Master Global Sourcing of Aluminum Pipes for Competitive

Introduction: Navigating the Global Market for aluminum pipes

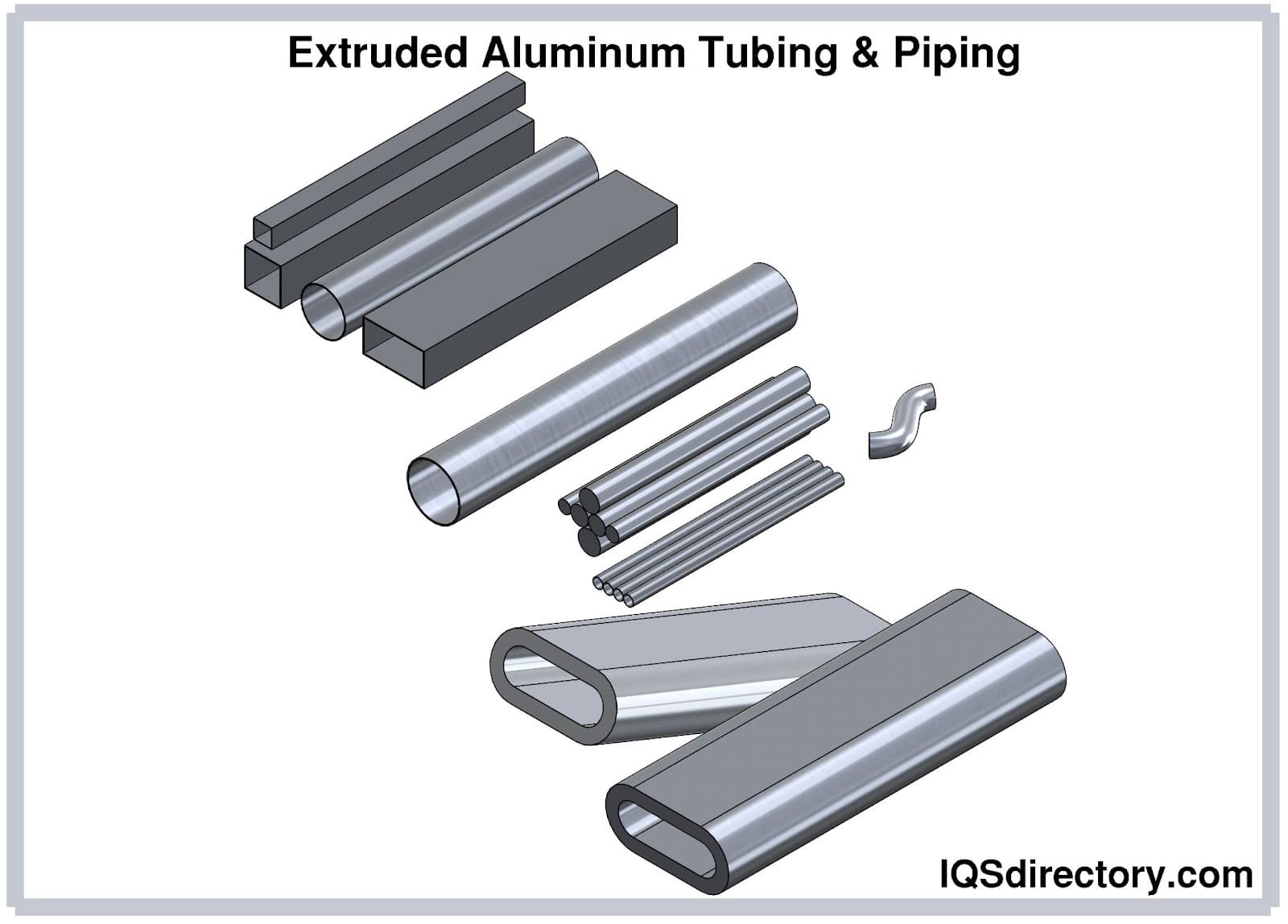

Aluminum pipes have emerged as a vital component across numerous industries, thanks to their lightweight, corrosion-resistant properties and versatility. As global demand continues to rise, B2B buyers from Africa, South America, the Middle East, and Europe are presented with both significant opportunities and intricate challenges in sourcing these essential materials. Understanding the nuances of aluminum pipe fabrication is crucial for organizations aiming to enhance their supply chain efficiency and product performance.

