Master the Types of Plugs and Sockets for Seamless Global

Introduction: Navigating the Global Market for types of plugs and sockets

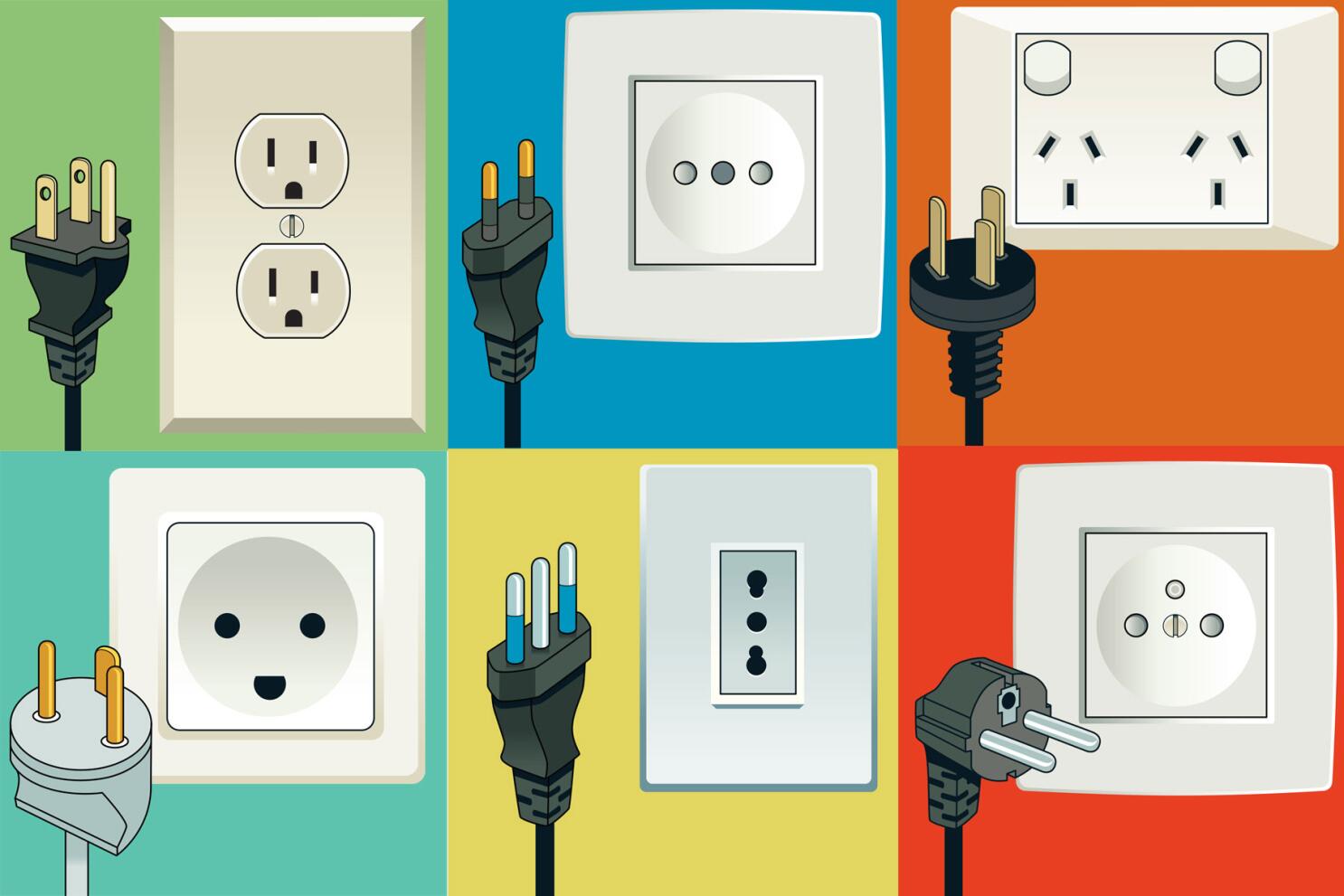

In today’s interconnected world, the importance of understanding the various types of electrical plugs and sockets cannot be overstated. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe engage in global trade, the implications of plug and socket compatibility become critical. Whether powering industrial machinery or consumer electronics, selecting the right plug type ensures operational efficiency, safety, and compliance with local regulations.

