Your Ultimate Guide to Sourcing Aluminium Oxide Ceramic

Introduction: Navigating the Global Market for aluminium oxide ceramic

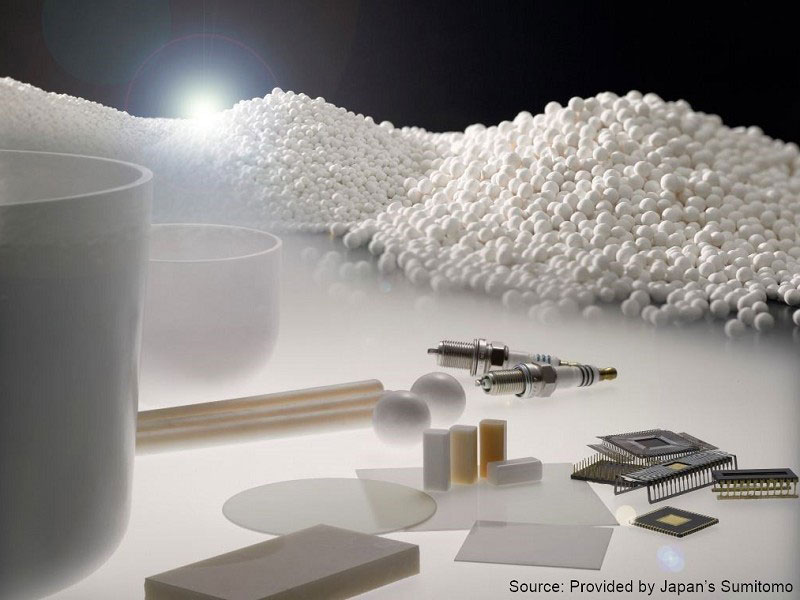

Aluminium oxide ceramic, renowned for its exceptional hardness and thermal stability, plays a pivotal role in various industries, including electronics, aerospace, and automotive. As global demand for high-performance materials continues to rise, understanding the nuances of aluminium oxide ceramics becomes crucial for B2B buyers seeking reliable and efficient sourcing solutions.

This comprehensive guide will delve into the myriad aspects of aluminium oxide ceramics, from the diverse types available to the critical materials involved in their manufacture. You will gain insights into the manufacturing processes, quality control measures, and the importance of selecting reputable suppliers. Furthermore, we will explore cost structures and market trends that influence pricing and availability.

By arming international buyers—especially those from Africa, South America, the Middle East, and Europe, including Spain and Mexico—with actionable insights, this guide empowers you to make informed sourcing decisions. Whether you are looking to procure materials for cutting-edge applications or enhance your supply chain efficiency, this resource is designed to facilitate your journey through the complex landscape of aluminium oxide ceramics. Prepare to unlock the potential of this versatile material and elevate your business operations with strategic knowledge and expert guidance.

Understanding aluminium oxide ceramic Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alpha-Alumina (α-Al2O3) | High purity, excellent hardness, and thermal stability. | Cutting tools, wear-resistant components, electronics. | Pros: High durability; Cons: Higher cost. |

| Beta-Alumina (β-Al2O3) | Lower thermal stability, good ionic conductivity. | Battery technology, solid oxide fuel cells. | Pros: Cost-effective; Cons: Limited applications. |

| Alumina Ceramics with Additives | Enhanced properties through additives (e.g., zirconia). | Aerospace, automotive, biomedical implants. | Pros: Tailored properties; Cons: More complex sourcing. |

| Porous Alumina Ceramics | High porosity, lightweight, and good thermal insulation. | Filtration, biomedical applications, catalyst supports. | Pros: Lightweight; Cons: Lower mechanical strength. |

| Alumina-Silicate Ceramics | Combination of alumina and silica, good thermal shock resistance. | Electrical insulators, thermal barriers. | Pros: Good thermal stability; Cons: Lower wear resistance. |

Alpha-Alumina (α-Al2O3)

Alpha-alumina is the most common form of aluminum oxide ceramic, known for its exceptional hardness and thermal stability. It is primarily used in applications requiring high wear resistance, such as cutting tools and components in the electronics industry. Buyers should consider the higher cost associated with this material but can benefit from its long lifespan and reliability in demanding environments.

Beta-Alumina (β-Al2O3)

Beta-alumina features lower thermal stability compared to alpha-alumina but offers good ionic conductivity. This makes it particularly suitable for applications in battery technology and solid oxide fuel cells. Its cost-effectiveness is appealing for B2B buyers; however, the limited range of applications may restrict its use in more specialized fields.

