Master the Types of Wire Rope for Optimal B2B Sourcing

Introduction: Navigating the Global Market for types of wire rope

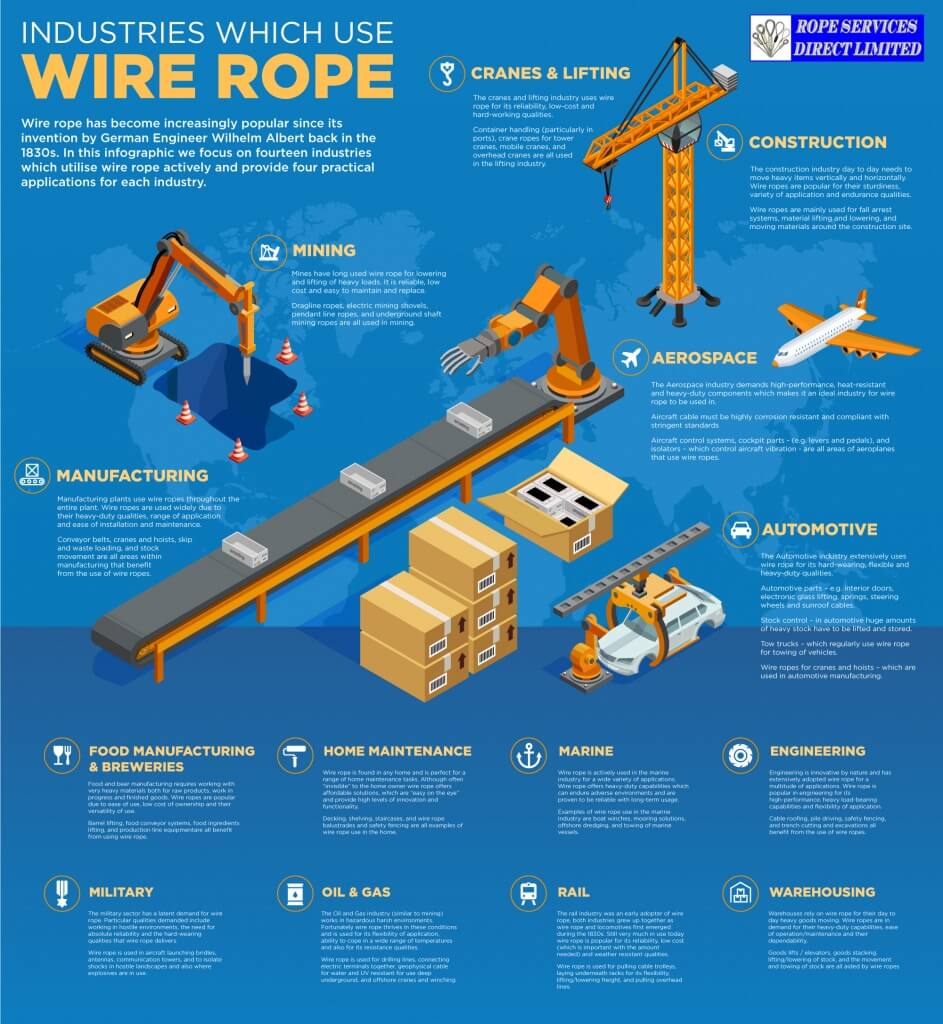

Navigating the global market for wire rope is a critical endeavor for international B2B buyers, especially those operating in diverse and dynamic regions such as Africa, South America, the Middle East, and Europe. Wire ropes serve as vital components in various industries, from construction and mining to marine and aerospace, underscoring their importance in ensuring safety, efficiency, and compliance with regulatory standards. The right selection of wire rope types can significantly impact operational performance, making informed sourcing decisions essential for mitigating risks and optimizing costs.

This comprehensive guide delves into the multifaceted world of wire ropes, offering actionable insights into different types, material specifications, manufacturing and quality control practices, and cost considerations. B2B buyers will benefit from a detailed analysis of supplier reliability, market trends, and unique challenges posed by regional environments, such as climate and regulatory variations.

Furthermore, the guide addresses frequently asked questions and emerging industry trends, equipping buyers with the knowledge necessary to navigate potential pitfalls and capitalize on opportunities. By understanding the nuances of wire rope types and their applications, international buyers can make strategic decisions that enhance safety, performance, and overall value in their operations. Empower yourself to secure the best wire rope solutions tailored to your specific needs and regional requirements.

