Your Ultimate Guide to Sourcing Filter Fluid

Introduction: Navigating the Global Market for filter fluid

Navigating the complexities of the global market for filter fluid is essential for international B2B buyers aiming to optimize their operations. Filter fluid plays a pivotal role in ensuring the efficiency and longevity of filtration systems across various industries, from pharmaceuticals to manufacturing. With inadequate filtration leading to costly downtime, compromised product quality, and potential regulatory penalties, the selection of the right filter fluid cannot be underestimated.

This comprehensive guide delves into the critical aspects of filter fluid procurement. It encompasses an array of topics, including the various types and materials of filter fluids, manufacturing and quality control standards, supplier evaluations, and cost considerations. Additionally, we will address market trends and frequently asked questions to provide a holistic understanding of this vital component.

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe—where operational demands and regulatory environments can differ significantly—this guide is designed to empower informed sourcing decisions. By leveraging the insights provided herein, businesses can enhance their filtration processes, reduce operational costs, and ensure compliance with local and international standards. Equip yourself with the knowledge to navigate this critical market effectively and secure a competitive edge in your industry.

Understanding filter fluid Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mineral Oil | Derived from refining crude oil; excellent lubricity. | Metalworking, automotive, and machinery. | Pros: Cost-effective, good thermal stability. Cons: Environmental concerns, limited biodegradability. |

| Synthetic Fluid | Man-made fluids designed for specific properties. | Aerospace, automotive, and high-performance machinery. | Pros: Superior performance, wider temperature range. Cons: Higher initial costs, potential compatibility issues. |

| Biodegradable Fluid | Made from natural sources, environmentally friendly. | Agriculture, food processing, and eco-sensitive industries. | Pros: Eco-friendly, reduces regulatory risks. Cons: Generally higher cost, may require specialized disposal. |

| Water-based Fluid | Composed mainly of water with additives; low viscosity. | Cleaning, cooling, and hydraulic applications. | Pros: Non-toxic, cost-effective. Cons: Lower lubrication properties, potential for corrosion. |

| Emulsifiable Fluid | Combines oil and water for cooling and lubrication. | Machining, grinding, and metalworking. | Pros: Versatile, effective cooling and lubrication. Cons: Requires careful maintenance, potential for microbial growth. |

Mineral Oil

Mineral oil is a traditional choice for many industrial applications due to its excellent lubricating properties. It is widely used in metalworking, automotive, and machinery sectors. When purchasing mineral oil, buyers should consider the oil’s viscosity, thermal stability, and potential environmental impacts. While it is cost-effective and readily available, concerns about biodegradability and environmental regulations are increasingly influencing buyer decisions.

Synthetic Fluid

Synthetic fluids are engineered to provide enhanced performance characteristics, making them suitable for demanding applications such as aerospace and high-performance machinery. These fluids can operate over a wider temperature range and often offer better lubrication and longevity compared to mineral oils. However, buyers must weigh the higher upfront costs against potential long-term savings in maintenance and efficiency. Compatibility with existing systems is another critical factor to consider.

Biodegradable Fluid

Biodegradable fluids are gaining traction in industries where environmental concerns are paramount, such as agriculture and food processing. Made from natural sources, these fluids minimize ecological impact and reduce regulatory risks. While they are generally more expensive than traditional fluids, their use can enhance a company’s sustainability profile. Buyers should assess the performance characteristics and disposal requirements to ensure they meet operational needs.

Water-based Fluid

Water-based fluids are primarily composed of water and are often used for cleaning, cooling, and hydraulic applications. They are non-toxic and cost-effective, making them an appealing option for many businesses. However, they offer lower lubrication properties and may lead to corrosion in certain systems. Buyers should evaluate the specific application requirements and potential corrosion inhibitors when considering water-based fluids.

