Master CNC Machine Milling: Essential Strategies for B2B

Introduction: Navigating the Global Market for cnc machine milling

CNC milling has emerged as a pivotal technology in the realm of modern manufacturing, serving as a cornerstone for industries such as aerospace, automotive, and medical devices. For international B2B buyers, particularly those in dynamic markets across Africa, South America, the Middle East, and Europe, mastering the art of CNC milling procurement is vital. The ability to source high-quality components efficiently can significantly enhance your competitive edge, reduce lead times, and streamline production processes.

This comprehensive guide is designed to equip you with the knowledge needed to navigate the global CNC milling landscape effectively. It covers essential topics including types of CNC milling, the materials suited for various applications, and critical manufacturing and quality control standards. Furthermore, it delves into supplier selection strategies, offering practical insights tailored to the unique challenges of emerging and established markets. Understanding cost structures and market dynamics will empower you to negotiate effectively and maximize value, while our FAQs section addresses common concerns that may arise during the sourcing process.

By leveraging the actionable insights presented in this guide, you will be well-prepared to make informed sourcing decisions, mitigate risks, and establish strong supplier partnerships. In today’s interconnected marketplace, this knowledge is crucial for driving growth and innovation within your organization.

Understanding cnc machine milling Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vertical CNC Milling | Spindle oriented vertically; versatile 3-axis setup | Prototyping, precision components | Cost-effective, easy to operate; height limits |

| Horizontal CNC Milling | Spindle parallel to work table; supports heavier/larger work | Automotive, heavy equipment, large runs | High removal rates, robust for tough jobs; higher cost |

| 5-Axis CNC Milling | Simultaneous movement along 5 axes for complex geometries | Aerospace, medical, advanced tooling | Complex shapes, fewer setups; higher purchase price |

| Gantry Milling | Large open working area with a moving gantry or bed | Large panels, aerospace frames, energy sector | Handles oversized components; requires large space |

| CNC Micro Milling | Miniature tooling for extremely fine features | Electronics, medical devices, miniaturized parts | Ultra-high precision; limited to small parts |

Vertical CNC Milling

Vertical CNC milling machines are characterized by their vertically oriented spindle, enabling easy access to the workpiece from above. This type is particularly suitable for B2B applications such as prototyping and producing precision components in smaller batches. Buyers often prefer vertical mills due to their lower costs and user-friendly operation, making them ideal for companies with varying production needs. However, vertical mills may struggle with larger, heavier workpieces, which could limit their use in certain high-volume production scenarios.

Horizontal CNC Milling

Horizontal CNC milling machines feature a spindle positioned horizontally, allowing for the effective handling of larger and heavier components. This configuration is advantageous for industries like automotive and heavy equipment manufacturing, where high production volumes and robust machining capabilities are required. While horizontal mills provide faster material removal rates and consistent surface finishes, they come with higher initial costs and require more floor space. B2B buyers should consider the long-term production needs and available facility space before investing in this type of milling.

5-Axis CNC Milling

5-axis CNC milling machines offer advanced capabilities by allowing simultaneous movement along five axes, making them ideal for producing complex geometries with tight tolerances. Industries such as aerospace and medical device manufacturing benefit from the efficiency and precision of 5-axis milling. While these machines can significantly reduce lead times and minimize handling errors, they require a higher initial investment and skilled operators. Buyers should evaluate their production complexity and potential ROI when considering this sophisticated milling option.

Gantry Milling

Gantry milling machines are distinguished by their large working area, facilitated by a moving gantry or bed. This type is particularly suitable for machining oversized components or large panels, making it popular in sectors like aerospace and energy. While gantry milling can handle significant workpieces, it requires a larger facility and higher installation costs. B2B buyers should assess their operational capabilities and space requirements to ensure that gantry milling aligns with their production goals.

CNC Micro Milling

CNC micro milling machines specialize in producing extremely fine features and intricate details, making them essential for industries such as electronics and medical devices. These machines deliver ultra-high precision, which is crucial for miniaturized parts. However, their limitations include a focus on small-scale production and increased tooling wear. Buyers looking for micro milling solutions must weigh the benefits of precision against the constraints of size and potential maintenance costs.