This comprehensive guide delves into the myriad of plug and socket types currently in use worldwide, spanning from the ubiquitous Type A to the versatile Type N. We will explore the materials commonly used in manufacturing these essential components, the quality control measures that guarantee their reliability, and the leading suppliers in the market. Additionally, the guide will provide insights into pricing structures, enabling buyers to make informed financial decisions.

By addressing frequently asked questions and offering actionable insights, this guide empowers B2B buyers to navigate the complexities of sourcing plugs and sockets effectively. With a clear understanding of the global landscape, businesses can enhance their procurement strategies, mitigate risks associated with electrical compatibility, and ultimately drive success in their operations.

Understanding types of plugs and sockets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type A | Two flat parallel pins | North American appliances, consumer electronics | Pros: Widely used, easy to find; Cons: No grounding, less safe for high-power devices |

| Type C | Two round pins | European appliances, lightweight devices | Pros: Common in Europe, versatile; Cons: Not suitable for high-wattage appliances |

| Type G | Three rectangular pins | UK, Ireland, and some Middle Eastern countries | Pros: Grounding for safety, robust design; Cons: Bulky, may not fit in all sockets |

| Type I | Two flat pins with a grounding pin | Australia, New Zealand, and China | Pros: Grounding for safety, high compatibility; Cons: Less common outside Oceania |

| Type N | Two round pins with grounding | Brazil and some South American countries | Pros: Grounding for safety, suitable for modern appliances; Cons: Limited global usage |

Type A

Type A plugs feature two flat parallel pins and are primarily used in North America and parts of Central America. They are commonly found in consumer electronics and lightweight appliances. For B2B buyers, it is essential to consider that while Type A plugs are prevalent, they lack grounding, making them less suitable for high-wattage or sensitive electronic equipment. When sourcing equipment for use in regions with Type A sockets, ensure that the devices are compatible and that safety standards are met.

Type C

The Type C plug, characterized by its two round pins, is widely used across Europe and is compatible with many lightweight devices and appliances. This plug type is advantageous for B2B buyers because of its versatility and availability. However, it is not designed for high-wattage applications, which could pose safety risks if used improperly. Buyers should ensure that devices intended for Type C sockets are rated for the appropriate voltage and current levels.

Type G

Type G plugs are known for their three rectangular pins and are primarily used in the UK, Ireland, and some Middle Eastern countries. This plug type is favored for its robust design and grounding feature, making it safer for high-wattage appliances. B2B buyers should consider Type G plugs when sourcing equipment intended for these regions, particularly for industrial or commercial applications where safety is paramount. However, the bulkiness of Type G plugs can be a drawback, as they may not fit in all socket types.

Type I

Featuring two flat pins and a grounding pin, Type I plugs are predominantly used in Australia, New Zealand, and parts of China. They are known for their compatibility with high-wattage devices, making them suitable for various applications, including industrial and commercial equipment. For B2B buyers, sourcing devices that utilize Type I plugs ensures compliance with local electrical standards. However, this plug type is less common outside Oceania, which may limit its applicability for international operations.

Type N

The Type N plug, which includes two round pins with a grounding pin, is primarily found in Brazil and select South American countries. This plug type is designed for modern appliances and offers grounding for enhanced safety. B2B buyers should consider Type N plugs when importing or exporting devices to Brazil, as compatibility is crucial for operational efficiency. However, due to its limited global presence, sourcing equipment that accommodates Type N sockets may be more challenging compared to more common plug types.