This guide is designed to equip international buyers with comprehensive insights into the aluminum pipe market. It covers a wide range of topics, including types of aluminum pipes, optimal materials for specific applications, manufacturing and quality control processes, supplier evaluation criteria, cost analysis strategies, and current market trends. Each section is tailored to address the unique needs and contexts of buyers operating in diverse global markets.

By leveraging this guide, procurement teams can make informed sourcing decisions that mitigate risks and optimize value. Whether you are navigating regulatory landscapes in Africa, assessing supplier capabilities in South America, or seeking innovative solutions in Europe and the Middle East, this resource provides actionable strategies and practical answers to pressing questions. Embrace the potential of aluminum pipes to drive your business forward in a competitive global marketplace.

Understanding aluminum pipes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Seamless Aluminum Pipes | Manufactured without seams, offering uniform strength and durability | Oil & gas, construction, automotive | Pros: High pressure resistance; Cons: Higher cost due to manufacturing complexity |

| Welded Aluminum Pipes | Formed by welding flat sheets into a pipe shape | Plumbing, HVAC, structural applications | Pros: Cost-effective for large runs; Cons: Potential for weak points at welds |

| Anodized Aluminum Pipes | Treated to enhance corrosion resistance and surface hardness | Aerospace, marine, electrical systems | Pros: Improved durability; Cons: Additional processing costs may apply |

| Aluminum Alloy Pipes | Composed of various aluminum alloys for enhanced properties | Transportation, military, construction | Pros: Tailored properties for specific applications; Cons: Alloy selection can be complex |

| Thin-Walled Aluminum Pipes | Lightweight and cost-effective, suitable for non-structural uses | Packaging, furniture, decorative items | Pros: Low weight and cost; Cons: Limited structural integrity |

Seamless Aluminum Pipes

Seamless aluminum pipes are crafted from a single piece of aluminum, eliminating the need for welding or joints. This manufacturing process results in pipes that exhibit exceptional strength and uniformity, making them ideal for high-pressure applications such as oil and gas transport and heavy-duty construction. B2B buyers should consider the higher cost associated with seamless pipes, but the benefits of reliability and reduced risk of failure often justify the investment, particularly in critical applications.

Illustrative Image (Source: Google Search)

Welded Aluminum Pipes

Welded aluminum pipes are produced by joining flat aluminum sheets, making them a cost-effective solution for various applications, including plumbing and HVAC systems. This method allows for flexibility in design and dimensions, catering to specific project requirements. However, buyers must be cautious about the integrity of the welds, as they can introduce potential weak points. Ensuring that suppliers adhere to quality standards and certifications is essential for mitigating risks associated with welded joints.

Anodized Aluminum Pipes

Anodized aluminum pipes undergo an electrochemical process that enhances their corrosion resistance and surface hardness. This treatment makes them particularly suitable for applications in harsh environments, such as aerospace and marine industries. While anodized pipes offer significant advantages in durability and aesthetics, buyers should be aware of the additional processing costs involved. Selecting suppliers with expertise in anodization will ensure that the pipes meet necessary performance standards.

Aluminum Alloy Pipes

Aluminum alloy pipes are made from a mixture of aluminum and other metals, enhancing specific properties such as strength, ductility, and resistance to corrosion. These pipes are widely used in the transportation and military sectors, where performance and reliability are paramount. For B2B buyers, understanding the specific alloy composition and its implications for application is crucial. Collaboration with suppliers who can provide detailed information on alloy properties can facilitate informed purchasing decisions.