Related Video: How milling on a 4-axis CNC machine works

Key Industrial Applications of cnc machine milling

| Industry/Sector | Specific Application of CNC Machine Milling | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Production of complex engine components | High precision and reduced lead times for critical parts | Supplier certifications (AS9100), advanced machining capabilities |

| Automotive | Manufacturing of custom parts and prototypes | Flexibility in design and rapid iteration | Understanding of material specifications and design tolerances |

| Medical Devices | Creation of surgical instruments and implants | Enhanced precision for safety and effectiveness | Compliance with medical regulations (ISO 13485), material traceability |

| Consumer Electronics | Production of casings and internal components | Cost-effective, high-volume production | Supplier experience with plastics and lightweight materials |

| Energy Sector | Fabrication of turbine and generator parts | Durability and performance under extreme conditions | Expertise in machining tough materials and adherence to industry standards |

Aerospace

CNC machine milling is crucial in the aerospace industry for producing complex engine components, structural parts, and intricate assemblies. The precision required in this sector is critical, as any deviation can lead to catastrophic failures. International B2B buyers must prioritize suppliers with certifications such as AS9100, which ensures adherence to quality standards. Furthermore, advanced machining capabilities are essential for producing lightweight yet durable parts that meet stringent aerospace regulations.

Automotive

In the automotive sector, CNC milling is widely used for manufacturing custom parts and prototypes. This technology allows for rapid design iterations, which is vital for staying competitive in a fast-paced market. B2B buyers should look for suppliers that understand specific material specifications and design tolerances, ensuring that components can withstand the rigors of automotive applications. The ability to scale production efficiently without sacrificing quality is a significant benefit of CNC milling in this industry.

Medical Devices

The medical device industry relies heavily on CNC milling for the creation of surgical instruments, implants, and other critical components. The need for high precision is paramount, as even minor errors can impact patient safety and device efficacy. International buyers should ensure that their suppliers comply with medical regulations such as ISO 13485, which governs quality management systems. Additionally, material traceability is crucial, as it guarantees that all components meet safety and performance standards.

Consumer Electronics

CNC milling is extensively utilized in the consumer electronics sector for producing casings and internal components. This application benefits from the technology’s ability to deliver cost-effective, high-volume production while maintaining high quality. B2B buyers should seek suppliers experienced in working with various materials, particularly lightweight plastics and metals, to ensure that products are both functional and aesthetically pleasing. Understanding the supplier’s production capabilities can help mitigate risks associated with lead times and quality control.

Energy Sector

In the energy sector, CNC milling is employed to fabricate turbine blades, generator parts, and other components that must endure extreme conditions. The durability and performance of these parts are critical for operational efficiency and safety. Buyers in this sector should focus on sourcing suppliers with expertise in machining tough materials and a proven track record of adhering to industry standards. This focus not only ensures the reliability of components but also enhances overall system performance.

Strategic Material Selection Guide for cnc machine milling

When selecting materials for CNC machine milling, international B2B buyers must consider various factors, including the properties of the materials, their suitability for specific applications, and the implications for manufacturing processes. Here, we analyze four common materials used in CNC milling: Aluminum, Stainless Steel, Polycarbonate, and Titanium. Each material presents unique characteristics that can influence product performance and manufacturing efficiency.

Aluminum

Key Properties: Aluminum is lightweight, exhibits excellent corrosion resistance, and has good thermal and electrical conductivity. It has a melting point of about 660°C, making it suitable for various applications that require heat dissipation.

Pros & Cons: The primary advantages of aluminum include its low density and ease of machining, which can lead to lower manufacturing costs. However, it is less durable than other metals and can deform under high stress. This makes it suitable for applications where weight savings are critical, but it may not be ideal for heavy-duty components.

Impact on Application: Aluminum is commonly used in aerospace, automotive, and consumer electronics, where lightweight yet strong materials are essential. Its compatibility with various media, including air and water, enhances its versatility.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of local regulations regarding aluminum use, including compliance with standards such as ASTM and DIN. Additionally, sourcing aluminum from local suppliers can reduce lead times and shipping costs.

Stainless Steel

Key Properties: Stainless steel is known for its high strength, excellent corrosion resistance, and ability to withstand high temperatures. It typically has a melting point above 1400°C, making it suitable for demanding environments.

