Master the Art of Sourcing Grated Metal Sheet for Optimal

Introduction: Navigating the Global Market for grated metal sheet

Unlocking the potential of the grated metal market is essential for international B2B buyers engaged in infrastructure, construction, and industrial projects. Grated metal products—such as platform gratings, safety walkways, and drainage covers—are integral to modern development, providing safety, durability, and functional versatility. As urban landscapes evolve across regions like Africa, South America, the Middle East, and Europe, the demand for high-quality grated metal solutions continues to grow, making informed sourcing a critical success factor.

This comprehensive guide serves as your roadmap to navigating the complexities of grated metal procurement. It delves into various types of grated metal, including welded, press-locked, and swage-locked options, each tailored for specific applications and environments. Buyers will gain insights into material selection, assessing the benefits of steel, stainless steel, aluminum, and specialty alloys, alongside an understanding of manufacturing and quality control processes that ensure product reliability.

Additionally, the guide addresses supplier evaluation, offering strategies to identify reputable partners who align with your project requirements. It also covers cost benchmarking and provides an overview of current market trends to help buyers stay ahead in a competitive landscape. Common challenges and frequently asked questions are answered, equipping you with the knowledge to make confident, future-proof procurement choices. Empower your sourcing strategy with actionable insights that foster operational efficiency and long-term value in the global grated metal marketplace.

Understanding grated metal sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Welded Bar Grating | Crossbars welded to bearing bars at each intersection | Industrial flooring, walkways, platforms | Pros: Strong, cost-effective; Cons: Less customizable than other types |

| Press-Locked Grating | Bearing and cross bars pressure-locked without welding | Architectural facades, public spaces | Pros: Clean aesthetics, precise tolerance; Cons: Higher cost, not for heavy loads |

| Swage-Locked Grating | Crossrods swaged into bearing bars | Oil & gas, marine, chemical processing | Pros: Lightweight, corrosion-resistant; Cons: May need special orders for large spans |

| Riveted Grating | Components fastened by riveting | Vintage renovations, bridges, heavy-duty sectors | Pros: Outstanding durability; Cons: Generally higher cost and weight |

| Perforated Metal Grating | Sheet metal punched with patterns of holes or slots | Slip-resistant flooring, filtration, ventilation | Pros: Superior drainage, anti-slip; Cons: Lower load-bearing than bar gratings |

