Your Ultimate Guide to Sourcing Different Types Of Mounting

Introduction: Navigating the Global Market for different types of mounting brackets

In today’s interconnected global economy, the selection of the right mounting brackets is crucial for enhancing product functionality and user experience across various industries. As businesses increasingly integrate advanced technologies, including IoT devices, the demand for robust and versatile mounting solutions has surged. These components are not merely functional; they play a pivotal role in ensuring safety, usability, and aesthetic appeal in applications ranging from medical equipment to consumer electronics.

This comprehensive guide delves into the diverse types of mounting brackets available in the market, examining essential aspects such as materials, manufacturing processes, quality control standards, and supplier options. B2B buyers will find valuable insights into cost considerations and market trends that influence purchasing decisions. Each section is designed to equip international buyers, particularly those from Africa, South America, the Middle East, and Europe—such as Italy and Mexico—with the knowledge necessary to make informed sourcing choices.

Furthermore, the guide addresses frequently asked questions, demystifying complex technical specifications and helping buyers navigate potential challenges in the procurement process. By understanding the critical importance of different types of mounting brackets, businesses can optimize their operations, enhance product design, and ultimately deliver superior value to their customers. Empower your sourcing strategy today by leveraging the insights provided in this essential resource.

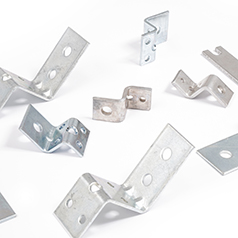

Illustrative Image (Source: Google Search)

Understanding different types of mounting brackets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fixed Mount Brackets | Rigid, non-adjustable design | Retail displays, signage, and panels | Pros: Cost-effective, easy to install. Cons: Limited adjustability, not suitable for dynamic setups. |

| Adjustable Mount Brackets | Allows for angle and height adjustments | Medical equipment, kiosks, and monitors | Pros: Enhanced user ergonomics, versatile. Cons: Potentially higher costs, more complex installation. |

| Swivel Mount Brackets | Features rotating arms for side-to-side motion | Conference rooms, video displays | Pros: Flexible viewing angles, ideal for collaborative settings. Cons: May require more maintenance, higher mechanical wear. |

| Ceiling Mount Brackets | Designed for overhead installation | Projectors, large displays | Pros: Saves floor space, optimal for large areas. Cons: Installation complexity, potential structural concerns. |

| VESA Mount Brackets | Compliant with VESA standards for compatibility | Monitors, TVs, and digital signage | Pros: Wide compatibility, easy integration. Cons: Requires VESA-compatible devices, may not support heavier models. |

Fixed Mount Brackets

Fixed mount brackets are characterized by their rigid design, providing a stable and secure attachment for displays and signage. These mounts are most suitable for applications where the viewing angle does not need to change frequently, such as in retail displays and signage installations. For B2B buyers, the primary considerations include cost-effectiveness and ease of installation, although the lack of adjustability may limit their versatility in dynamic environments.

Adjustable Mount Brackets

Adjustable mount brackets offer the flexibility of changing the angle and height of the mounted equipment. This makes them ideal for applications like medical equipment and interactive kiosks, where user ergonomics are paramount. When purchasing, businesses should consider the potential for increased costs due to the added complexity of installation and mechanisms. However, the benefits of enhanced user experience often outweigh these drawbacks.

Swivel Mount Brackets

Swivel mount brackets allow for side-to-side motion, making them particularly suitable for environments like conference rooms where multiple viewers may need to adjust the screen’s position. The key advantage for B2B buyers is the flexibility in viewing angles, which facilitates collaboration and presentations. However, these mounts may require more maintenance due to their moving parts, and the mechanical components can experience wear over time.

Ceiling Mount Brackets

Ceiling mount brackets are designed for overhead installations, making them a great solution for projectors and large displays in open areas. By saving floor space, they can enhance the aesthetic of a room while providing an unobstructed view. B2B buyers should be aware of the installation complexity and potential structural concerns, as the mounting surface must support the weight of the equipment securely.