Understanding types of wire rope Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wire Rope | Composed of multiple strands of wires twisted around a core | Lifting, construction, mining, marine operations | Versatile; strength varies by construction—requires careful selection. |

| Left Lay / Right Lay | Direction of twist affects rope behavior and performance | Cranes, elevators, and hoisting applications | Directional stability; important for specific applications, but may require specialized knowledge. |

| Galvanized Wire Rope | Coated with zinc for corrosion resistance | Marine, outdoor, and industrial uses | Enhanced durability; may be more expensive than uncoated options. |

| Point Contact Rope | Uniform wire diameter with high contact stress | Heavy lifting and industrial applications | Simple manufacturing; prone to wear, requiring frequent inspection. |

| Line Contact Rope | Different thicknesses of wires for reduced stress | Construction, hoisting, and rigging | Longer lifespan; better flexibility, but may be more complex to source. |

Wire Rope

Wire ropes are constructed by twisting several high-strength steel wires into strands, which are then twisted around a core. This design provides versatility and high strength, making wire ropes suitable for various applications, including lifting, construction, and marine operations. B2B buyers should consider the specific requirements of their projects when selecting wire ropes, as the strength and flexibility can vary significantly based on the construction type and materials used.

Left Lay / Right Lay

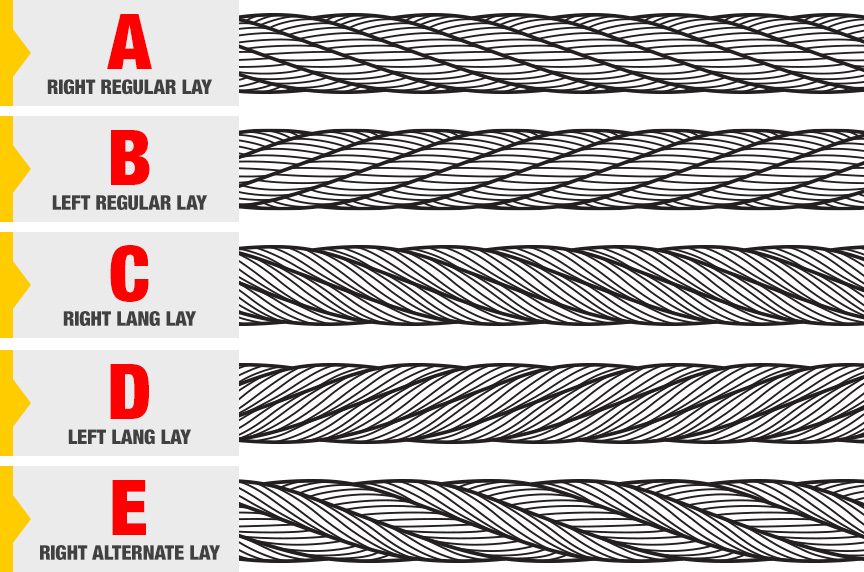

Wire ropes can be classified based on the direction of the twist—left lay or right lay. This distinction is crucial as it affects the rope’s behavior under load. Right lay ropes are commonly used in lifting applications, while left lay ropes may be preferred in other contexts. Buyers must ensure they understand the operational demands of their applications to choose the appropriate lay type, as improper selection can lead to performance issues or safety hazards.

Galvanized Wire Rope

Galvanized wire ropes are coated with zinc to enhance their corrosion resistance, making them ideal for outdoor and marine applications. This type of wire rope is commonly used in environments where moisture or exposure to harsh elements is a concern. B2B buyers should weigh the initial cost against the long-term benefits of reduced maintenance and extended lifespan, especially in regions with high humidity or saltwater exposure, such as coastal areas in Africa or the Middle East.

Point Contact Rope

Point contact ropes feature wires of uniform diameter that create high contact stress during operation. While they are simpler to manufacture and can be cost-effective, they are more prone to wear and breakage, necessitating regular inspections and maintenance. Buyers in heavy lifting or industrial sectors must consider the trade-off between cost and durability, ensuring they have a robust maintenance plan in place to mitigate the risks associated with point contact ropes.

Line Contact Rope

Line contact ropes utilize wires of varying thicknesses, allowing for reduced contact stress and increased flexibility. This design leads to a longer lifespan and improved performance in construction and rigging applications. However, sourcing line contact ropes may be more complex due to their specialized manufacturing processes. Buyers should prioritize suppliers with proven expertise in this area to ensure they receive high-quality products that meet their operational needs.

