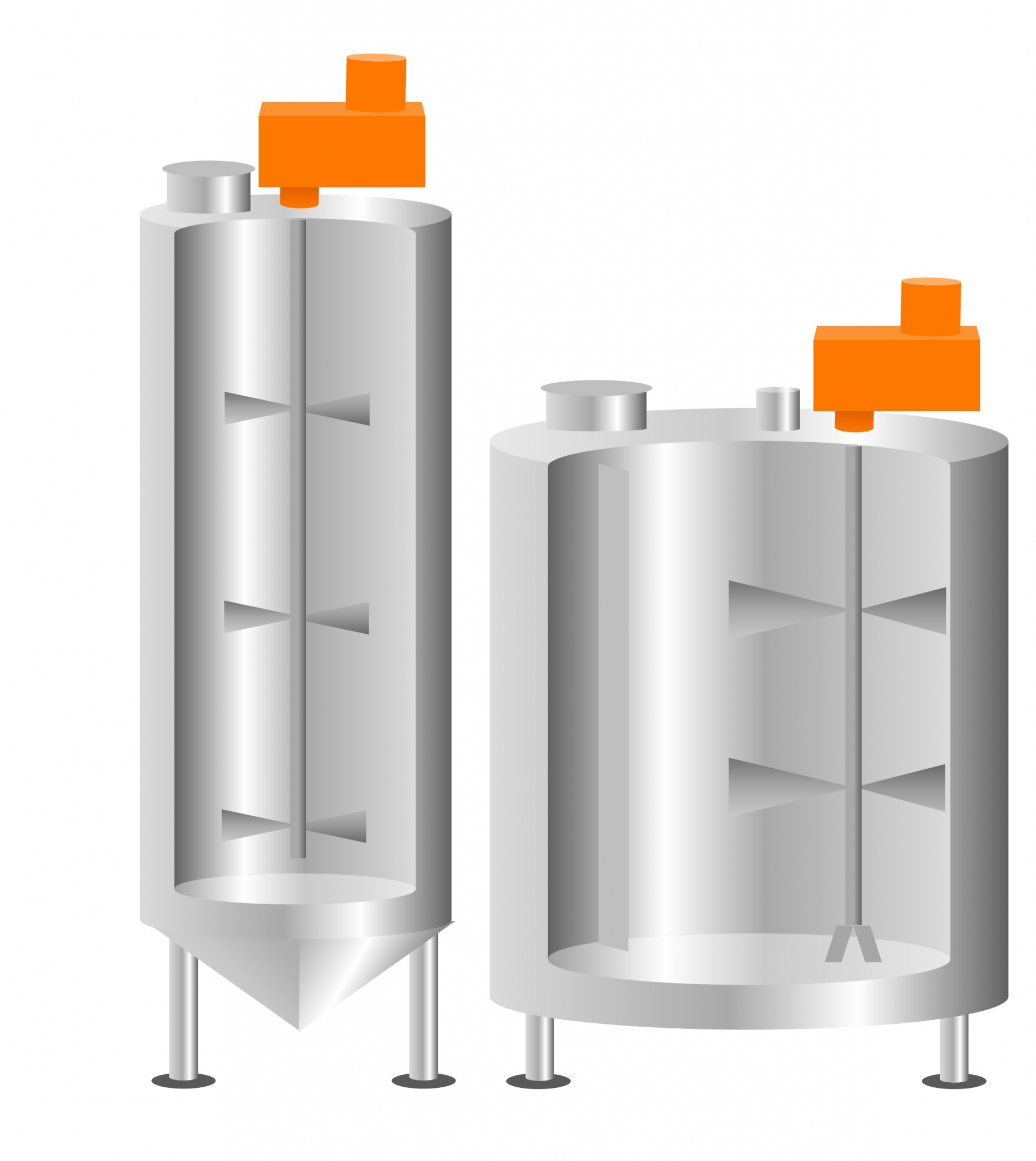

Illustrative Image (Source: Google Search)

- Material Specifications: Ensure materials meet industry standards (e.g., ASTM, ASME) for chemical resistance, temperature tolerance, and structural integrity.

- Pre-treatment: Materials may undergo surface treatments to enhance corrosion resistance or improve adhesion for coatings.

2. Forming

This stage involves shaping the selected materials into the desired tank and agitator configurations.

