Master Sourcing Stranded Wire: Essential Guide for B2B

Introduction: Navigating the Global Market for stranded wire

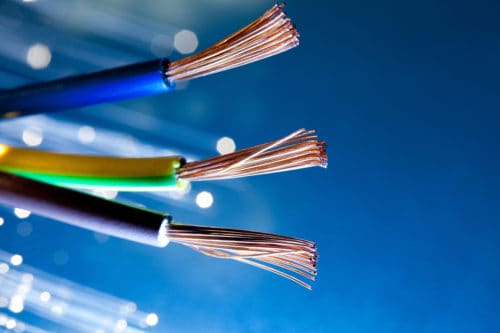

Stranded wire is a critical component in various industries, serving as the backbone for electrical connectivity and signal transmission in applications ranging from telecommunications to construction. Its unique construction, comprising multiple strands twisted together, offers enhanced flexibility and strength, making it indispensable for projects that demand durability and adaptability. As international B2B buyers navigate the complexities of sourcing stranded wire, understanding its myriad applications and specifications becomes paramount.

This comprehensive guide delves into the essential aspects of stranded wire, including types (such as copper and aluminum strands), materials used in manufacturing, and quality control practices that ensure reliability and performance. Buyers will gain insights into the cost factors influencing stranded wire pricing and explore a curated list of reputable suppliers across regions like Africa, South America, the Middle East, and Europe, including key markets such as South Africa and Turkey.

Additionally, we will address common FAQs to equip buyers with the knowledge necessary for informed sourcing decisions. By empowering stakeholders with actionable insights and a holistic understanding of the stranded wire market, this guide serves as a vital resource for businesses looking to optimize their procurement strategies and establish robust supply chains in an increasingly interconnected world.

Understanding stranded wire Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Multi-Strand Wire | Composed of numerous thin strands for flexibility | Electrical wiring, automotive | Pros: Highly flexible, suitable for tight spaces; Cons: May require more handling care. |

| Braided Wire | Woven structure providing superior strength and shielding | Telecommunications, aerospace | Pros: Excellent shielding from electromagnetic interference; Cons: More complex to manufacture, potentially higher costs. |

| Coated Stranded Wire | Strands coated with insulating material | Marine applications, outdoor cables | Pros: Enhanced durability and corrosion resistance; Cons: Coating may add to weight and cost. |

| Tinned Copper Wire | Copper strands coated with tin for oxidation resistance | Electrical connections, circuit boards | Pros: Improved conductivity and corrosion resistance; Cons: Tin can wear off over time in harsh environments. |

| Steel Stranded Wire | Strong and durable, often used in heavy applications | Construction, lifting equipment | Pros: High tensile strength, ideal for heavy loads; Cons: Less flexible than other types, can be harder to work with. |

Multi-Strand Wire

Multi-strand wire consists of many thin strands twisted together, making it highly flexible. This type is particularly suitable for applications where space is limited, such as in electrical wiring for residential or automotive uses. When purchasing multi-strand wire, buyers should consider the wire gauge and strand count, as these factors affect flexibility and current-carrying capacity.

Braided Wire

Braided wire features multiple strands woven together, providing enhanced strength and the ability to shield against electromagnetic interference. This wire type is commonly used in telecommunications and aerospace applications where signal integrity is crucial. Buyers should assess the braid’s density and material composition to ensure it meets specific shielding requirements and environmental conditions.

Coated Stranded Wire

Coated stranded wire has an insulating layer, typically PVC or rubber, which offers protection against corrosion and environmental factors. This type is ideal for marine applications and outdoor installations. When selecting coated stranded wire, buyers should evaluate the type of coating for durability and the wire’s flexibility, as thicker coatings may reduce flexibility.

Tinned Copper Wire

Tinned copper wire is made from copper strands that are coated with a layer of tin, enhancing oxidation resistance. This wire type is commonly used for electrical connections and circuit boards. Buyers should consider the environment in which the wire will be used, as well as the potential for tin wear over time, which could affect conductivity.

