Master Sourcing for Normally Closed Push Button: A Complete

Introduction: Navigating the Global Market for normally closed push button

Navigating the global market for normally closed push buttons is essential for international B2B buyers seeking reliable components for their machinery and control systems. These switches, characterized by their ability to interrupt current flow when activated, play a crucial role in safety applications, such as emergency stops, ensuring that systems can be quickly shut down in critical situations.

This guide offers a comprehensive overview of normally closed push buttons, covering various types, materials, and manufacturing quality control processes. Buyers will gain insights into selecting the right push button for their needs, understanding the implications of different materials—such as metal and plastic—and evaluating manufacturers based on quality standards and certifications.

Additionally, this guide explores the global supply landscape, highlighting key suppliers and market trends across regions including Africa, South America, the Middle East, and Europe. It also addresses cost considerations and provides answers to frequently asked questions, empowering B2B buyers to make informed sourcing decisions.

By equipping buyers with in-depth knowledge and actionable insights, this resource aims to facilitate better purchasing strategies, ultimately enhancing operational efficiency and safety in diverse applications. Whether you are based in Brazil, South Africa, or any other region, understanding the dynamics of normally closed push buttons will enable you to navigate the complexities of global sourcing effectively.

Understanding normally closed push button Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Normally Closed | Simple push mechanism, typically metal or plastic | Machinery control, safety systems | Pros: Reliable, cost-effective. Cons: Limited customization options. |

| Emergency Stop Button | Brightly colored, large actuator, often with a cover | Industrial machinery, conveyor systems | Pros: High visibility, quick access. Cons: Can be accidentally triggered. |

| Illuminated Push Button | Integrated LED for status indication | Control panels, user interfaces | Pros: Clear operational status. Cons: Higher cost due to electronics. |

| Weatherproof Push Button | Sealed casing for outdoor use, resistant to elements | Outdoor machinery, transportation equipment | Pros: Durable, suitable for harsh environments. Cons: Heavier and bulkier. |

| Multi-Function Push Button | Combines multiple functions in one unit | Complex machinery, automation systems | Pros: Space-saving, versatile. Cons: More complex installation and maintenance. |

Standard Normally Closed

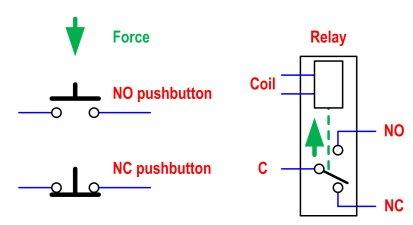

The standard normally closed push button is characterized by its straightforward design, often made from durable metal or plastic. It operates by keeping the circuit closed until pressed, which disconnects the current. This type is widely used in machinery control and safety systems, making it a fundamental component in industrial applications. Buyers should consider the reliability and cost-effectiveness of this option, though it may lack customization features.

Illustrative Image (Source: Google Search)

Emergency Stop Button

Emergency stop buttons are designed for immediate action in hazardous situations. They typically feature a large, easily accessible actuator and are often colored red for visibility. This type is critical in industrial settings, especially for machinery and conveyor systems where quick shutdown is necessary. While they provide safety advantages, the risk of accidental activation is a consideration for buyers.

Illuminated Push Button

Illuminated push buttons include an integrated LED that indicates the button’s status, enhancing user interface clarity. This feature is especially valuable in control panels and user interfaces where operators need to quickly ascertain the state of the machinery. While they offer clear operational cues, their electronic components can increase costs, making them a strategic investment for applications requiring visual feedback.

Weatherproof Push Button

Designed for outdoor use, weatherproof push buttons feature sealed casings to protect against moisture and dust. They are ideal for outdoor machinery and transportation equipment operating in harsh conditions. Buyers benefit from their durability and suitability for various environments; however, the added protection can result in a heavier and bulkier design, which may impact installation logistics.

Multi-Function Push Button

Multi-function push buttons are versatile components that integrate several operational functions into a single unit, making them suitable for complex machinery and automation systems. They help save space and reduce wiring complexity. However, their sophisticated nature requires careful consideration during installation and maintenance, as they may involve more intricate wiring and programming, which could increase costs and require specialized knowledge.