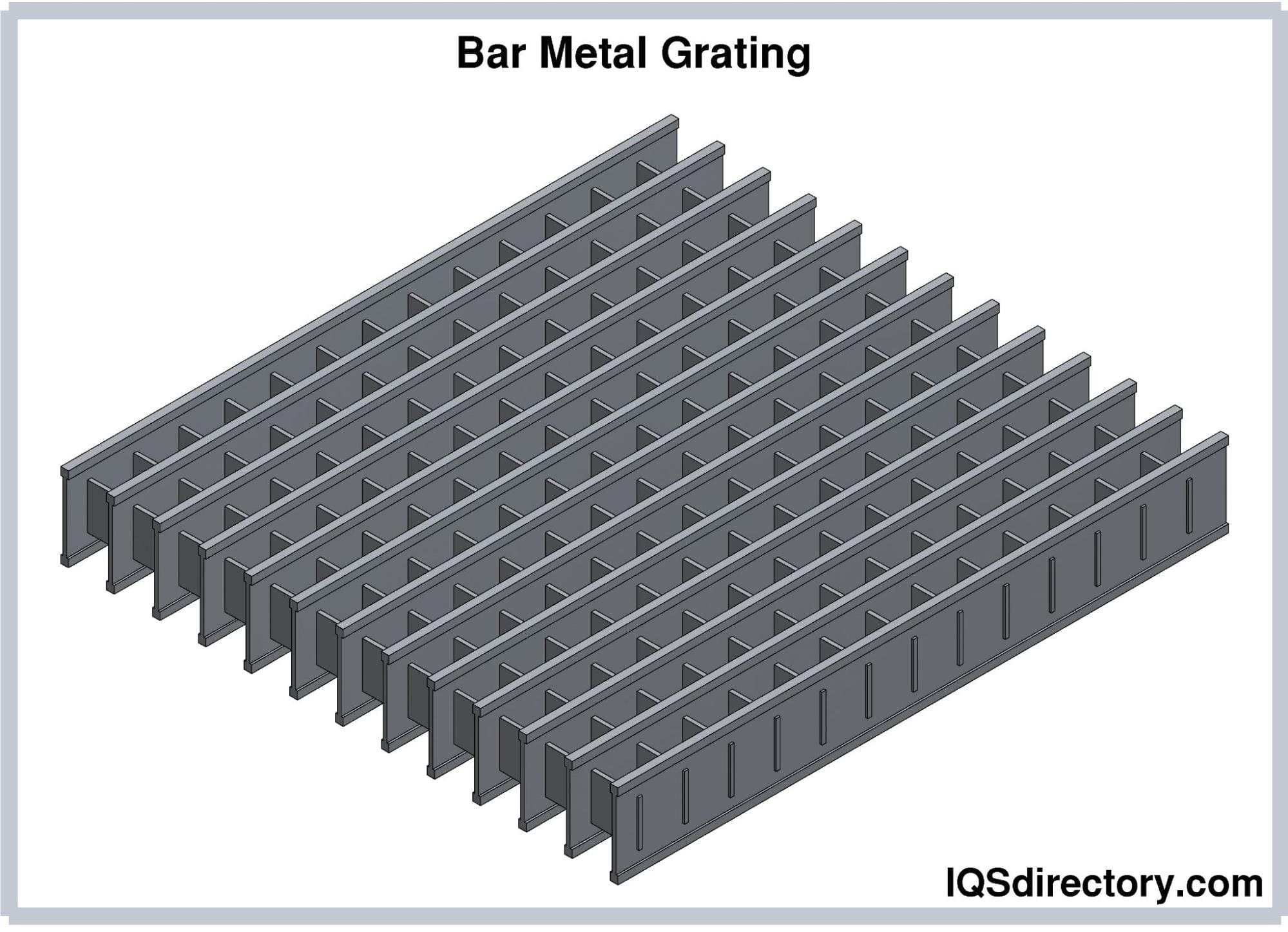

Welded Bar Grating

Welded bar grating is the most common type of grated metal, characterized by the welding of crossbars to bearing bars at every intersection. This design provides exceptional strength and rigidity, making it ideal for demanding industrial applications such as factory floors, walkways, and platforms. For B2B buyers, the primary considerations include load requirements, compliance with local standards, and potential corrosion treatments, especially in harsh environments. The cost-effectiveness of this type makes it a popular choice for large-scale projects.

Press-Locked Grating

Press-locked grating features bearing and cross bars that are interlocked under high pressure, eliminating the need for welding. This results in a sleek, uniform appearance, making it suitable for architectural applications and public spaces where aesthetics are important. While it offers precise tolerances and a modern look, the cost tends to be higher, and it is generally designed for lighter loads. Buyers should consider the specific load-bearing requirements and whether the visual appeal justifies the additional expense.

Swage-Locked Grating

Swage-locked grating utilizes a process where crossrods are pressed into pre-punched holes of the load bars, creating a lightweight yet strong structure. This type is favored in industries like oil & gas and marine applications due to its corrosion resistance and reduced weight. B2B buyers should evaluate material certifications and potential customization options for load and span requirements. While it may require special orders for larger spans, its durability and lightweight nature can lead to significant operational efficiencies.

Riveted Grating

Riveted grating is constructed by fastening the cross bars and bearing bars with rivets, offering superior impact resistance and longevity. This type is often seen in vintage renovations, bridges, and heavy-duty industrial applications due to its robust construction. While the initial costs and weight are generally higher, the durability and lower maintenance needs in demanding environments can provide long-term savings. Buyers should assess the specific application requirements to determine if the benefits align with their project goals.

Perforated Metal Grating

Perforated metal grating is made from sheet metal that is punched with patterns of holes or slots, providing excellent drainage and slip resistance. This type is frequently used in flooring, filtration systems, and ventilation panels. Although it offers unique advantages like anti-slip properties, it typically has lower load-bearing capabilities compared to other types of grating. B2B buyers should carefully consider the specific application and environmental factors to ensure that this type meets their operational needs while aligning with safety standards.