Emulsifiable Fluid

Emulsifiable fluids combine oil and water to deliver effective cooling and lubrication, particularly in machining and grinding processes. They are versatile and can be tailored for specific applications, but they require careful maintenance to prevent microbial growth and other issues. Buyers should consider the fluid’s stability, maintenance requirements, and the compatibility of the emulsion with existing equipment to ensure optimal performance.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of filter fluid

| Industry/Sector | Specific Application of filter fluid | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Hydraulic systems in machinery | Enhances equipment lifespan and reduces downtime | Compatibility with fluid types and pressure specifications |

| Pharmaceuticals | Sterile filtration in drug production | Ensures product safety and compliance with regulations | High-efficiency filters with precise micron ratings |

| Automotive | Paint spray systems for coating | Improves surface finish quality and reduces waste | Resistance to solvents and chemical compatibility |

| Food and Beverage | Water filtration in processing | Maintains product quality and safety standards | Compliance with food safety regulations and material certifications |

| Oil and Gas | Filtration in drilling fluids | Protects equipment and enhances operational efficiency | High durability under extreme conditions and chemical exposure |

Manufacturing

In the manufacturing sector, filter fluids are essential for hydraulic systems that power machinery. These fluids filter out particulate matter and contaminants, ensuring that the hydraulic systems operate smoothly and efficiently. For international buyers, particularly in regions like Africa and South America where manufacturing is rapidly evolving, sourcing filter fluids that are compatible with local environmental conditions and machinery specifications is critical. Effective filtration can lead to reduced maintenance costs and improved equipment lifespan, directly impacting the bottom line.

Pharmaceuticals

The pharmaceutical industry relies heavily on sterile filtration processes to ensure the safety and efficacy of drug products. Filter fluids used in this sector must achieve high efficiency levels, often up to 99.97% for particles as small as 0.3 microns. For B2B buyers in Europe and the Middle East, it is crucial to select suppliers who can provide filters that meet stringent regulatory standards. Implementing the right filtration solutions not only safeguards product quality but also prevents costly compliance violations.

Automotive

In automotive applications, filter fluids play a key role in paint spray systems, where they help maintain the quality of the finish by filtering out impurities. This is especially important in regions with high humidity or dust levels, which can affect paint adhesion. Buyers should consider sourcing filter fluids that are resistant to solvents and compatible with various paint types to minimize waste and ensure a superior finish. This attention to detail can significantly enhance customer satisfaction and reduce rework costs.

Food and Beverage

In the food and beverage industry, water filtration is critical to maintaining safety and quality standards. Filter fluids are used to purify water during processing, ensuring that contaminants do not compromise product integrity. For international B2B buyers, especially in emerging markets, it is vital to source filtration solutions that comply with local food safety regulations. Selecting the right filter fluids not only protects consumer health but also enhances brand reputation and marketability.

Oil and Gas

The oil and gas sector utilizes filter fluids in drilling operations to protect equipment from abrasive particles and other contaminants. High-performance filtration systems are necessary to ensure operational efficiency and minimize downtime. Buyers from regions such as the Middle East, where oil extraction is pivotal, should prioritize sourcing durable filter fluids that can withstand extreme conditions and chemical exposure. This strategic sourcing can lead to significant cost savings and enhanced operational performance.

Related Video: Types Of Flowmeters And Their Industrial Applications.

Strategic Material Selection Guide for filter fluid

When selecting materials for filter fluids, international B2B buyers must consider several factors that influence performance, durability, and compliance with regional standards. Below, we analyze four common materials used in filter fluid applications, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in diverse markets such as Africa, South America, the Middle East, and Europe.

1. Polypropylene (PP)

Key Properties:

Polypropylene is known for its excellent chemical resistance, making it suitable for a variety of applications. It typically operates effectively at temperatures up to 200°F (93°C) and pressures around 150 PSI, depending on the specific grade used.

Pros & Cons:

– Pros: Lightweight, cost-effective, and resistant to a wide range of chemicals. It also has good mechanical strength and can be easily molded into various shapes.

– Cons: Limited thermal stability compared to other materials and lower resistance to UV light, which may lead to degradation in outdoor applications.

Impact on Application:

Polypropylene is compatible with many solvents and acids, but it may not be suitable for strong oxidizing agents. Buyers should assess the chemical profiles of their applications to avoid premature failures.