Steel Stranded Wire

Steel stranded wire is known for its strength and durability, making it suitable for heavy-duty applications like construction and lifting equipment. While it offers high tensile strength, it is less flexible compared to other stranded wire types, which can complicate installation. Buyers should assess the specific load requirements and installation conditions to determine if steel stranded wire is the right choice for their needs.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of stranded wire

| Industry/Sector | Specific Application of Stranded Wire | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electrical Engineering | Power distribution and transmission | High flexibility and durability for long-distance transmission | Ensure compliance with international electrical standards; consider local sourcing for reduced tariffs. |

| Telecommunications | Data and signal transmission cables | Enhanced signal integrity and reduced interference | Evaluate wire gauge and strand count for optimal performance; prioritize suppliers with proven reliability. |

| Construction | Reinforcement in concrete structures | Improved tensile strength and flexibility | Assess corrosion resistance properties; consider local climatic factors when sourcing materials. |

| Automotive | Wiring harnesses and electrical connections | Lightweight design aiding in fuel efficiency | Look for suppliers with quality certifications; consider lead times for just-in-time manufacturing. |

| Aerospace | Aircraft control systems and wiring | Reliable performance under extreme conditions | Ensure adherence to aerospace industry standards; prioritize suppliers with a track record in aerospace applications. |

Electrical Engineering

In electrical engineering, stranded wire is extensively used in power distribution and transmission systems. The flexibility of stranded wire allows for easier installation in confined spaces and enhances durability, making it suitable for long-distance transmission. International B2B buyers must ensure that the stranded wire complies with local and international electrical standards to avoid regulatory issues. Additionally, considering local sourcing options can help mitigate tariffs and logistical challenges.

Telecommunications

Stranded wire is crucial in telecommunications for data and signal transmission cables. It provides enhanced signal integrity and minimizes interference, which is essential for maintaining high-quality communications. Buyers should evaluate the wire gauge and strand count to ensure optimal performance based on their specific application requirements. Working with suppliers who have a proven reliability record can further ensure the quality of the cables.

Construction

In the construction industry, stranded wire is often utilized as reinforcement in concrete structures. This application significantly improves the tensile strength and flexibility of the concrete, allowing for more durable and resilient structures. When sourcing stranded wire for construction, it is vital to assess corrosion resistance properties, especially in regions prone to moisture or extreme weather. Understanding local climatic factors can also inform material selection.

Automotive

Stranded wire plays a critical role in the automotive sector, particularly in wiring harnesses and electrical connections. Its lightweight design contributes to overall vehicle fuel efficiency, making it a preferred choice among manufacturers. Buyers should prioritize suppliers with quality certifications to ensure compliance with industry standards. Additionally, considering lead times for just-in-time manufacturing can help optimize inventory management.

Aerospace

In aerospace applications, stranded wire is used in aircraft control systems and wiring due to its reliable performance under extreme conditions. The aerospace industry demands high-quality materials that meet stringent safety standards. International buyers must ensure that their suppliers adhere to aerospace industry regulations and have a track record of supplying to this sector. This diligence can mitigate risks associated with supplier performance and product reliability.

Related Video: Electrician Pro Tip: Working With Stranded Wire

Strategic Material Selection Guide for stranded wire

Stranded wire is a versatile solution used across various industries, and the selection of the right material is critical for optimizing performance and ensuring compliance with international standards. Below, we analyze four common materials used for stranded wire, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Copper

Key Properties: Copper stranded wire is known for its excellent electrical conductivity, with a conductivity rating of about 97% IACS (International Annealed Copper Standard). It also has good thermal conductivity and can operate effectively in temperatures ranging from -40°C to 70°C.

Pros & Cons: The primary advantage of copper is its superior conductivity, making it ideal for electrical applications. However, copper is susceptible to corrosion, especially in humid or saline environments, which can limit its use in outdoor applications without proper insulation. Additionally, copper is generally more expensive than other materials, which can affect overall project budgets.

Impact on Application: Copper stranded wire is widely used in electrical wiring, telecommunications, and automotive applications. Its high conductivity ensures efficient energy transfer, making it suitable for high-performance applications.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B3 and B8 for copper wire. In regions like Africa and South America, where humidity can be high, considerations for corrosion protection are paramount.