Related Video: Lecture 1 Two compartment models

Key Industrial Applications of grated metal sheet

| Industry/Sector | Specific Application of grated metal sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Safety walkways and platforms | Enhances worker safety, reduces liability | Load capacity, corrosion resistance, compliance with local standards |

| Oil & Gas | Grated platforms for drilling rigs and refineries | Provides durable, slip-resistant surfaces in hazardous environments | Material certifications, customization for environmental conditions |

| Manufacturing | Industrial flooring and drainage systems | Improves operational efficiency and safety | Load requirements, anti-corrosion treatments, maintenance needs |

| Transportation | Grated surfaces for bridges and railways | Increases safety and stability, supports heavy loads | Compliance with engineering standards, weight restrictions, local regulations |

| Agriculture | Grated drainage covers for irrigation systems | Prevents flooding, enhances water management | Material durability, resistance to chemicals, local sourcing options |

In the construction industry, grated metal sheets are essential for creating safety walkways and platforms. These applications enhance worker safety by providing slip-resistant surfaces, reducing the risk of accidents, and consequently minimizing liability for businesses. International buyers should consider the load capacity and corrosion resistance of the materials, ensuring compliance with local construction standards to meet safety regulations.

The oil and gas sector heavily relies on grated platforms for drilling rigs and refineries. Grated metal sheets provide durable, slip-resistant surfaces that are crucial in hazardous environments, where safety is paramount. Buyers must ensure that materials meet specific certifications for harsh conditions, and customization may be necessary to cater to environmental factors such as exposure to chemicals and extreme weather.

In manufacturing, grated metal sheets are widely used for industrial flooring and drainage systems. These applications not only enhance operational efficiency but also contribute to worker safety by providing robust surfaces that can withstand heavy machinery and foot traffic. Buyers should focus on load requirements, anti-corrosion treatments, and ease of maintenance to ensure long-lasting performance in demanding environments.

For the transportation industry, grated surfaces are utilized in the construction of bridges and railways. This application is critical for increasing safety and stability, as it supports heavy loads while allowing for drainage. B2B buyers must ensure compliance with engineering standards and consider weight restrictions, along with local regulations, to guarantee that their projects adhere to safety protocols.

In agriculture, grated drainage covers are employed in irrigation systems to prevent flooding and enhance water management. This application is vital for maintaining optimal soil conditions and crop health. Buyers should prioritize material durability and resistance to chemicals, while also considering local sourcing options to support regional supply chains and reduce lead times.

Related Video: Forming Sheet Metal & Metal Forming Tools – Uses Explained By Gene Winfield at SEMA

Strategic Material Selection Guide for grated metal sheet

When selecting materials for grated metal sheets, B2B buyers must consider various factors that impact performance, cost, and application suitability. Below is an analysis of four common materials used in grated metal sheets, focusing on their key properties, advantages, disadvantages, and specific considerations for international buyers.

Steel

Steel is a widely used material for grated metal sheets due to its strength and versatility. It typically offers excellent load-bearing capacity and can withstand high pressures, making it suitable for heavy-duty applications such as industrial flooring and walkways. However, steel is prone to corrosion unless treated or coated, which can increase maintenance costs over time.

Pros: Steel is durable, cost-effective, and readily available. Its high strength-to-weight ratio allows for efficient design in load-bearing applications.

Cons: The primary limitation is its susceptibility to rust, especially in humid or corrosive environments. Additionally, steel can be heavier than alternative materials, which may complicate installation.

Impact on Application: Steel is compatible with various media, including chemicals and heavy machinery. However, buyers must ensure appropriate coatings or treatments are applied for specific environments.

Considerations for Buyers: Compliance with local standards such as ASTM or DIN is crucial. Buyers in regions like South Africa or Brazil should also consider the availability of treated steel to mitigate corrosion risks.

Aluminum

Aluminum is another popular choice for grated metal sheets, particularly in applications where weight is a concern. It is lightweight, corrosion-resistant, and has good thermal conductivity. These properties make aluminum ideal for use in aerospace and automotive industries, as well as in architectural applications.