Thin-Walled Aluminum Pipes

Thin-walled aluminum pipes are characterized by their lightweight and cost-effective nature, making them suitable for non-structural applications like packaging and decorative elements. While they offer advantages in terms of handling and installation, their reduced wall thickness limits their structural integrity. Buyers should assess the specific requirements of their projects to determine whether thin-walled pipes meet their needs, particularly in applications where strength is a critical factor.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of aluminum pipes

| Industry/Sector | Specific Application of aluminum pipes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural frameworks and support systems | Lightweight yet strong, reducing transportation costs and time. | Compliance with local building codes and standards. |

| Automotive | Fuel lines and exhaust systems | Enhanced fuel efficiency and reduced weight for better performance. | Material grade compatibility and resistance to corrosion. |

| Energy | Heat exchangers and cooling systems | Improved thermal efficiency, leading to lower operational costs. | Supplier’s experience with high-temperature applications. |

| Aerospace | Aircraft fuselage and components | High strength-to-weight ratio, crucial for performance and safety. | Precision machining capabilities and adherence to aerospace standards. |

| Marine | Boat hulls and piping systems | Excellent corrosion resistance, extending lifespan in harsh environments. | Certification for marine applications and local regulations. |

Construction

In the construction sector, aluminum pipes are commonly utilized in structural frameworks and support systems. Their lightweight nature significantly reduces transportation costs and installation time, allowing for quicker project completion. Buyers in this sector need to ensure that the aluminum pipes meet local building codes and standards, which can vary significantly across different regions, particularly in Africa and South America, where regulations may be evolving.

Automotive

Aluminum pipes are extensively used in the automotive industry, particularly for fuel lines and exhaust systems. Their lightweight properties contribute to enhanced fuel efficiency and overall vehicle performance. B2B buyers must consider the specific material grades that offer adequate corrosion resistance and durability, especially in environments with varying climatic conditions across the Middle East and Europe.

Energy

In energy applications, aluminum pipes serve critical roles in heat exchangers and cooling systems. Their ability to conduct heat efficiently translates to lower operational costs for energy companies. Buyers should prioritize suppliers with proven expertise in high-temperature applications to ensure reliability and performance, particularly in regions with extreme environmental conditions, such as those found in parts of Africa and the Middle East.

Aerospace

The aerospace industry leverages aluminum pipes for aircraft fuselage and various components due to their high strength-to-weight ratio. This characteristic is essential for enhancing aircraft performance and safety. Buyers in this sector must focus on suppliers capable of precision machining and compliance with stringent aerospace standards, ensuring that the materials can withstand the unique stresses encountered in flight.

Marine

In marine applications, aluminum pipes are favored for boat hulls and piping systems due to their excellent corrosion resistance, which is vital in saltwater environments. This property extends the lifespan of marine vessels, providing significant cost savings over time. B2B buyers must ensure that suppliers are certified for marine applications and comply with local regulations to avoid potential legal and operational issues.

Strategic Material Selection Guide for aluminum pipes

When selecting aluminum pipes for various applications, understanding the properties and suitability of different aluminum alloys is crucial for international B2B buyers. Here’s an analysis of three common materials used in aluminum pipes, focusing on their key properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Aluminum Alloy 6061

Key Properties:

Aluminum 6061 is a versatile alloy known for its good mechanical properties and weldability. It has a temperature rating up to 150°C (302°F) and can withstand moderate pressures. Its corrosion resistance is excellent, particularly in marine environments, making it suitable for a variety of applications.

Pros & Cons:

The durability of 6061 is high, providing a good balance between strength and weight. However, it can be more expensive than other alloys due to its enhanced properties. The manufacturing complexity is moderate, as it can be easily extruded and welded.

Impact on Application:

6061 is ideal for structural applications, including pipelines in construction and transportation. Its compatibility with various media, including water and oil, makes it a popular choice.

Specific Considerations:

International buyers should ensure compliance with standards such as ASTM B241 and DIN 1725. Given its popularity, sourcing 6061 is generally straightforward, but buyers should confirm the alloy’s certification and traceability.

2. Aluminum Alloy 6063

Key Properties:

6063 aluminum is known for its excellent extrudability and surface finish. It has a lower strength compared to 6061 but offers better corrosion resistance, making it suitable for architectural applications. The temperature rating is similar, around 150°C (302°F).

Pros & Cons:

The key advantage of 6063 is its aesthetic appeal and ability to produce complex shapes. However, its lower strength may limit its use in high-stress applications. The cost is typically lower than 6061, making it a cost-effective option for non-structural applications.