Alumina Ceramics with Additives

These ceramics incorporate various additives, such as zirconia, to enhance their properties. This type is favored in industries like aerospace, automotive, and biomedical, where customized solutions are essential. While the tailored properties can meet specific requirements, buyers should be aware of the complexities involved in sourcing and manufacturing these specialized materials.

Porous Alumina Ceramics

Porous alumina ceramics are characterized by their lightweight and high porosity, making them excellent for thermal insulation and filtration applications. They are commonly used in biomedical applications and as catalyst supports. Buyers should consider the trade-off between weight and mechanical strength, as these ceramics may not withstand heavy loads but excel in thermal management roles.

Alumina-Silicate Ceramics

These ceramics combine alumina and silica, offering good thermal shock resistance, making them suitable for electrical insulators and thermal barriers. Their ability to withstand sudden temperature changes is a key advantage. However, buyers should note that while they provide good thermal stability, they may not perform as well under wear conditions compared to other types of alumina ceramics.

Related Video: Lecture 1 Two compartment models

Key Industrial Applications of aluminium oxide ceramic

| Industry/Sector | Specific Application of aluminium oxide ceramic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Engine components and thermal barriers | High strength-to-weight ratio, heat resistance | Supplier certifications, compliance with aerospace standards |

| Electronics | Substrates for integrated circuits | Excellent electrical insulation, thermal conductivity | Quality of raw materials, reliability in supply chain |

| Medical Devices | Orthopedic implants and dental materials | Biocompatibility, durability, and wear resistance | Regulatory approvals, customization capabilities |

| Automotive | Wear-resistant components for engines | Extended lifespan, reduced maintenance costs | Material specifications, performance testing |

| Defense | Armor materials for vehicles and personnel | High impact resistance and lightweight | Proven track record in military applications, sourcing stability |

Aerospace

In the aerospace industry, aluminium oxide ceramics are utilized in engine components and thermal barriers. These materials provide a high strength-to-weight ratio, which is essential for enhancing fuel efficiency and overall performance. Additionally, their exceptional heat resistance helps protect critical components from extreme temperatures. International buyers in this sector should prioritize suppliers with certifications that comply with aerospace standards, ensuring both reliability and quality.

Electronics

Aluminium oxide ceramics serve as substrates for integrated circuits in the electronics sector. Their excellent electrical insulation properties and thermal conductivity make them ideal for supporting complex electronic components, such as capacitors and resistors. For B2B buyers in regions like Europe and South America, sourcing high-quality raw materials is crucial, along with ensuring a reliable supply chain to meet production demands.

Medical Devices

In the medical field, aluminium oxide ceramics are extensively used for orthopedic implants and dental materials. The biocompatibility and durability of these ceramics make them suitable for applications that require long-lasting performance in the human body. International buyers should focus on suppliers that can provide regulatory approvals and customization capabilities to meet specific medical requirements, ensuring compliance with health standards.

Automotive

The automotive industry employs aluminium oxide ceramics in the production of wear-resistant components for engines. These materials contribute to extending the lifespan of engine parts, resulting in reduced maintenance costs and improved vehicle performance. When sourcing, businesses must consider material specifications and conduct performance testing to ensure that components meet the rigorous demands of automotive applications.

Defense

In the defense sector, aluminium oxide ceramics are vital for manufacturing armor materials used in vehicles and personal protective equipment. Their high impact resistance and lightweight characteristics provide enhanced protection without compromising mobility. Buyers in this industry should seek suppliers with a proven track record in military applications, alongside stability in sourcing to ensure consistent availability of materials.

Related Video: Uses of Aluminium | Environmental Chemistry | Chemistry | FuseSchool

Strategic Material Selection Guide for aluminium oxide ceramic

Aluminium oxide ceramics are widely recognized for their exceptional properties, making them suitable for a variety of industrial applications. This section analyzes several common materials used in the production of aluminium oxide ceramics, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

1. High-Purity Alumina (99.5% and above)

Key Properties:

High-purity alumina exhibits excellent thermal stability, withstanding temperatures up to 1700°C. It also possesses superior corrosion resistance, making it ideal for harsh environments.

Pros & Cons:

The primary advantage of high-purity alumina is its high mechanical strength and wear resistance, which enhances the durability of end products. However, the manufacturing process can be complex and costly due to the need for high-quality raw materials and specialized processing techniques.

