Master Sourcing Close Cell Foam: Essential Guide for B2B

Introduction: Navigating the Global Market for close cell foam

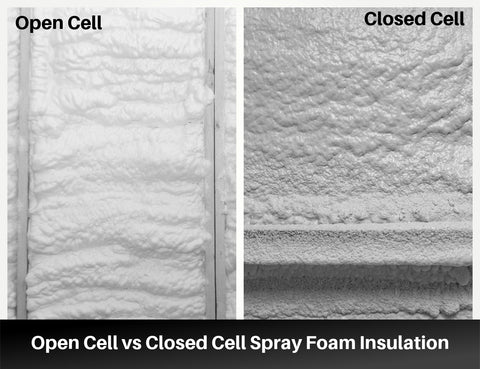

In today’s rapidly evolving global market, closed cell foam stands out as a crucial material across various industries, including automotive, healthcare, and construction. Its unique properties—such as water resistance, thermal insulation, and superior shock absorption—make it indispensable for applications ranging from protective packaging to specialized insulation solutions. Understanding the diverse types and applications of closed cell foam is vital for B2B buyers looking to optimize their sourcing strategies.

This comprehensive guide delves into the intricacies of closed cell foam, covering essential topics such as material types, manufacturing processes, and quality control measures. Buyers will gain insights into various formulations, including polyethylene, cross-linked polyethylene, and neoprene, each tailored to specific industry needs. Additionally, the guide will highlight reputable suppliers, pricing structures, and market trends that can influence purchasing decisions.

For international buyers from regions like Africa, South America, the Middle East, and Europe, this resource empowers informed sourcing decisions by equipping them with actionable insights and industry knowledge. By understanding the nuances of closed cell foam, buyers can better navigate the global market landscape, ensuring they select the right materials that align with their operational requirements and budget constraints. With this guide, you can confidently engage in strategic sourcing that enhances product performance and drives business success.

Understanding close cell foam Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Polyethylene Foam | Excellent strength-to-weight ratio; moisture, chemical, and stain resistance | Protective packaging, medical devices, insulation | Pros: Lightweight, flexible, cost-effective; Cons: Limited thermal resistance compared to others. |

| Cross-Linked Polyethylene Foam | Enhanced resilience; superior chemical and temperature resistance | HVAC insulation, sports padding, automotive interiors | Pros: Durable, aesthetically appealing; Cons: Higher cost than standard polyethylene. |

| Polystyrene Foam | High rigidity; available in various densities | Storage, packaging, construction | Pros: Strong and protective; Cons: Less flexible, can be brittle. |

| Neoprene Rubber Foam | Resistant to mildew, mold, and bacteria; excellent insulation | Flooring, wall paneling, athletic equipment | Pros: Durable, maintains cleanliness; Cons: Can be more expensive than other options. |

| Polypropylene Foam | High density; ideal for heavy-duty applications | Protective packaging, automotive components | Pros: Strong and protective; Cons: Limited flexibility, potentially heavier. |

Polyethylene Foam

Polyethylene foam is a versatile material known for its excellent strength-to-weight ratio and resistance to moisture, chemicals, and stains. Its tightly packed structure prevents liquid penetration, making it ideal for applications requiring water resistance, such as protective packaging and insulation in the construction industry. B2B buyers should consider its lightweight and flexible nature, which facilitates easy fabrication and installation. However, it may not offer the same thermal resistance as other foam types, which could be a drawback for specific applications.

Cross-Linked Polyethylene Foam

Cross-linked polyethylene (XLPE) foam is produced through a process that enhances its molecular structure, resulting in a tougher and more resilient product. This foam is particularly advantageous for applications requiring resistance to a wider range of chemicals and temperature extremes, such as HVAC insulation and sports padding. Buyers should appreciate its durability and aesthetic appeal, making it suitable for branded packaging. However, the higher cost compared to standard polyethylene foam may be a consideration when budgeting for projects.