Related Video: Codesys #3: Normally open/closed pushbutton & Normal/negated contacts in Codesys

Key Industrial Applications of normally closed push button

| Industry/Sector | Specific Application of normally closed push button | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Emergency stop systems in machinery | Enhances safety by providing immediate machine shutdown | Ensure compliance with local safety regulations and certifications. |

| Automotive | Control panels for assembly line machinery | Increases operational efficiency by allowing quick interventions | Look for durability and resistance to environmental factors. |

| Oil & Gas | Safety shutdown systems in drilling equipment | Minimizes risk of accidents and equipment damage | Assess compatibility with existing systems and reliability under extreme conditions. |

| Food & Beverage | Automated production line control | Ensures product safety by allowing quick shutdown in emergencies | Evaluate hygiene standards and ease of cleaning for food safety compliance. |

| HVAC Systems | Control for ventilation and air conditioning systems | Improves energy efficiency and safety in climate control | Focus on temperature and humidity resistance for long-term performance. |

Manufacturing

In the manufacturing sector, normally closed push buttons are pivotal in emergency stop systems for machinery. When pressed, they immediately disconnect power, halting operations and preventing accidents. This application is critical for ensuring worker safety and compliance with industry regulations. Buyers must prioritize sourcing buttons that meet local safety standards and certifications to avoid liability issues. Additionally, the durability of these components under industrial conditions is essential for long-term reliability.

Automotive

In automotive assembly lines, normally closed push buttons are integrated into control panels for machinery. Their ability to provide immediate shutdown capabilities enhances operational efficiency, allowing workers to quickly address malfunctions or safety concerns. B2B buyers in the automotive sector should consider the push buttons’ durability and resistance to various environmental factors, ensuring they can withstand the rigors of a production environment while maintaining functionality.

Oil & Gas

The oil and gas industry employs normally closed push buttons in safety shutdown systems for drilling equipment. These buttons are crucial for minimizing risks associated with hazardous operations, enabling rapid response to emergencies. Buyers must assess the compatibility of these buttons with existing systems and their reliability under extreme conditions, such as high pressure and temperature, to ensure operational safety and compliance with industry standards.

Food & Beverage

In the food and beverage industry, normally closed push buttons are used in automated production line controls. Their role is vital in ensuring product safety by allowing for quick shutdowns during emergencies, preventing contamination or product loss. Buyers should evaluate hygiene standards and ease of cleaning when sourcing these components, as compliance with food safety regulations is paramount in this sector.

HVAC Systems

Normally closed push buttons are utilized in HVAC systems to control ventilation and air conditioning units. They contribute to improved energy efficiency and safety by allowing for quick shutdowns during maintenance or emergencies. Buyers should focus on sourcing buttons that can withstand temperature and humidity variations, ensuring reliable performance in diverse environmental conditions. This consideration is crucial for maintaining optimal operation and energy efficiency in HVAC applications.

Related Video: Normally Open, Normally Closed, Relays, Contactors, and Push Buttons Explained

Strategic Material Selection Guide for normally closed push button

Analysis of Common Materials for Normally Closed Push Buttons

When selecting materials for normally closed push buttons, it is essential to consider their properties, advantages, disadvantages, and suitability for specific applications. Below are analyses of four common materials used in the manufacturing of these components.

1. Metal (Stainless Steel or Aluminum)

Key Properties:

Metal push buttons, particularly stainless steel and aluminum, exhibit excellent strength and durability. They can withstand high temperatures (up to 200°C) and pressures, making them suitable for harsh industrial environments. Additionally, stainless steel offers superior corrosion resistance, while aluminum is lightweight and easier to machine.

Pros & Cons:

The durability of metal push buttons is a significant advantage, as they can endure frequent use without significant wear. However, they tend to be more expensive than plastic options and may require more complex manufacturing processes. The aesthetic appeal of metal can enhance the design of industrial equipment, but the higher cost may deter budget-conscious buyers.