- Techniques: Common forming techniques include:

- Welding: Used for joining sections of the tank and constructing the agitator. TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding are popular choices.

- Rolling: Steel sheets are rolled into cylindrical shapes for the tank body.

- Bending and Cutting: Precise cutting and bending techniques are employed to achieve the required geometries.

3. Assembly

Once formed, the components are assembled into the final product.

- Joining Techniques: Various methods, including welding, bolting, and using gaskets, are applied to ensure a leak-proof assembly.

- Integration of Agitators: Depending on the design, agitators (e.g., paddle, turbine) are installed within the tank, often requiring precise alignment to ensure optimal mixing efficiency.

4. Finishing

Finishing processes enhance the durability and aesthetic appeal of the agitator tanks.

- Surface Treatment: Processes like polishing, sandblasting, or coating with protective materials (e.g., epoxy) are performed to improve resistance to corrosion and facilitate cleaning.

- Final Inspection: Before leaving the manufacturing facility, the tanks undergo a series of inspections to ensure they meet design specifications and quality standards.

Quality Assurance in Agitator Tank Manufacturing

Quality assurance (QA) is vital in the production of agitator tanks to ensure safety, reliability, and performance. The following international and industry-specific standards are crucial:

Relevant International Standards

- ISO 9001: This standard ensures that manufacturers maintain quality management systems to enhance customer satisfaction and ensure consistent quality.

- CE Marking: Particularly relevant in Europe, CE marking indicates that the product meets EU safety, health, and environmental requirements.

- API Standards: For tanks used in the oil and gas industries, adherence to American Petroleum Institute (API) standards ensures quality and safety in design and manufacturing.

Key Quality Control Checkpoints

Quality control (QC) should occur at multiple stages of the manufacturing process:

- Incoming Quality Control (IQC): Materials received are inspected for quality and compliance with specifications.

- In-Process Quality Control (IPQC): Regular inspections during manufacturing ensure that processes are being followed correctly and that the product meets specifications.

- Final Quality Control (FQC): Comprehensive testing and inspections of the finished product, including dimensional checks and functional tests, are conducted before shipping.

Common Testing Methods

Testing methods for agitator tanks can include:

- Pressure Testing: Ensures the tank can withstand operational pressures without leaking.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing or dye penetrant testing can be used to detect flaws without damaging the tank.

- Performance Testing: Verifies that the agitator functions as intended, achieving the desired mixing efficiency.

Verifying Supplier Quality Control

For international B2B buyers, especially those in regions with varying regulatory environments, verifying a supplier’s quality control practices is essential. Here are actionable steps:

- Supplier Audits: Conduct regular audits of the manufacturing facility to evaluate adherence to quality standards and processes.

- Request Quality Assurance Reports: Suppliers should provide documentation that details their quality control processes and results from testing.

- Third-Party Inspections: Engage independent third-party inspection services to assess compliance with international standards before shipment.

- Certifications: Verify that suppliers hold relevant certifications (e.g., ISO, CE) and that these certifications are up-to-date.

QC and Certification Nuances for International Buyers

Navigating the quality assurance landscape can be complex for international buyers. Here are key considerations:

- Cultural Differences: Understand that manufacturing and quality practices can vary significantly across regions. Buyers should be prepared to adapt their expectations based on local practices.

- Regulatory Compliance: Ensure that the agitator tanks comply with the regulations of the buyer’s home country, as different countries may have different safety and quality requirements.

- Language Barriers: Consider language differences when communicating quality standards and expectations; having bilingual staff or translation services can facilitate clearer communication.

Conclusion

An in-depth understanding of the manufacturing processes and quality assurance practices for agitator tanks is crucial for international B2B buyers. By focusing on material preparation, forming, assembly, finishing, and maintaining stringent quality control measures, buyers can make informed decisions that ensure they receive high-quality agitator tanks that meet their operational needs. Prioritizing supplier verification and understanding the nuances of international quality standards will empower buyers to foster successful partnerships across diverse markets.

Related Video: Water Quality Testing Methods

Comprehensive Cost and Pricing Analysis for agitator tank Sourcing

Understanding the Cost Structure of Agitator Tanks

When sourcing agitator tanks, it is essential to grasp the key cost components that influence pricing. The total cost of an agitator tank encompasses several elements:

-

Materials: The choice of materials significantly impacts the cost. Stainless steel is commonly used due to its durability and resistance to corrosion, but alternative materials may be less expensive, albeit at the cost of longevity and performance.