Pros: The main advantages of aluminum include its lightweight nature, ease of fabrication, and resistance to corrosion. This material can be anodized to enhance its durability and aesthetic appeal.

Cons: Aluminum is generally more expensive than steel and may not provide the same load-bearing capacity, making it less suitable for heavy-duty applications.

Impact on Application: Aluminum is particularly effective in environments where corrosion resistance is critical, such as coastal areas or chemical plants.

Considerations for Buyers: International buyers must consider the cost fluctuations of aluminum and ensure that suppliers comply with relevant standards, such as JIS or ASTM, to guarantee quality.

Stainless Steel

Stainless steel is renowned for its exceptional corrosion resistance and hygienic properties, making it an excellent choice for applications in the food processing and pharmaceutical industries. It can withstand extreme temperatures and pressures, ensuring reliability in demanding environments.

Pros: The key advantages of stainless steel include its long lifespan, low maintenance requirements, and resistance to staining and corrosion.

Cons: The primary drawback is its higher cost compared to carbon steel and aluminum, which may impact budget considerations for large-scale projects.

Impact on Application: Stainless steel is ideal for environments that require cleanliness and durability, such as hospitals and food processing plants.

Considerations for Buyers: Buyers should ensure compliance with health and safety standards, particularly in the food and medical sectors. Understanding regional preferences for specific grades of stainless steel is also essential.

Composite Materials

Composite materials, such as fiberglass-reinforced plastic (FRP), are increasingly used in grated metal sheets due to their lightweight and corrosion-resistant properties. These materials are particularly effective in environments where traditional metals may fail due to chemical exposure or extreme weather conditions.

Pros: Composites are lightweight, non-corrosive, and can be molded into various shapes, providing design flexibility.

Cons: The main limitations include lower load-bearing capacity compared to metals and potential higher costs for specialized applications.

Impact on Application: Composites are suitable for chemical processing and marine applications where exposure to harsh conditions is common.

Considerations for Buyers: Buyers must assess the specific requirements of their applications and ensure compliance with relevant standards. Understanding the regional market for composites is also critical, as availability may vary.

Summary Table

| Material | Typical Use Case for grated metal sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Industrial flooring, walkways | Durable and cost-effective | Prone to corrosion | Medium |

| Aluminum | Aerospace, automotive, architectural | Lightweight and corrosion-resistant | Higher cost, lower load capacity | High |

| Stainless Steel | Food processing, pharmaceuticals | Exceptional corrosion resistance | Higher cost | High |

| Composite Materials | Chemical processing, marine applications | Lightweight and design flexibility | Lower load capacity | Medium to High |

In-depth Look: Manufacturing Processes and Quality Assurance for grated metal sheet

Manufacturing Processes for Grated Metal Sheet

The manufacturing of grated metal sheets involves several distinct stages, each critical to achieving the desired quality and functionality. Understanding these processes allows international B2B buyers to make informed decisions and ensure that the products meet their specific needs.

Material Preparation

The first step in the production of grated metal sheets is material preparation. This involves selecting the appropriate raw materials, which can include various metals such as steel, stainless steel, aluminum, and specialty alloys. The materials are often sourced based on their mechanical properties, corrosion resistance, and suitability for the intended application.

Once the materials are selected, they undergo cutting to manageable sizes. This is typically done using plasma cutting or laser cutting techniques, which provide precision and minimize waste. During this phase, it’s essential to verify the material certifications to ensure compliance with industry standards.

Forming

After preparation, the next stage is forming. This involves shaping the raw materials into the desired configurations. Key techniques in this stage include:

- Welding: For welded bar gratings, crossbars are welded to the bearing bars at each intersection. This method provides high strength and rigidity.

- Press-Locking: In press-locked gratings, high pressure is used to interlock the bearing bars and crossbars without welding, resulting in a cleaner aesthetic.

- Swage-Locking: This involves swaging crossrods through pre-punched holes in bearing bars, suitable for lightweight applications.

- Riveting: This traditional method involves fastening components using rivets, often used in heavy-duty applications.