Polystyrene Foam

Polystyrene foam is characterized by its rigidity and availability in various densities, making it a popular choice for storage and packaging applications. Its strength provides excellent protection for products during transport, particularly in the construction sector. B2B buyers should note that while polystyrene foam is robust, it can be less flexible and may become brittle under certain conditions. This limitation could impact its usability in applications requiring more adaptability.

Neoprene Rubber Foam

Neoprene rubber foam stands out for its resistance to mildew, mold, and bacteria, making it an excellent choice for applications that prioritize cleanliness, such as flooring and wall paneling in medical or athletic environments. Its durability and insulation properties further enhance its appeal for B2B buyers. However, the cost of neoprene can be higher compared to other foam types, which may be a critical factor in budget-sensitive projects.

Polypropylene Foam

Polypropylene foam is known for its high density and suitability for heavy-duty applications, particularly in protective packaging and automotive components. Its strength provides robust protection against impact, making it a preferred option for B2B buyers seeking reliable material for demanding environments. While polypropylene foam offers excellent protective qualities, its limited flexibility and potentially heavier weight may restrict its use in applications requiring lighter materials.

Related Video: Lecture 1 Two compartment models

Key Industrial Applications of close cell foam

| Industry/Sector | Specific Application of Closed Cell Foam | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Sound dampening and vibration control | Enhances ride quality and passenger comfort, reducing noise levels. | Sourcing should focus on durability, temperature resistance, and compliance with automotive standards. |

| Construction | Insulation for HVAC and plumbing systems | Improves energy efficiency, leading to reduced operational costs. | Consider thickness, density, and moisture resistance; ensure compliance with local building codes. |

| Medical | Cushioning for medical devices and equipment | Protects sensitive components and enhances patient comfort. | Look for biocompatibility, sterility options, and customization for specific device designs. |

| Packaging | Protective packaging for fragile items | Reduces damage during transit, minimizing replacement costs. | Evaluate material properties for shock absorption and moisture resistance; consider eco-friendly options. |

| Marine | Buoyancy aids and flotation devices | Ensures safety and compliance with maritime regulations. | Focus on water resistance, UV stability, and customization for specific applications. |

Automotive Applications

In the automotive sector, closed cell foam is utilized for sound dampening and vibration control. This foam is strategically placed within vehicle interiors to absorb sound waves and vibrations, significantly enhancing passenger comfort and ride quality. For international buyers, particularly from regions with stringent automotive regulations, sourcing foam that meets specific durability and temperature resistance standards is crucial to ensure compliance and performance.

Construction Applications

Closed cell foam serves as an effective insulation material in HVAC and plumbing systems within the construction industry. Its moisture-resistant properties help prevent condensation, thereby improving energy efficiency and reducing operational costs. Buyers from Africa, South America, and the Middle East should prioritize sourcing foam that complies with local building codes and offers the desired thickness and density for optimal performance.

Medical Applications

In the medical field, closed cell foam is essential for cushioning medical devices and equipment. This foam protects sensitive components from damage and enhances patient comfort during use. International buyers should focus on sourcing biocompatible foams that meet sterility requirements, as well as customization options to fit specific device designs, ensuring safety and efficacy in healthcare applications.

Packaging Applications

Closed cell foam is widely used in protective packaging for fragile items, such as electronics and glassware. Its shock-absorbing properties significantly reduce damage during transit, which minimizes replacement costs and enhances customer satisfaction. When sourcing for packaging applications, businesses should evaluate the material properties for shock absorption and moisture resistance while considering eco-friendly options to meet sustainability goals.

Marine Applications

In the marine industry, closed cell foam is critical for buoyancy aids and flotation devices. Its water-resistant and UV-stable characteristics ensure safety and compliance with maritime regulations. Buyers from Europe and other regions should focus on sourcing foams that can withstand harsh marine environments, ensuring reliability and performance in life-saving applications. Customization options can also enhance the functionality of these products.