Related Video: Electrical Plugs And Sockets Types

Key Industrial Applications of types of plugs and sockets

| Industry/Sector | Specific Application of types of plugs and sockets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Power supply for machinery and equipment | Ensures efficient operation and reduces downtime | Compliance with local electrical standards and compatibility with existing systems |

| Construction | Temporary power setups on job sites | Facilitates the use of tools and lighting, enhancing safety | Durability under harsh conditions and flexibility for various plug types |

| Healthcare | Medical equipment connections | Guarantees reliable power for critical devices | High safety standards and non-interference with sensitive equipment |

| Telecommunications | Data center power management | Maintains uptime and operational integrity | Need for redundancy and compliance with international power standards |

| Hospitality | Guest room electrical outlets | Enhances guest experience with universal access | Versatility in plug types to accommodate international guests |

Manufacturing

In the manufacturing sector, types of plugs and sockets are crucial for powering machinery and equipment. A reliable power supply is essential to ensure efficient operation and minimize downtime, directly impacting productivity. International B2B buyers must consider local electrical standards and the compatibility of plugs with existing systems to avoid interruptions. Additionally, investing in high-quality plugs and sockets can prevent equipment damage and enhance safety in the workplace.

Construction

Construction sites often require temporary power setups to operate tools, lighting, and equipment. The use of appropriate plugs and sockets is vital for creating a safe and functional work environment. These components must be durable enough to withstand harsh conditions while providing flexibility for various plug types. Buyers should prioritize sourcing robust products that comply with local regulations and can handle the demands of a construction site, ensuring safety and efficiency.

Healthcare

In healthcare, the connection of medical equipment to power sources is critical. Types of plugs and sockets used in this sector must guarantee reliable power to critical devices, such as life-support machines and diagnostic equipment. Buyers in the healthcare industry need to ensure that their sourced plugs meet high safety standards and do not interfere with sensitive medical devices. This reliability is essential to maintaining patient safety and operational integrity.

Telecommunications

Telecommunications rely heavily on data centers that require efficient power management. Types of plugs and sockets are integral to maintaining uptime and ensuring the operational integrity of servers and networking equipment. International B2B buyers should focus on sourcing equipment that includes redundancy features and complies with international power standards to prevent outages and data loss, which can be costly for businesses.

Hospitality

In the hospitality industry, guest room electrical outlets must accommodate a variety of plug types to enhance guest experience. Providing versatile options allows international travelers to use their devices without the need for additional adapters. Buyers should focus on sourcing universal or region-specific plugs that comply with local electrical codes while ensuring ease of use for guests. This attention to detail can significantly improve customer satisfaction and loyalty.

Related Video: WEG – Industrial Plugs and Sockets

Strategic Material Selection Guide for types of plugs and sockets

When selecting materials for plugs and sockets, it is crucial to consider their properties, durability, and suitability for specific applications. The following analysis examines four common materials used in the manufacturing of plugs and sockets: thermoplastics, thermosetting plastics, metals, and rubber. Each material has distinct characteristics that can significantly influence performance and compliance with international standards.

Thermoplastics

Key Properties:

Thermoplastics, such as polyvinyl chloride (PVC) and nylon, are known for their excellent electrical insulation properties, flexibility, and resistance to impact. They can withstand temperatures ranging from -40°C to 85°C, making them suitable for various environments.

Pros & Cons:

Thermoplastics are lightweight and cost-effective, which makes them popular for mass production. However, they may not be as durable as other materials under extreme conditions, such as high temperatures or prolonged exposure to UV light. Additionally, their manufacturing process is relatively straightforward, allowing for quick production cycles.

Impact on Application:

Thermoplastics are ideal for residential and light commercial applications where electrical safety is paramount. However, they may not be suitable for high-power applications due to their limited thermal resistance.

Considerations for International Buyers:

Buyers should verify compliance with local standards such as IEC and ASTM when sourcing thermoplastic plugs and sockets. In regions like Africa and South America, where environmental conditions can vary, ensuring the material meets local climate challenges is essential.

Thermosetting Plastics

Key Properties:

Thermosetting plastics, such as epoxy and phenolic resins, are characterized by their high heat resistance and structural integrity. Once cured, they maintain their shape and resist deformation under high temperatures, typically up to 150°C.

Pros & Cons:

These materials offer excellent mechanical strength and are highly resistant to chemicals and electrical currents. However, they can be more expensive than thermoplastics and are less flexible, which may limit their applications. The manufacturing process is also more complex, often requiring specialized equipment.

Impact on Application:

Thermosetting plastics are suitable for heavy-duty applications, including industrial machinery and high-wattage devices. Their durability makes them a preferred choice for environments with high electrical and thermal stress.