Impact on Application:

This alloy is commonly used in architectural applications, such as window frames and decorative elements. It is compatible with various media but is not recommended for high-pressure applications.

Specific Considerations:

Buyers should consider local standards and regulations, especially in construction. Compliance with European standards (EN 755) and local building codes is essential.

3. Aluminum Alloy 5083

Key Properties:

5083 aluminum is known for its exceptional performance in extreme environments. It has a high resistance to corrosion, particularly in seawater, and can handle higher pressures and temperatures (up to 65°C or 149°F).

Pros & Cons:

The durability of 5083 is outstanding, making it suitable for marine and heavy-duty applications. However, it is more expensive than 6061 and 6063 due to its specialized properties. The manufacturing process can be complex, requiring skilled labor for welding and fabrication.

Impact on Application:

5083 is ideal for marine applications, pressure vessels, and heavy-duty structures. Its compatibility with aggressive media, including seawater, makes it a preferred choice for shipbuilding and offshore structures.

Specific Considerations:

International buyers should ensure compliance with marine standards such as ASTM B928 and DNV GL. Given its specialized nature, sourcing may require more effort, and buyers should verify the supplier’s capability to meet stringent quality controls.

Summary Table

| Material | Typical Use Case for aluminum pipes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum 6061 | Structural applications | Good mechanical properties | Higher cost compared to others | Medium |

| Aluminum 6063 | Architectural applications | Excellent surface finish | Lower strength | Low |

| Aluminum 5083 | Marine and heavy-duty applications | Exceptional corrosion resistance | More expensive and complex to manufacture | High |

This analysis provides a comprehensive overview of aluminum pipe materials, enabling B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for aluminum pipes

The manufacturing of aluminum pipes involves a series of well-defined processes that ensure quality and durability, which are essential for various applications across industries such as construction, automotive, and aerospace. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these processes and the associated quality assurance measures is crucial for informed procurement decisions.

Manufacturing Processes for Aluminum Pipes

The production of aluminum pipes can generally be divided into four main stages: material preparation, forming, assembly, and finishing. Each stage employs specific techniques and technologies that contribute to the final product’s quality.

1. Material Preparation

Material Selection: The first step is selecting the appropriate aluminum alloy, which is vital for the pipe’s intended application. Common alloys used include 6061 and 6063, known for their excellent corrosion resistance and mechanical properties.

Billet Preparation: The selected aluminum is typically supplied in the form of billets. These billets are cut to size and preheated to make them easier to form.

Quality Control Checkpoint (IQC): Incoming Quality Control (IQC) involves inspecting the aluminum billets for compliance with specifications such as alloy type, dimensions, and surface defects. This initial quality check is crucial to prevent issues later in the manufacturing process.

2. Forming

Extrusion Process: Aluminum pipes are primarily produced through an extrusion process, where heated aluminum billets are forced through a die to create the desired pipe shape. This method allows for a variety of diameters and wall thicknesses to be achieved, depending on the die design.

Alternative Processes: In some cases, aluminum pipes may also be produced through rolling or drawing techniques. Rolling involves reducing the thickness of aluminum sheets, while drawing involves pulling the aluminum through a die to elongate it into pipe form.

Quality Control Checkpoint (IPQC): In-Process Quality Control (IPQC) is conducted during the forming stage to monitor parameters such as temperature, pressure, and dimensional accuracy, ensuring that the pipes meet predefined specifications.

3. Assembly

Joining Techniques: If the pipe requires additional components, various joining methods such as welding or brazing may be employed. These methods must be selected based on the application and the mechanical properties required.

Quality Assurance: The assembly stage also involves visual inspections and non-destructive testing methods (such as ultrasonic testing) to ensure that joints are sound and free from defects.

4. Finishing

Surface Treatment: Once formed and assembled, aluminum pipes undergo surface treatments such as anodizing, painting, or powder coating to enhance corrosion resistance and aesthetic appeal. These treatments also help improve the surface hardness and durability of the pipes.

Final Inspection (FQC): Final Quality Control (FQC) checks the finished products against specifications. This includes dimensional checks, surface quality assessments, and mechanical property testing.