Related Video: Types of Sling | Types of wire rope sling/web belt sling/chain sling | How to calculate SWL of sling

Key Industrial Applications of types of wire rope

| Industry/Sector | Specific Application of types of wire rope | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Lifting and rigging for cranes and hoists | Enhances operational efficiency and safety on site | Ensure compliance with local regulations and standards |

| Marine | Mooring and anchoring systems | Provides reliable stability and safety in harsh waters | Assess corrosion resistance and durability for marine use |

| Mining | Cable systems for hoisting and hauling materials | Increases productivity and reduces downtime | Consider load ratings and compatibility with existing systems |

| Transportation & Logistics | Securing cargo in shipping and freight operations | Prevents loss and damage during transit | Evaluate weight limits and environmental resistance |

| Energy | Lifting equipment in oil and gas extraction | Ensures safe handling of heavy loads and equipment | Focus on strength ratings and reliability under stress |

Construction

In the construction industry, wire ropes are essential for lifting and rigging applications involving cranes and hoists. These ropes are designed to handle heavy loads, ensuring safety and efficiency on job sites. International buyers, particularly from regions with stringent safety regulations, must prioritize sourcing ropes that comply with local standards and certifications. Additionally, understanding the working environment—whether urban or remote—can influence the choice of wire rope, as factors like temperature and humidity affect performance.

Marine

In marine applications, wire ropes are critical for mooring and anchoring systems. They provide the necessary stability and safety for vessels in challenging environments, such as rough seas or strong currents. For buyers in coastal regions of Africa or the Middle East, selecting ropes with high corrosion resistance is crucial to ensure longevity and reliability. Buyers should also consider the rope’s breaking strength and its ability to withstand dynamic loads, ensuring it meets the specific demands of maritime operations.

Mining

Wire ropes play a vital role in the mining sector, particularly in hoisting and hauling operations. These ropes are engineered to lift heavy materials efficiently, directly impacting productivity and operational uptime. For international buyers in South America or Africa, sourcing wire ropes that meet high load ratings and durability standards is essential. Additionally, understanding local mining regulations and safety standards can guide buyers in selecting the most appropriate wire ropes for their specific applications.

Transportation & Logistics

In the transportation and logistics sector, wire ropes are used to secure cargo during shipping and freight operations. This prevents loss or damage to goods while in transit, which is critical for maintaining customer satisfaction and operational efficiency. Buyers must evaluate the weight limits of the wire ropes and their environmental resistance, especially in regions with extreme weather conditions. Ensuring compliance with international shipping standards can also mitigate risks associated with cargo handling.

Energy

The energy sector, particularly oil and gas extraction, relies heavily on wire ropes for lifting equipment and materials. These ropes must handle substantial weights and dynamic forces, ensuring safe operations in potentially hazardous environments. Buyers should focus on sourcing wire ropes with high strength ratings and proven reliability under stress. Additionally, understanding the unique challenges of the energy sector—such as exposure to chemicals and extreme temperatures—can aid in selecting the best wire ropes for specific applications.

Related Video: WIRE ROPE | ROPE USED IN MINES | MINE MACHINERY | TYPES OF WIRE ROPES #wirerope #minemachinery

Strategic Material Selection Guide for types of wire rope

Analysis of Common Materials for Wire Rope

When selecting wire rope for various applications, the choice of material is critical. Different materials offer unique properties that can significantly impact performance, durability, and overall cost-effectiveness. Below, we analyze four common materials used in wire rope manufacturing, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Carbon Steel

Key Properties:

Carbon steel wire ropes are known for their high tensile strength and durability. They typically have a temperature rating up to 200°C and can withstand high pressures, making them suitable for various industrial applications.

Pros & Cons:

Carbon steel is relatively inexpensive and widely available, making it a go-to choice for many applications. However, it is prone to corrosion if not properly treated, which can limit its lifespan in harsh environments. The manufacturing process is straightforward, but the need for protective coatings (like galvanization) can increase costs.

Impact on Application:

Carbon steel wire ropes are ideal for lifting and rigging operations in construction and mining. However, they are less suitable for marine environments without adequate protection due to corrosion risks.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure compliance with local standards (e.g., ASTM A1023) and consider the environmental factors that may affect the performance of carbon steel ropes.