Considerations for International Buyers:

Buyers should ensure that thermosetting plastics comply with relevant safety standards, especially in regions like the Middle East where high temperatures are common. Understanding the specific requirements for industrial applications in different countries can aid in selecting the right material.

Metals

Key Properties:

Common metals used in plugs and sockets include copper and aluminum. These materials are known for their excellent conductivity and strength, with copper typically rated for temperatures up to 200°C.

Pros & Cons:

Metal components provide superior electrical performance and durability. However, they can be prone to corrosion, especially in humid environments, and may require additional coatings or treatments to enhance their longevity. The manufacturing process can also be more expensive due to the need for specialized tooling.

Impact on Application:

Metals are essential for high-power applications, such as industrial equipment and electrical appliances. Their conductivity makes them suitable for environments where efficient power transfer is critical.

Considerations for International Buyers:

When sourcing metal plugs and sockets, buyers should consider corrosion resistance, particularly in coastal or humid regions. Compliance with international standards such as UL and IEC is vital to ensure safety and reliability.

Rubber

Key Properties:

Rubber is known for its excellent elasticity and resistance to wear and tear. It can withstand temperatures between -30°C and 70°C and is often used in environments where flexibility is essential.

Pros & Cons:

Rubber provides superior insulation and is resistant to moisture and chemicals. However, it can degrade over time when exposed to UV light or extreme temperatures, limiting its lifespan. The cost of rubber components can vary based on quality and sourcing.

Impact on Application:

Rubber is commonly used in outdoor plugs and sockets where moisture resistance is crucial. Its flexibility makes it suitable for applications that require frequent movement or bending.

Considerations for International Buyers:

When purchasing rubber plugs and sockets, buyers should ensure they meet local safety standards and are suitable for the specific environmental conditions of their region. In areas with high UV exposure, selecting UV-resistant rubber is advisable.

Summary Table

| Material | Typical Use Case for types of plugs and sockets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastics | Residential and light commercial applications | Lightweight and cost-effective | Limited thermal resistance | Low |

| Thermosetting Plastics | Heavy-duty industrial applications | High heat resistance and strength | Higher cost and manufacturing complexity | High |

| Metals | High-power industrial equipment | Superior conductivity and durability | Prone to corrosion | Medium |

| Rubber | Outdoor plugs and sockets | Excellent moisture resistance | Degrades under UV exposure | Medium |

This strategic material selection guide provides insights into the various materials used in plugs and sockets, helping international B2B buyers make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for types of plugs and sockets

The manufacturing of plugs and sockets is a detailed process that requires precision and adherence to safety standards. Understanding these processes and the associated quality assurance measures is crucial for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, where compliance with international standards is increasingly important.

Manufacturing Processes

The production of electrical plugs and sockets typically involves several main stages:

1. Material Preparation

The first step in manufacturing plugs and sockets is the selection and preparation of materials. Common materials include:

– Plastics: High-quality thermoplastics such as polycarbonate or nylon are used for casings due to their durability and insulating properties.

– Metals: Copper is predominantly used for prongs because of its excellent conductivity. Other metals like brass may also be used for their corrosion resistance.

– Insulation materials: Rubber or silicone may be utilized for additional safety and insulation.

Materials undergo thorough inspections to ensure they meet specified standards before moving to the next stage.

2. Forming

In this stage, the prepared materials are shaped into the required components:

– Injection Molding: Plastics are heated and injected into molds to form the outer casing of plugs and sockets.

– Metal Stamping: Copper or brass is cut and shaped into prongs using stamping techniques, ensuring precise dimensions and fit.

– Machining: Some components may require additional machining to achieve the desired specifications.

This stage requires high-quality molds and dies to ensure uniformity and precision.

3. Assembly

Once individual components are formed, they are assembled into final products:

– Manual Assembly: Skilled workers may manually insert prongs into plastic housings, ensuring that they are securely fitted and correctly aligned.

– Automated Assembly: In high-volume production, automated machines may handle assembly, significantly increasing efficiency and consistency.

– Soldering and Welding: Connections between components may be soldered or welded to ensure robust electrical connections.

During this phase, attention to detail is crucial to prevent defects that could compromise safety and functionality.