-

Labor: Skilled labor is required for the manufacturing and assembly of agitator tanks. The labor cost can vary greatly depending on the region and the complexity of the tank design.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment depreciation, which are allocated across production.

-

Tooling: Custom designs may require specialized tooling, which can add to the upfront costs but may lead to efficiencies in production.

-

Quality Control (QC): Effective QC processes ensure that the tanks meet industry standards, which can incur additional costs but are crucial for maintaining product quality.

-

Logistics: Transportation costs can vary widely based on distance, shipping methods, and the size of the shipment. Import duties and tariffs must also be considered, especially for international buyers.

-

Margin: Suppliers typically add a profit margin to cover risks and ensure sustainability. This margin can be influenced by market competition and the supplier’s positioning.

Price Influencers in Agitator Tank Sourcing

Several factors can influence the pricing of agitator tanks:

-

Volume/MOQ: Bulk orders usually attract discounts. Understanding the minimum order quantity (MOQ) can help in negotiating better prices.

-

Specifications/Customization: Custom specifications can increase costs due to additional design and manufacturing requirements. It is advisable to balance between necessary custom features and standard options to control costs.

-

Materials Quality/Certifications: Higher-quality materials and relevant certifications can increase initial costs but may lead to lower maintenance and longer lifespan, impacting the Total Cost of Ownership (TCO).

-

Supplier Factors: The supplier’s reputation, reliability, and geographic location can influence pricing. Suppliers in regions with lower labor costs may offer more competitive pricing.

-

Incoterms: Understanding Incoterms is crucial for pricing negotiations. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect how costs are structured and who bears the risk during transit.

Tips for International B2B Buyers

For international buyers, particularly from Africa, South America, the Middle East, and Europe, here are actionable insights to enhance cost efficiency:

-

Negotiate Wisely: Leverage your purchasing power by negotiating prices based on volume and long-term partnerships. Suppliers may be more willing to offer discounts for repeat business.

-

Evaluate Total Cost of Ownership: Instead of focusing solely on purchase price, consider the long-term costs associated with maintenance, operation, and potential downtime. A slightly higher upfront cost may be justified by lower operating expenses.

-

Research Market Prices: Familiarize yourself with market rates for agitator tanks in your region. This knowledge empowers you during negotiations and helps identify fair pricing.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers can provide insight into competitive pricing and help you make informed decisions.

-

Understand Local Regulations: Be aware of any regional regulations that may impact pricing, such as environmental standards or import tariffs, particularly in markets like the UAE or France, where compliance can affect costs.

Conclusion

In summary, understanding the comprehensive cost structure and pricing factors for agitator tanks is vital for international B2B buyers. By considering all aspects from material choices to supplier factors, buyers can negotiate effectively and make informed purchasing decisions that align with their operational needs. Always remember that indicative prices can fluctuate based on market conditions, making thorough research and strategic negotiation essential in the sourcing process.

Spotlight on Potential agitator tank Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘agitator tank’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for agitator tank

Understanding the technical specifications and trade terminology associated with agitator tanks is essential for international B2B buyers. This knowledge not only helps in making informed purchasing decisions but also facilitates effective communication with suppliers and manufacturers.

Key Technical Properties of Agitator Tanks

-

Material Grade

– Definition: The quality of materials used to construct the tank, typically stainless steel or carbon steel.

– Importance: The choice of material affects the tank’s durability, corrosion resistance, and suitability for specific applications (e.g., food-grade materials for the food industry). Buyers must ensure that the material meets industry standards and regulations. -

Capacity

– Definition: The maximum volume of liquid the tank can hold, often measured in liters or gallons.

– Importance: Understanding capacity is crucial for operational efficiency. An oversized tank can lead to wasted resources, while an undersized tank may result in production bottlenecks. Buyers should assess current and future production needs to select an appropriate capacity. -

Agitator Type

– Definition: The mechanism used to mix contents within the tank, such as paddle, turbine, or anchor agitators.