2. Stainless Steel

Key Properties:

Stainless steel wire ropes exhibit excellent corrosion resistance and can handle temperatures up to 400°C. They are often used in environments where exposure to moisture or chemicals is a concern.

Pros & Cons:

The primary advantage of stainless steel is its durability and resistance to rust, making it suitable for marine and chemical applications. However, it is more expensive than carbon steel, and the manufacturing process is more complex, which can lead to higher costs.

Impact on Application:

Stainless steel wire ropes are perfect for applications in food processing, marine industries, and areas with high humidity. Their resistance to corrosion ensures longevity, reducing the frequency of replacements.

Considerations for International Buyers:

For buyers in Europe and the Middle East, adherence to standards like EN 10088 is crucial. Additionally, understanding the specific grades of stainless steel (e.g., 304 vs. 316) can impact performance and cost.

3. Galvanized Steel

Key Properties:

Galvanized steel wire ropes are carbon steel ropes coated with zinc to enhance corrosion resistance. They can withstand temperatures similar to carbon steel and are suitable for outdoor applications.

Pros & Cons:

The galvanization process significantly extends the lifespan of the wire rope in corrosive environments, such as construction sites exposed to moisture. However, the coating can wear off over time, especially in abrasive conditions, which may lead to rusting if not monitored.

Impact on Application:

Galvanized steel is commonly used in construction, agriculture, and outdoor rigging applications. It strikes a balance between cost and performance, making it a popular choice for many industries.

Considerations for International Buyers:

Buyers should verify that the galvanized steel ropes meet local standards (such as ASTM A475) and consider the environmental conditions of their specific applications, especially in humid or coastal areas.

4. Synthetic Fiber

Key Properties:

Synthetic fiber ropes, such as those made from polyester or nylon, are lightweight and flexible. They can handle a range of temperatures but generally have lower tensile strength compared to metal wire ropes.

Pros & Cons:

The main advantage of synthetic fibers is their resistance to corrosion and UV rays, making them ideal for marine and outdoor applications. However, they are not suitable for heavy lifting and can degrade over time under extreme conditions.

Impact on Application:

These ropes are best suited for applications where weight and flexibility are more critical than strength, such as in sailing or recreational activities.

Considerations for International Buyers:

International buyers should check for compliance with standards like ISO 2307 for synthetic ropes and consider the specific requirements of their applications, especially in regions with extreme weather conditions.

Summary Table

| Material | Typical Use Case for types of wire rope | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Construction, mining, general lifting | High strength, low cost | Prone to corrosion without treatment | Low |

| Stainless Steel | Marine, food processing, chemical industries | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Galvanized Steel | Outdoor construction, agriculture | Enhanced corrosion resistance | Coating can wear off | Medium |

| Synthetic Fiber | Sailing, recreational activities | Lightweight, flexible | Lower tensile strength | Medium |

This guide serves as a strategic resource for international B2B buyers, enabling informed decisions on wire rope material selection based on specific operational needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for types of wire rope

Manufacturing Processes for Wire Rope

Understanding the manufacturing processes of wire rope is crucial for B2B buyers, especially those in regions with specific operational challenges such as Africa, South America, the Middle East, and Europe. The production of wire rope involves several key stages that ensure the final product meets the stringent requirements of safety, durability, and performance.

Main Stages of Manufacturing

-

Material Preparation

– The primary raw materials for wire rope include high-strength carbon steel wires, which are typically drawn to specified diameters ranging from 0.3 to 3mm.

– Wire Coating: Before twisting, wires may undergo surface treatments like galvanization or oiling to enhance corrosion resistance and reduce friction. -

Forming

– Stranding: The prepared wires are twisted into strands, with different configurations such as 6×19 or 6×37. The choice of strand configuration affects flexibility and strength.

– Laying: Multiple strands are then twisted around a core, which can be made of various materials, including steel or synthetic fibers. This step is crucial for maintaining the rope’s structural integrity under load. -

Assembly

– End Termination: Wire ropes often require fittings for specific applications. This process may involve swaging or other mechanical deformation methods to secure fittings to the cable ends.

– Pre-assembly Testing: Manufacturers may conduct initial tests to ensure that the rope can withstand the intended loads before finalizing the assembly. -

Finishing

– Coating and Lubrication: Final treatments include applying protective coatings and lubricants, which enhance the rope’s lifespan and performance in harsh environments.