4. Finishing

The finishing stage involves several processes to enhance the product’s performance and appearance:

– Surface Treatment: Components may undergo treatments such as plating to improve corrosion resistance and conductivity.

– Quality Coating: A protective coating may be applied to the plastic parts to enhance durability.

– Labeling: Clear labeling indicating voltage, current ratings, and safety certifications is added.

This stage not only improves aesthetics but also increases the longevity and safety of the plugs and sockets.

Quality Assurance

Quality assurance is integral to the manufacturing process, ensuring that products meet international safety and performance standards.

International Standards

B2B buyers should be aware of various international quality standards, such as:

– ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

– CE Marking: A certification that indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

– UL Certification: Underwriters Laboratories certification is essential for products sold in North America, ensuring compliance with safety standards.

Illustrative Image (Source: Google Search)

Compliance with these standards is critical, particularly for buyers in Europe and the Middle East, where regulations are stringent.

Quality Control Checkpoints

Effective quality control (QC) involves several checkpoints during the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, regular checks are conducted to identify defects early. This includes monitoring machinery settings and inspecting components at various stages.

– Final Quality Control (FQC): Finished products undergo rigorous testing to ensure they meet safety and performance standards before shipment.

Common Testing Methods

Testing methods employed during the QC process may include:

– Electrical Testing: Ensuring that plugs and sockets can handle their rated voltage and current without overheating or failing.

– Insulation Resistance Testing: Verifying that the insulation effectively prevents electrical leakage.

– Mechanical Testing: Assessing the durability of the casing and prongs through stress tests.

These tests help identify potential failures and ensure that products are safe for consumer use.

Verifying Supplier Quality Control

B2B buyers can take several steps to verify the quality control processes of potential suppliers:

– Audits: Conducting regular audits of suppliers’ manufacturing facilities can help ensure compliance with quality standards and identify areas for improvement.

– Quality Reports: Requesting detailed quality reports from suppliers can provide insight into their QC processes, testing results, and adherence to international standards.

– Third-Party Inspections: Engaging independent inspection agencies can provide unbiased evaluations of suppliers’ production and quality control practices.

QC and Certification Nuances for International Buyers

When sourcing plugs and sockets internationally, buyers should consider specific nuances:

– Regional Compliance: Understand the specific regulations in your target market. For instance, plugs and sockets used in Europe must comply with the Low Voltage Directive and relevant IEC standards.

– Supply Chain Transparency: Engage suppliers who can provide transparency in their manufacturing and sourcing processes, helping to mitigate risks associated with substandard materials or practices.

– Traceability: Ensure that suppliers maintain traceability of materials and components, which is essential for addressing any safety recalls or compliance issues.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing plugs and sockets. This ensures that the products not only meet their operational needs but also comply with necessary safety standards across different markets.

Related Video: What is Production? Types of Production, Factors of Production

Comprehensive Cost and Pricing Analysis for types of plugs and sockets Sourcing

Understanding the cost structure and pricing of electrical plugs and sockets is crucial for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. This analysis provides insights into the various cost components, pricing influencers, and tips for effective procurement.

Cost Components

-

Materials: The primary materials used in manufacturing plugs and sockets include plastics, metals (such as copper for conductive parts), and insulation materials. The choice of materials affects both the durability and safety of the products. For instance, high-quality plastics and copper components may lead to higher initial costs but can reduce long-term maintenance and replacement expenses.

-

Labor: Labor costs vary significantly by region. In countries with lower labor costs, such as some parts of Africa and South America, manufacturers may offer more competitive pricing. However, labor costs in Europe and the Middle East can be higher, often reflecting better-skilled labor and more stringent labor laws.

-

Manufacturing Overhead: This includes costs associated with utilities, factory maintenance, and administrative expenses. Efficient factories tend to have lower overhead costs, which can be advantageous for buyers seeking competitive pricing.

-

Tooling: Tooling costs are significant, especially for custom or specialized plugs and sockets. The initial investment in molds and tools can be substantial, but these costs can be amortized over large production runs, leading to lower per-unit costs for high-volume orders.