Quality Assurance Standards

Quality assurance in aluminum pipe manufacturing is governed by various international standards and industry-specific regulations. For B2B buyers, particularly those operating in different international markets, understanding these standards is essential.

International Standards

-

ISO 9001: This is a globally recognized standard for quality management systems. Manufacturers adhering to ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

-

ISO 14001: Environmental management standards that ensure manufacturers minimize their environmental impact during the production process.

Industry-Specific Certifications

-

CE Marking: Required for products sold in the European Economic Area, indicating compliance with safety and environmental protection standards.

-

API Specifications: For aluminum pipes used in the oil and gas industry, compliance with American Petroleum Institute (API) specifications is crucial, ensuring that products meet rigorous safety and performance standards.

Quality Control Checkpoints

Quality control throughout the manufacturing process involves several checkpoints:

- Incoming Quality Control (IQC): Checks the quality of raw materials before production begins.

- In-Process Quality Control (IPQC): Monitors production processes to catch defects early.

- Final Quality Control (FQC): Conducts comprehensive testing of finished products.

Common Testing Methods

B2B buyers should be familiar with several testing methods to verify product quality:

- Dimensional Inspection: Ensures that the pipes meet specified dimensions and tolerances.

- Mechanical Testing: Assesses properties such as tensile strength, yield strength, and elongation.

- Non-Destructive Testing (NDT): Methods such as ultrasonic testing and radiographic inspection help identify internal defects without damaging the product.

Verifying Supplier Quality Assurance

B2B buyers can take several steps to verify a supplier’s quality assurance processes:

-

Supplier Audits: Conduct regular audits of potential suppliers to evaluate their manufacturing capabilities and quality control practices.

-

Quality Assurance Reports: Request detailed reports that outline the supplier’s quality control processes, including results from IQC, IPQC, and FQC.

-

Third-Party Inspections: Engage independent third-party inspection services to assess product quality before shipment.

Quality Control Nuances for International Buyers

For buyers in Africa, South America, the Middle East, and Europe, several nuances should be considered:

-

Regulatory Compliance: Ensure that suppliers comply with local regulations and international standards relevant to your market.

-

Cultural Differences: Be aware of cultural differences in business practices that may affect quality assurance processes.

-

Logistical Considerations: Understand the implications of shipping and customs regulations on product delivery and quality assurance.

By comprehensively understanding the manufacturing processes and quality assurance measures for aluminum pipes, B2B buyers can make informed decisions that enhance their supply chain efficiency and product reliability. This knowledge not only helps in selecting the right suppliers but also in negotiating favorable terms that align with their operational needs and market demands.

Related Video: Top 5 Mass Production Techniques: Manufacturing Process

Comprehensive Cost and Pricing Analysis for aluminum pipes Sourcing

Understanding the Cost Structure of Aluminum Pipes

Sourcing aluminum pipes involves navigating a complex cost structure that influences pricing and overall procurement strategies. Below are the main components that contribute to the total cost of ownership for aluminum pipes:

-

Materials: The primary cost driver, accounting for a significant portion of the total expense. Aluminum prices fluctuate based on global market conditions, raw material availability, and production costs. Bauxite, the main raw material, has seen rising prices, which can directly impact the cost of aluminum pipes.

-

Labor: This includes wages for skilled workers involved in manufacturing processes such as extrusion, machining, and quality control. Labor costs can vary significantly by region, affecting the overall pricing structure for international buyers.

-

Manufacturing Overhead: This encompasses expenses related to facility maintenance, utilities, equipment depreciation, and administrative costs. Efficient manufacturing processes can reduce overhead costs, thus impacting pricing.

-

Tooling: The costs associated with designing and creating the molds or dies used in the production of aluminum pipes. Tooling expenses can be substantial, especially for custom specifications, and are often amortized over larger production runs.

-

Quality Control (QC): Ensuring that aluminum pipes meet regulatory and industry standards incurs additional costs. Comprehensive QC processes help mitigate risks associated with product defects but can also add to the overall expense.