– Cutting and Packaging: The ropes are cut to specified lengths and packaged for shipment, ensuring they remain free from damage during transit.

Key Techniques in Wire Rope Manufacturing

- Twisting Techniques: The twisting method (left lay, right lay, etc.) significantly impacts the rope’s flexibility and load-bearing capacity. Understanding these methods helps buyers select the appropriate type for their applications.

- Quality of Raw Materials: Sourcing high-quality raw materials is essential. Buyers should verify that suppliers use steel that meets international standards for strength and ductility.

- Advanced Machinery: Modern manufacturing facilities employ CNC machines and automated processes to ensure precision and consistency in wire production.

Quality Assurance in Wire Rope Manufacturing

Quality assurance is vital in wire rope manufacturing to ensure safety and performance. B2B buyers should be aware of international standards and the specific quality control processes that manufacturers should implement.

Relevant International Standards

- ISO 9001: This standard outlines the requirements for a quality management system, ensuring that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: This certification indicates compliance with European health, safety, and environmental protection standards.

- API Standards: For wire ropes used in oil and gas applications, adherence to American Petroleum Institute (API) standards is crucial, as they specify requirements for performance and safety.

Quality Control Checkpoints

-

Incoming Quality Control (IQC):

– This initial stage involves inspecting raw materials upon arrival to ensure they meet specified standards. Key attributes include tensile strength, diameter, and surface condition. -

In-Process Quality Control (IPQC):

– Throughout the manufacturing process, regular inspections should be conducted to monitor production consistency. Common checks include dimensional accuracy and the integrity of stranding. -

Final Quality Control (FQC):

– Before packaging, finished wire ropes undergo rigorous testing, including load testing and visual inspections for defects. This step ensures that only products meeting quality standards reach customers.

Common Testing Methods

- Tensile Testing: Measures the maximum load a wire rope can bear before failure, providing essential data for safety assessments.

- Fatigue Testing: Evaluates how the rope performs under repeated loading, crucial for applications subject to dynamic loads.

- Corrosion Resistance Testing: Determines the rope’s ability to withstand environmental factors, especially for operations in harsh climates.

Verifying Supplier Quality Control

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is critical. Here are actionable steps to ensure supplier reliability:

- Conduct Supplier Audits: Regular audits of manufacturing facilities can uncover potential quality issues. Buyers should look for certifications and compliance with international standards during these visits.

- Request Quality Reports: Suppliers should provide documentation of their quality assurance processes and test results for products. These reports should detail all testing methods used and their outcomes.

- Engage Third-Party Inspectors: Hiring independent inspection agencies can provide an unbiased assessment of the supplier’s manufacturing processes and product quality. This is especially important for buyers dealing with high-stakes applications, such as construction or mining.

Quality Certification Nuances for International Buyers

International buyers must consider specific regional regulations and standards. For instance, European buyers may require CE certification, while buyers in the Middle East might look for compliance with local safety standards. Understanding these nuances helps buyers navigate potential regulatory hurdles and ensures that the sourced products are suitable for their specific applications.

In summary, a thorough understanding of manufacturing processes and quality assurance practices is essential for international B2B buyers. By focusing on these areas, buyers can make informed decisions that enhance safety, compliance, and operational efficiency in their projects.

Related Video: Heavy Duty Rope Fabricating Production – Wire Cable Manufacturing Process – Amazing Factory Machines

Comprehensive Cost and Pricing Analysis for types of wire rope Sourcing

When sourcing wire rope, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers, particularly those operating in diverse regions like Africa, South America, the Middle East, and Europe. This analysis will help buyers navigate pricing complexities, negotiate better deals, and ensure cost-effective procurement strategies.

Cost Components

-

Materials: The primary cost driver in wire rope pricing is the raw material, typically high-strength carbon steel. Variations in steel prices, driven by global market fluctuations, can significantly impact overall costs. Additionally, the choice of wire surface treatment (e.g., galvanized vs. smooth) can alter material costs.

-

Labor: Labor costs encompass both manufacturing and skilled installation. Regions with higher labor costs may see increased prices, while countries with lower labor rates may offer more competitive pricing. Skilled labor is essential for specific fittings like swage fittings, where installation requires specialized knowledge.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can lead to lower overhead costs, which may be reflected in pricing.