Each of these techniques has its advantages and applications, and buyers should consider the specific requirements of their projects when evaluating options.

Assembly

Once the individual components are formed, they are assembled into gratings. This may involve additional welding, locking, or riveting based on the design specifications. During assembly, it is crucial to adhere to strict dimensional tolerances to ensure the final product meets design requirements.

Moreover, for buyers concerned with safety and performance, it is advisable to inquire about the assembly methods used, as this can affect the durability and load-bearing capacity of the gratings.

Finishing

The final stage of manufacturing is finishing, which enhances the aesthetic and functional properties of the grated metal sheets. Finishing processes may include:

- Surface Treatments: These can include galvanization for corrosion resistance, powder coating for aesthetics, or anodizing for aluminum products.

- Quality Inspection: Before the final product is shipped, it undergoes thorough inspection and testing to ensure it meets specified standards.

Buyers should discuss finishing options with suppliers to ensure compatibility with their project requirements, particularly in terms of environmental exposure and maintenance.

Quality Assurance in Grated Metal Production

Quality assurance (QA) is a critical component of the manufacturing process for grated metal sheets. It ensures that the final products meet the specified standards and are fit for their intended applications. International buyers should be aware of the relevant standards and quality control measures employed by suppliers.

International Standards

Several international standards govern the quality assurance processes in the manufacturing of grated metal sheets:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS). Suppliers certified to ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold in the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: In industries like oil and gas, adherence to American Petroleum Institute (API) standards is crucial for ensuring the quality and safety of materials used.

Buyers should verify that their suppliers are compliant with these standards, as this not only signifies quality but also mitigates risks associated with product failures.

Quality Control Checkpoints

Effective quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specified quality criteria.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor compliance with production standards and specifications.

- Final Quality Control (FQC): This final inspection phase ensures that the finished products meet all design and quality requirements before shipping.

By understanding these QC checkpoints, buyers can better assess the reliability of their suppliers.

Common Testing Methods

To ensure the integrity and performance of grated metal sheets, various testing methods are employed, including:

- Load Testing: To assess the load-bearing capacity of gratings.

- Corrosion Testing: To evaluate the resistance of materials to environmental factors.

- Dimensional Inspection: To confirm that products meet specified dimensions and tolerances.

Buyers should request documentation of testing procedures and results to gain confidence in the quality of the products they are procuring.

Verifying Supplier Quality Control

When sourcing grated metal sheets, B2B buyers must take proactive steps to verify the quality control practices of their suppliers. Here are some actionable strategies:

- Supplier Audits: Conducting regular audits of suppliers can help assess their adherence to quality standards and manufacturing processes. This can be done through on-site visits or remote assessments.

- Requesting Quality Reports: Buyers should ask suppliers for detailed quality reports that document testing results, compliance with standards, and production metrics.

- Third-Party Inspections: Engaging third-party inspection services can provide an independent evaluation of the supplier’s quality control processes and product integrity.

Navigating Quality Control Nuances

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Regional regulations, material availability, and logistical considerations can all impact quality assurance practices.

- Cultural and Regulatory Differences: Buyers should be aware of the local regulations governing manufacturing and quality standards in the supplier’s country. This knowledge can help ensure compliance and mitigate risks.

- Material Sourcing: In regions with fluctuating material availability, buyers should verify the sourcing practices of their suppliers to ensure consistent quality and performance.

By implementing these strategies and understanding the manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions and secure high-quality grated metal sheets that meet their operational needs.

Related Video: Galvanized Steel Metal Sheet Milk Cans Manufacturing Process

Comprehensive Cost and Pricing Analysis for grated metal sheet Sourcing

When sourcing grated metal sheets, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. The costs associated with grated metal sheet procurement can be categorized into several key components:

Cost Components

-

Materials: The choice of material significantly impacts the overall cost. Common materials include carbon steel, stainless steel, and aluminum, each with varying prices based on market demand and availability. Stainless steel, for example, tends to be the most expensive due to its corrosion resistance and durability.