– Importance: Different types of agitators are suited for varying viscosities and mixing requirements. For example, paddle agitators are ideal for low-viscosity liquids, while turbine agitators handle thicker substances. Selecting the right agitator type is vital for achieving the desired mixing results.

Illustrative Image (Source: Google Search)

-

Design Specifications

– Definition: Specific features such as tank shape (cylindrical, conical), dimensions, and internal geometry.

– Importance: The design impacts mixing efficiency and maintenance ease. For instance, a conical bottom facilitates better drainage of viscous materials. Buyers should consider how design will affect their operational processes. -

Tolerance and Finish

– Definition: The allowable deviation in dimensions and the surface finish of the tank.

– Importance: Tight tolerances ensure that the tank fits within the intended space and functions correctly. Surface finish affects cleaning ease and hygiene, especially in industries like food and pharmaceuticals. Buyers need to specify these requirements to avoid operational issues.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Significance: Understanding OEM relationships is crucial for buyers seeking reliable parts and equipment that meet specific industry standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Significance: Knowing the MOQ helps buyers plan their purchases effectively and manage inventory costs. It is particularly important for businesses with limited storage capacity. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and other details for a specific product or service.

– Significance: An RFQ is a key tool for buyers to obtain competitive pricing and assess supplier capabilities. Crafting a clear RFQ can lead to better proposals and negotiations. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce, defining the responsibilities of buyers and sellers in international transactions.

– Significance: Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery responsibilities, ensuring smoother international transactions. -

Lead Time

– Definition: The amount of time it takes from placing an order to receiving the product.

– Significance: Knowing lead times is essential for planning production schedules and avoiding delays. Buyers should communicate clearly with suppliers to establish realistic timelines.

By grasping these essential technical properties and trade terms, B2B buyers can enhance their purchasing strategies, improve supplier interactions, and ultimately drive operational success.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the agitator tank Sector

Market Overview & Key Trends

The agitator tank market is experiencing dynamic shifts driven by globalization, technological advancements, and changing consumer preferences. Key global drivers include the increasing demand for efficient mixing processes across industries such as food and beverage, pharmaceuticals, and chemicals. This demand is fueled by the need for improved product consistency and quality, as well as compliance with stringent regulatory standards.

Emerging trends in B2B sourcing highlight the adoption of smart technology and automation. Buyers are increasingly looking for agitator tanks equipped with IoT capabilities that allow for real-time monitoring and control, enhancing operational efficiency. Moreover, the integration of artificial intelligence in mixing processes is gaining traction, enabling predictive maintenance and reducing downtime. Additionally, the rise of e-commerce platforms is transforming traditional procurement methods, allowing international buyers from regions like Africa, South America, and the Middle East to source equipment more conveniently and competitively.

Regional dynamics also play a crucial role; for instance, Europe is seeing a push towards more energy-efficient systems, while African and South American markets are rapidly expanding, driven by industrialization and infrastructural development. Buyers should also consider the importance of local suppliers who understand regional challenges and can provide tailored solutions, ensuring a smoother procurement process.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of procurement strategies in the agitator tank sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as reducing carbon footprints and utilizing eco-friendly materials.

Ethical sourcing is equally critical, as buyers seek to partner with companies that uphold fair labor practices and transparency in their supply chains. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are valuable indicators of a supplier’s commitment to sustainability and ethical practices. Furthermore, the use of recyclable materials and energy-efficient designs in agitator tanks can significantly reduce their environmental impact.

Buyers from Africa, South America, the Middle East, and Europe should actively seek suppliers who provide “green” certifications for their products, as these credentials not only contribute to environmental stewardship but can also enhance brand reputation and customer loyalty in increasingly eco-conscious markets.

Brief Evolution/History

The evolution of agitator tanks reflects the broader advancements in industrial mixing technology. Initially designed for basic mixing applications, these tanks have evolved significantly due to the demands of modern manufacturing processes.

In the early 20th century, agitator tanks were primarily constructed from simple materials and featured basic mechanical designs. However, with the advent of advanced materials like stainless steel and the integration of high-efficiency impellers, today’s agitator tanks offer enhanced durability, performance, and versatility.

This evolution is particularly relevant for B2B buyers, as understanding the historical context allows them to appreciate the technological innovations that inform current options, ensuring they choose equipment that meets contemporary operational needs while also considering future scalability.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of agitator tank

-

What criteria should I use to vet suppliers of agitator tanks?