VESA Mount Brackets

VESA mount brackets adhere to the Video Electronics Standards Association (VESA) specifications, ensuring compatibility with a wide range of monitors and TVs. This standardization simplifies the integration process for businesses looking to install multiple displays. Buyers should note that while these mounts offer broad compatibility, they require VESA-compatible devices and may not support heavier models effectively, necessitating careful consideration of weight limits during procurement.

Related Video: SCR Mounting (Basics, Types & working) Explained | Lead Mounting, Bolt Mounting & Stud Mounting

Key Industrial Applications of different types of mounting brackets

| Industry/Sector | Specific Application of different types of mounting brackets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Mounting brackets for medical monitors in patient rooms and surgical areas | Enhanced patient monitoring and ergonomic design | Compliance with medical standards, durability, and ease of cleaning |

| Manufacturing | Brackets for mounting screens and controls on factory machinery | Improved operational efficiency and worker safety | Resistance to vibration, load capacity, and material quality |

| Retail | Kiosks with integrated monitors for customer interaction | Increased customer engagement and sales opportunities | Aesthetic design, ease of installation, and adaptability to various environments |

| Automotive | Mounting brackets for dashboards and infotainment systems | Improved user experience and vehicle functionality | Compatibility with various vehicle models and ease of integration |

| Construction | Brackets for mounting HVAC systems and control panels | Optimized space utilization and system performance | Material strength, corrosion resistance, and compliance with building codes |

Detailed Applications

Healthcare

In healthcare settings, mounting brackets are crucial for securing medical monitors in patient rooms and surgical areas. These brackets ensure that monitors are positioned for optimal visibility, enhancing patient monitoring and staff efficiency. For international B2B buyers, especially in regions like Africa and the Middle East, sourcing brackets that comply with medical standards is vital. Durability and ease of cleaning are critical factors, as these environments require stringent hygiene protocols.

Manufacturing

In the manufacturing sector, mounting brackets are used to secure screens and control panels on machinery. This application is essential for maintaining operational efficiency and ensuring worker safety. The brackets must withstand vibrations and heavy loads, making material quality and resistance to wear key considerations for buyers in South America and Europe. Ensuring that the brackets can handle the specific environmental conditions of a factory is paramount.

Retail

In retail, mounting brackets are utilized for integrating monitors into kiosks, enhancing customer interaction. This application not only improves customer engagement but also drives sales opportunities. Buyers must consider the aesthetic design of the brackets, as they need to complement the retail environment while being easy to install and adaptable. Sourcing from local manufacturers can help mitigate shipping costs and delays, especially for buyers in Europe and Africa.

Automotive

Mounting brackets play a significant role in the automotive industry, particularly for securing dashboards and infotainment systems. These brackets enhance the user experience by ensuring that screens are easily accessible and functional. Buyers should focus on compatibility with various vehicle models and the ease of integration into existing systems. This is particularly important for B2B buyers in South America, where diverse vehicle types are common.

Construction

In the construction industry, mounting brackets are essential for securing HVAC systems and control panels. Properly mounted systems optimize space utilization and enhance overall performance. Buyers must consider the material strength and corrosion resistance of the brackets, especially in regions with harsh climates. Compliance with local building codes is also a critical factor for international B2B buyers, ensuring that installations meet safety and regulatory standards.

Related Video: Types of Bearing | All in One Guide to Industrial Bearing Types

Strategic Material Selection Guide for different types of mounting brackets

When selecting materials for mounting brackets, it is essential to consider the specific application requirements and environmental conditions. Here, we analyze four common materials used in the manufacturing of mounting brackets: steel, aluminum, plastic, and stainless steel. Each material has unique properties, advantages, and limitations that impact their suitability for various applications.

Steel

Key Properties: Steel is known for its high tensile strength, making it an excellent choice for heavy-duty applications. It typically has a temperature rating of up to 400°F (204°C) and can withstand significant pressure.

Pros & Cons: The durability of steel is one of its primary advantages, providing long-lasting performance even under heavy loads. However, steel is prone to corrosion if not properly treated, which can limit its application in humid or corrosive environments. Additionally, steel brackets can be heavier and may require more complex manufacturing processes.