-

Quality Control (QC): Ensuring compliance with international safety and quality standards (such as IEC, UL, or CE certifications) incurs additional costs. Buyers should consider these costs when evaluating suppliers, as rigorous QC processes can prevent costly recalls and liability issues.

-

Logistics: Transportation costs, including shipping and handling, can significantly influence the final price. Factors such as distance, shipping method, and customs duties should be carefully considered. For instance, sourcing from Asia may offer lower manufacturing costs but could be offset by higher shipping expenses.

-

Margin: Supplier margins vary based on market demand, competition, and brand reputation. Established brands with a strong reputation for quality may command higher prices, while lesser-known brands might offer lower prices but could compromise on quality.

Price Influencers

-

Volume/MOQ: Purchasing larger volumes typically results in lower per-unit pricing due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to optimize cost savings.

-

Specifications/Customization: Custom designs or specific certifications can increase costs. It is essential for buyers to balance their customization needs with budget constraints.

-

Materials and Quality: Higher-quality materials and certifications often lead to increased costs. Buyers must evaluate whether the additional expense aligns with their operational requirements and safety standards.

-

Supplier Factors: A supplier’s location, reputation, and production capabilities can influence pricing. Engaging with multiple suppliers can provide leverage in negotiations.

-

Incoterms: Understanding the implications of different Incoterms (such as FOB, CIF, or DDP) is crucial, as they dictate who bears the costs and risks during shipping. This knowledge can help in assessing total landed costs accurately.

Buyer Tips

-

Negotiation: Leverage volume purchasing and long-term contracts to negotiate better pricing. Establishing strong relationships with suppliers can also lead to more favorable terms.

-

Cost-Efficiency: Consider not just the purchase price but the Total Cost of Ownership (TCO), which includes maintenance, energy consumption, and replacement costs over the product’s lifespan.

-

Pricing Nuances for International Buyers: Currency fluctuations, import taxes, and tariffs can affect pricing for international transactions. Buyers should factor these elements into their budget planning.

In conclusion, understanding the comprehensive cost structure and pricing dynamics of plugs and sockets is vital for international B2B buyers. By considering the outlined cost components, price influencers, and negotiation strategies, buyers can make informed decisions that align with their operational needs and budget constraints.

- Disclaimer: Prices and cost components mentioned are indicative and subject to market fluctuations and specific supplier agreements.*

Spotlight on Potential types of plugs and sockets Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘types of plugs and sockets’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for types of plugs and sockets

When sourcing plugs and sockets for international trade, understanding their technical properties and industry terminology is crucial for making informed decisions. This section outlines essential specifications and common trade terms relevant to B2B buyers in Africa, South America, the Middle East, and Europe.

Key Technical Properties

-

Material Grade

– Definition: The material grade refers to the quality and type of materials used in the manufacturing of plugs and sockets, such as thermoplastic, metal, or copper.

– B2B Importance: Selecting the right material grade affects durability, conductivity, and safety. High-quality materials can reduce the risk of overheating and electrical failure, which is vital for compliance with safety standards. -

Voltage Rating

– Definition: Voltage rating indicates the maximum voltage that a plug or socket can safely handle, commonly expressed in volts (V).

– B2B Importance: Understanding voltage ratings is essential for ensuring compatibility with local electrical systems. Mismatched voltage ratings can lead to appliance damage or safety hazards, making it crucial for buyers to verify specifications before procurement. -

Current Rating (Amperage)

– Definition: Current rating specifies the maximum amount of current (in amperes, A) that a plug or socket can carry without overheating.

– B2B Importance: Choosing plugs and sockets with appropriate current ratings ensures that they can handle the electrical load of connected devices. This is particularly important in industrial applications where high power devices are used.

Illustrative Image (Source: Google Search)

-

Insulation Resistance

– Definition: Insulation resistance measures how well the insulation material prevents electrical leakage, typically measured in megaohms (MΩ).

– B2B Importance: High insulation resistance is crucial for safety, preventing electrical shocks and equipment damage. Buyers should prioritize plugs and sockets with high insulation resistance values, especially in humid or high-risk environments. -

Temperature Rating

– Definition: This specification indicates the maximum operating temperature that plugs and sockets can withstand.