Considerations for International Buyers:

Buyers should ensure that the selected polypropylene meets local compliance standards such as ASTM or DIN. In regions with high UV exposure, additional protective measures may be necessary.

2. Stainless Steel

Key Properties:

Stainless steel offers high corrosion resistance and can withstand temperatures exceeding 1000°F (538°C) and high pressures, making it ideal for demanding environments.

Pros & Cons:

– Pros: Exceptional durability, longevity, and resistance to corrosion and extreme temperatures. It is also easy to clean and sterilize, making it suitable for food and pharmaceutical industries.

– Cons: Higher initial cost and weight compared to plastic materials. It may also require specialized machining for complex designs.

Impact on Application:

Stainless steel is compatible with a wide range of fluids, including aggressive chemicals. Its robustness makes it ideal for high-pressure applications, but its cost may be a barrier for smaller operations.

Considerations for International Buyers:

Ensure compliance with international standards such as ISO and JIS for quality assurance. Buyers should also consider the availability of stainless steel grades that meet local corrosion resistance requirements.

3. Polyvinyl Chloride (PVC)

Key Properties:

PVC is a versatile plastic that can handle temperatures up to 140°F (60°C) and moderate pressures. It is known for its good chemical resistance, particularly to acids and alkalis.

Pros & Cons:

– Pros: Cost-effective, lightweight, and easy to process. It is also resistant to a variety of chemicals, making it suitable for many applications.

– Cons: Limited temperature range and potential for brittleness at low temperatures. It may also release harmful chemicals when burned.

Impact on Application:

PVC is suitable for low-pressure applications and is commonly used in water filtration systems. However, its limitations in high-temperature applications must be considered.

Considerations for International Buyers:

Buyers should verify that PVC products comply with local regulations regarding safety and environmental impact. In regions with stringent environmental laws, alternatives may be preferred.

4. Teflon (PTFE)

Key Properties:

Teflon is renowned for its exceptional chemical resistance and can operate at temperatures up to 500°F (260°C) and high pressures. Its non-stick properties make it ideal for applications requiring minimal fluid adhesion.

Pros & Cons:

– Pros: Outstanding chemical resistance, low friction, and high-temperature tolerance. It is also non-reactive, making it suitable for sensitive applications.

– Cons: Higher cost and lower mechanical strength compared to metals. It can also be challenging to bond with other materials.

Impact on Application:

Teflon is ideal for applications involving aggressive chemicals and high temperatures. Its non-stick nature can enhance performance in certain filtration processes but may require specialized fittings.

Considerations for International Buyers:

Ensure compliance with global standards such as FDA for food applications. Buyers should also consider the availability of Teflon products in their region, as sourcing can be more complex.

| Material | Typical Use Case for filter fluid | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Chemical filtration | Cost-effective and lightweight | Limited thermal stability | Low |

| Stainless Steel | High-pressure applications | Exceptional durability and corrosion resistance | Higher initial cost | High |

| Polyvinyl Chloride | Water filtration | Cost-effective and easy to process | Limited temperature range | Low |

| Teflon | Aggressive chemical applications | Outstanding chemical resistance | Higher cost and lower mechanical strength | High |

This material selection guide provides international B2B buyers with critical insights into the properties and applications of various filter fluid materials, enabling informed purchasing decisions that align with operational needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for filter fluid

Manufacturing Processes for Filter Fluid

The manufacturing of filter fluids involves a series of well-defined stages that ensure the final product meets both functional and regulatory standards. Understanding these processes can help international B2B buyers select the right suppliers and products for their specific needs.

Main Stages of Manufacturing

-

Material Preparation

– Raw Material Sourcing: The first step involves sourcing high-quality raw materials, including various chemical compounds and additives. Suppliers should be able to provide documentation on the origin and purity of these materials.

– Chemical Mixing: After sourcing, materials undergo precise mixing to achieve the desired chemical properties. This phase may involve the use of specialized equipment to ensure uniform distribution and consistency. -

Forming

– Filtration Media Production: The mixed materials are processed to create the filtration media, which can include membranes, granules, or other forms. Techniques such as extrusion or molding may be employed to shape the media according to specifications.