Impact on Application: Steel is suitable for applications requiring high strength and stability, such as in construction or heavy machinery. However, its susceptibility to rust necessitates protective coatings or galvanization, especially in regions with high humidity.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN. In regions like Europe, where environmental regulations are stringent, selecting coated or galvanized steel may be necessary.

Aluminum

Key Properties: Aluminum is lightweight and has excellent corrosion resistance, making it suitable for various applications. It has a lower temperature rating than steel, typically around 300°F (149°C).

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which reduces shipping costs and makes installation easier. However, aluminum lacks the same tensile strength as steel, which may limit its use in heavy-load applications. Manufacturing processes for aluminum can be less complex than those for steel, often resulting in lower production costs.

Impact on Application: Aluminum is ideal for applications where weight savings are critical, such as in the aerospace or automotive industries. Its corrosion resistance makes it suitable for marine environments.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider the availability of aluminum and its cost-effectiveness compared to steel. Compliance with local standards for aluminum alloys is also essential.

Plastic

Key Properties: Plastic materials, such as polycarbonate or ABS, are lightweight and resistant to corrosion and chemicals. They typically have a lower temperature tolerance, around 180°F (82°C).

Pros & Cons: The main advantage of plastic is its resistance to corrosion and chemicals, making it suitable for various environments. However, plastics generally have lower strength and durability compared to metals, which may limit their use in heavy-duty applications. Manufacturing plastic brackets can be cost-effective due to simpler processes.

Impact on Application: Plastic brackets are often used in electronic equipment or in environments where moisture is a concern. Their lightweight nature makes them easy to handle and install.

Considerations for International Buyers: Buyers should ensure that the selected plastic meets relevant safety and environmental standards, particularly in Europe, where regulations are strict regarding plastic materials.

Stainless Steel

Key Properties: Stainless steel combines the strength of steel with excellent corrosion resistance, making it suitable for harsh environments. It can withstand temperatures up to 1,500°F (815°C) depending on the alloy.

Pros & Cons: The key advantage of stainless steel is its durability and resistance to rust, making it ideal for outdoor applications or in industries like food processing. However, stainless steel is typically more expensive than other materials, which can impact budget considerations.

Impact on Application: Stainless steel is perfect for applications requiring both strength and corrosion resistance, such as in marine or chemical processing industries.

Considerations for International Buyers: Compliance with international standards such as ASTM or JIS is crucial for stainless steel products. Buyers from the Middle East and Europe should consider the specific grades of stainless steel suitable for their applications.

| Material | Typical Use Case for different types of mounting brackets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, construction | High tensile strength | Prone to corrosion | Medium |

| Aluminum | Aerospace, automotive | Lightweight and corrosion resistant | Lower strength than steel | Medium |

| Plastic | Electronics, moisture-sensitive environments | Corrosion and chemical resistance | Lower durability | Low |

| Stainless Steel | Marine, food processing | Excellent corrosion resistance | Higher cost | High |

In-depth Look: Manufacturing Processes and Quality Assurance for different types of mounting brackets

Manufacturing Processes for Mounting Brackets

The manufacturing process for mounting brackets is crucial to ensure durability, functionality, and compliance with industry standards. Understanding the key stages involved in the production can help international B2B buyers make informed decisions when sourcing these components.

Material Preparation

The first step in the manufacturing of mounting brackets involves selecting the appropriate materials. Common materials include:

- Steel: Known for its strength and durability.

- Aluminum: Lightweight and corrosion-resistant, ideal for applications where weight is a concern.

- Plastic: Used for lighter applications or where electrical insulation is necessary.

Once the material is selected, it undergoes preparation, which may include cutting, cleaning, and treating to enhance properties such as corrosion resistance. This preparation is vital as it directly affects the performance and longevity of the final product.

Forming Techniques

The forming process is where the raw material is shaped into the desired bracket configuration. Key techniques include:

- Stamping: A cost-effective method for high-volume production, where sheets of metal are cut and formed into shapes using dies.

- Machining: Involves removing material from a solid block to achieve precise dimensions. This is common for custom or low-volume brackets.