Impact on Application:

Metal buttons are ideal for applications requiring high durability and resistance to environmental factors, such as in chemical plants or outdoor machinery. However, their conductivity can be a concern in certain electronic applications, necessitating careful design considerations.

International Considerations:

Buyers should ensure compliance with international standards like ASTM for metals. In regions like Europe and the Middle East, certifications for corrosion resistance (e.g., EN 10088) may be required.

2. Plastic (Polycarbonate or PBT)

Key Properties:

Plastic materials such as polycarbonate (PC) and polybutylene terephthalate (PBT) are known for their excellent insulation properties and resistance to impact. They can operate effectively in temperature ranges from -40°C to +85°C, making them versatile for various applications.

Pros & Cons:

Plastic push buttons are generally more cost-effective and easier to produce than metal buttons. They are lightweight and can be molded into various shapes and colors, enhancing design flexibility. However, they may not offer the same level of durability as metal and can be susceptible to UV degradation over time.

Impact on Application:

Plastic buttons are suitable for applications in consumer electronics and household appliances, where aesthetics and cost are critical. They are less ideal for heavy industrial use, where exposure to harsh chemicals or extreme conditions may lead to failure.

International Considerations:

B2B buyers should verify compliance with safety standards like UL and IEC, especially in regions like South America and Africa, where regulations may vary.

3. Rubber

Key Properties:

Rubber push buttons provide excellent tactile feedback and can be designed to be waterproof or resistant to various chemicals. They typically operate effectively within a temperature range of -20°C to +70°C.

Pros & Cons:

The primary advantage of rubber is its flexibility and ability to absorb shocks, making it ideal for portable devices. However, rubber can degrade over time due to environmental exposure, leading to potential performance issues. Additionally, the manufacturing process can be more complex, impacting costs.

Impact on Application:

Rubber buttons are commonly used in consumer electronics, medical devices, and automotive applications where user interaction is critical. Their waterproof nature makes them suitable for outdoor applications, but they may not be suitable for high-temperature environments.

International Considerations:

Buyers should consider compliance with environmental regulations regarding rubber materials, particularly in Europe, where REACH regulations apply.

4. Composite Materials

Key Properties:

Composite materials combine the benefits of plastics and metals, offering high strength-to-weight ratios and excellent corrosion resistance. They can withstand a wide temperature range and are often designed to meet specific performance criteria.

Pros & Cons:

Composites provide a balance between durability and weight, making them suitable for various applications. However, they can be more expensive than traditional materials and may require specialized manufacturing processes, which can lead to longer lead times.

Impact on Application:

Composite push buttons are ideal for aerospace and automotive applications where weight savings are crucial without compromising strength. Their versatility allows for customization based on specific application requirements.

International Considerations:

B2B buyers should ensure that composite materials meet relevant industry standards, such as those set by ASTM and ISO, particularly in regions with stringent safety regulations.

Summary Table

| Material | Typical Use Case for normally closed push button | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Metal (Stainless Steel/Aluminum) | Industrial machinery, outdoor equipment | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic (Polycarbonate/PBT) | Consumer electronics, household appliances | Cost-effective and versatile | Less durable, UV degradation potential | Low |

| Rubber | Medical devices, portable electronics | Excellent tactile feedback and waterproof | Degradation over time, complex mfg | Medium |

| Composite Materials | Aerospace, automotive applications | High strength-to-weight ratio | Higher cost and specialized manufacturing | High |

In-depth Look: Manufacturing Processes and Quality Assurance for normally closed push button

The manufacturing process for normally closed push buttons involves several critical stages, each essential for ensuring the final product meets industry standards and customer expectations. Understanding these stages and the associated quality control measures is crucial for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe.

Manufacturing Processes

Material Preparation

The first step in manufacturing normally closed push buttons is material selection and preparation. Typically, these switches are composed of metal (such as stainless steel or aluminum) for the actuator and housing, and high-quality plastics (like polycarbonate or PBT) for insulation and aesthetic purposes. The materials must meet specifications for conductivity, durability, and environmental resistance.