Impact on Application:

High-purity alumina is particularly suitable for applications in electronics and aerospace, where high thermal and chemical stability is crucial. It is compatible with aggressive media, which is essential in environments like chemical processing.

Considerations for International Buyers:

Buyers must ensure compliance with international standards such as ASTM and DIN. Additionally, sourcing from reputable suppliers who adhere to quality control measures is critical, especially in regions with stringent regulations.

2. Alumina-Titanium Composite

Key Properties:

This composite material combines alumina with titanium, enhancing toughness and wear resistance while maintaining a high-temperature rating.

Pros & Cons:

The key advantage is improved mechanical properties, making it suitable for applications where impact resistance is necessary. However, the complexity of the manufacturing process can lead to higher costs compared to standard alumina.

Impact on Application:

Alumina-titanium composites are particularly effective in cutting tools and wear-resistant components, where both hardness and toughness are required. They perform well in abrasive environments, extending the lifespan of tools.

Considerations for International Buyers:

Buyers should consider the availability of raw materials and the environmental regulations surrounding their extraction and processing. Understanding local market dynamics and compliance with international standards is also essential.

3. Low-Fired Alumina

Key Properties:

Low-fired alumina is characterized by its lower sintering temperature, which results in reduced energy consumption during manufacturing.

Pros & Cons:

The main advantage is cost-effectiveness due to lower energy requirements and faster production times. However, it may not offer the same level of strength and thermal stability as high-purity alumina.

Impact on Application:

This material is suitable for applications in the electronics industry, particularly for insulators and substrates where high performance is not critical. It is compatible with less aggressive media.

Considerations for International Buyers:

Buyers should evaluate the trade-offs in performance versus cost and ensure that the material meets the required specifications for their applications. Compliance with industry standards is also necessary to avoid issues during certification processes.

4. Reinforced Alumina

Key Properties:

Reinforced alumina incorporates additives such as silicon carbide or zirconia to enhance mechanical properties.

Pros & Cons:

The key advantage is the significant improvement in toughness and thermal shock resistance, making it suitable for demanding applications. However, the addition of reinforcements can increase manufacturing complexity and costs.

Impact on Application:

Reinforced alumina is ideal for high-performance applications, including aerospace and automotive components, where both strength and thermal stability are critical. It is compatible with a wide range of media, including corrosive environments.

Considerations for International Buyers:

International buyers should be aware of the supply chain logistics for sourcing reinforcements and the potential impact on overall costs. Additionally, they must ensure that the materials comply with local and international standards to facilitate smooth trade.

Summary Table

| Material | Typical Use Case for aluminium oxide ceramic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Purity Alumina | Electronics and aerospace applications | High thermal stability and strength | High manufacturing complexity and cost | High |

| Alumina-Titanium Composite | Cutting tools and wear-resistant components | Improved toughness and wear resistance | Higher production costs | Med |

| Low-Fired Alumina | Insulators and substrates in electronics | Cost-effective with lower energy usage | Lower strength and thermal stability | Low |

| Reinforced Alumina | Aerospace and automotive components | Enhanced toughness and thermal shock resistance | Increased manufacturing complexity and cost | High |

This guide provides essential insights for international B2B buyers, enabling them to make informed decisions when selecting materials for aluminium oxide ceramics. Understanding the properties, advantages, and limitations of each material is crucial for optimizing performance and ensuring compliance with industry standards.

In-depth Look: Manufacturing Processes and Quality Assurance for aluminium oxide ceramic

The manufacturing of aluminum oxide ceramics is a multi-stage process that requires precision and adherence to quality assurance protocols. For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, understanding these processes is crucial for making informed purchasing decisions. Below, we explore the typical manufacturing stages, quality control measures, and relevant international standards to ensure that buyers can effectively evaluate suppliers.

Manufacturing Process of Aluminum Oxide Ceramics

1. Material Preparation

The initial stage involves sourcing high-purity raw materials, primarily aluminum oxide (alumina) powder. The quality of the alumina is critical as it directly impacts the final product’s properties.

- Key Techniques:

- Purification: Raw bauxite ore undergoes refining to extract alumina, ensuring minimal impurities.

- Additives: Binders and other additives are mixed with the alumina to enhance performance characteristics such as strength and thermal stability.