-

Labor: Labor costs involve the workforce required for manufacturing, assembly, and installation. This can vary by region; for instance, labor is generally less expensive in South America compared to Europe, which can influence sourcing decisions.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Understanding these costs can help buyers gauge the pricing structure of different suppliers.

-

Tooling: Depending on the complexity of the design and specifications, tooling costs can vary significantly. Custom designs may require specialized tooling, which adds to the initial investment.

-

Quality Control (QC): Ensuring the quality of grated metal sheets is critical, especially for applications in safety-sensitive environments. QC processes may involve additional costs but are essential for maintaining compliance with industry standards.

-

Logistics: Transportation and handling costs play a crucial role in the total cost of ownership. Factors such as distance, mode of transport, and shipping regulations must be considered, especially for international shipments.

-

Margin: Suppliers typically add a profit margin to their costs. This can vary based on market conditions, supplier reputation, and the complexity of the order.

Price Influencers

Several factors influence the pricing of grated metal sheets:

-

Volume/MOQ: Larger orders often attract discounts. Understanding the minimum order quantities (MOQ) can help buyers leverage better pricing.

-

Specifications/Customization: Custom designs or specific tolerances can lead to higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials: The choice of metal affects not only the price but also the long-term performance and maintenance costs. Buyers should weigh the upfront costs against the durability and lifespan of the materials.

-

Quality/Certifications: Suppliers offering certified products may charge a premium. However, these certifications can provide assurance of quality and compliance with local regulations.

-

Supplier Factors: The supplier’s location, reputation, and financial stability can influence pricing. Established suppliers may offer better reliability but at a higher price.

-

Incoterms: The chosen Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers concerning shipping, risk, and costs. Understanding these terms is crucial to avoid hidden fees.

Buyer Tips

To optimize costs and ensure effective procurement, consider the following strategies:

-

Negotiate: Don’t hesitate to negotiate pricing, especially for larger orders. Suppliers may offer better terms to secure significant contracts.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership, including installation and maintenance costs, rather than just the purchase price. Sometimes, a higher upfront cost can lead to lower overall expenses.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, tariffs, and taxes that can impact final costs.

-

Local Market Insights: Leverage local market knowledge and relationships to negotiate better prices and terms, particularly in regions like Africa and South America where local suppliers may offer competitive advantages.

-

Request Detailed Quotes: Always ask for itemized quotes from suppliers to understand the breakdown of costs. This can aid in comparing offers and identifying areas for negotiation.

In conclusion, navigating the cost structure and pricing of grated metal sheets requires careful consideration of various factors. By understanding these components and employing strategic sourcing techniques, international B2B buyers can achieve significant cost savings and enhance their procurement outcomes.

Spotlight on Potential grated metal sheet Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘grated metal sheet’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for grated metal sheet

Understanding the technical properties and terminology associated with grated metal sheets is essential for international B2B buyers. This knowledge not only aids in making informed procurement decisions but also helps in navigating supplier negotiations and project specifications.

Critical Specifications for Grated Metal Sheets

-

Material Grade

The material grade refers to the specific classification of the metal used, such as steel, stainless steel, or aluminum. Each grade has unique properties that affect strength, corrosion resistance, and suitability for various applications. For B2B buyers, selecting the appropriate material grade ensures that the product meets the required performance standards, particularly in demanding environments. -

Load Capacity

Load capacity indicates the maximum weight a grated metal sheet can safely support. This specification is crucial for applications such as industrial flooring or walkways, where safety and durability are paramount. Buyers should assess load capacity based on the intended use to avoid potential safety hazards or structural failures.

Illustrative Image (Source: Google Search)

-

Thickness

Thickness is a critical dimension that impacts both the strength and weight of the grated metal sheet. Typically measured in millimeters, the thickness should align with the specific application requirements. For instance, thicker sheets may be necessary for heavy-duty applications, while lighter thicknesses might suffice for decorative or non-load-bearing uses. -

Tolerance

Tolerance refers to the allowable deviation from specified dimensions during manufacturing. This specification is vital for ensuring that the grated metal sheets fit precisely within a larger assembly or structure. Buyers must consider tolerance levels to avoid complications during installation and to ensure compatibility with other components.