- Casting: Used for complex shapes that are difficult to create through stamping or machining. It involves pouring molten material into a mold.

Each technique has its advantages, and the choice depends on factors such as the complexity of the design, material type, and production volume.

Assembly

Once the individual components are formed, they are assembled into the final product. This stage may involve:

- Welding: Joining metal parts together, often used for steel brackets due to its strength.

- Riveting: A mechanical fastening method that provides good structural integrity.

- Screwing and Bolting: Common for brackets that require disassembly or adjustments.

Proper assembly techniques are essential to ensure that the mounting brackets can withstand the forces they will encounter during use.

Finishing Processes

The finishing stage enhances the aesthetic and functional properties of the mounting brackets. Common finishing processes include:

- Coating: Application of paints, powder coatings, or plating to improve corrosion resistance and aesthetics.

- Deburring: Removal of sharp edges or burrs left from machining or stamping processes.

- Surface Treatment: Methods such as anodizing or galvanizing to enhance surface properties.

Finishing not only improves appearance but also contributes to the longevity and performance of the brackets.

Quality Assurance in Manufacturing

Quality assurance is a critical component in the manufacturing of mounting brackets, ensuring that products meet industry standards and customer expectations.

International Standards

International standards such as ISO 9001 play a significant role in quality assurance. This standard focuses on effective quality management systems and continuous improvement. In addition, industry-specific certifications such as CE marking for the European market and API standards for the oil and gas sector are essential for compliance and market access.

Quality Control Checkpoints

Quality control (QC) is integrated throughout the manufacturing process, with several key checkpoints:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Ongoing checks during production to identify defects early and prevent further issues.

- Final Quality Control (FQC): Comprehensive testing and inspection of the finished product before it is shipped to customers.

These checkpoints help maintain a high standard of quality and reduce the risk of defects in the final product.

Common Testing Methods

To verify the quality of mounting brackets, manufacturers often employ various testing methods, including:

- Load Testing: Assessing the bracket’s ability to withstand expected loads without failure.

- Corrosion Testing: Evaluating the effectiveness of protective coatings.

- Dimensional Inspection: Ensuring that the dimensions of the brackets meet specified tolerances.

These tests provide valuable data that can help buyers assess the reliability and suitability of the mounting brackets for their applications.

Verifying Supplier Quality Assurance

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, it is crucial to verify the quality assurance practices of potential suppliers. Here are several actionable strategies:

- Conduct Audits: Regular audits of suppliers can provide insights into their quality management practices. This includes reviewing production processes, quality control measures, and compliance with international standards.

- Request Quality Reports: Suppliers should provide documentation that outlines their quality assurance processes, testing results, and certifications.

- Engage Third-Party Inspectors: Independent inspections can offer an unbiased assessment of the supplier’s quality control practices and product reliability.

QC and Certification Nuances

Buyers should be aware of specific nuances related to quality control and certification in different regions. For instance, in Europe, CE marking is mandatory for many products, while in other regions, local certifications may be required. Understanding these requirements can facilitate smoother transactions and compliance with local regulations.

Conclusion

In summary, the manufacturing processes and quality assurance practices for mounting brackets are integral to ensuring product reliability and performance. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ultimately leading to better outcomes for their projects. Maintaining a focus on quality assurance and compliance with international standards will help buyers mitigate risks and enhance the overall value of their sourcing strategies.

Related Video: What is Production? Types of Production, Factors of Production

Comprehensive Cost and Pricing Analysis for different types of mounting brackets Sourcing

When sourcing mounting brackets, B2B buyers must navigate a complex landscape of costs and pricing structures. Understanding the various cost components and price influencers is crucial for making informed purchasing decisions.

Cost Components

-

Materials: The type of materials used for manufacturing mounting brackets significantly impacts cost. Common materials include steel, aluminum, and plastics, each varying in price based on market conditions and sourcing availability. High-grade materials may offer better durability but at a higher cost.

-

Labor: Labor costs can fluctuate based on geographical location and the skill level required. Regions with lower labor costs, such as parts of South America and Africa, may provide competitive pricing, but buyers should consider the trade-off in quality and expertise.