Aluminum

Key Properties: Aluminum stranded wire is lightweight and has a conductivity rating of about 61% IACS. It is resistant to corrosion due to the formation of a protective oxide layer, making it suitable for various environmental conditions.

Pros & Cons: The lightweight nature of aluminum makes it easier to handle and install, reducing labor costs. However, its lower conductivity compared to copper means that larger gauge wires are required for the same performance, potentially increasing material costs. Additionally, aluminum can be less durable under mechanical stress compared to copper.

Impact on Application: Aluminum is commonly used in overhead power lines and telecommunications due to its lightweight and corrosion-resistant properties. It is particularly effective in applications where weight is a critical factor.

Considerations for International Buyers: Compliance with standards such as ASTM B231 and B232 is essential. Buyers in Europe and the Middle East should be aware of local regulations regarding aluminum use in construction and electrical applications.

Stainless Steel

Key Properties: Stainless steel stranded wire offers excellent tensile strength and corrosion resistance, with a temperature rating that can exceed 300°C depending on the alloy. It is also resistant to oxidation and can withstand harsh environments.

Pros & Cons: The durability and strength of stainless steel make it ideal for applications requiring high mechanical performance. However, it is more expensive than both copper and aluminum, and its conductivity is significantly lower, which may limit its use in electrical applications.

Impact on Application: Stainless steel stranded wire is often used in industrial settings, marine applications, and where high strength is needed, such as in lifting and rigging.

Considerations for International Buyers: Buyers should verify compliance with standards such as ASTM A313 and A580. In regions like Turkey and South Africa, the choice of stainless steel grade may impact corrosion resistance and suitability for specific applications.

PVC Coated Wire

Key Properties: PVC-coated stranded wire combines the flexibility of stranded wire with the protective properties of PVC insulation. It can operate effectively in temperatures ranging from -20°C to 60°C.

Pros & Cons: The PVC coating provides excellent insulation and protection against moisture and chemicals, making it suitable for outdoor and industrial applications. However, the coating can limit the wire’s flexibility and may degrade over time under UV exposure.

Impact on Application: PVC-coated stranded wire is commonly used in electrical installations, outdoor lighting, and applications requiring additional insulation and protection from environmental factors.

Considerations for International Buyers: Compliance with standards such as ASTM D3032 for PVC insulation is critical. Buyers should consider local environmental conditions, particularly UV exposure, when selecting PVC-coated wire.

Summary Table

| Material | Typical Use Case for stranded wire | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical wiring, telecommunications | Superior conductivity | Susceptible to corrosion | High |

| Aluminum | Overhead power lines, telecommunications | Lightweight and corrosion-resistant | Lower conductivity than copper | Medium |

| Stainless Steel | Industrial applications, marine use | High tensile strength and durability | Higher cost and lower conductivity | High |

| PVC Coated Wire | Electrical installations, outdoor use | Excellent insulation and protection | Limited flexibility, UV degradation risk | Medium |

This guide provides a comprehensive overview of the materials used in stranded wire, offering actionable insights for international B2B buyers to make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for stranded wire

Manufacturing Processes for Stranded Wire

Stranded wire is an essential component in various industries, serving applications in electrical wiring, construction, and telecommunications. Understanding the manufacturing processes involved can help B2B buyers make informed purchasing decisions. Here’s a detailed breakdown of the typical stages involved in the production of stranded wire:

1. Material Preparation

The first step in the manufacturing process is material preparation. The most commonly used materials for stranded wire include copper, aluminum, and steel due to their conductivity and strength.

- Material Selection: Buyers should ensure that the selected material meets their specific application needs, including corrosion resistance and tensile strength.

- Wire Drawing: Raw materials are drawn through dies to reduce their diameter and increase length. This process is crucial for achieving the desired wire gauge.

- Cleaning and Treatment: The wires are cleaned to remove any oxidation or impurities, and may undergo treatments such as annealing to enhance flexibility.

2. Forming

The forming stage involves twisting multiple strands of wire together to create stranded wire.

- Stranding Process: Stranding machines twist several wires together in a helical pattern. The number of strands and their arrangement can vary based on the required flexibility and strength.

- Layering Technique: Wires are often layered in opposite directions to enhance structural integrity. This method reduces the likelihood of deformation under tension.