-

Tooling: The cost of specialized tooling and machinery for wire rope production can be substantial. Advanced manufacturing techniques that improve quality and reduce waste may require higher initial investment, impacting pricing.

-

Quality Control (QC): Rigorous quality assurance processes ensure compliance with industry standards and safety regulations. Suppliers that uphold stringent QC measures may charge higher prices, reflecting the added value of reliability and safety.

-

Logistics: Transportation and shipping costs are critical, especially for international buyers. Factors such as distance, shipping method, and regional tariffs can influence final pricing. Incoterms should be clearly defined to avoid unexpected costs.

-

Margin: Supplier margins vary based on market competition, brand reputation, and service offerings. Understanding these margins can help buyers identify the most cost-effective suppliers.

Price Influencers

-

Volume/MOQ: Buying in bulk often yields better pricing. Minimum order quantities (MOQs) can affect unit costs, so negotiating larger orders can lead to significant savings.

-

Specifications/Customization: Custom orders tailored to specific applications often come at a premium. Buyers should assess whether standard products can meet their needs to avoid unnecessary costs.

-

Quality/Certifications: Suppliers offering high-quality products with recognized certifications (e.g., ISO, ASTM) may charge more. Investing in certified products can reduce long-term risks and maintenance costs.

-

Supplier Factors: Reliability, reputation, and service levels of suppliers play a crucial role in pricing. Established suppliers may command higher prices due to perceived value, but they also provide assurance of quality and support.

-

Incoterms: Understanding the responsibilities and liabilities associated with different Incoterms can help buyers manage logistics costs and risks effectively.

Buyer Tips

-

Negotiation: Leverage competitive bids from multiple suppliers to negotiate better terms. Highlighting long-term partnership potential can also yield favorable pricing.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes initial purchase price, installation, maintenance, and operational costs. A lower upfront cost may lead to higher long-term expenses if quality is compromised.

-

Pricing Nuances: Be aware of regional pricing variations due to local economic conditions, currency fluctuations, and demand-supply dynamics. For example, buyers in Africa or South America may encounter different pricing structures compared to those in Europe.

-

Market Research: Stay informed about market trends and steel prices to time purchases strategically. Engaging with industry associations can provide insights into pricing benchmarks and supplier performance.

Disclaimer

The prices discussed in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and regional factors. Buyers are encouraged to conduct thorough research and obtain multiple quotations to ensure the best pricing for their specific needs.

Spotlight on Potential types of wire rope Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘types of wire rope’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for types of wire rope

Wire ropes are essential components in various industrial applications, and understanding their technical properties and relevant trade terminology is crucial for international B2B buyers. This section outlines key specifications and industry terms that can help buyers make informed procurement decisions.

Critical Specifications of Wire Rope

-

Material Grade

– Wire ropes are typically made from high-strength carbon steel, with grades determining their tensile strength and corrosion resistance. Common grades include 1770 MPa and 1960 MPa, which indicate the maximum load they can withstand.

– B2B Importance: Selecting the appropriate material grade is vital for ensuring safety and reliability in high-stress applications, particularly in industries like construction, mining, and marine. -

Diameter

– Wire ropes come in various diameters, typically ranging from 3 mm to 50 mm. The diameter impacts the rope’s strength and flexibility.

– B2B Importance: Buyers must choose the right diameter to meet specific load requirements. A thicker rope can handle heavier loads, while a thinner rope may offer better maneuverability in tight spaces. -

Lay Type

– The lay type refers to the direction in which the wires are twisted together. Common lay types include right lay and left lay, affecting the rope’s handling characteristics.

– B2B Importance: Understanding lay types helps buyers select ropes suitable for specific applications, such as lifting or rigging, where twisting direction can influence performance and longevity. -

Construction

– Wire ropes are classified based on the number of strands and wires they contain, such as 6×19 or 6×37. The construction affects flexibility, strength, and abrasion resistance.

– B2B Importance: Buyers should consider the construction that best suits their operational needs, as it can significantly impact the rope’s performance under dynamic loads. -

Coating and Finish

– Wire ropes may be coated with materials such as zinc (galvanization) or painted for additional corrosion resistance. The finish can also affect wear and tear.

– B2B Importance: Selecting the right coating is crucial for applications in harsh environments, such as coastal regions or industrial settings with high humidity. -

Breaking Strength

– The breaking strength is the maximum load the rope can bear before failing, typically measured in kilonewtons (kN). This is determined by the rope’s material and construction.