2. Forming

Once the material is prepared, the next step is shaping it into the desired forms. This is typically achieved through various forming techniques:

- Pressing: This method involves compacting the alumina mixture in a mold under high pressure to form “green bodies.”

- Extrusion: For specific applications, the mixture can be extruded into continuous shapes like tubes or rods.

3. Assembly

While assembly is less common in the traditional sense for ceramics, it may involve combining various components for applications like electronics or machinery parts.

- Joining Techniques: Some products may require joining multiple ceramic pieces, which can be done through adhesive bonding or thermal bonding processes.

4. Finishing

The final stage focuses on enhancing the aesthetic and functional properties of the ceramic products.

- Drying: Green bodies are carefully dried to remove moisture, preventing defects during firing.

- Sintering: The dried ceramics are fired in kilns at high temperatures (typically above 1500°C) to achieve densification and improved mechanical properties.

- Surface Treatment: Additional treatments like glazing or coating can be applied to improve wear resistance, corrosion resistance, and surface finish.

Quality Assurance Protocols

Quality assurance is essential in the manufacturing of aluminum oxide ceramics to ensure product reliability and performance.

International Standards

B2B buyers should look for suppliers who adhere to recognized international standards:

- ISO 9001: This standard outlines the criteria for a quality management system, ensuring consistent product quality and customer satisfaction.

- CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: In industries such as oil and gas, adherence to API (American Petroleum Institute) standards is crucial for components used in drilling and production.

QC Checkpoints

The manufacturing process involves several critical quality control checkpoints:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials for quality and compliance with specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early.

- Final Quality Control (FQC): A thorough inspection of finished products ensures they meet all quality requirements before shipping.

Common Testing Methods

Various testing methods are employed to ensure product quality:

- Mechanical Testing: Assessing properties such as hardness, tensile strength, and fracture toughness.

- Thermal Testing: Evaluating thermal conductivity and stability under high temperatures.

- Dimensional Inspection: Utilizing precision measurement tools to ensure products meet specified dimensions.

Verifying Supplier Quality Control

International B2B buyers must take proactive steps to verify the quality control processes of their suppliers:

- Supplier Audits: Conducting regular audits allows buyers to assess the manufacturing processes, quality systems, and compliance with international standards.

- Quality Reports: Requesting detailed quality control reports, including test results and compliance documentation, can provide insights into a supplier’s reliability.

- Third-Party Inspections: Engaging independent inspection agencies to evaluate product quality before shipment can mitigate risks.

Quality Control Nuances for International Buyers

When sourcing aluminum oxide ceramics, international buyers should consider several nuances that may affect quality control:

- Cultural Differences: Understanding local manufacturing practices and quality expectations in regions like Africa and South America can help buyers communicate their requirements effectively.

- Regulatory Compliance: Buyers from Europe, particularly Spain, should be aware of EU regulations that govern product safety and environmental impact.

- Supply Chain Considerations: Assessing the geopolitical landscape of supplier countries can impact lead times and reliability, particularly in the Middle East.

Conclusion

For B2B buyers in diverse regions, understanding the manufacturing processes and quality assurance measures for aluminum oxide ceramics is vital. By focusing on material preparation, forming techniques, and stringent quality control protocols, buyers can ensure they select reliable suppliers. Additionally, being aware of international standards and verification methods will enhance their procurement strategies, leading to successful partnerships and high-quality product acquisitions.

Related Video: Ceramic tiles manufacturing process by Ceratec – How it’s made?

Comprehensive Cost and Pricing Analysis for aluminium oxide ceramic Sourcing

Aluminum oxide ceramics are increasingly critical in various industries due to their durability, thermal resistance, and electrical insulation properties. Understanding the cost structure and pricing nuances associated with sourcing these materials is essential for international B2B buyers, especially from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary cost driver is the high-purity alumina powder. Prices can vary significantly based on the source and purity level, with fluctuations influenced by global bauxite prices and mining regulations. Secondary materials, such as binders and additives, also contribute to overall costs.

-

Labor: Labor costs are influenced by the manufacturing location. Countries with higher wage standards may present higher labor costs but could also offer more skilled labor. In contrast, lower-wage regions may reduce costs but could impact quality.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and administrative expenses. Efficient manufacturing processes can help minimize overhead costs. Investing in technology to streamline production can result in long-term savings.

-

Tooling: Depending on the complexity of the parts being manufactured, tooling costs can vary. Custom molds and specialized machinery can be significant upfront investments, but they are essential for high-volume production.