- Braid Formation: In some cases, wires may be braided instead of stranded. Braiding provides additional flexibility and is often used for applications requiring electromagnetic shielding.

3. Assembly

After forming, the stranded wire may undergo assembly with insulation and other components.

- Insulation Application: A protective layer, often made of PVC or rubber, is applied to prevent electrical leakage and protect against environmental factors.

- Connector Attachment: Depending on the application, connectors or terminals may be attached to facilitate integration into larger systems.

- Coiling and Packaging: The finished stranded wire is coiled for easy handling and transportation. Proper packaging is essential to prevent damage during shipping.

4. Finishing

The finishing stage ensures that the product meets quality and performance standards.

- Surface Treatment: Depending on the application, stranded wire may undergo additional treatments such as galvanization or coating to enhance durability and resistance to corrosion.

- Final Inspection: A thorough inspection is conducted to ensure the wire meets specifications before it is shipped to customers.

Quality Assurance in Stranded Wire Production

Quality assurance (QA) is crucial in manufacturing stranded wire to ensure safety, reliability, and compliance with international standards. Here are the key elements of a robust QA program:

International Standards

B2B buyers should look for manufacturers that adhere to recognized international quality standards, including:

- ISO 9001: A widely recognized standard for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: Indicates that the product meets European safety and health standards, essential for buyers in Europe.

- API Standards: Relevant for applications in the oil and gas industry, ensuring that products meet specific performance criteria.

Quality Control Checkpoints

Effective quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitors production processes to identify any deviations from standards in real-time.

- Final Quality Control (FQC): Conducts a comprehensive inspection of finished products, including dimensional checks and electrical testing.

Common Testing Methods

Manufacturers may employ various testing methods to verify the quality of stranded wire:

- Tensile Testing: Measures the strength and elasticity of the wire.

- Electrical Conductivity Testing: Ensures that the wire meets conductivity specifications.

- Visual Inspections: Checks for surface defects, insulation integrity, and overall appearance.

How B2B Buyers Can Verify Supplier Quality Control

When sourcing stranded wire, particularly from international suppliers, buyers should take proactive steps to verify quality control practices:

- Supplier Audits: Conduct on-site audits of potential suppliers to assess their manufacturing processes, quality control measures, and adherence to international standards.

- Quality Reports: Request detailed quality reports that document testing results, non-conformance issues, and corrective actions taken.

- Third-Party Inspections: Engage third-party inspection services to conduct independent evaluations of product quality before shipment.

Quality Control Nuances for International B2B Buyers

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control:

- Regulatory Compliance: Different regions may have varying regulatory requirements. Buyers must ensure that the products comply with local standards, which may differ from international ones.

- Cultural Factors: Understanding cultural differences in business practices can aid in building effective relationships with suppliers, ensuring better communication regarding quality expectations.

- Supply Chain Logistics: Consider logistics challenges that may affect product quality during transportation. Collaborating with suppliers who have robust logistics and handling practices can mitigate these risks.

By understanding the manufacturing processes and quality assurance practices associated with stranded wire, international B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

Related Video: How to Amazing Electrical Wire Manufacturing in Factory Process

Comprehensive Cost and Pricing Analysis for stranded wire Sourcing

When considering the sourcing of stranded wire, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This section delves into the key cost components, price influencers, and provides actionable tips for buyers, particularly from regions such as Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary cost driver in stranded wire production is the raw materials used. Common materials include copper, aluminum, and steel. The choice of material not only affects the price but also the performance characteristics of the wire. For instance, copper offers superior conductivity but is generally more expensive than aluminum.

-

Labor: Labor costs vary significantly depending on the region of production. In countries with higher labor costs, such as those in Western Europe, the overall production costs may be elevated. Conversely, sourcing from regions with lower labor costs can reduce expenses but may involve trade-offs in quality or compliance.

-

Manufacturing Overhead: This includes expenses related to the facilities, equipment, and utilities required for production. Manufacturers often allocate a percentage of these costs to each unit produced, impacting overall pricing.