– Initial Testing: Samples from the forming stage are often subjected to preliminary testing to check for consistency in properties like porosity and permeability. -

Assembly

– Component Integration: Once the filtration media is ready, it is assembled with other components such as casings, seals, and fittings. This assembly must ensure compatibility and functionality.

– Sealing and Packaging: After assembly, products are sealed to prevent contamination and packaged according to international shipping standards, taking care to comply with local regulations in target markets. -

Finishing

– Quality Control Checks: The final products undergo rigorous quality control assessments. This includes visual inspections, performance testing, and compliance checks to ensure that products meet specified standards.

– Labeling and Documentation: Proper labeling is crucial for international shipping, ensuring that all regulatory and safety information is provided. Documentation should include certificates of compliance and material safety data sheets (MSDS).

Quality Assurance in Filter Fluid Manufacturing

Quality assurance (QA) is critical in the production of filter fluids, as it directly impacts product reliability and compliance with regulations. B2B buyers must understand the QA processes to ensure they are partnering with reputable suppliers.

Relevant International Standards

- ISO 9001: This standard outlines a framework for quality management systems and is applicable to any organization. Suppliers should be certified to ISO 9001, which demonstrates their commitment to continuous improvement and customer satisfaction.

- CE Marking: For products sold in the European market, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: The American Petroleum Institute (API) provides standards specific to filter fluids used in the oil and gas industry. Compliance with these standards is essential for suppliers targeting this sector.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– This stage involves inspecting raw materials upon arrival to ensure they meet specified quality standards. B2B buyers should inquire about the supplier’s IQC procedures and records. -

In-Process Quality Control (IPQC)

– During the manufacturing process, random samples are taken to test for consistency and performance. This can include checks for viscosity, filtration efficiency, and chemical stability. -

Final Quality Control (FQC)

– Once the product is completed, a final inspection is conducted to ensure it meets all specifications. This step is critical for identifying defects before products are shipped.

Common Testing Methods

- Performance Testing: This includes measuring the filtration efficiency, pressure drop, and flow rates under standard operating conditions.

- Chemical Analysis: Suppliers often conduct chemical composition tests to ensure that the filter fluid will perform as expected in its intended environment.

- Durability Testing: This involves subjecting products to various stress conditions to assess their longevity and reliability.

Verifying Supplier Quality Control

B2B buyers from Africa, South America, the Middle East, and Europe should consider several methods to verify the quality control processes of potential suppliers:

- Audits: Conducting on-site audits can provide valuable insights into a supplier’s manufacturing processes and quality assurance protocols. This is particularly useful for long-term partnerships.

- Quality Reports: Requesting detailed quality control reports, including IQC, IPQC, and FQC results, can help in evaluating supplier reliability.

- Third-Party Inspections: Engaging independent third-party inspection agencies can provide an unbiased assessment of the supplier’s quality practices and product conformity.

Quality Control Nuances for International Buyers

International B2B buyers need to be aware of specific nuances that may affect quality assurance:

- Regulatory Differences: Compliance requirements can vary significantly between regions. Buyers should ensure that suppliers are familiar with and compliant with local regulations in their target markets.

- Cultural Considerations: Understanding the cultural context can help buyers navigate supplier relationships more effectively. For instance, communication styles and negotiation practices may differ across regions.

- Logistical Challenges: The international shipping of filter fluids may require additional documentation and compliance checks. Buyers should ensure that suppliers have experience in exporting to their specific regions, particularly in handling customs regulations and product safety standards.

By comprehensively understanding the manufacturing processes and quality assurance practices for filter fluids, international B2B buyers can make informed decisions, mitigate risks, and foster successful supplier partnerships.

Related Video: Inspection and Quality control in Manufacturing

Comprehensive Cost and Pricing Analysis for filter fluid Sourcing

Understanding the cost structure and pricing dynamics for filter fluid sourcing is crucial for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. The complexity of the market demands a thorough analysis of cost components and price influencers to ensure effective procurement strategies.