-

Quality Control (QC): Rigorous QC processes are critical in ensuring product reliability. While these processes add to costs, they can prevent expensive recalls or replacements, thereby enhancing the overall value proposition.

Illustrative Image (Source: Google Search)

-

Logistics: Transportation and warehousing significantly impact total costs, especially for international shipments. Factors such as shipping distances, customs duties, and local taxes can substantially affect pricing.

-

Margin: Suppliers typically add a markup to cover their operational costs and profit margin. This margin can vary based on market conditions and competition.

Price Influencers

-

Volume/MOQ: Purchasing larger quantities often leads to lower per-unit costs. Understanding minimum order quantities (MOQs) is crucial for negotiating better pricing.

-

Specifications/Customization: Customized products or specialized specifications usually command higher prices due to increased production complexity. Buyers should clarify their needs upfront to avoid unexpected costs.

-

Materials Quality/Certifications: Higher-quality materials with recognized certifications (e.g., ISO, ASTM) generally come at a premium. However, these certifications can be vital for applications in highly regulated industries.

-

Supplier Factors: Supplier reputation, reliability, and service levels can influence pricing. Established suppliers may charge more, but they often offer better guarantees and support.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can significantly affect total costs. For example, opting for DDP (Delivered Duty Paid) might seem more expensive initially but can simplify logistics and reduce unexpected costs.

Buyer Tips

-

Negotiation: Don’t hesitate to negotiate pricing, especially when placing large orders. Leverage quotes from multiple suppliers to create competitive pressure.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO), which includes not just the purchase price but also factors like maintenance, logistics, and potential downtime costs.

-

Pricing Nuances for International Buyers: Understand the economic context of the supplier’s country, including currency fluctuations and local market conditions, which can impact pricing.

-

Research Local Regulations: Be aware of any import duties or taxes that may apply to aluminum oxide ceramics in your country. These can affect the overall cost and should be factored into your budget.

-

Request Indicative Prices: Always ask for indicative prices and quotes that reflect current market conditions, but be cautious as prices can fluctuate based on supply and demand dynamics.

Disclaimer

Prices provided in discussions and quotes can vary widely based on market conditions, supplier negotiations, and specific buyer requirements. Always obtain multiple quotes and conduct thorough due diligence before finalizing any purchasing decisions.

Spotlight on Potential aluminium oxide ceramic Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘aluminium oxide ceramic’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for aluminium oxide ceramic

Aluminium oxide ceramics, known for their superior mechanical, thermal, and electrical properties, are essential in various industrial applications. Understanding their technical specifications and trade terminology is crucial for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

Key Technical Properties

-

Material Grade

– Definition: Material grade indicates the purity and composition of aluminium oxide, typically classified as 99%, 95%, or lower percentages. Higher grades contain fewer impurities and offer better performance.

– Importance: Selecting the appropriate material grade is vital for applications requiring high strength, wear resistance, or thermal stability. Buyers must ensure they source the correct grade to meet their specific application needs. -

Density

– Definition: Density refers to the mass per unit volume of the ceramic material, usually measured in grams per cubic centimeter (g/cm³). Aluminium oxide ceramics generally have a density ranging from 3.5 to 4.0 g/cm³.

– Importance: A higher density often correlates with improved mechanical strength and durability, making it critical for industries such as aerospace and automotive, where component reliability is paramount. -

Flexural Strength

– Definition: Flexural strength measures the ability of a ceramic to resist deformation under load, usually expressed in megapascals (MPa). High-performance aluminium oxide ceramics can achieve flexural strengths exceeding 300 MPa.

– Importance: Understanding flexural strength helps buyers assess the suitability of ceramics for structural applications. Components that will endure significant stress must have adequate flexural strength to prevent failure. -

Thermal Conductivity

– Definition: Thermal conductivity measures how well a material can conduct heat, expressed in watts per meter-kelvin (W/m·K). Aluminium oxide ceramics typically exhibit thermal conductivities ranging from 20 to 30 W/m·K.

– Importance: High thermal conductivity is crucial for applications in electronics and thermal management systems. Buyers in these sectors should prioritize materials that effectively dissipate heat to enhance performance and longevity. -

Hardness

– Definition: Hardness indicates a material’s resistance to scratching or indentation, commonly measured using the Mohs scale or Vickers hardness tests. Aluminium oxide typically ranks around 8 to 9 on the Mohs scale.