-

Tooling: The setup costs for machinery and tools used in the production of stranded wire can be substantial, especially for custom orders. These costs are typically spread across the production run, influencing the unit price.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the stranded wire meets industry standards and specifications. While this adds to the cost, it is crucial for maintaining product quality and reducing returns or failures in the field.

-

Logistics: Shipping and handling costs, including freight, customs duties, and insurance, must be factored into the total cost. These costs can fluctuate based on the Incoterms agreed upon and the distance between the supplier and buyer.

-

Margin: Suppliers will apply a profit margin on top of their costs. This margin can vary widely based on market conditions, demand, and the supplier’s business model.

Price Influencers

-

Volume/MOQ: Pricing is often tiered based on the quantity ordered. Larger volumes typically yield lower per-unit costs due to economies of scale.

-

Specifications/Customization: Custom specifications can lead to increased costs due to the need for specialized tooling or processes. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials: The choice of material significantly impacts pricing. High-quality materials may result in higher initial costs but could lead to better performance and longevity.

-

Quality/Certifications: Stranded wire products that meet specific quality standards or certifications (e.g., ISO, ASTM) may come at a premium but can ensure reliability and safety.

-

Supplier Factors: The supplier’s reputation, manufacturing capabilities, and geographic location all influence pricing. Established suppliers may charge more for their experience and reliability.

-

Incoterms: The agreed-upon Incoterms affect logistics costs and responsibilities. Understanding these terms can help buyers optimize their total cost.

Buyer Tips

-

Negotiation: Always negotiate pricing based on volume and long-term partnership potential. Suppliers may be willing to offer discounts for bulk orders or repeated business.

-

Cost-Efficiency: Evaluate total cost of ownership (TCO) rather than just the purchase price. Consider factors like durability, maintenance, and potential downtime costs.

-

Pricing Nuances: Be aware of regional pricing variations. For instance, suppliers in Africa may have different pricing structures compared to those in Europe due to local market conditions and production costs.

-

Supplier Selection: Conduct thorough due diligence on suppliers. Look for those with a proven track record of quality and reliability, especially when sourcing from international markets.

-

Stay Informed: Keep abreast of market trends and fluctuations in raw material prices, as these can directly affect your sourcing strategy and costs.

Disclaimer

Prices for stranded wire can vary significantly based on the factors outlined above. Buyers are encouraged to obtain multiple quotes and conduct thorough research to ensure they are making informed purchasing decisions.

Spotlight on Potential stranded wire Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘stranded wire’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for stranded wire

Stranded wire is a versatile product used in various industries, from telecommunications to construction. Understanding its essential technical properties and relevant trade terminology is crucial for B2B buyers, especially those sourcing from diverse global markets.

Key Technical Properties of Stranded Wire

-

Material Grade

Stranded wire can be made from various materials, including copper, aluminum, and steel. The grade of material affects conductivity, flexibility, and corrosion resistance. For instance, copper is often preferred for its excellent conductivity, while aluminum is chosen for its lightweight and cost-effectiveness. Selecting the appropriate material grade is essential for ensuring that the wire meets the specific requirements of your application. -

Stranding Configuration

This refers to how the individual wires are twisted or braided together. Common configurations include concentric and helical stranding. The configuration impacts the wire’s flexibility and strength. A higher strand count generally increases flexibility, making it easier to work with in tight spaces. For B2B buyers, understanding these configurations can aid in selecting the right product for their projects. -

AWG (American Wire Gauge) Size

The AWG size indicates the diameter of the wire. Smaller AWG numbers correspond to thicker wires, which can carry more current but may be less flexible. Understanding AWG sizes is crucial for ensuring compatibility with electrical systems and meeting safety standards. -

Electrical Resistance

This property measures how much the wire resists the flow of electric current, typically expressed in ohms per unit length. Lower resistance is preferable for applications requiring efficient power transmission. Buyers must consider the resistance levels to ensure optimal performance and compliance with industry standards. -

Tensile Strength

Tensile strength indicates the maximum load the wire can withstand without breaking. This property is vital in applications where the wire will be subject to tension or mechanical stress. B2B buyers should assess tensile strength to ensure the wire’s reliability under operational conditions. -