Pros & Cons: The durability and strength of stainless steel make it ideal for applications in the medical, automotive, and food processing industries. However, it is more challenging to machine than aluminum, leading to higher manufacturing costs and longer lead times.

Impact on Application: Stainless steel is often used in components that require high durability and resistance to harsh environments, such as valves, pumps, and medical instruments. Its compatibility with various chemicals makes it a preferred choice in the food and pharmaceutical sectors.

Considerations for International Buyers: Buyers must consider the specific grade of stainless steel required for their applications, as different grades offer varying properties. Compliance with international standards like ASTM and JIS is crucial, particularly for sectors with stringent regulations.

Polycarbonate

Key Properties: Polycarbonate is a high-performance thermoplastic known for its impact resistance and optical clarity. It can withstand temperatures up to 135°C and is often used in applications requiring transparency and strength.

Pros & Cons: The lightweight nature of polycarbonate makes it easy to machine and mold, reducing production costs. However, it has lower heat resistance compared to metals and can be prone to scratching, which may limit its use in certain applications.

Impact on Application: Polycarbonate is widely used in the manufacturing of safety glasses, electronic housings, and automotive components. Its compatibility with various media, including water and oils, enhances its application range.

Considerations for International Buyers: When sourcing polycarbonate, buyers should be aware of regional preferences for specific grades and formulations. Compliance with environmental standards, particularly in Europe, is essential to ensure sustainable sourcing.

Titanium

Key Properties: Titanium is renowned for its high strength-to-weight ratio, excellent corrosion resistance, and ability to withstand extreme temperatures. Its melting point exceeds 1660°C, making it suitable for high-performance applications.

Pros & Cons: The primary advantage of titanium is its durability and lightweight nature, making it ideal for aerospace and medical applications. However, it is one of the more expensive materials to machine, leading to higher production costs.

Impact on Application: Titanium is often used in aerospace components, medical implants, and high-performance automotive parts where strength and weight are critical. Its compatibility with a wide range of environments enhances its application versatility.

Considerations for International Buyers: Buyers should consider the cost implications of titanium machining and the need for specialized equipment and skilled labor. Compliance with international standards such as ASTM and ISO is vital, particularly in regulated industries.

Summary Table

| Material | Typical Use Case for cnc machine milling | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace, automotive, consumer electronics | Lightweight and easy to machine | Less durable under high stress | Low |

| Stainless Steel | Medical devices, automotive, food processing | High strength and corrosion resistance | Higher machining costs and complexity | High |

| Polycarbonate | Safety glasses, electronic housings, automotive components | Impact resistance and clarity | Lower heat resistance and scratch-prone | Medium |

| Titanium | Aerospace components, medical implants | High strength-to-weight ratio | Expensive to machine | High |

This strategic material selection guide provides B2B buyers with critical insights into the properties, advantages, and limitations of common materials used in CNC milling. Understanding these factors will enable informed decision-making and enhance the efficiency of sourcing processes in diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc machine milling

CNC machining is a sophisticated manufacturing process that involves several critical stages, each designed to ensure precision and quality in the final product. For B2B buyers, understanding these stages and the associated quality assurance measures is essential for making informed purchasing decisions.

Manufacturing Processes in CNC Milling

The CNC milling process can be broken down into several key stages:

-

Material Preparation

The first step in CNC milling involves selecting and preparing the material. Common materials include metals such as aluminum, steel, and titanium, as well as plastics and composites. Material preparation may involve cutting the raw material to size, deburring edges, and ensuring it is free from contaminants. Buyers should verify that suppliers source materials from reputable vendors and that they adhere to relevant material standards (e.g., ASTM, ISO). -

Forming

This stage involves the actual machining of the part using CNC milling machines. The process typically includes:

– Tool Selection: Depending on the material and desired finish, different cutting tools and techniques are employed. For instance, carbide tools are often used for metals, while high-speed steel may be suitable for softer materials.

– Machining Operations: Common operations include face milling, contour milling, and drilling. The choice of operation impacts the dimensional accuracy and surface finish of the final product.