Cost Components of Filter Fluid Sourcing

-

Materials: The primary cost driver in filter fluid sourcing is the raw materials used in production. Depending on the type of filter fluid, these materials can vary significantly in price. Buyers should pay attention to the quality of the materials as they directly impact the performance and longevity of the filtration systems.

-

Labor: Labor costs encompass both direct labor for manufacturing and indirect labor for support functions. In regions with varying wage scales, such as Africa and South America, labor costs can significantly affect overall pricing.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and administrative expenses. Understanding the manufacturing environment of suppliers can reveal cost efficiencies that may benefit buyers.

-

Tooling: Specialized tooling for production can lead to substantial upfront costs. However, these costs may be amortized over larger production runs, making high-volume orders more cost-effective.

-

Quality Control (QC): Investments in QC processes are essential to ensure product reliability and compliance with industry standards. Enhanced QC measures may increase upfront costs but can reduce long-term liabilities related to product failures.

-

Logistics: Transporting filter fluids can incur significant costs, especially for international shipments. This includes freight charges, insurance, and customs duties. Buyers must consider the logistics capabilities of suppliers to optimize delivery times and costs.

-

Margin: The supplier’s profit margin will also play a role in the final pricing. Understanding the competitive landscape can help buyers negotiate better terms.

Price Influencers

-

Volume/MOQ: Minimum Order Quantities (MOQ) can greatly influence pricing. Suppliers often provide better unit prices for larger orders. Buyers should assess their consumption rates to leverage bulk purchasing when feasible.

-

Specifications/Customization: Customized filter fluids tailored to specific applications generally come at a premium. Buyers need to balance customization needs with budget constraints.

-

Materials: The choice of materials can affect both performance and price. High-performance materials will usually command higher prices, but the long-term benefits may justify the investment.

-

Quality/Certifications: Products with industry certifications typically have higher costs due to the rigorous testing and compliance processes. However, these certifications can mitigate risk and enhance reliability.

-

Supplier Factors: The reputation, reliability, and service capabilities of suppliers are critical. Established suppliers may charge more but often provide superior support and quality assurance.

-

Incoterms: Understanding shipping terms can help buyers negotiate better pricing and manage risks associated with transportation. Different Incoterms can alter the cost structure and responsibilities involved in the shipping process.

Buyer Tips for Cost Efficiency

-

Negotiation: Always engage in thorough negotiations. Leverage volume commitments and long-term partnerships to secure better pricing and terms.

-

Total Cost of Ownership (TCO): Assess the total cost of ownership, including maintenance and operational costs, rather than focusing solely on purchase price. A cheaper filter fluid may lead to higher operational costs if it requires frequent replacements or results in system inefficiencies.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and local economic conditions that can impact pricing. Establishing contracts in stable currencies can help mitigate risks.

-

Supplier Evaluation: Conduct comprehensive evaluations of potential suppliers, considering their production capabilities, financial stability, and past performance. This diligence can prevent costly disruptions down the line.

In conclusion, a well-rounded understanding of the cost structure and pricing dynamics in filter fluid sourcing is essential for international B2B buyers. By considering the outlined components and influencers, and applying strategic buyer tips, organizations can make informed purchasing decisions that enhance operational efficiency and reduce costs.

Disclaimer: Prices and costs mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements.

Spotlight on Potential filter fluid Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘filter fluid’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for filter fluid

Critical Specifications for Filter Fluid

When selecting filter fluid, understanding its technical properties is essential for ensuring optimal filtration performance and operational efficiency. Below are key specifications that B2B buyers should consider:

-

Material Grade

The material grade refers to the quality and composition of the fluid used in filtration systems. Common materials include mineral oils, synthetic fluids, and biodegradable options. The choice of material affects the fluid’s thermal stability, lubrication properties, and compatibility with various filter media. Selecting the appropriate material grade minimizes wear and tear on equipment, ensuring longevity and reliability. -

Viscosity

Viscosity measures the fluid’s resistance to flow, which is crucial for filter performance. Fluids with the right viscosity ensure proper movement through the filtration system, impacting flow rates and filtration efficiency. For example, high-viscosity fluids may be beneficial in applications requiring robust filtration but can lead to increased energy consumption. Proper viscosity selection can enhance system efficiency and reduce operational costs. -