- Material Testing: Before production begins, materials undergo rigorous testing to ensure they comply with relevant safety and performance standards. This includes checking for electrical conductivity, mechanical strength, and resistance to environmental factors.

Forming

Once materials are prepared, the next stage is forming, which involves shaping the components of the push button.

-

Stamping and Molding: Metal parts are often produced through stamping, where sheets of metal are cut and shaped using high-pressure machinery. Plastic components are typically created using injection molding, ensuring precise dimensions and complex shapes.

-

Machining: Some components may require additional machining processes, such as drilling or milling, to achieve specific tolerances or features.

Assembly

After forming, the various components are assembled into the final push button switch.

-

Component Assembly: The assembly process includes attaching the actuator, housing, and internal contacts. This may involve automated systems for precision or manual assembly for complex configurations.

-

Spring Mechanism Installation: A crucial aspect of normally closed push buttons is the spring mechanism, which ensures the switch returns to its original state when not pressed. This requires careful installation to maintain functionality and reliability.

Finishing

The final stage of manufacturing involves finishing processes that enhance the product’s performance and appearance.

-

Surface Treatment: Treatments such as anodizing for metals or coating for plastics may be applied to improve corrosion resistance and aesthetic appeal.

-

Final Inspection: Before packaging, each push button undergoes a final inspection to verify that all components are properly assembled and functioning.

Quality Assurance

Quality assurance is vital in ensuring that normally closed push buttons are safe, reliable, and meet international standards. B2B buyers should be aware of the following key aspects of quality control:

International Standards

Manufacturers must comply with various international standards to ensure product safety and reliability.

-

ISO 9001: This standard focuses on quality management systems and is critical for manufacturers aiming to demonstrate their commitment to quality in production processes.

-

CE Marking: In Europe, push buttons must meet safety, health, and environmental protection standards to receive CE marking, which is essential for selling in the EU market.

-

API Standards: For applications in the oil and gas sector, adherence to API standards is crucial for ensuring safety and performance.

Quality Control Checkpoints

Quality control is integrated throughout the manufacturing process, with specific checkpoints established to catch defects early.

-

Incoming Quality Control (IQC): This step involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps detect and address issues in real-time.

-

Final Quality Control (FQC): At this stage, completed push buttons are thoroughly tested for functionality, safety, and compliance with standards before shipment.

Common Testing Methods

Various testing methods are employed to validate the quality and functionality of normally closed push buttons.

-

Electrical Testing: This includes checking the continuity and resistance of the contacts to ensure proper operation.

-

Mechanical Testing: Tests for durability and stress resistance, including push force tests and lifecycle testing, are performed to simulate real-world usage.

-

Environmental Testing: Push buttons may undergo exposure to extreme temperatures, humidity, and corrosive substances to ensure reliability under diverse conditions.

Verifying Supplier Quality Control

B2B buyers should take proactive measures to verify the quality control practices of potential suppliers:

-

Supplier Audits: Conducting on-site audits can provide valuable insights into the manufacturing processes and quality assurance measures in place. This includes reviewing documentation related to ISO certifications and production practices.

-

Quality Reports: Requesting detailed quality reports, including testing results and compliance certificates, can help assess a supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s manufacturing quality and adherence to international standards.

Regional Considerations

For buyers in Africa, South America, the Middle East, and Europe, understanding the nuances of quality certification and manufacturing standards is critical.

-

Local Regulations: Each region may have specific regulations and compliance requirements that differ from international standards. Familiarity with these can help buyers make informed decisions and ensure that products are suitable for their markets.

-

Supplier Relationships: Building strong relationships with suppliers can facilitate better communication about quality expectations and enable quicker resolution of any issues that arise.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for normally closed push buttons enables B2B buyers to make informed decisions. By focusing on material quality, production integrity, and compliance with international standards, buyers can ensure they source reliable and safe components for their applications.

Related Video: Inspection and Quality control in Manufacturing

Comprehensive Cost and Pricing Analysis for normally closed push button Sourcing

When sourcing normally closed push buttons, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe. This analysis outlines the key cost components, price influencers, and actionable buyer tips to facilitate informed purchasing decisions.