– Programming: CNC machines are programmed using CAD/CAM software, allowing for precise control over tool paths, speeds, and feeds. Buyers should inquire about the software capabilities and the level of expertise of the programming staff. -

Assembly

After machining, components may require assembly, especially if they are part of a larger system. This stage may involve fitting parts together, welding, or fastening with screws and bolts. For B2B buyers, understanding the assembly capabilities of a supplier is vital, especially for complex parts that require precision alignment. -

Finishing

The final stage involves applying surface treatments to enhance the product’s appearance and durability. Common finishing techniques include anodizing, plating, painting, and polishing. Buyers should evaluate the finishing options available and any additional costs associated with these processes.

Quality Assurance in CNC Milling

Quality assurance is critical in CNC milling, ensuring that products meet specified requirements and standards. Several international and industry-specific standards govern quality practices:

- ISO 9001: This internationally recognized standard outlines requirements for a quality management system (QMS). Suppliers adhering to ISO 9001 demonstrate their commitment to continuous improvement and customer satisfaction.

- CE Marking: For products sold in the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For industries such as oil and gas, American Petroleum Institute (API) standards provide guidelines for quality assurance in manufacturing processes.

Key QC Checkpoints

B2B buyers should be aware of the following quality control checkpoints:

-

Incoming Quality Control (IQC): This initial inspection phase verifies the quality of raw materials and components before they enter the production process. Suppliers should have documented procedures for material inspection and testing.

-

In-Process Quality Control (IPQC): Throughout the machining process, various checks should be performed to ensure that the production adheres to specifications. This can include monitoring tool wear, dimensional checks, and surface finish evaluations.

-

Final Quality Control (FQC): Once machining and assembly are complete, the final inspection phase verifies that the finished product meets all specifications. This may involve detailed measurements, visual inspections, and functional testing.

Common Testing Methods

Several testing methods are employed to ensure product quality:

- Dimensional Inspection: Utilizing calipers, micrometers, and coordinate measuring machines (CMM) to verify dimensions.

- Surface Roughness Testing: Assessing surface finish using profilometers to ensure the required texture is achieved.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and dye penetrant testing to detect subsurface defects without damaging the part.

Verifying Supplier Quality Control

To ensure that a supplier maintains high-quality standards, B2B buyers should consider the following verification methods:

- Supplier Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing processes, equipment, and quality control practices. This is particularly important when sourcing from emerging markets where standards may vary.

- Quality Reports: Requesting regular quality reports from suppliers can help track performance over time. These reports should detail inspection results, defect rates, and corrective actions taken.

- Third-Party Inspections: Engaging independent inspection services can provide an unbiased assessment of the supplier’s capabilities and adherence to quality standards. This is especially useful for buyers operating in regions where they cannot easily visit suppliers.

QC and Certification Nuances for International Buyers

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is crucial:

- Cultural Differences: Different regions may have varying approaches to quality assurance and compliance. Buyers should be aware of local practices and standards that may affect their procurement strategy.

- Regulatory Compliance: Ensure that suppliers comply with both local and international regulations, which can impact product eligibility in different markets.

- Language Barriers: Clear communication is essential in ensuring quality standards are met. Buyers may need to engage translators or local representatives to facilitate effective dialogue with suppliers.

By understanding the manufacturing processes and quality assurance protocols associated with CNC milling, B2B buyers can make informed decisions, mitigate risks, and establish long-term partnerships with reliable suppliers. This strategic approach not only enhances operational efficiency but also positions companies to adapt to the evolving demands of the global marketplace.