– B2B Importance: Different applications may expose electrical components to varying temperatures. Selecting products with the appropriate temperature rating is essential to ensure safe and reliable operation over time. -

Design Standard Compliance

– Definition: Compliance with international standards (such as IEC, UL, or CE) ensures that plugs and sockets meet specific safety and performance criteria.

– B2B Importance: Products that comply with recognized standards can facilitate smoother customs processes and enhance market acceptance. Buyers should verify compliance to avoid potential liabilities and ensure product safety.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM partnerships can help buyers find reliable suppliers and assess product authenticity and quality. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ helps buyers determine budget constraints and negotiate better terms with suppliers, especially when considering bulk purchases. -

RFQ (Request for Quotation)

– Definition: A document that a buyer sends to suppliers to request pricing and other terms for specific products.

– Relevance: Submitting an RFQ is a crucial step in the procurement process, allowing buyers to compare offers and negotiate better deals. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities, aiding in smoother logistics and contract negotiations. -

Certification

– Definition: A process by which a product is verified to meet certain safety and performance standards.

– Relevance: Buyers should ensure that plugs and sockets are certified for their intended markets to comply with local regulations and guarantee product safety. -

Lead Time

– Definition: The time taken from placing an order to receiving the goods.

– Relevance: Understanding lead times is essential for planning inventory and managing supply chain logistics effectively.

By grasping these technical specifications and industry terms, B2B buyers can navigate the complex landscape of plugs and sockets more effectively, ensuring that their procurement decisions meet both operational needs and safety standards.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the types of plugs and sockets Sector

Market Overview & Key Trends

The global market for plugs and sockets is influenced by several key drivers, including the rapid expansion of electronic devices and the increasing demand for reliable power connections. As technology evolves, there is a growing emphasis on smart home integration, which necessitates advanced plug and socket solutions capable of supporting high-wattage devices and varied voltage requirements. Emerging markets in Africa, South America, and the Middle East are witnessing a surge in construction and infrastructure projects, further driving demand for electrical components.

B2B buyers must stay informed about sourcing trends, particularly the shift towards standardized plug types and universal compatibility. This trend facilitates easier international trade and reduces logistical challenges. Additionally, the rise of e-commerce platforms has transformed procurement processes, enabling buyers to access a wider range of suppliers and products. International buyers are also increasingly focused on certifications, such as IEC and UL, to ensure safety and compliance with local regulations.

Market dynamics are also shaped by geopolitical factors, which can affect supply chains and pricing. Economic fluctuations and trade policies can create uncertainties in sourcing, making it essential for buyers to develop flexible procurement strategies that account for these variables. Establishing relationships with reliable suppliers who understand the local market conditions can provide a competitive edge.

Sustainability & Ethical Sourcing in B2B

As the global economy shifts towards sustainability, B2B buyers in the plugs and sockets sector must prioritize environmentally responsible sourcing practices. The production of electrical components can have significant environmental impacts, including the use of non-renewable materials and energy-intensive manufacturing processes. Therefore, buyers should seek suppliers who employ sustainable practices, such as using recycled materials and minimizing waste.

Ethical supply chains are becoming increasingly important, particularly in regions with stringent labor laws and environmental regulations. Buyers should look for suppliers that have transparency in their sourcing practices and adhere to international labor standards. Certifications such as ISO 14001 for environmental management systems and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to sustainability.

Furthermore, the adoption of ‘green’ certifications for plugs and sockets can enhance marketability and appeal to environmentally conscious consumers. Products made from biodegradable or recyclable materials not only meet regulatory requirements but also align with the growing trend of corporate social responsibility. By prioritizing sustainable sourcing, international B2B buyers can contribute to environmental preservation while ensuring compliance and enhancing their brand reputation.

Brief Evolution/History

The evolution of plugs and sockets dates back to the late 19th century when electrical systems began to be standardized. Initially, the designs were rudimentary and varied significantly across regions, leading to compatibility issues. The introduction of standardized plug types, such as Type A and Type C, facilitated international trade and the global expansion of electrical appliances.