Chemical Compatibility

This specification assesses the fluid’s ability to withstand interactions with various chemicals present in the application environment. Inadequate chemical compatibility can lead to fluid degradation, resulting in system failures or safety hazards. B2B buyers must evaluate the chemical exposure profiles of their operations to ensure that the filter fluid selected can maintain integrity and performance over time. -

Temperature Range

The operational temperature range indicates the fluid’s effectiveness under varying thermal conditions. Filter fluids must remain stable and effective within the specific temperature limits of the application. Extreme temperatures can alter fluid properties, leading to reduced filtration efficiency or equipment damage. Understanding the temperature requirements is vital for selecting the right filter fluid for specific operational contexts. -

Filtration Efficiency

This property measures the ability of the fluid to capture and remove particles from the system. Efficiency is often expressed as a percentage, indicating the size of particles the fluid can effectively filter. High filtration efficiency is essential in industries such as pharmaceuticals and food processing, where product purity is critical. Selecting fluids with appropriate filtration efficiency can prevent costly contamination issues.

Common Trade Terms in Filter Fluid Procurement

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several essential terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of filter fluids, knowing the OEM can help buyers ensure compatibility with existing systems and validate the quality of the product. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it impacts inventory management and cost-effectiveness. Buyers should negotiate MOQs to align with their operational needs without incurring excess inventory costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products or services. For filter fluid procurement, issuing an RFQ helps buyers compare costs, terms, and conditions from different suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is critical for B2B buyers, as they clarify shipping responsibilities, risk management, and cost allocation, ensuring smoother logistics and compliance in cross-border trade. -

Lead Time

Lead time refers to the time it takes from placing an order until it is delivered. For filter fluids, shorter lead times can significantly impact operational efficiency, especially in industries where downtime is costly. Buyers should inquire about lead times to plan their procurement strategies effectively. -

SDS (Safety Data Sheet)

An SDS is a document that provides detailed information about a substance, including its hazards, handling, and emergency measures. For filter fluids, having access to the SDS is vital for ensuring compliance with safety regulations and fostering a safe working environment.

By understanding these specifications and trade terms, B2B buyers can make informed choices regarding filter fluids, ultimately leading to enhanced operational efficiency and reduced costs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the filter fluid Sector

Market Overview & Key Trends

The filter fluid sector is witnessing significant transformation driven by global industrial demands and technological advancements. Key market drivers include the need for enhanced operational efficiency, compliance with stringent environmental regulations, and the pursuit of sustainable practices. As industries evolve, particularly in regions like Africa, South America, the Middle East, and Europe, buyers are increasingly seeking filtration solutions that not only meet performance standards but also integrate seamlessly with automated systems.

Emerging B2B tech trends are reshaping the sourcing landscape. Digital transformation, characterized by the adoption of IoT and AI technologies, is enabling real-time monitoring and predictive maintenance of filtration systems. This shift not only minimizes downtime but also optimizes maintenance schedules, resulting in substantial cost savings. Furthermore, the rise of e-procurement platforms is streamlining the vendor selection process, allowing buyers to compare products and services efficiently.

Market dynamics are also influenced by regional considerations. In Africa and South America, the emphasis on local sourcing is growing, driven by a desire to support domestic industries and reduce lead times. Conversely, European and Middle Eastern markets are leaning towards global suppliers who can provide advanced filtration technologies and sustainable solutions. As a result, international B2B buyers must navigate these varying dynamics to make informed sourcing decisions that align with their operational goals.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical component of the filter fluid sector, influencing purchasing decisions and corporate strategies. The environmental impact of filtration processes, including waste generation and energy consumption, is prompting companies to adopt more sustainable practices. For B2B buyers, understanding the lifecycle of filter fluids—from production to disposal—is essential in minimizing ecological footprints.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing practices, including transparency in sourcing materials and adherence to labor standards. The demand for ‘green’ certifications, such as ISO 14001 and EcoLabel, is on the rise, reflecting buyers’ preferences for environmentally friendly products. These certifications not only validate a supplier’s sustainability claims but also enhance brand reputation in a market that values corporate responsibility.