-

Logistics: Transportation and handling costs are crucial, particularly for international shipments. Factors such as distance, shipping method, and Incoterms can significantly influence logistics expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary based on supplier reputation, market demand, and competition.

Key Influencers on Pricing

Several factors influence the pricing of aluminum pipes, especially for B2B buyers in emerging markets:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs carefully to avoid overcommitting to large orders that may not be utilized efficiently.

-

Specifications and Customization: Custom sizes, shapes, and alloys can increase costs. Buyers should clearly define their requirements to avoid unexpected price hikes.

-

Quality and Certifications: Pipes that meet specific quality standards or certifications (e.g., ISO, ASTM) may command higher prices. Buyers should weigh the benefits of certified products against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their proven track record, while newer entrants may offer competitive rates to gain market share.

-

Incoterms: Understanding international shipping terms is crucial. Incoterms dictate who is responsible for shipping costs and risks, influencing the overall cost structure.

Buyer Tips for Cost-Efficiency

International buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the following strategies to optimize costs:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Leveraging volume commitments can lead to more favorable terms.

-

Evaluate Total Cost of Ownership: Beyond the purchase price, consider logistics, maintenance, and potential downtime costs. A lower initial price may result in higher long-term expenses.

-

Stay Informed on Market Trends: Monitor aluminum price trends and forecasts to time purchases effectively. Being aware of market fluctuations can lead to significant savings.

-

Utilize Local Suppliers: Whenever possible, source from local suppliers to reduce shipping costs and lead times, while also supporting regional economies.

-

Assess Alternative Materials: In some applications, alternative materials may offer cost advantages without compromising performance. Evaluate all available options before making a decision.

Disclaimer

The prices and cost components discussed are indicative and may vary based on market conditions, supplier negotiations, and specific project requirements. Always conduct thorough market research and supplier evaluations to obtain accurate pricing information tailored to your needs.

Spotlight on Potential aluminum pipes Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘aluminum pipes’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for aluminum pipes

Key Technical Properties of Aluminum Pipes

When sourcing aluminum pipes, understanding the essential technical properties is crucial for making informed purchasing decisions. Below are critical specifications that B2B buyers should consider:

-

Material Grade: Aluminum pipes are classified into various grades, such as 6061 and 6063, which denote different mechanical properties and corrosion resistance. The choice of grade affects the pipe’s strength, weldability, and suitability for specific applications. Selecting the appropriate material grade ensures that the pipes meet the required performance standards for industries like construction, automotive, and aerospace.

-

Wall Thickness: This specification indicates the thickness of the pipe walls, which directly influences the pipe’s strength and pressure rating. Thicker walls provide enhanced durability and resistance to deformation under load, making them suitable for high-pressure applications. Buyers must evaluate wall thickness based on the operational environment and expected loads to avoid failures.

-

Tolerance: Tolerance refers to the allowable variation in the dimensions of the pipe, such as diameter and length. Precise tolerances are critical in applications requiring exact fits and connections. Understanding tolerance levels helps buyers ensure compatibility with other components, minimizing the risk of assembly issues.

-

Surface Finish: The surface finish of aluminum pipes can affect corrosion resistance and aesthetic appeal. Common finishes include anodized, polished, and mill finish. Buyers should consider the environmental conditions the pipes will face—such as exposure to saltwater in coastal regions—when selecting the appropriate surface treatment.

-

Temper: The temper of aluminum pipes indicates the heat treatment process they have undergone, affecting their mechanical properties. Common tempers include T6 and T5, with T6 providing higher strength due to artificial aging. Selecting the correct temper is essential for ensuring that the pipes perform as expected under operational stresses.

Common Trade Terminology

Familiarizing yourself with industry jargon is essential for effective communication and negotiation in aluminum pipe procurement. Here are some key terms:

-

OEM (Original Equipment Manufacturer): An OEM produces parts or equipment that may be marketed by another manufacturer. Understanding the role of OEMs can help buyers identify reliable suppliers capable of producing custom aluminum pipes that meet specific requirements.

-

MOQ (Minimum Order Quantity): This term refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to assess whether a supplier’s terms align with their project needs and budget constraints.