When vetting suppliers, prioritize their industry experience, reputation, and customer reviews. Request references and case studies to gauge their capability. Check if they have relevant certifications (ISO, CE) that ensure quality and compliance with international standards. Additionally, assess their manufacturing processes and technology to ensure they can meet your specific requirements. Engaging with suppliers who have a robust after-sales support system can also be beneficial, especially for maintenance and troubleshooting. -

Can I customize my agitator tank, and what is the process?

Yes, many suppliers offer customization options for agitator tanks. Begin by discussing your specific requirements regarding size, material, and agitator type. Provide detailed specifications on the intended application, including viscosity of materials and mixing speed. The supplier will typically present a design proposal for approval. It’s advisable to request a prototype or 3D model before finalizing the order to ensure the design meets your expectations. -

What are the typical minimum order quantities (MOQ) and lead times for agitator tanks?

MOQs can vary significantly based on the supplier and the complexity of the agitator tank. Generally, standard models may have lower MOQs, while customized tanks could require higher quantities. Lead times often range from 4 to 12 weeks, depending on the supplier’s workload and the tank’s specifications. Always confirm these details upfront and consider potential delays in shipping, especially when importing from different regions. -

What payment terms should I expect when ordering agitator tanks internationally?

Payment terms can vary widely among suppliers. Common practices include a deposit (20-50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer financing options or extended payment terms based on your creditworthiness. It’s crucial to clarify payment methods accepted (e.g., bank transfer, letters of credit) and ensure that all terms are documented in a formal contract to avoid disputes later. -

How can I ensure quality assurance (QA) and certifications for my agitator tank?

Before placing an order, request documentation of the supplier’s QA processes and relevant certifications. Look for ISO certifications that indicate adherence to quality standards. Additionally, inquire about their testing procedures for the agitator tanks, such as performance testing and inspections. Some suppliers may offer third-party inspection services to validate the tank’s quality before shipping, providing added assurance. -

What logistics considerations should I keep in mind when importing agitator tanks?

Logistics can be complex when importing agitator tanks. Ensure that the supplier provides a comprehensive shipping plan that includes transportation modes, estimated shipping times, and handling procedures. Familiarize yourself with import regulations in your country to avoid customs issues. Partnering with a reliable freight forwarder can help navigate these challenges and ensure timely delivery. -

How should I handle disputes with suppliers regarding agitator tank orders?

To effectively handle disputes, ensure that all agreements are documented in a formal contract, including specifications, timelines, and payment terms. If a dispute arises, initiate communication with the supplier to discuss the issue directly. If resolution is not possible, consider mediation or arbitration as stipulated in your contract. Maintaining a professional demeanor throughout the process can help preserve the business relationship. -

What are the best practices for ongoing maintenance of agitator tanks?

Regular maintenance is crucial for ensuring the longevity and efficiency of agitator tanks. Establish a maintenance schedule that includes routine inspections, cleaning, and lubrication of moving parts. Train your staff on proper operational procedures to minimize wear and tear. Additionally, keep a log of maintenance activities and any repairs made, which can be useful for warranty claims and future troubleshooting. Engaging with the supplier for guidance on maintenance practices can also be beneficial.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for agitator tank

In conclusion, the selection and strategic sourcing of agitator tanks are pivotal for enhancing operational efficiency and product quality across various industries. Understanding the specific needs of your business—whether in chemicals, food and beverage, or pharmaceuticals—will guide you in choosing the right type, size, and capacity of agitator tank.

Key takeaways for B2B buyers include:

- Assessment of Needs: Analyze the material properties, mixing requirements, and future production goals.

- Type Selection: Choose the appropriate agitator type based on viscosity and mixing intensity.

- Cost Consideration: Factor in not only the initial purchase price but also the long-term maintenance and operational costs.

As international B2B buyers from Africa, South America, the Middle East, and Europe (including France and the UAE) navigate an increasingly competitive landscape, leveraging strategic sourcing can lead to significant advantages. Investing in the right agitator tank today is an investment in your operational excellence and future growth.

Take action now—evaluate your current processes, explore innovative options, and partner with reliable suppliers to secure the best solutions for your business needs. The future of your production efficiency starts with informed choices today.