Temperature Rating

Each stranded wire has a specific temperature rating that indicates the maximum temperature it can withstand without degrading. This property is crucial for applications in high-heat environments, such as industrial machinery. Understanding temperature ratings helps buyers select the appropriate wire for their specific operational conditions.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is critical for buyers when considering sourcing components that fit specific machinery or systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This concept is essential for international buyers to understand, as it can impact inventory management and cost efficiency. Knowing the MOQ can help in planning procurement strategies. -

RFQ (Request for Quotation)

An RFQ is a formal document used to solicit price bids from suppliers for specific products or services. It is a vital tool for B2B buyers when comparing prices and ensuring they receive competitive offers from multiple suppliers. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international contracts to clarify the responsibilities of buyers and sellers. Familiarity with Incoterms is crucial for B2B buyers to understand shipping costs, risks, and the delivery process. -

Certification Standards

Certifications like ISO 9001 or RoHS indicate that a product meets specific quality or safety standards. For international buyers, ensuring that stranded wire complies with relevant certification standards is critical for regulatory compliance and quality assurance.

Illustrative Image (Source: Google Search)

- Lead Time

Lead time is the time taken from placing an order to receiving it. Understanding lead times is important for managing project timelines and ensuring that materials are available when needed.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that they procure stranded wire that meets their operational needs while navigating international supply chains effectively.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the stranded wire Sector

Market Overview & Key Trends

The stranded wire market is witnessing significant growth driven by the increasing demand for flexible and durable wiring solutions across various industries, including construction, automotive, and telecommunications. Key drivers include the expansion of renewable energy projects and infrastructure development, particularly in emerging markets in Africa and South America. For international B2B buyers, understanding local market dynamics is crucial, as factors such as regulatory environments, labor costs, and material availability can vary widely.

Emerging technology trends are reshaping sourcing strategies, with digital platforms facilitating direct connections between buyers and suppliers. Tools like e-procurement systems and supplier management software allow businesses to streamline sourcing processes, improving efficiency and reducing costs. Additionally, the rise of Industry 4.0 technologies—such as IoT and AI—enables better tracking of supply chains, enhancing transparency and responsiveness to market changes.

For buyers in Europe and the Middle East, there is a growing emphasis on quality certifications, such as ISO 9001 and ISO 14001, which indicate adherence to international standards and sustainability practices. As the market evolves, B2B buyers must remain agile and informed about these trends to leverage opportunities and mitigate risks effectively.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a central pillar in the procurement of stranded wire, driven by increasing environmental regulations and consumer expectations. The production of stranded wire can have a significant environmental impact, particularly in terms of energy consumption and resource depletion. Therefore, B2B buyers are encouraged to prioritize suppliers that demonstrate commitment to sustainable practices.

Ethical sourcing is critical in maintaining a responsible supply chain. This involves ensuring that materials are sourced from suppliers who adhere to fair labor practices and environmental stewardship. Certifications such as FSC (Forest Stewardship Council) for wood-based products, or specific standards for metals, can help buyers identify ethical sources.

Moreover, the use of “green” materials, such as recycled metals or eco-friendly insulation materials, is gaining traction. Buyers should look for suppliers who offer products with these certifications, as they not only reduce environmental impact but also appeal to a growing segment of environmentally conscious customers. Engaging in sustainability initiatives can enhance brand reputation and customer loyalty, making it a strategic advantage in the competitive B2B landscape.

Illustrative Image (Source: Google Search)

Brief Evolution/History

The concept of stranded wire dates back to the early 19th century, when it was first used in telegraphy. Over time, advancements in metallurgy and manufacturing processes improved the flexibility and strength of stranded wire, making it ideal for various applications. The introduction of electrical wiring in the late 19th century further expanded its use, particularly in telecommunications and residential wiring.

As industries evolved, so did the design and application of stranded wire, with innovations leading to the development of specialized types, such as braided wire for electromagnetic shielding. Today, stranded wire is not only pivotal in electrical applications but also in construction and transportation, reflecting its importance in modern infrastructure. For B2B buyers, understanding this evolution provides context for the product’s capabilities and potential applications in their specific sectors.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of stranded wire

-

What should I consider when vetting suppliers of stranded wire?