Related Video: Insulating Metal Buildings With Closed Cell Spray Foam

Strategic Material Selection Guide for close cell foam

Closed cell foam is an essential material in various industries due to its unique properties. This section analyzes four common materials used in closed cell foam, providing insights into their performance, advantages, disadvantages, and considerations for international B2B buyers.

Polyethylene Foam

Key Properties:

Polyethylene foam is known for its excellent shock absorption, moisture resistance, and lightweight characteristics. It maintains performance across a temperature range of -40°F to 175°F (-40°C to 80°C) and exhibits good chemical resistance.

Pros & Cons:

The durability of polyethylene foam makes it suitable for protective packaging and cushioning. However, its lower density can limit its applications in high-load environments. The manufacturing process is relatively straightforward, keeping costs moderate.

Impact on Application:

This material is ideal for applications requiring buoyancy, such as flotation devices, and is compatible with various media, including water and chemicals.

Considerations for International Buyers:

B2B buyers in regions like Africa and South America should ensure compliance with local regulations regarding material safety and environmental impact. Common standards like ASTM and ISO certifications are critical for ensuring quality.

Cross-Linked Polyethylene Foam (XLPE)

Key Properties:

XLPE foam features enhanced durability and resistance to moisture, air, and chemicals. It can withstand temperatures from -40°F to 200°F (-40°C to 93°C) and is known for its low thermal conductivity.

Pros & Cons:

XLPE is highly resilient and offers superior energy absorption, making it suitable for demanding applications. However, its more complex manufacturing process can lead to higher costs.

Impact on Application:

The foam’s high thermal stability makes it ideal for HVAC insulation and automotive interiors, where temperature fluctuations are common. It is also compatible with various cleaning agents, making it suitable for medical applications.

Considerations for International Buyers:

Buyers in Europe and the Middle East should be aware of specific certifications required for medical and automotive applications. Compliance with standards such as DIN and JIS is essential for market acceptance.

Neoprene Foam

Key Properties:

Neoprene foam is known for its excellent insulation properties and resistance to oil, chemicals, and weathering. It operates effectively within a temperature range of -40°F to 200°F (-40°C to 93°C).

Pros & Cons:

Its durability and resistance to mildew and bacteria make it ideal for healthcare and sports applications. However, neoprene foam can be more expensive than other options, which may deter budget-conscious buyers.

Impact on Application:

Neoprene is particularly effective in applications requiring cleanliness and insulation, such as flooring and wall paneling in medical facilities. Its compatibility with various chemicals makes it versatile.

Considerations for International Buyers:

For buyers in regions like Egypt and Thailand, understanding local sourcing and manufacturing capabilities is crucial. Compliance with environmental regulations regarding material disposal is also a significant factor.

Polypropylene Foam

Key Properties:

Polypropylene foam is characterized by its rigidity and high density, making it suitable for heavy-duty applications. It can withstand temperatures from -40°F to 200°F (-40°C to 93°C) and is resistant to moisture and chemicals.

Pros & Cons:

The high density provides excellent protection for sensitive items, but it can be heavier and more expensive than other foam types. The manufacturing process is complex, which may affect lead times.

Impact on Application:

Polypropylene foam is ideal for protective packaging in electronics and automotive parts. Its compatibility with various media, including oils and solvents, enhances its application range.

Considerations for International Buyers:

B2B buyers in South America and Africa should consider the availability of local suppliers who can meet specific material requirements. Adherence to international standards like ASTM is crucial for quality assurance.