Cost Components

-

Materials: The primary materials used in manufacturing normally closed push buttons include metal (often steel or aluminum) and high-grade plastics (like PBT or PA). The choice of materials directly influences durability and performance. For example, metal buttons typically offer higher durability and a longer lifespan compared to plastic alternatives.

-

Labor: Labor costs vary significantly based on the region of production. For instance, manufacturing in countries with lower wage standards can reduce overall costs but may impact quality. Understanding local labor laws and wage scales is essential for accurate cost forecasting.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and maintenance. Overhead can significantly affect pricing, particularly if manufacturers are located in regions with high operational costs.

-

Tooling: Initial tooling costs for manufacturing can be substantial, especially for custom designs. These costs are often amortized over the production run, making them a critical consideration for large volume orders.

-

Quality Control (QC): Effective QC processes ensure product reliability and compliance with international standards. Investing in rigorous QC can increase upfront costs but may reduce long-term expenses related to defects and returns.

-

Logistics: Shipping costs can vary widely based on distance, freight methods, and regional tariffs. Additionally, understanding Incoterms (International Commercial Terms) is vital to determining who bears responsibility for shipping costs, insurance, and customs duties.

-

Margin: Suppliers typically add a markup to cover their costs and ensure profitability. This margin can be influenced by competition, demand, and the perceived value of the product.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities often leads to discounts. Buyers should evaluate their needs against potential savings from bulk ordering.

-

Specifications/Customization: Customized push buttons, such as those with specific colors or functions, can lead to higher costs. Clear communication of requirements can mitigate unexpected expenses.

-

Materials and Quality Certifications: Higher quality materials and certifications (like ISO or CE marks) enhance product reliability but can increase costs. Buyers should weigh the importance of these factors against their budget constraints.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can significantly impact pricing. Established suppliers may charge more due to their proven quality and service levels.

-

Incoterms: Understanding Incoterms is crucial for determining the total landed cost of products. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can shift financial responsibilities between buyer and seller.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing, especially for large orders. Highlighting your potential as a long-term partner can yield better terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes initial purchase price, shipping, and potential maintenance costs over the product’s life. This perspective may lead to choosing higher quality options that reduce long-term expenses.

-

Pricing Nuances for International Buyers: Buyers in regions like Africa and South America should be aware of currency fluctuations and potential import tariffs, which can affect overall costs. Establishing a clear understanding of local regulations can also prevent unexpected expenses.

Disclaimer

Prices for normally closed push buttons can vary significantly based on the factors outlined above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing while considering the specific needs of their applications.

Spotlight on Potential normally closed push button Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘normally closed push button’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for normally closed push button

When selecting a normally closed push button switch, understanding its technical properties and the relevant trade terminology is crucial for effective procurement and application. Below are essential specifications and industry terms that B2B buyers should consider.

Critical Technical Properties

-

Material Composition

– Definition: Normally closed push buttons are typically made from a combination of metal and plastic. Common materials include PBT, PA, and PC for plastics, and silver-copper alloys for contacts.

– B2B Importance: The choice of materials affects durability, insulation properties, and conductivity. Buyers must ensure that the materials meet industry standards for their specific applications, especially in demanding environments. -

Contact Rating

– Definition: This specifies the maximum current and voltage that the push button can handle. Common ratings include 5A at 250VAC.

– B2B Importance: Understanding contact ratings is vital for ensuring the switch operates safely within the electrical specifications of the machinery or equipment. Overloading can lead to failures and safety hazards. -

Actuation Force

– Definition: This refers to the amount of force required to operate the switch, usually measured in grams or Newtons.

– B2B Importance: The required actuation force can impact user experience and operational efficiency. Buyers should consider the ergonomics of the application, especially for frequently used controls. -

Ingress Protection (IP) Rating

– Definition: This rating indicates the degree of protection against dust and water ingress. Common ratings include IP65 (dust-tight and protected against water jets).