-

RFQ (Request for Quotation): An RFQ is a formal document sent to suppliers requesting pricing information for specific products or services. Crafting a detailed RFQ can lead to more accurate quotes and better negotiations, ensuring that buyers secure favorable terms.

-

Incoterms (International Commercial Terms): These are standardized trade terms used in international contracts to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and risks during transportation, facilitating smoother international transactions.

-

Lead Time: This term refers to the time taken from placing an order until it is delivered. Understanding lead times is crucial for project planning and ensuring that materials arrive on schedule, avoiding delays in production or construction.

-

Certification: This refers to third-party validation of the quality and compliance of aluminum pipes with industry standards (e.g., ISO, ASTM). Buyers should seek certified products to ensure they meet safety and performance criteria, which can prevent costly failures and enhance product reliability.

By grasping these technical properties and trade terminologies, B2B buyers can make more strategic sourcing decisions, ultimately leading to enhanced operational efficiency and cost savings in their projects.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the aluminum pipes Sector

Global drivers and current trends are reshaping the aluminum pipes sector, making it essential for international B2B buyers to stay informed. The demand for lightweight, durable materials across industries such as construction, automotive, and energy is driving the growth of aluminum pipes. Emerging markets in Africa and South America are experiencing infrastructure booms, while established markets in Europe and the Middle East are increasingly prioritizing efficiency and sustainability. These dynamics create both opportunities and challenges for buyers, particularly in navigating supplier reliability, pricing volatility, and regulatory compliance.

Key Trends Impacting the Aluminum Pipes Market

-

Technological Advancements: Innovations in manufacturing processes, such as advanced extrusion techniques and automation, are enhancing production efficiency and reducing costs. Buyers should seek suppliers who leverage these technologies to ensure competitive pricing and quality.

-

Digital Sourcing Platforms: The rise of e-procurement tools is simplifying the sourcing process. Buyers can utilize online platforms to compare suppliers, manage contracts, and track shipments, ensuring greater transparency and efficiency in procurement.

-

Customization and Flexibility: As industries demand tailored solutions, suppliers are increasingly offering customized aluminum pipe products. B2B buyers should prioritize suppliers that can accommodate specific design requirements while maintaining quality standards.

-

Global Supply Chain Dynamics: With geopolitical tensions and trade policies influencing the supply chain, buyers must remain vigilant about sourcing strategies. Diversifying supplier bases and considering local suppliers can mitigate risks associated with disruptions.

Sustainability & Ethical Sourcing in B2B

The environmental impact of aluminum production is significant, with traditional processes contributing to high CO2 emissions. Consequently, sustainability has become a critical consideration for B2B buyers in the aluminum pipes sector. Ethical sourcing practices are essential not only for compliance with regulations but also for enhancing brand reputation and meeting consumer expectations.

-

Green Certifications: Buyers should seek suppliers that possess recognized sustainability certifications, such as ISO 14001 or LEED, which demonstrate commitment to environmental management.

-

Recycled Materials: The use of recycled aluminum in pipe manufacturing reduces energy consumption and lowers the carbon footprint. Buyers can benefit from sourcing pipes made from recycled materials, aligning their procurement strategies with sustainability goals.

-

Carbon Neutral Initiatives: Engaging with suppliers who are actively working towards carbon neutrality can significantly enhance a buyer’s sustainability profile. This includes suppliers investing in cleaner technologies, carbon capture, and renewable energy sources.

Brief Evolution/History

The aluminum pipes industry has evolved significantly over the past few decades. Initially dominated by traditional manufacturing methods, the sector has witnessed a shift towards more efficient and sustainable practices. The introduction of advanced extrusion and casting technologies has enabled higher production rates and better material properties. Moreover, the growing awareness of environmental issues has compelled manufacturers to adopt recycling processes and seek sustainable sourcing options. As a result, aluminum pipes have emerged as a preferred choice across various sectors, reflecting the changing landscape of global manufacturing and procurement.

In summary, international B2B buyers must navigate the evolving dynamics of the aluminum pipes market with a focus on technological innovations, sustainability, and strategic sourcing to remain competitive and meet the demands of their respective industries.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of aluminum pipes

-

How can I effectively vet suppliers of aluminum pipes?