Illustrative Image (Source: Google Search)

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and facility management. Factories with advanced technology may have higher overhead but can yield better efficiency and quality control.

-

Tooling: Custom tooling can be a significant upfront investment, particularly for specialized brackets. Buyers should assess whether the tooling costs are justified based on projected order volumes and customization needs.

-

Quality Control (QC): Ensuring quality is paramount, especially for applications requiring stringent specifications. Implementing robust QC processes can add to the cost but ultimately reduces the risk of product failures.

-

Logistics: Shipping and handling costs vary widely depending on the origin of the products, the shipping method chosen, and the destination. International buyers must factor in potential customs duties and taxes.

-

Margin: Suppliers will add a profit margin to their cost base, which can vary depending on market competition and the perceived value of their product.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Ordering in bulk often leads to reduced per-unit costs. Buyers should evaluate their needs against supplier MOQ requirements to optimize savings.

-

Specifications/Customization: Customized brackets may incur additional costs. Buyers should communicate their exact needs upfront to avoid unexpected charges later in the process.

-

Quality/Certifications: Products that meet international quality standards or have specific certifications may command a premium price. Buyers should weigh the benefits of these certifications against the cost.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers may charge more but offer better quality assurance and customer service.

-

Incoterms: Understanding Incoterms is critical for international transactions. Different terms affect who is responsible for costs at various stages of shipping, which can impact total pricing.

Buyer Tips

-

Negotiation: Engage in negotiations with suppliers to secure better pricing, especially for larger orders. Building a relationship can lead to long-term benefits and discounts.

-

Cost Efficiency: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also maintenance, durability, and potential replacement costs over time.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and how they can affect pricing. Additionally, be cautious of hidden fees in shipping and customs that can inflate costs.

In conclusion, while sourcing mounting brackets, buyers must conduct a thorough analysis of the cost structure and pricing influencers. By understanding these elements, B2B buyers can make strategic decisions that align with their operational needs and budget constraints. Always consider indicative prices as they may vary based on market conditions and supplier negotiations.

Spotlight on Potential different types of mounting brackets Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘different types of mounting brackets’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for different types of mounting brackets

Key Technical Properties of Mounting Brackets

When evaluating mounting brackets for various applications, understanding their technical properties is crucial for ensuring functionality and durability. Here are some of the most critical specifications:

-

Material Grade

Mounting brackets are typically made from materials such as steel, aluminum, or plastic. The material grade affects strength, weight, and corrosion resistance. For instance, stainless steel is often preferred for outdoor or industrial applications due to its resistance to rust and environmental wear. Buyers should assess the material grade to ensure it meets the specific demands of their application. -

Load Capacity

This specification indicates the maximum weight a mounting bracket can support without failure. It is essential for ensuring that the bracket can safely hold the intended load, whether it’s a monitor, a shelf, or industrial equipment. Understanding load capacity helps in selecting the right bracket for the job, preventing accidents and equipment damage. -

Tolerance

Tolerance refers to the permissible variation in dimensions of the bracket. High tolerance levels are crucial for applications requiring precise alignment and fit. For example, in electronic equipment, even minor misalignments can affect performance. Ensuring that the chosen bracket meets the required tolerance levels is vital for operational efficiency. -

Finish and Coating

The finish of a mounting bracket, such as powder coating or galvanization, impacts its durability and resistance to environmental factors. A well-finished bracket can withstand moisture, UV exposure, and chemical contact, making it suitable for various environments. Buyers should consider the specific environmental conditions the bracket will face to select the appropriate finish. -

Adjustability

Many mounting brackets feature adjustable components that allow users to position devices at various angles. This property is particularly important in ergonomic applications where user comfort is a priority. Understanding the adjustability of a bracket helps ensure that it meets the end-user’s needs effectively.