– B2B Importance: A higher IP rating is crucial for applications in harsh environments, such as outdoors or in factories, where dust and moisture can cause equipment failure. -

Mechanical Life Cycle

– Definition: This measures the number of operational cycles a push button can endure before failure, often rated in thousands of cycles.

– B2B Importance: A longer mechanical life means lower maintenance costs and reduced downtime, making it essential for industries that rely on continuous operation. -

Mounting Style

– Definition: This specifies how the push button is installed, including panel-mounted, flush-mounted, or through-hole types.

– B2B Importance: The mounting style affects installation ease and compatibility with existing equipment. Buyers should ensure that the selected style fits their panel designs and application needs.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify reliable sources for components that meet specific quality and compatibility standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Recognizing MOQ is crucial for budgeting and inventory management. Buyers should consider their needs and ensure that they can meet the supplier’s minimum requirements. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products.

– Importance: An RFQ helps buyers compare offers from different suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international rules that define the responsibilities of sellers and buyers in international transactions.

– Importance: Familiarity with Incoterms is essential for understanding shipping costs, risks, and responsibilities, which is particularly relevant for international buyers from diverse regions. -

Lead Time

– Definition: The time taken from placing an order to delivery.

– Importance: Knowing the lead time is essential for project planning and avoiding production delays. Buyers should clarify lead times during negotiations to ensure timely delivery. -

Certification Standards

– Definition: Standards that products must meet to ensure safety and performance, such as CE, UL, or ISO certifications.

– Importance: Certification ensures that the product meets specific quality and safety benchmarks, which is critical for compliance in various industries and regions.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing normally closed push button switches, ensuring they select the right components for their specific applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the normally closed push button Sector

Market Overview & Key Trends

The global market for normally closed push buttons is experiencing notable growth, driven by advancements in industrial automation and increasing demand for safety devices across sectors. As industries pivot towards automation, the need for reliable control mechanisms like normally closed push buttons becomes paramount. These switches are often used in emergency stop applications, making them critical in ensuring operational safety.

Emerging trends indicate a shift towards smart technology integration. This includes the development of push buttons with IoT capabilities, allowing for remote monitoring and control. International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should pay attention to suppliers who offer these advanced features. Additionally, there is a growing preference for customizable solutions that cater to specific operational needs, enhancing functionality and user experience.

Sourcing practices are also evolving, with buyers increasingly seeking suppliers who can demonstrate agility in their production processes. This is particularly relevant for companies in fast-paced markets like Brazil and South Africa, where responsiveness can significantly impact competitiveness. Furthermore, as the market continues to globalize, buyers must navigate varying regulatory standards and compliance requirements, making it essential to partner with suppliers who understand local regulations and can ensure product conformity.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a central theme in the B2B landscape, including the normally closed push button sector. The environmental impact of manufacturing processes, particularly concerning waste and energy consumption, is under scrutiny. Buyers are encouraged to prioritize suppliers who implement eco-friendly practices, such as using recycled materials or renewable energy sources in production.

Ethical sourcing has gained traction as a key consideration for international B2B transactions. Buyers should look for suppliers who are transparent about their supply chains and who adhere to fair labor practices. This includes ensuring that materials are sourced responsibly, avoiding conflict minerals, and supporting local communities.

Certifications can serve as a valuable tool for verifying sustainability claims. Look for suppliers with recognized ‘green’ certifications, such as ISO 14001 for environmental management or RoHS compliance for hazardous substances. Such certifications not only enhance the credibility of suppliers but also align with the growing consumer demand for sustainable products.

Brief Evolution/History

The concept of push button switches dates back to the early days of electrical engineering, evolving significantly over the decades. Initially, push buttons were simple mechanical devices, primarily used in basic applications. However, with the rise of automation and sophisticated machinery, the design and functionality of push buttons have advanced dramatically.