Over the decades, safety concerns prompted the development of grounding mechanisms and more robust designs. Today, there are over 15 recognized plug types worldwide, each tailored to specific voltage and current requirements. This evolution reflects the industry’s response to technological advancements, safety standards, and the increasing complexity of global electrical systems. As the market continues to innovate, understanding this history is crucial for B2B buyers seeking to navigate the current landscape effectively.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of types of plugs and sockets

-

What factors should I consider when vetting suppliers for plugs and sockets?

When vetting suppliers, consider their industry experience, certifications (like ISO, CE, UL), and client testimonials. Ensure they have a solid reputation in international trade, particularly in your target regions. Request samples to evaluate product quality and assess their production capabilities, including technology and labor force. Additionally, inquire about their ability to comply with local regulations and standards specific to your market. -

Can plugs and sockets be customized for my specific needs?

Yes, many manufacturers offer customization options, including specific designs, sizes, and voltage ratings. When requesting customization, provide detailed specifications and intended applications. It’s essential to discuss the feasibility of these modifications and any additional costs involved. Establish a clear timeline for development to ensure your requirements align with your project schedules. -

What are the typical minimum order quantities (MOQs) and lead times for plugs and sockets?

MOQs can vary significantly between suppliers and product types, often ranging from 100 to 1,000 units. Lead times typically depend on the complexity of the order and the supplier’s production capacity, averaging between 4 to 12 weeks. Always clarify these terms upfront to manage expectations and align your purchasing strategies with your operational needs. -

What payment terms should I negotiate with suppliers?

Payment terms often include options like a deposit upfront, followed by payment on delivery or against an irrevocable letter of credit. Common practices involve negotiating terms such as 30% upfront and 70% upon shipment. Ensure that the payment method is secure and that you understand any fees associated with international transactions. It’s advisable to work with suppliers who are flexible and willing to accommodate your financial processes. -

How can I ensure quality assurance for plugs and sockets?

Request quality assurance certifications from suppliers, such as ISO 9001 or specific electrical safety standards relevant to your market. It’s beneficial to establish a quality control process, including inspections at various production stages. Consider hiring third-party inspection services to verify compliance with specifications before shipment, ensuring that the products meet your standards and reducing the risk of returns or disputes. -

What certifications should I look for when sourcing plugs and sockets?

Look for certifications that align with your market’s regulations, such as CE for Europe, UL for the USA, or SABS for South Africa. These certifications indicate compliance with safety and performance standards. Additionally, inquire if the products meet international standards set by organizations like IEC. Certifications can significantly influence product acceptance in your local market and ensure safety for end-users. -

What logistics considerations should I keep in mind when importing plugs and sockets?

Logistics involve understanding shipping methods, customs regulations, and import duties for your region. Determine the most cost-effective shipping options, whether by air or sea, and factor in lead times for each. Collaborate with a reliable freight forwarder familiar with your product category and destination to navigate customs clearance efficiently. Ensure that all necessary documentation is prepared to avoid delays during importation. -

How should I handle disputes with suppliers regarding product quality or delivery?

Establish clear communication channels and document all agreements, specifications, and timelines upfront to minimize misunderstandings. In case of a dispute, address the issue directly with the supplier, providing evidence such as inspection reports or photographs. If resolution is not achieved, consider mediation or arbitration as outlined in your contract. Maintaining a professional relationship is crucial, as it could impact future transactions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of plugs and sockets

In summary, the strategic sourcing of plugs and sockets is essential for ensuring compatibility and safety in electrical systems across diverse markets. Understanding the various types, such as two-pronged and three-pronged plugs, alongside the specific requirements of different regions—including voltage, frequency, and safety standards—can significantly impact operational efficiency and compliance.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, prioritizing suppliers who offer high-quality, certified products is crucial. This not only mitigates risks associated with electrical failures but also enhances the reliability of electrical installations. Additionally, leveraging local expertise can facilitate smoother logistics and adherence to regional standards.

As global trade continues to evolve, the demand for innovative and adaptable electrical solutions will only increase. Buyers are encouraged to stay ahead of trends by actively seeking partnerships with manufacturers who prioritize sustainability and technological advancements. By doing so, they can enhance their competitive edge and contribute to the growth of their respective markets. Embrace strategic sourcing as a pathway to not just meeting current needs, but also anticipating future demands in the dynamic landscape of electrical infrastructure.