When vetting suppliers, consider their industry reputation, certifications (like ISO 9001), and experience in your specific sector. Request references from past clients, especially those within your region, to gauge reliability. Evaluate their production capacity and technology to ensure they can meet your requirements. Additionally, assess their compliance with international standards, particularly regarding material quality and environmental regulations, as this can affect your supply chain’s sustainability and cost. -

What customization options are available for aluminum pipes?

Customization options often include diameter, wall thickness, length, and alloy selection based on application needs. Suppliers may also offer additional services like cutting, machining, or coating to enhance corrosion resistance. Ensure you communicate your specific requirements clearly and ask for samples or prototypes to validate the customization before placing large orders. This will help mitigate risks associated with product performance in diverse environments. -

What are typical minimum order quantities (MOQ) and lead times?

MOQs for aluminum pipes can vary significantly based on the supplier and the specific product. Generally, they may range from a few hundred to several thousand units. Lead times depend on the supplier’s production schedule, with typical ranges from 2-6 weeks for standard orders. For urgent needs, some suppliers may offer expedited services at a premium. Always clarify these details upfront to avoid disruptions in your supply chain. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should implement robust quality assurance (QA) processes, including material inspections, dimensional checks, and performance testing. Request documentation of their QA protocols and any relevant certifications (e.g., ASTM standards). Additionally, inquire about their return policies and guarantees, which can provide insights into their commitment to quality and customer satisfaction. Regular audits can also be arranged to ensure ongoing compliance with your standards. -

What certifications should aluminum pipes have for international trade?

Key certifications include ISO 9001 for quality management, ISO 14001 for environmental management, and specific alloy certifications (like ASTM or EN standards). Depending on your region, compliance with local regulations (e.g., CE marking in Europe) may also be necessary. Ensure that suppliers provide documentation to prove these certifications, as they can significantly affect your product’s acceptance in various markets and industries. -

How should I approach logistics for importing aluminum pipes?

Effective logistics management involves understanding shipping methods, customs regulations, and potential tariffs. Work with suppliers who have experience in international shipping to streamline the process. Consider partnering with a logistics provider familiar with your target markets to navigate customs clearance efficiently. Additionally, factor in lead times for both production and shipping when planning your inventory to ensure timely availability. -

What steps should I take in case of a dispute with a supplier?

In the event of a dispute, first, attempt to resolve the issue through direct communication with the supplier. Document all correspondence and agreements for reference. If resolution is not achieved, consider mediation or arbitration as alternative dispute resolution methods, which can be less costly and time-consuming than legal action. Ensure your contracts include clear terms regarding dispute resolution to protect your interests and facilitate a smoother process.

Illustrative Image (Source: Google Search)

- What factors influence the pricing of aluminum pipes in international markets?

Pricing is affected by several factors, including raw material costs, production methods, and market demand. Fluctuations in aluminum prices, driven by global supply and demand dynamics, can significantly impact your costs. Additionally, transportation fees, tariffs, and exchange rates should be considered when budgeting for international purchases. Engage in regular market analysis and supplier negotiations to secure competitive pricing while ensuring quality and reliability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for aluminum pipes

In conclusion, strategic sourcing of aluminum pipes is pivotal for international B2B buyers aiming to enhance operational efficiency and reduce costs. By understanding the nuances of aluminum fabrication processes, such as extrusion and rolling, buyers can select the most suitable materials and suppliers to meet their specific application needs. The growing global demand for aluminum, coupled with advancements in production technologies, underscores the necessity for a proactive sourcing strategy that considers factors such as supplier reliability, quality assurance, and compliance with environmental regulations.

For businesses in Africa, South America, the Middle East, and Europe, the emphasis on sustainable practices and innovative production methods is more critical than ever. As industries evolve towards greater efficiency and reduced carbon footprints, investing in advanced sourcing strategies will not only mitigate risks but also position companies as leaders in their respective markets.

We encourage international B2B buyers to leverage this guide to refine their sourcing approaches, fostering partnerships that drive value and innovation. Embrace the opportunities presented by the aluminum market and position your organization for success in the years to come.