Illustrative Image (Source: Google Search)

-

Surface Finish

The surface finish of a grated metal sheet affects its appearance and resistance to corrosion. Common finishes include galvanized, powder-coated, or untreated. For B2B buyers, choosing the right surface finish can enhance the aesthetic appeal while providing necessary protection against environmental factors. -

Weight per Unit Area

This specification indicates how much a given area of the grated metal sheet weighs. It is essential for logistics, as it influences shipping costs and handling requirements. Buyers should factor in weight when planning transportation and installation processes.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking for high-quality components that meet specific standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is important for B2B buyers to understand as it affects budgeting and inventory management. Buyers should negotiate MOQs to align with their project needs and financial constraints. -

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotes from suppliers for specific products or services. Crafting a detailed RFQ ensures that suppliers provide accurate pricing and terms, facilitating better comparison and decision-making. -

Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms that define the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with Incoterms is essential for international transactions, as they clarify cost allocation, risk management, and transportation responsibilities. -

Lead Time

Lead time is the period between placing an order and the delivery of the product. For B2B buyers, understanding lead times helps in project planning and ensures that timelines are met without unnecessary delays. -

Certification

Certification refers to the verification that a product meets specific standards set by regulatory bodies. Certifications are crucial for ensuring compliance with safety, quality, and environmental regulations, providing buyers with confidence in their procurement choices.

By understanding these critical specifications and trade terms, B2B buyers can navigate the grated metal market with greater confidence, ensuring they select the right products for their projects while optimizing supplier interactions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the grated metal sheet Sector

Market Overview & Key Trends

The grated metal sheet market is currently experiencing dynamic shifts, driven by several global factors. Urbanization in regions such as Africa and South America is spurring demand for infrastructure projects, which require durable and versatile materials like grated metal. Additionally, the growth of sectors such as renewable energy and industrial manufacturing in the Middle East and Europe is increasing the need for customized grated metal solutions.

One of the most significant trends is the adoption of advanced manufacturing technologies, including automation and digital fabrication. These innovations enable suppliers to offer tailored solutions that meet the specific requirements of B2B buyers, from custom dimensions to unique load-bearing specifications. Furthermore, the rise of Industry 4.0 is enhancing supply chain transparency and efficiency, allowing buyers to track their materials from production to delivery.

Sourcing trends are also evolving, with a growing emphasis on local suppliers to mitigate supply chain disruptions. Buyers are increasingly seeking regional partners who understand local regulations and can provide timely delivery. Moreover, sustainability is emerging as a central theme in procurement decisions, with B2B buyers prioritizing suppliers who demonstrate a commitment to environmentally friendly practices.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration for B2B buyers in the grated metal sheet sector. The environmental impact of production processes, including resource consumption and waste generation, is prompting companies to seek greener alternatives. This shift is not only beneficial for the planet but also enhances brand reputation and aligns with the values of increasingly eco-conscious consumers.

Ethical sourcing practices are gaining traction as buyers demand transparency in their supply chains. This includes ensuring that materials are sourced from suppliers who adhere to labor rights and fair trade principles. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) can provide reassurance to buyers about the sustainability of their suppliers.

In terms of materials, opting for recycled metals or those with low embodied energy can significantly reduce the environmental footprint of projects. B2B buyers should actively seek suppliers who offer sustainable options and can demonstrate their commitment through certifications and documented practices.

Brief Evolution/History

The use of grated metal sheets has evolved significantly over the decades. Initially, these materials were primarily utilized in heavy industrial applications, such as manufacturing and construction, where durability was paramount. However, advancements in metalworking technology have diversified the applications of grated metal sheets, allowing for their use in architectural design and public spaces.

Today, the market encompasses a range of products that not only fulfill functional requirements but also contribute to aesthetic and sustainable building practices. As industries continue to innovate, the future of grated metal sheets promises even more customization and efficiency, driven by technological advancements and a commitment to sustainability.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of grated metal sheet

-

How can I effectively vet international suppliers of grated metal sheets?