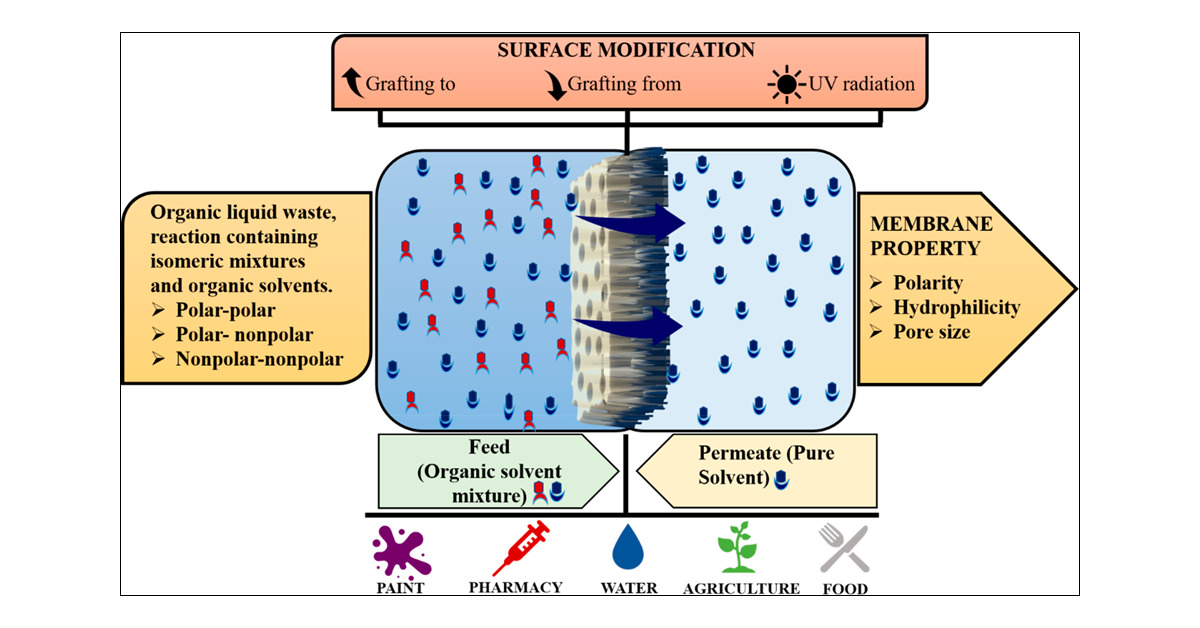

Illustrative Image (Source: Google Search)

Moreover, the integration of biodegradable materials and the development of recyclable filter fluids are setting new standards in the industry. By prioritizing sustainability, B2B buyers can not only meet regulatory requirements but also align with consumer expectations, ultimately driving long-term profitability and market competitiveness.

Brief Evolution/History

The filter fluid sector has evolved significantly over the past few decades, transitioning from basic filtration solutions to sophisticated, high-efficiency systems. Initially focused on mechanical filtration methods, the industry has incorporated advanced technologies such as membrane filtration and automation. These advancements have enabled higher levels of filtration efficiency and compliance with stringent regulatory standards.

Historically, the sector was characterized by a fragmented supply base, with local suppliers dominating the landscape. However, globalization has prompted the emergence of multinational corporations that offer comprehensive filtration solutions. This evolution reflects the growing complexity of industrial processes and the increasing need for integrated systems that enhance operational efficiency while minimizing environmental impact. As the market continues to evolve, international B2B buyers must stay informed about technological advancements and emerging trends to navigate the competitive landscape effectively.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of filter fluid

-

What criteria should I use to vet suppliers of filter fluid?

When vetting suppliers, prioritize their industry experience, certifications, and customer reviews. Check if they have a history of successful international transactions and compliance with local regulations in your region. Request references from other businesses similar to yours to gauge their reliability. Additionally, evaluate their capacity for customization, which can indicate flexibility in meeting your specific needs. Finally, consider their responsiveness and support services, as these can significantly impact your ongoing operational efficiency. -

Can filter fluid be customized to meet specific operational needs?