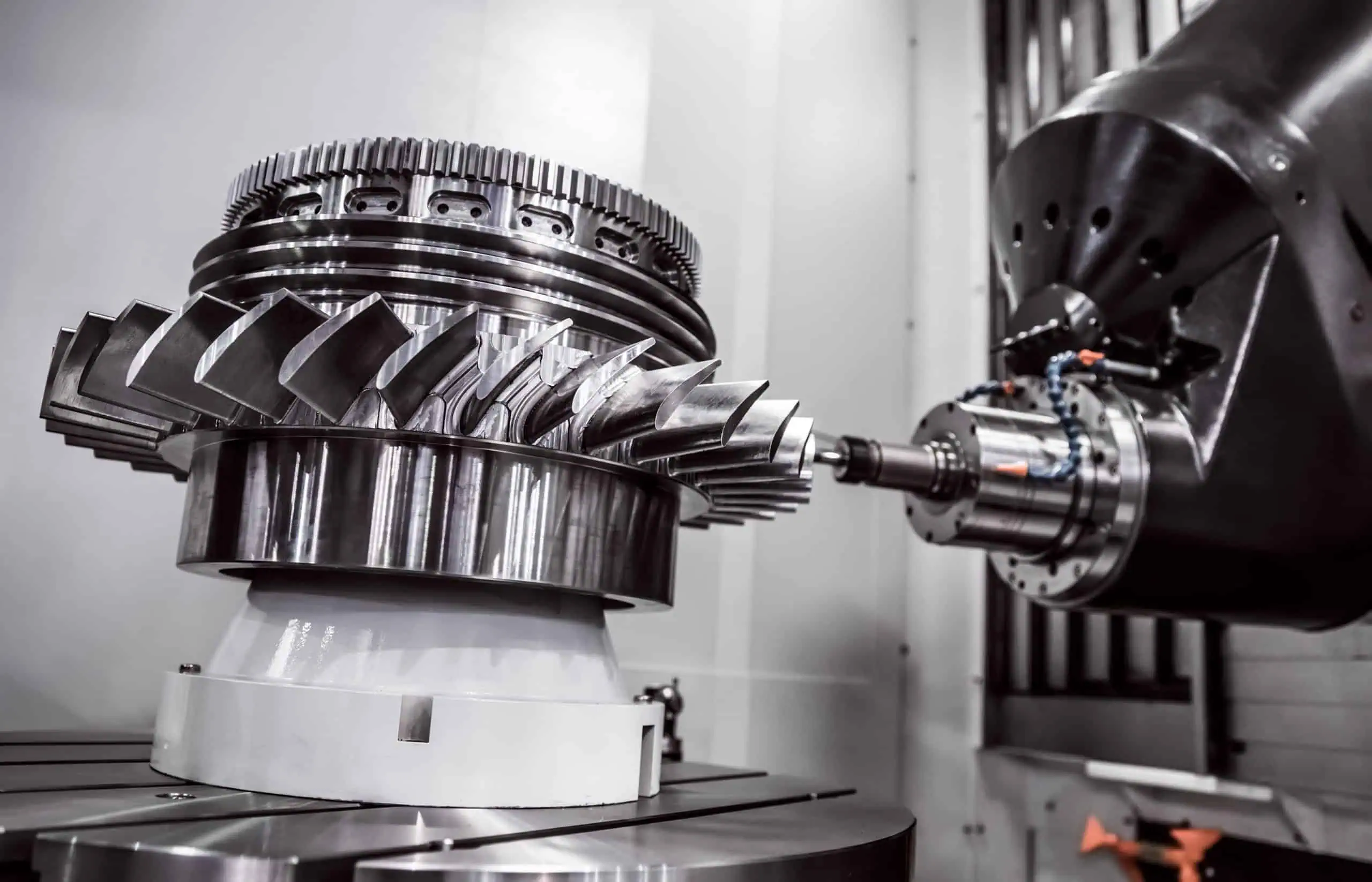

Related Video: The World’s Largest Bevel Gear CNC Machine- Modern Gear Production Line. Steel Wheel Manufacturing

Comprehensive Cost and Pricing Analysis for cnc machine milling Sourcing

In the dynamic landscape of CNC machine milling, understanding the cost structure and pricing dynamics is essential for international B2B buyers. This knowledge enables businesses to make informed decisions, optimize sourcing strategies, and enhance overall profitability. Below is a comprehensive analysis of the cost components, price influencers, and actionable tips for buyers.

Cost Components of CNC Machine Milling

-

Materials: The choice of raw materials significantly impacts overall costs. Common materials such as aluminum, steel, and plastics have varying price points. Buyers should consider the material’s properties, availability, and current market trends to avoid price fluctuations.

-

Labor: Labor costs include wages for skilled operators and programmers. In regions with higher labor costs, such as Western Europe, buyers may face increased pricing. Conversely, sourcing from markets with lower labor costs can help mitigate expenses.

-

Manufacturing Overhead: This encompasses costs related to utilities, equipment maintenance, and facility expenses. Overhead can vary widely based on the supplier’s location and operational efficiency. Buyers should inquire about these costs during negotiations.

-

Tooling: Tooling costs are often significant in CNC milling, especially for custom or complex parts. The initial investment in specialized tools can be offset by their longevity and efficiency in high-volume production.