When vetting suppliers, prioritize their industry experience, certifications, and reputation. Look for suppliers with ISO certifications, which indicate adherence to international quality standards. Request references from previous clients to assess reliability and service quality. Additionally, consider their manufacturing capabilities, product range, and flexibility in meeting your specific requirements. Online platforms like Thomasnet can provide insights into supplier backgrounds and customer reviews, aiding in informed decision-making. -

Can stranded wire be customized to meet specific requirements?

Yes, many manufacturers offer customization options for stranded wire, including variations in strand count, gauge, material, and insulation type. When discussing customization, clearly outline your technical specifications, application requirements, and any regulatory standards that must be met. It’s advisable to request samples before committing to larger orders to ensure the customized product aligns with your needs and expectations. -

What are the typical minimum order quantities (MOQs) and lead times for stranded wire?

MOQs for stranded wire can vary significantly depending on the supplier and the specifics of your order. Generally, MOQs range from 100 to 1,000 meters, but some suppliers may accommodate smaller orders. Lead times can also differ based on the complexity of your order and the supplier’s production capacity, typically ranging from 2 to 6 weeks. Always confirm these details upfront to avoid unexpected delays. -

What payment terms are commonly offered by stranded wire suppliers?

Payment terms can vary widely, but common arrangements include upfront payments, deposits, or net payment terms (e.g., net 30 or net 60). International buyers should be aware of currency exchange risks and consider using secure payment methods such as letters of credit, which provide protection for both parties. It’s essential to clarify payment terms in advance to ensure mutual understanding and avoid disputes later. -

How can I ensure quality assurance and certifications for stranded wire?

To ensure quality, request documentation of certifications such as ISO 9001, which indicates a robust quality management system. Additionally, inquire about the supplier’s quality control processes, including testing procedures and inspection protocols. A reputable supplier will provide test reports and certifications for their products, demonstrating compliance with industry standards. Regular audits and inspections can also help maintain quality throughout the supply chain. -

What logistics considerations should I keep in mind when importing stranded wire?

Logistics is crucial when importing stranded wire. Assess shipping options, costs, and delivery timelines, considering factors like freight forwarding services and customs clearance procedures. Ensure that the supplier can provide necessary documentation, such as packing lists and certificates of origin, to facilitate smooth customs processing. Additionally, factor in potential tariffs or trade regulations that may impact costs and delivery times in your region. -

How should I handle disputes with stranded wire suppliers?

To effectively manage disputes, establish clear communication channels and maintain detailed records of all transactions and agreements. If a dispute arises, attempt to resolve it amicably through direct negotiation. If necessary, refer to the terms outlined in your contract regarding dispute resolution, which may include mediation or arbitration clauses. Engaging legal counsel familiar with international trade can also be beneficial in navigating complex disputes. -

What are the common applications of stranded wire in various industries?

Stranded wire is widely used across numerous industries due to its flexibility and strength. Common applications include electrical wiring in residential and commercial buildings, automotive wiring, and telecommunications. It is also utilized in manufacturing machinery, aerospace components, and marine applications. Understanding the specific requirements of your industry will help you choose the right type of stranded wire for your needs, ensuring optimal performance and compliance with relevant standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for stranded wire

As the global demand for stranded wire continues to rise across various industries, it is crucial for international B2B buyers to embrace strategic sourcing practices. Key takeaways include understanding the diverse applications of stranded wire, the importance of supplier reliability, and the benefits of flexibility and durability in product selection. By leveraging these insights, businesses can enhance their operational efficiencies and drive cost savings.

The value of strategic sourcing lies not only in securing competitive pricing but also in fostering long-term partnerships with trusted suppliers. This approach enables buyers to navigate market fluctuations and supply chain challenges more effectively. For buyers in Africa, South America, the Middle East, and Europe, particularly in regions like South Africa and Turkey, establishing connections with reputable manufacturers can unlock new opportunities for growth.

Looking ahead, the landscape of stranded wire sourcing is set to evolve with technological advancements and increasing sustainability demands. International buyers are encouraged to stay informed about industry trends and innovations, which will be pivotal in making informed purchasing decisions. Take proactive steps today to refine your sourcing strategies and position your business for future success in this dynamic market.