– Importance: Hardness is a key factor for applications involving wear resistance, such as cutting tools and grinding media. Buyers should consider hardness ratings when selecting materials for abrasive environments.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships is essential for B2B buyers looking for reliable suppliers who can provide components that fit specific machinery or systems. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ helps buyers plan their purchasing strategies. Buyers should assess whether the MOQ aligns with their project needs to avoid excess inventory or unnecessary costs. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services.

– Relevance: Submitting an RFQ allows buyers to compare prices, terms, and conditions from different suppliers, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of internationally recognized rules that define the responsibilities of sellers and buyers in international transactions.

– Relevance: Familiarity with Incoterms is crucial for buyers to understand shipping responsibilities, risk management, and cost allocation during international transactions. -

Lead Time

– Definition: Lead time refers to the total time taken from placing an order to the delivery of goods.

– Relevance: Understanding lead times is essential for planning production schedules and ensuring timely project execution. Buyers should communicate clearly with suppliers about lead times to avoid delays.

By mastering these technical properties and trade terms, international B2B buyers can navigate the complexities of sourcing aluminium oxide ceramics more effectively, ensuring they select the right materials for their specific applications while optimizing procurement processes.

Illustrative Image (Source: Google Search)

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the aluminium oxide ceramic Sector

Global demand for aluminum oxide ceramics is driven by a variety of factors, including the rapid growth of the electronics and automotive industries. As a crucial material for high-performance ceramics, aluminum oxide is increasingly utilized in cutting tools, wear-resistant components, and thermal insulators. Emerging technologies, such as advanced manufacturing techniques and the integration of artificial intelligence in production processes, are transforming the sourcing landscape. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, it’s essential to stay informed about these trends to make strategic sourcing decisions.

Another significant trend is the push towards digital procurement solutions. Platforms that facilitate online sourcing and supplier verification are becoming more popular, enabling buyers to connect with manufacturers globally. Additionally, the rise of Industry 4.0 has led to improved supply chain efficiencies, which can reduce lead times and costs. International buyers should leverage these technological advancements to enhance their procurement strategies.

Lastly, geopolitical dynamics and regulatory changes are influencing the aluminum oxide market. Tariffs, trade agreements, and environmental regulations can affect sourcing strategies, particularly for businesses in regions like Europe and North America. It is crucial for buyers to monitor these developments closely to adapt their sourcing approaches accordingly.

Sustainability & Ethical Sourcing in B2B

As sustainability becomes a central focus for industries worldwide, the aluminum oxide ceramic sector is not exempt. The environmental impact of aluminum oxide production, particularly concerning bauxite mining and processing, necessitates a commitment to ethical sourcing practices. For B2B buyers, ensuring that suppliers adhere to sustainable practices can significantly enhance their brand reputation and comply with regulatory requirements.

Buyers should prioritize suppliers that have received green certifications, such as ISO 14001, which demonstrates a commitment to environmental management. Additionally, sourcing materials from suppliers that utilize recycled aluminum oxide can reduce the overall carbon footprint and support circular economy initiatives. Ethical sourcing not only aligns with corporate social responsibility goals but also increasingly influences purchasing decisions among consumers and businesses alike.

To further enhance sustainability, buyers should engage in supplier audits and assessments to ensure compliance with environmental standards. Collaborating with suppliers to improve production processes and reduce waste can also yield significant benefits. Ultimately, a focus on sustainability and ethical sourcing will drive long-term success and resilience in the aluminum oxide ceramic sector.

Brief Evolution/History

The use of aluminum oxide ceramics dates back to the early 20th century, primarily in industrial applications such as grinding and cutting tools. Over the decades, advancements in material science have expanded its applications significantly. The introduction of high-purity alumina in the 1960s marked a turning point, allowing for the development of advanced ceramics used in electronics, aerospace, and medical devices.

In recent years, the drive for innovation has propelled the industry towards developing more sustainable and efficient manufacturing processes. The evolution of aluminum oxide ceramics is characterized by a continuous pursuit of performance enhancement, making it a vital material in modern technology and industrial applications. For international B2B buyers, understanding this evolution provides context for the current market dynamics and future trends in sourcing strategies.

Related Video: Chapter 9: International Trade

Frequently Asked Questions (FAQs) for B2B Buyers of aluminium oxide ceramic

-

What criteria should I consider when vetting suppliers of aluminum oxide ceramics?