– B2B Importance: Understanding breaking strength is essential for ensuring safety and compliance with industry standards, as underestimating this can lead to catastrophic failures.

Common Industry Terms

-

OEM (Original Equipment Manufacturer)

– Refers to companies that produce parts or equipment that may be marketed by another manufacturer. In wire rope, OEMs often provide specialized products tailored to specific applications.

– B2B Importance: Buyers should engage with reputable OEMs to ensure high-quality products that meet their operational needs. -

MOQ (Minimum Order Quantity)

– The smallest number of units a supplier is willing to sell. This can vary widely based on the product and supplier.

– B2B Importance: Understanding MOQ is crucial for budget planning and inventory management, especially for smaller businesses or projects. -

RFQ (Request for Quotation)

– A formal document issued by a buyer to suppliers to request pricing and terms for specific products or services.

– B2B Importance: Submitting RFQs helps buyers obtain competitive pricing and ensures clarity on specifications and delivery timelines. -

Incoterms (International Commercial Terms)

– A set of international rules that define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping costs, insurance, and risk.

– B2B Importance: Familiarity with Incoterms helps buyers avoid misunderstandings and ensures a smooth supply chain operation. -

Lead Time

– The time it takes from placing an order to receiving the goods. This can vary based on product availability, manufacturing processes, and shipping logistics.

– B2B Importance: Understanding lead times is essential for project planning and ensuring that operations are not delayed due to supply chain issues. -

Tensile Strength

– The resistance of a material to breaking under tension. It is a critical property for wire ropes, affecting their load-bearing capacity.

– B2B Importance: Buyers must evaluate tensile strength to ensure that the wire rope will perform adequately under expected loads, thus maintaining safety and efficiency in operations.

By grasping these technical properties and trade terms, B2B buyers from diverse regions can make better-informed decisions, optimizing their procurement strategies and enhancing operational reliability.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the types of wire rope Sector

Market Overview & Key Trends

The global wire rope market is witnessing substantial growth driven by increasing demand across various industries such as construction, mining, and marine operations. Key trends influencing the market include the adoption of advanced materials and manufacturing techniques, which enhance the strength and durability of wire ropes. For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, understanding the specific applications and properties of different wire rope types is crucial.

Emerging technologies, such as digital sourcing platforms and real-time inventory management systems, are reshaping procurement strategies. These technologies enable buyers to streamline their sourcing processes, reduce lead times, and optimize supply chain logistics. Additionally, the growing importance of compliance with international standards, such as ISO and ASTM, has led suppliers to invest in quality assurance practices, ensuring that products meet stringent safety and performance requirements.

Market dynamics are also influenced by regional factors, including fluctuating raw material costs and varying regulations. For instance, buyers in the Middle East may face unique challenges related to extreme temperatures and humidity, necessitating specialized wire rope solutions. On the other hand, European buyers may prioritize eco-friendly sourcing practices. Recognizing these nuances can help B2B buyers make informed decisions that align with their operational needs and regulatory environments.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal concern in the wire rope sector, as buyers increasingly seek to mitigate their environmental impact. The production of wire ropes often involves significant energy consumption and emissions. Therefore, selecting suppliers committed to sustainable practices is vital. This includes sourcing materials from manufacturers who utilize renewable energy and implement waste reduction strategies in their production processes.

Ethical sourcing is equally important, as buyers must ensure that their supply chains are free from human rights abuses and comply with labor regulations. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices. Additionally, the use of recycled materials in wire rope production is gaining traction, allowing buyers to reduce their carbon footprint while maintaining product quality.

By prioritizing sustainability and ethical sourcing, B2B buyers not only contribute to environmental conservation but also enhance their brand reputation and meet the growing consumer demand for responsible products. This strategic approach can lead to long-term cost savings and improved supply chain resilience.

Brief Evolution/History

The wire rope industry has evolved significantly since its inception in the 19th century. Initially developed for use in mining and construction, wire ropes were made from hemp and later transitioned to steel, offering greater strength and durability. The introduction of various twisting methods and core materials allowed for a broader range of applications, including marine and industrial uses.

As technology advanced, the manufacturing processes became more sophisticated, leading to the development of specialized wire ropes tailored for specific environments and applications. Today, the focus on safety, performance, and sustainability continues to drive innovation within the sector, making it essential for B2B buyers to stay informed about the latest trends and technologies. Understanding this evolution aids buyers in appreciating the diversity of wire rope products available and their respective advantages in different operational contexts.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of types of wire rope

-

How do I vet suppliers for wire rope?