-

Quality Control (QC): Effective QC processes ensure that products meet specified standards. Although this adds to the upfront costs, it can prevent expensive rework and returns, ultimately saving money in the long run.

-

Logistics: Transportation costs play a crucial role, particularly for international sourcing. Factors such as distance, shipping method, and local tariffs can influence total logistics costs.

-

Margin: Suppliers will include a profit margin in their pricing. This margin varies based on supplier reputation, service quality, and market competition.

Price Influencers in CNC Milling

-

Volume/MOQ: Purchasing larger quantities often leads to lower per-unit costs due to economies of scale. Buyers should assess their needs and negotiate minimum order quantities (MOQ) accordingly.

-

Specifications/Customization: Customized parts typically incur higher costs due to the additional design and manufacturing efforts involved. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials: As mentioned, the choice of material directly affects pricing. Premium materials may enhance performance but also increase costs.

-

Quality/Certifications: Suppliers with high-quality certifications (ISO, AS9100) may charge more, reflecting their commitment to quality. Buyers should weigh the benefits of higher quality against cost.

-

Supplier Factors: The supplier’s location, expertise, and operational capacity can influence pricing. Established suppliers might offer reliability at a premium, while newer entrants may provide competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining who bears the risk and cost at different stages of shipping. This can affect the final price and delivery time.

Buyer Tips for Cost-Efficiency

-

Negotiate: Leverage volume and long-term relationships to negotiate better pricing and terms. Building a rapport with suppliers can lead to favorable adjustments.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial costs but also the long-term implications of sourcing decisions, including maintenance, operational efficiency, and potential downtime.

-

Stay Informed on Pricing Trends: Regularly monitor material and labor market trends to make timely purchasing decisions. Subscribing to industry reports can provide valuable insights.

-

Evaluate Multiple Suppliers: Obtain quotes from various suppliers to compare pricing structures and terms. This not only helps in finding the best price but also highlights different service levels.

-

Factor in Currency Risks: For international buyers, fluctuations in exchange rates can impact costs. Consider using hedging strategies to mitigate this risk.

Disclaimer

Prices and cost structures can vary widely based on specific project requirements, market conditions, and supplier capabilities. The information provided herein is indicative and should be used as a guideline for discussions with potential suppliers. Always conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing tailored to your unique needs.

Spotlight on Potential cnc machine milling Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘cnc machine milling’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for cnc machine milling

When navigating the CNC milling landscape, understanding essential technical properties and industry terminology is crucial for effective decision-making. The following outlines key specifications and common trade terms that international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be familiar with.

Key Technical Properties

-

Material Grade

Material grade refers to the classification of the raw materials used in CNC milling, such as metals, plastics, or composites. Each grade has distinct mechanical properties, including tensile strength, hardness, and corrosion resistance. Understanding material grades is vital for buyers to ensure that the finished components meet the required performance specifications for their applications, particularly in industries like aerospace and automotive. -

Tolerance

Tolerance indicates the permissible limit of variation in a physical dimension. In CNC milling, it defines how much deviation from a specified measurement is acceptable. Tight tolerances (e.g., ±0.001 mm) are crucial for parts that require high precision, such as those used in medical devices or aerospace components. Buyers must specify their tolerance requirements clearly to ensure that suppliers can deliver components that meet their quality standards. -

Surface Finish

Surface finish refers to the texture and smoothness of a machined part’s surface, which can significantly affect its performance and aesthetic appeal. Different milling processes yield various surface finishes, such as rough, machined, or polished. Buyers should consider the required surface finish for their applications, as it can impact factors like friction, wear resistance, and overall product functionality. -

Feed Rate

Feed rate is the speed at which the cutting tool moves through the material during machining, typically measured in millimeters per minute (mm/min). It influences the machining time, surface finish, and tool wear. Buyers must understand the relationship between feed rate and other parameters, such as spindle speed and material type, to optimize production efficiency and minimize costs. -