Common Trade Terminology

In the B2B landscape, certain terms are frequently used and understanding them is essential for successful transactions and negotiations. Here are some common terms related to mounting brackets:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can help in sourcing high-quality components that are guaranteed to be compatible with existing systems. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units that a supplier is willing to sell. This term is crucial for buyers to understand, as it impacts inventory management and cost efficiency. Knowing the MOQ helps buyers plan their purchases effectively, especially when entering new markets or scaling operations. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a company solicits bids from suppliers for specific products or services. For B2B buyers, submitting an RFQ can help in obtaining competitive pricing and better terms from multiple suppliers, streamlining the procurement process. -

Incoterms (International Commercial Terms)

These are predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery obligations, which is essential for international transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. This term is significant for planning purposes, as long lead times can affect project timelines. Buyers should always clarify lead times with suppliers to ensure timely project execution.

Understanding these technical properties and trade terms can significantly enhance the decision-making process for international B2B buyers, ensuring they make informed choices that align with their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the different types of mounting brackets Sector

Market Overview & Key Trends

The mounting brackets sector is experiencing significant transformations driven by advancements in technology, shifting consumer preferences, and evolving market dynamics. Globally, the integration of mounting solutions in various applications—from industrial machinery to consumer electronics—is on the rise. This trend is particularly pronounced in emerging markets across Africa, South America, and the Middle East, where infrastructure development is accelerating. In these regions, there is an increasing demand for versatile and reliable mounting solutions that can accommodate a wide range of devices, including monitors, cameras, and other electronic displays.

One of the current trends influencing sourcing strategies is the adoption of smart mounting solutions that incorporate Internet of Things (IoT) technology. These innovative mounts not only offer enhanced user experience through adjustable features but also provide data analytics capabilities, allowing businesses to optimize their operations. Additionally, manufacturers are focusing on modular designs that facilitate easy installation and maintenance, thus catering to the needs of international buyers looking for cost-effective solutions.

Furthermore, the competitive landscape is evolving as more suppliers enter the market, leading to increased options for buyers. However, this also means that buyers must navigate a complex array of choices, requiring a clear understanding of their specific application needs and the associated technical specifications. For B2B buyers in Italy and Mexico, aligning sourcing decisions with local regulations and standards is critical to ensure compliance and reduce operational risks.

Sustainability & Ethical Sourcing in B2B

As sustainability becomes a central concern for businesses globally, the mounting brackets sector is also responding to this imperative. The environmental impact of manufacturing processes and material choices is under scrutiny, prompting B2B buyers to prioritize ethical sourcing practices. Companies that adopt sustainable practices not only reduce their carbon footprint but also enhance their brand image, which is increasingly important in competitive markets.

The use of recycled materials in the production of mounting brackets is gaining traction. Buyers should look for suppliers who utilize eco-friendly materials and possess certifications such as ISO 14001, which indicates a commitment to environmental management. Additionally, sourcing from manufacturers that adhere to fair labor practices and ethical supply chains is essential. This not only ensures compliance with regulations but also aligns with the values of increasingly conscious consumers and businesses.

In regions such as Europe, where environmental regulations are stringent, B2B buyers must consider the sustainability credentials of their suppliers. This includes evaluating the lifecycle impacts of products and opting for solutions that minimize waste, such as reusable or recyclable mounting systems. By prioritizing sustainability, buyers can contribute to a circular economy while also meeting the demands of their stakeholders.

Brief Evolution/History

The evolution of mounting brackets has been closely tied to advancements in technology and changing user requirements. Initially, mounting solutions were simplistic and primarily focused on securing equipment in fixed positions. However, as the demand for ergonomic designs grew, particularly in office and industrial settings, manufacturers began to innovate.

The introduction of adjustable and articulating mounts marked a significant shift, allowing users to customize their viewing angles and improve ergonomics. The proliferation of screens in various applications—from medical devices to digital signage—further accelerated this trend. Today, the market is characterized by a diverse range of mounting solutions that not only fulfill functional requirements but also enhance user experience through smart technology integration. As businesses continue to prioritize adaptability and user-centric designs, the mounting brackets sector is poised for further evolution, driven by ongoing technological advancements and sustainability initiatives.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of different types of mounting brackets

-

How do I vet suppliers for mounting brackets?