Today, normally closed push buttons are integral to industrial safety systems, especially in emergency stop applications. Their design has evolved to include features such as enhanced durability, waterproofing, and even smart technology integration, allowing them to meet the demands of modern industrial environments. This evolution reflects broader trends in technology and safety, making these switches essential for any B2B buyer focused on operational efficiency and safety compliance.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of normally closed push button

-

What should I consider when vetting suppliers for normally closed push buttons?

When vetting suppliers, prioritize their industry experience, reputation, and customer reviews. Check for certifications like ISO 9001, which indicate quality management systems. Request samples to evaluate product quality and performance. Additionally, assess their production capacity and lead times to ensure they can meet your demands. Engaging in direct communication to understand their responsiveness and customer service approach can also provide insights into their reliability as a partner. -

Can normally closed push buttons be customized for specific applications?

Yes, many manufacturers offer customization options for normally closed push buttons. You can specify the size, material, color, and functionality based on your application needs. Discussing your requirements with the supplier early in the procurement process is crucial. Ensure that they have the capability to produce custom designs and that you receive prototypes to validate the design before mass production. -

What are the typical minimum order quantities (MOQs) and lead times for normally closed push buttons?

MOQs can vary significantly among suppliers, often ranging from 100 to 1,000 units depending on the manufacturer and the complexity of customization. Lead times typically range from 2 to 8 weeks, influenced by production schedules and shipping logistics. It’s advisable to clarify these terms during your initial discussions to avoid surprises and align your purchasing strategy with your project timelines. -

What payment terms should I expect when sourcing normally closed push buttons internationally?

Payment terms can vary by supplier and region, but common practices include upfront payment, partial payment upon order confirmation, and balance before shipment. Consider using secure payment methods like letters of credit or escrow services for larger transactions to mitigate risk. Always clarify payment terms in your contract and be aware of any additional fees related to currency exchange or international transactions. -

What quality assurance measures should I verify with suppliers?

Request documentation of quality assurance processes, including inspection reports and testing certifications. Inquire about their adherence to international standards, such as IEC or UL certifications, which indicate compliance with safety and performance regulations. It’s also beneficial to establish a clear return policy for defective products and to understand their process for handling quality disputes. -

How do I manage logistics and shipping for normally closed push buttons?

Effective logistics management involves selecting reliable shipping partners and understanding the customs requirements of your country. Discuss shipping options with your supplier, including air freight for faster delivery or sea freight for cost savings. Ensure that the supplier provides all necessary shipping documents to facilitate customs clearance. Consider working with a freight forwarder who can assist with logistics and reduce potential delays. -

What steps can I take to resolve disputes with suppliers?

To effectively manage disputes, ensure that you have a well-defined contract that outlines the terms of your agreement, including quality standards and delivery timelines. Open lines of communication are crucial; address issues promptly and professionally. If disputes arise, try negotiation first. If resolution is not achieved, consider mediation or arbitration as alternative dispute resolution methods, as these can be less costly and time-consuming than litigation. -

What are the best practices for maintaining a long-term relationship with suppliers?

Building a strong relationship with suppliers involves regular communication and feedback on their products and services. Consider establishing performance metrics to evaluate their reliability and quality consistently. Engage in collaborative discussions about future projects, and show appreciation for their efforts through timely payments and recognition of their contributions. Regular visits to their facilities can also strengthen ties and foster trust.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for normally closed push button

In conclusion, the strategic sourcing of normally closed push buttons presents a unique opportunity for international B2B buyers, especially in emerging markets like Africa, South America, the Middle East, and Europe. Understanding the technical specifications and applications of these components can significantly enhance operational safety and efficiency. By prioritizing quality and reliability, companies can mitigate risks associated with equipment failure and ensure compliance with safety standards.

Furthermore, leveraging a diverse supplier base can provide competitive pricing and innovative solutions tailored to specific market needs. As industries continue to evolve, the demand for robust and versatile push button switches will only increase.

To capitalize on this trend, B2B buyers should actively engage with suppliers, explore new technologies, and stay informed about industry advancements. By doing so, companies can not only secure a reliable supply chain but also position themselves as leaders in their respective markets. As we move forward, the emphasis on strategic sourcing will be paramount in driving growth and sustainability in the industrial sector.