Spindle Speed

Spindle speed, measured in revolutions per minute (RPM), indicates how fast the cutting tool spins during the milling process. It directly affects the material removal rate and the quality of the finished part. Buyers should be aware of the optimal spindle speeds for different materials to ensure efficient machining and avoid damaging the workpiece or tools.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces components that are used in another company’s end product. In CNC milling, buyers often source parts from OEMs to integrate into their own products. Understanding OEM relationships can help buyers negotiate better terms and ensure consistent quality. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. This term is crucial for buyers, especially in emerging markets, as it impacts inventory management and cash flow. Knowing the MOQ helps buyers plan their procurement strategies effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products or services. It typically includes detailed specifications, quantities, and delivery requirements. For B2B buyers, issuing RFQs is essential for comparing supplier capabilities and costs, ensuring competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers navigate the complexities of international logistics, reducing the risk of misunderstandings or unexpected costs. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. It is a critical factor in supply chain management, impacting production schedules and inventory levels. Buyers must communicate their lead time expectations to suppliers to ensure timely delivery and avoid disruptions in their operations.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions, streamline their procurement processes, and enhance their competitive edge in the global CNC milling market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the cnc machine milling Sector

Market Overview & Key Trends

The global CNC milling market is witnessing robust growth driven by increasing demand for precision engineering across various sectors, including aerospace, automotive, and healthcare. Key drivers include the rise of Industry 4.0, which emphasizes automation, data exchange, and smart manufacturing solutions. International B2B buyers are now focusing on advanced technologies like 5-axis milling and hybrid manufacturing processes, which enable the production of complex geometries with improved efficiency and reduced lead times.

Emerging markets in Africa and South America are also becoming significant players in the CNC milling landscape. Countries such as Kenya and Colombia are investing in technology upgrades and skilled workforce development to enhance their manufacturing capabilities. European nations, particularly Poland and Spain, are leveraging their established industrial bases to adopt sustainable practices and innovative manufacturing techniques, positioning themselves as leaders in quality and compliance.

Illustrative Image (Source: Google Search)

Moreover, the trend toward digital procurement tools is reshaping sourcing strategies. B2B buyers can now utilize platforms that provide real-time data on supplier capabilities, material costs, and delivery timelines, enhancing decision-making processes. This digital shift is critical for buyers looking to optimize their supply chains and gain a competitive edge in an increasingly interconnected global market.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a paramount consideration in the CNC milling sector, with environmental impacts prompting buyers to seek eco-friendly practices. The machining process can generate significant waste and energy consumption, making it essential for businesses to partner with suppliers who prioritize sustainable operations. This includes using energy-efficient machinery, recycling metal scraps, and reducing coolant and lubricant waste.

Ethical sourcing also plays a crucial role in supplier selection. B2B buyers should prioritize suppliers who adhere to fair labor practices and demonstrate transparency in their supply chains. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as benchmarks for assessing supplier commitments to sustainability.

Additionally, the use of green materials, such as biodegradable lubricants and recycled metals, is gaining traction. These materials not only reduce environmental impact but can also enhance product quality and performance. As buyers increasingly demand sustainable solutions, aligning sourcing strategies with these principles is vital for long-term success and brand reputation.

Brief Evolution/History

CNC milling technology has evolved significantly since its inception in the 1950s. Originally a manual process, the introduction of computer numerical control revolutionized manufacturing by allowing for automated, precise, and repeatable machining. Over the decades, advancements in software, machine design, and materials have led to the development of sophisticated CNC milling machines capable of handling complex tasks with minimal human intervention.

Today, CNC milling is integral to the global manufacturing landscape, supporting industries that require high precision and efficiency. The shift towards automation and smart manufacturing solutions continues to shape the future of CNC milling, making it an essential area of focus for international B2B buyers seeking competitive advantages in their respective markets. As technology progresses, the emphasis on sustainability and ethical practices will further drive innovation and transformation in the sector.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of cnc machine milling

-

What criteria should I use to vet CNC milling suppliers?

When vetting CNC milling suppliers, consider their industry certifications, such as ISO 9001 or AS9100, which indicate adherence to quality management standards. Evaluate their experience in your specific industry and request case studies or references to assess their reliability. Additionally, inspect their manufacturing capabilities and technology. A visit to their facility can provide insights into their operational standards and workforce competency. Don’t forget to analyze their customer service responsiveness and after-sales support, which are crucial for long-term partnerships. -

Can I customize my CNC milling orders?