When vetting suppliers, consider their experience in the industry, production capacity, and reputation for quality. Request references from previous clients and check online reviews. Verify their certifications, such as ISO 9001, which indicates adherence to quality management standards. Additionally, assess their ability to meet your specific needs, such as customization options and lead times. Establishing clear communication and understanding their after-sales support can also be pivotal in ensuring a successful partnership. -

Can aluminum oxide ceramics be customized to meet specific requirements?

Yes, many manufacturers offer customization options for aluminum oxide ceramics, including variations in size, shape, and mechanical properties. When discussing customization, provide detailed specifications and any performance requirements your application demands. It’s advisable to work closely with the supplier’s engineering team to ensure that the end product meets your standards. Be aware that customization may affect lead times and minimum order quantities (MOQs), so clarify these aspects upfront. -

What are the typical minimum order quantities (MOQs) and lead times for aluminum oxide ceramics?

MOQs for aluminum oxide ceramics can vary significantly based on the supplier and the complexity of the products. Generally, MOQs can range from a few dozen pieces to several hundred. Lead times typically depend on the supplier’s production schedule and your order’s customization level, ranging from a few weeks to several months. Discussing these details early in the negotiation process will help set realistic expectations and avoid delays. -

What payment terms are commonly used in international transactions for aluminum oxide ceramics?

Payment terms can vary widely, but common practices include partial upfront payments (20-50%) with the balance due upon delivery or after inspection. Letters of Credit (LC) are also popular for international transactions, as they provide security for both parties. Understand your supplier’s preferred payment methods and negotiate terms that protect your interests while ensuring they have the cash flow needed for production. Always clarify any additional fees related to currency conversion or international transactions. -

What quality assurance measures should I expect from suppliers of aluminum oxide ceramics?

Reputable suppliers should implement rigorous quality assurance (QA) processes throughout production. This includes raw material testing, in-process inspections, and final product evaluations. Request information about their QA protocols and any relevant certifications. It’s also beneficial to inquire about the availability of test reports or certifications for your specific order, which can validate the product’s quality and compliance with industry standards. -

How should I handle logistics and shipping for international orders of aluminum oxide ceramics?

When arranging logistics, consider the total cost of shipping, including freight, insurance, and customs duties. Choose a reliable freight forwarder experienced in handling ceramics to ensure safe delivery. Discuss with your supplier whether they handle shipping or if you need to arrange it. Be aware of any potential delays at customs and ensure all necessary documentation is complete to avoid complications. Establish clear communication with your supplier regarding shipping timelines and tracking. -

What steps can I take to resolve disputes with suppliers of aluminum oxide ceramics?

To effectively resolve disputes, first attempt to address the issue directly with the supplier through clear and respectful communication. Document all correspondence for reference. If direct communication fails, refer to the terms of your contract regarding dispute resolution processes, which may include mediation or arbitration. Consider involving a third party to facilitate discussions if necessary. Always maintain professionalism, as a positive relationship can lead to better outcomes in resolving issues. -

What certifications should I look for in aluminum oxide ceramics?

Look for certifications that indicate compliance with industry standards, such as ISO 9001 for quality management systems and ISO 14001 for environmental management. Depending on your application, additional certifications may be relevant, such as RoHS for hazardous substances or ASTM standards for specific material properties. These certifications provide assurance of the product’s quality and safety, which is especially important for applications in sensitive industries like aerospace or healthcare.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for aluminium oxide ceramic

Strategic sourcing of aluminium oxide ceramics is essential for international B2B buyers aiming to enhance their operational efficiency and product quality. As a high-performance material, aluminium oxide ceramics are crucial in various applications, from aerospace to electronics. Buyers should prioritize suppliers with robust quality control measures, proven track records, and the ability to customize solutions to meet specific needs.

Key Takeaways for B2B Buyers:

- Evaluate Supplier Reputation: Focus on manufacturers known for high-quality production and reliability in supply chain management.

- Consider Bulk Purchasing: Wholesale options can significantly reduce costs while ensuring that your production needs are met without delays.

- Assess Market Trends: Stay informed about global demand fluctuations, particularly in regions rich in bauxite reserves, as this will impact sourcing strategies.

As we look ahead, the demand for aluminium oxide ceramics is expected to grow, driven by advancements in technology and increased applications across industries. Buyers from Africa, South America, the Middle East, and Europe, including Spain and Mexico, should leverage strategic sourcing to secure competitive advantages in their respective markets. Engage with reputable suppliers today to position your business for future growth and innovation.