Yes, many suppliers offer customizable filter fluid solutions tailored to your operational requirements. This can include modifications in viscosity, chemical composition, or performance characteristics based on your industry standards. When discussing customization, provide detailed specifications regarding your application, including temperature, pressure, and filtration needs. Collaborate closely with your supplier to ensure the final product aligns with your expectations, as this can enhance system performance and longevity. -

What are the typical minimum order quantities (MOQs) and lead times for filter fluid?

Minimum order quantities can vary significantly by supplier and the type of filter fluid required. Generally, MOQs range from 200 to 1000 liters, depending on the product and supplier capabilities. Lead times typically span from two to six weeks, influenced by factors such as production schedules, customization requirements, and shipping logistics. Always clarify these details upfront to avoid disruptions in your supply chain, especially if you operate in regions with fluctuating demand. -

What payment terms should I expect when sourcing filter fluid internationally?

Payment terms can vary widely among suppliers, but common practices include advance payment, letters of credit, or open account terms. For international transactions, it’s prudent to negotiate terms that balance risk and cash flow. Ensure you understand the currency exchange implications and potential fees associated with different payment methods. Establishing a payment schedule that aligns with your operational cash flow can help maintain a steady supply of filter fluid while managing financial risk. -

What quality assurance measures should I look for in filter fluid suppliers?

Ensure that your supplier adheres to recognized quality assurance standards, such as ISO 9001 or industry-specific certifications. Request documentation that verifies product quality, including batch testing results and compliance with relevant safety and environmental regulations. A reputable supplier should also have a clear quality control process in place, including regular audits and testing of their products. This ensures that the filter fluid you receive consistently meets your specifications and operational requirements. -

How can I ensure compliance with local regulations when sourcing filter fluid?

Familiarize yourself with the regulatory requirements in your country regarding the import and use of filter fluids. This may include safety standards, environmental regulations, and chemical handling protocols. When selecting a supplier, verify that they are compliant with both international standards and your local regulations. Request documentation that demonstrates compliance, and consider engaging with local regulatory bodies or industry associations for guidance on specific requirements. -

What logistics considerations should I keep in mind when importing filter fluid?

Logistics play a crucial role in the timely delivery of filter fluid. Assess shipping methods, customs regulations, and potential tariffs that may apply to your order. Choose suppliers who have experience with international shipping and can provide you with transparent logistics support. Additionally, consider warehousing options if you anticipate fluctuating demand, as this can help mitigate delays and ensure a steady supply chain. Efficient logistics management can significantly reduce costs and enhance your operational efficiency.

Illustrative Image (Source: Google Search)

- What steps should I take to resolve disputes with filter fluid suppliers?

To address disputes effectively, first review your contract for terms related to dispute resolution. Open communication is key; initiate a discussion with the supplier to clarify the issue and seek a mutually agreeable solution. If informal resolution fails, consider mediation or arbitration, as these methods can be less costly and time-consuming than litigation. Maintain thorough documentation of all communications and transactions, as this can support your position in any disputes and facilitate a smoother resolution process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for filter fluid

In the rapidly evolving landscape of industrial filtration, strategic sourcing emerges as a critical factor for success. International B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, must prioritize thorough vendor evaluations and equipment specifications to mitigate risks associated with filtration-related downtime and maintenance costs. By understanding specific filtration requirements and future-proofing investments, companies can enhance operational efficiency and product quality while complying with increasingly stringent regulations.

Investing in high-efficiency filtration solutions not only reduces energy costs—potentially by 15-20% in the first year—but also safeguards against compliance violations and product quality issues that can lead to significant financial losses. Establishing robust partnerships with reliable vendors ensures ongoing support and access to critical parts, which is vital for maintaining optimal performance.

As we look ahead, the emphasis on sustainable and innovative filtration technologies will continue to grow. B2B buyers are encouraged to stay informed about market trends and invest in solutions that align with their operational goals. By doing so, they position themselves not just as participants in the industry, but as leaders ready to tackle the challenges of tomorrow.