When sourcing mounting brackets, it’s crucial to conduct thorough supplier vetting. Start by checking supplier credentials, such as certifications (ISO, CE) and industry experience. Request references from previous clients, especially those in your region, to gauge reliability. Utilize online platforms for supplier ratings and reviews. Consider visiting the supplier’s facility if feasible, or engage in virtual tours. This due diligence helps ensure that your supplier can meet your quality and delivery expectations. -

Can I customize the mounting brackets to fit my specific needs?

Yes, many manufacturers offer customization options for mounting brackets. When discussing your requirements, clearly outline specifications such as size, weight capacity, and material preferences. Be sure to ask about the design process and any additional costs associated with customization. It’s also beneficial to request prototypes to assess the functionality before full-scale production. Collaborating closely with the supplier can lead to a product that perfectly fits your application. -

What are the typical minimum order quantities (MOQ) and lead times?

Minimum order quantities for mounting brackets can vary significantly by supplier and the complexity of the design. Generally, MOQs range from 100 to 1,000 units. Lead times also depend on the supplier’s production capacity and the complexity of your order, typically ranging from 2 to 8 weeks. Always clarify these details before committing to an order, and consider negotiating terms that suit your procurement needs, especially if you require smaller quantities. -

What payment terms are commonly used in international B2B transactions?

Payment terms can differ based on supplier policies and regional practices. Common methods include letters of credit, bank transfers, and PayPal. It’s advisable to negotiate terms that balance security and cash flow, such as a 30% upfront payment with the balance due upon delivery. Ensure you understand any fees associated with international payments and confirm that the supplier is comfortable with the chosen method to avoid disputes later. -

How can I ensure quality assurance and certifications for the mounting brackets?

To ensure quality, request documentation of the supplier’s quality assurance processes and any relevant certifications (e.g., ISO 9001). Ask for samples or test reports that demonstrate compliance with industry standards. Establish clear quality metrics upfront and consider implementing a quality control protocol where you inspect the products upon arrival. This proactive approach helps mitigate risks associated with product quality. -

What logistics considerations should I be aware of when importing mounting brackets?

Logistics can significantly impact the efficiency of your supply chain. Consider shipping methods, customs regulations, and potential tariffs based on the countries involved. Work with freight forwarders experienced in handling industrial goods to streamline the process. Also, account for lead times and plan for potential delays, especially during peak shipping seasons. Establishing a good relationship with your logistics provider can facilitate smoother transactions. -

How do I handle disputes with suppliers over mounting brackets?

Disputes can arise due to quality issues, delivery delays, or payment discrepancies. Establish clear communication channels and document all agreements to reduce misunderstandings. If a dispute occurs, start by discussing the issue directly with the supplier to seek a resolution. If necessary, refer to the contract terms, and consider mediation or arbitration as a last resort. Maintaining a professional relationship can often lead to amicable solutions. -

What are the best practices for maintaining a long-term relationship with my suppliers?

Building a strong, long-term relationship with your suppliers requires consistent communication and transparency. Regularly provide feedback on product quality and service, and be open to discussing improvements. Consider visiting the supplier’s facility or inviting them to your site for discussions on future projects. Establishing mutual trust can lead to better pricing, priority service, and collaboration on product development, ultimately benefiting both parties.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for different types of mounting brackets

In conclusion, the strategic sourcing of mounting brackets is a pivotal element for international B2B buyers across various sectors, particularly in Africa, South America, the Middle East, and Europe. Understanding the diverse types of mounting brackets available—ranging from fixed mounts to adjustable and articulating designs—enables businesses to make informed decisions that enhance product functionality and user experience.

Key Takeaways:

– Customization is Crucial: Tailoring the mounting solutions to specific applications can significantly improve usability and efficiency.

– Quality Assurance: Prioritize suppliers who offer durable, reliable products that meet safety standards and performance requirements.

– Cost Efficiency: Evaluate total cost of ownership, including installation and maintenance, rather than focusing solely on initial purchase price.

As the market evolves with technological advancements and an increasing emphasis on ergonomics, the demand for innovative mounting solutions will continue to rise. International buyers are encouraged to engage with suppliers who demonstrate a commitment to quality and innovation. By doing so, they can secure a competitive edge in their respective industries and ensure their mounting solutions are not only functional but also future-proof.