Yes, most CNC milling suppliers offer customization options to meet specific project requirements. This can include tailored designs, material selections, and finishes. When discussing customization, provide detailed specifications and any relevant drawings or models. Understand that complex customizations may affect lead times and costs. Engage in a collaborative dialogue with your supplier to ensure that your needs are met while adhering to their manufacturing capabilities. Clear communication about your expectations will minimize misunderstandings and enhance satisfaction with the final product. -

What are the typical minimum order quantities (MOQs) and lead times for CNC milling?

Minimum order quantities (MOQs) for CNC milling can vary significantly based on the supplier, the complexity of the parts, and the materials used. Generally, MOQs can range from a few pieces for simple components to several hundred for complex or specialized items. Lead times typically range from two to six weeks, but this can fluctuate based on the supplier’s workload and the intricacy of the order. For timely delivery, consider discussing your project timelines upfront and exploring options for expedited services if necessary. -

How can I ensure quality assurance and compliance with certifications?

To ensure quality assurance, request documentation of the supplier’s quality control processes and certifications. Suppliers should provide inspection reports and test data for the components produced. Additionally, consider requesting samples or prototypes before committing to larger orders. Establishing clear quality standards in your contracts can also protect your interests. Regular audits and performance reviews of the supplier can further ensure ongoing compliance with the agreed-upon quality metrics. -

What payment options are typically available for international CNC milling orders?

Payment options for international CNC milling orders can include wire transfers, letters of credit, or payment through escrow services. The choice often depends on the supplier’s policies and your company’s risk tolerance. Discuss payment terms upfront, including deposits and final payment schedules, to avoid misunderstandings. It’s also advisable to negotiate terms that protect your interests, such as milestone payments tied to production stages, which can help manage cash flow while ensuring supplier accountability. -

What logistics considerations should I be aware of when sourcing CNC milling parts internationally?

When sourcing CNC milling parts internationally, consider logistics aspects such as shipping methods, customs clearance, and delivery times. Partnering with a logistics provider experienced in international trade can facilitate smoother transport and compliance with regulations. Understand the Incoterms (International Commercial Terms) that define the responsibilities of buyers and sellers regarding shipping and insurance. Additionally, ensure that your supplier provides accurate documentation to avoid delays at customs, which can impact lead times and costs. -

How should I handle disputes with my CNC milling supplier?

Disputes can arise over quality, delivery times, or contract terms. To manage disputes effectively, establish a clear communication channel with your supplier. Document all agreements and communications to provide a record of expectations and commitments. If a dispute occurs, attempt to resolve it amicably through direct negotiation. Should this fail, consider mediation or arbitration, as these methods can be less costly and time-consuming than litigation. Including a dispute resolution clause in your contract can provide a predefined approach to handling disagreements. -

What are the common challenges in international CNC milling procurement?

Common challenges in international CNC milling procurement include language barriers, cultural differences, and variations in quality standards. Time zone differences can also complicate communication and project management. To mitigate these issues, establish a clear communication protocol and utilize technology for real-time updates. Conduct thorough research on the supplier’s operational practices and market conditions to align expectations. Building strong relationships with suppliers can facilitate smoother collaboration and problem-solving throughout the procurement process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cnc machine milling

In summary, strategic sourcing in CNC machine milling is not merely about cost savings; it is about building robust supply chains that enhance competitiveness in the global marketplace. B2B buyers across Africa, South America, the Middle East, and Europe must prioritize understanding the diverse milling technologies available, such as vertical, horizontal, and 5-axis milling, to align their sourcing decisions with specific production needs.

Key takeaways include:

- Assessing Supplier Capabilities: Evaluate suppliers not only on cost but also on their adherence to quality standards and their ability to meet complex design requirements.

- Leveraging Regional Strengths: Utilize local manufacturing capabilities while considering international suppliers for specialized needs, ensuring a balanced approach to sourcing.

- Investing in Technology: Embrace advanced CNC milling technologies to drive efficiency and precision in production, ultimately enhancing product quality and reducing lead times.

As you navigate the evolving landscape of CNC milling, remain proactive in exploring new partnerships and technologies that can propel your business forward. The future of manufacturing is interconnected, and by making informed sourcing decisions today, you position your company to thrive in tomorrow’s competitive environment. Engage with potential suppliers, leverage digital tools for procurement, and stay ahead of industry trends to maximize your operational success.

Illustrative Image (Source: Google Search)