When sourcing wire rope, it’s crucial to assess suppliers based on their manufacturing standards, certifications, and reputation in the market. Look for ISO certifications and compliance with international standards such as EN or ASTM. Request product samples and check for customer references, particularly from industries similar to yours. Additionally, consider their financial stability and the reliability of their supply chain, especially if you require large volumes or have tight deadlines. -

Can wire rope be customized for specific applications?

Yes, many suppliers offer customization options for wire rope to meet specific operational needs. Customizations can include variations in diameter, strand construction, core material, and surface treatment. When engaging with suppliers, clearly communicate your requirements and intended applications. This will help ensure that the customized wire rope meets the necessary safety and performance standards for your projects. -

What are typical minimum order quantities (MOQs) and lead times?

Minimum order quantities (MOQs) can vary significantly by supplier and region, typically ranging from 100 meters to several kilometers. For international buyers, lead times can also differ based on the supplier’s location and production capacity. On average, expect lead times of 4-12 weeks for standard orders, but customization may extend this period. Always confirm these details upfront to align with your project timelines.

Illustrative Image (Source: Google Search)

-

What payment terms should I expect when sourcing wire rope internationally?

Payment terms can vary widely among suppliers and regions, but common practices include advance payments, letters of credit, or payment upon delivery. For international transactions, it’s advisable to negotiate terms that protect both parties. Using secure payment methods such as PayPal or escrow services can help mitigate risks. Ensure that the payment terms align with your cash flow and project funding to avoid disruptions. -

How important are quality assurance (QA) certifications for wire rope?

Quality assurance certifications are essential when sourcing wire rope, as they ensure that the product meets safety and performance standards. Look for suppliers who possess relevant certifications such as ISO 9001 or specific industry-related standards. These certifications indicate adherence to quality management systems and can significantly reduce the risk of product failures. Always request documentation of these certifications during the procurement process. -

What logistics considerations should I be aware of when importing wire rope?

Logistics plays a critical role in the sourcing process for wire rope. Consider factors such as shipping methods, customs regulations, and potential tariffs or duties that may apply in your region. Work with suppliers who have experience in international shipping to streamline the process. Additionally, ensure that adequate insurance is in place to cover potential damages during transit, and plan for potential delays at customs. -

How can I resolve disputes with wire rope suppliers?

Dispute resolution begins with clear communication and documentation of agreements. Ensure all terms, including specifications, delivery timelines, and payment conditions, are documented in contracts. If a dispute arises, engage in direct communication with the supplier to seek a resolution. If necessary, consider mediation or arbitration as alternative methods for resolving conflicts, especially when dealing with international suppliers where legal frameworks may differ. -

What emerging trends should I be aware of in wire rope sourcing?

International buyers should stay informed about emerging trends such as the increased demand for eco-friendly materials and advanced manufacturing techniques. Innovations like synthetic wire ropes are gaining traction due to their lightweight and corrosion-resistant properties. Additionally, digital procurement tools are streamlining sourcing processes, allowing for better supplier comparison and tracking of orders. Keeping abreast of these trends can provide a competitive edge in the sourcing process and enhance operational efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of wire rope

In conclusion, strategic sourcing of wire rope is essential for ensuring operational efficiency and safety across various industries. International B2B buyers must prioritize quality, compliance, and local environmental conditions when selecting wire rope types and fittings. Understanding the distinctions between wire rope classifications—such as core materials, twisting methods, and surface treatments—enables buyers to make informed decisions that enhance performance and longevity.

Effective supplier evaluation is vital; consider factors such as manufacturing standards, certifications, and supply chain reliability. The right partnerships can mitigate risks associated with climate challenges and regulatory complexities prevalent in regions like Africa, South America, the Middle East, and Europe.

As the global market evolves, remaining adaptable to emerging trends and technological advancements will empower buyers to stay ahead. By investing in strategic sourcing practices today, businesses can ensure not only compliance and safety but also cost-efficiency and competitive advantage in their operations.

Now is the time to reassess your sourcing strategies—explore reliable suppliers, and leverage the insights shared in this guide to secure the best wire rope solutions for your needs. The future of your projects depends on the choices you make today.

Illustrative Image (Source: Google Search)