To vet international suppliers, start by researching their reputation through industry reviews and testimonials. Verify their certifications, such as ISO 9001 for quality management, to ensure they meet international standards. Request references from past clients, particularly those in your region, to gauge reliability and performance. Evaluate their production capabilities and ask for samples to assess quality firsthand. Finally, consider their responsiveness and communication skills, as these are crucial for ongoing collaboration. -

What customization options should I consider when sourcing grated metal sheets?

Customization is vital for ensuring that the grated metal sheets meet specific project requirements. Key factors include material selection, dimensions, load-bearing capabilities, and surface treatments (like anti-corrosion coatings). Discuss your design specifications with potential suppliers to understand their capabilities for custom fabrication. Additionally, inquire about the minimum order quantity (MOQ) for customized products, as this can vary significantly between suppliers. -

What are typical lead times and minimum order quantities (MOQ) for grated metal sheets?

Lead times for grated metal sheets can vary based on the supplier’s location, production capacity, and the complexity of your order. Generally, expect lead times of 4-8 weeks for standard products and longer for custom orders. Minimum order quantities (MOQ) can also differ; some suppliers may offer low MOQs for standard items, while custom orders may require larger quantities. Always confirm these details upfront to align your project timelines with supplier capabilities. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should have robust quality assurance processes in place, including in-house testing and third-party inspections. Look for certifications like ISO 9001, which indicates a commitment to quality management. Suppliers should also provide documentation of material certifications, such as ASTM standards, to verify compliance with industry specifications. Discuss their quality control procedures, including how they handle defects and ensure consistent product quality. -

How should I manage logistics when sourcing grated metal sheets internationally?

Managing logistics for international sourcing involves coordinating shipping, customs clearance, and delivery timelines. Work with suppliers who have experience in exporting to your region and can provide detailed shipping options. Consider using freight forwarders to streamline the process, ensuring compliance with local regulations. Additionally, factor in delivery costs and potential delays at customs, as these can impact your overall project timeline and budget. -

What steps can I take to resolve disputes with suppliers?

To resolve disputes with suppliers, first, ensure that all agreements are documented clearly, including specifications, timelines, and payment terms. Maintain open communication to address issues as they arise, and try to negotiate a solution collaboratively. If necessary, refer to your contract’s dispute resolution clause, which may include mediation or arbitration procedures. In extreme cases, consider involving legal counsel to protect your interests, especially in cross-border transactions. -

What payment terms are common in international grated metal sheet transactions?

Payment terms can vary widely based on supplier policies, the buyer’s creditworthiness, and the transaction’s size. Common methods include advance payment, letters of credit, and payment upon delivery. It’s advisable to negotiate terms that mitigate risk while ensuring supplier confidence. Establishing a clear payment schedule tied to project milestones can help maintain cash flow and ensure accountability from both parties. -

How can I stay informed about market trends affecting grated metal sheet prices?

Staying informed about market trends requires active engagement with industry news and analysis. Subscribe to relevant trade publications and follow market reports that discuss commodity pricing, supply chain dynamics, and technological advancements. Networking with industry peers and participating in trade shows can also provide insights into emerging trends. Additionally, leveraging market intelligence platforms can help you anticipate price fluctuations and make informed purchasing decisions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for grated metal sheet

In today’s competitive global market, strategic sourcing of grated metal sheets is essential for international B2B buyers aiming to enhance operational efficiency and project sustainability. By thoroughly understanding the various types of gratings—such as welded, press-locked, and swage-locked—buyers can select materials that align with specific project requirements, ensuring both performance and compliance with safety standards.

Key takeaways include:

– Evaluate the material properties and fabrication techniques that best suit your application, whether it be for industrial flooring or architectural features.

– Conduct comprehensive supplier assessments to ensure reliability, quality, and cost-effectiveness, particularly when sourcing from diverse regions like Africa, South America, the Middle East, and Europe.

– Stay informed on emerging market trends and technological advancements that can influence sourcing decisions and operational efficiencies.

As global infrastructure demands grow, now is the time for buyers to leverage strategic sourcing to mitigate risks and unlock new opportunities. Embrace a proactive approach to procurement, and position your business for success in an increasingly interconnected marketplace. The future of your projects depends on the choices you make today—let’s build a resilient tomorrow together.