Summary Table

| Material | Typical Use Case for close cell foam | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene Foam | Protective packaging | Excellent shock absorption | Limited load capacity | Medium |

| Cross-Linked Polyethylene | HVAC insulation | High thermal stability | Higher manufacturing costs | High |

| Neoprene Foam | Medical applications | Resistant to mildew and bacteria | Higher cost compared to other foams | High |

| Polypropylene Foam | Protective packaging for electronics | Excellent protection for sensitive items | Heavier and more expensive | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for close cell foam

The manufacturing process of closed cell foam involves several key stages, each contributing to the final product’s performance and quality. Understanding these stages, along with the quality assurance protocols in place, is crucial for B2B buyers, especially those sourcing from diverse regions such as Africa, South America, the Middle East, and Europe.

Manufacturing Process

1. Material Preparation

The first step in manufacturing closed cell foam is the selection and preparation of raw materials. Common materials used include polyethylene, cross-linked polyethylene, neoprene rubber, and polystyrene. Each material offers unique properties that cater to different applications, such as moisture resistance, thermal insulation, and shock absorption.

Illustrative Image (Source: Google Search)

- Material Selection: Buyers should consider the specific requirements of their application when selecting materials. For instance, polyethylene is suitable for buoyancy applications, while neoprene is preferred for its cleanliness and insulation properties.

- Blending and Compounding: The raw materials are often blended with additives such as blowing agents to enhance their properties. The choice of blowing agent is critical, as it influences the foam’s density and cell structure.

2. Forming

Once the materials are prepared, the forming stage begins. This involves creating the foam structure through one of two primary methods:

- Direct Gas Exposure: In this method, the base material is exposed to high-pressure gas, allowing for uniform cell formation. This technique is widely used for manufacturing lightweight, high-performance foams.

- Use of Blowing Agents: Chemical blowing agents are mixed into the foam material, releasing gas during the curing process. This creates the closed cellular structure that characterizes closed cell foam.

The forming stage is crucial as it determines the foam’s density, thickness, and overall mechanical properties.

3. Assembly

After the foam has been formed, it may undergo further processing depending on the intended application. This can include cutting, shaping, and laminating the foam to meet specific customer requirements.

- Cutting Techniques: Various cutting methods, such as die-cutting, water jet cutting, and CNC machining, can be employed. Each technique offers different advantages in terms of precision and scalability.

- Lamination and Coating: In some applications, foam may be laminated with other materials (like fabrics or films) to enhance its properties, such as abrasion resistance or aesthetic appeal.

4. Finishing

The final stage of manufacturing involves finishing processes that ensure the foam meets the desired specifications. This may include:

- Surface Treatment: Techniques such as sanding or chemical treatment can be applied to achieve a specific finish.

- Quality Testing: Before packaging, the foam is subjected to various tests to ensure it meets industry standards and customer requirements.

Quality Assurance

Quality assurance is a critical aspect of the closed cell foam manufacturing process, ensuring that products are consistent, reliable, and meet regulatory requirements.

International Standards

For B2B buyers, understanding the relevant international standards is essential. Key standards include:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is applicable to any organization seeking to enhance customer satisfaction through effective processes.

- CE Marking: In Europe, products must meet safety, health, and environmental protection standards to obtain CE marking.

- API Standards: For industries like oil and gas, products may need to adhere to American Petroleum Institute (API) standards.

Quality Control Checkpoints

To ensure quality throughout the manufacturing process, several checkpoints are established:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): During manufacturing, processes are monitored to detect any deviations from quality standards. This can include checks on density, thickness, and cell structure.

- Final Quality Control (FQC): Once the foam is completed, final inspections are conducted to verify that the product meets all specifications before shipment.

Common Testing Methods

Various testing methods are employed to assess the performance characteristics of closed cell foam:

- Compression Testing: Determines the foam’s ability to withstand compressive loads.

- Water Absorption Tests: Measures the foam’s resistance to moisture penetration.

- Thermal Conductivity Tests: Assesses the insulation properties of the foam.

- Flammability Testing: Ensures that the foam meets safety standards regarding fire resistance.

Verifying Supplier Quality Control

B2B buyers should take proactive steps to verify the quality control measures of their suppliers:

- Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices.

- Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s products and processes.

Quality Control and Certification Nuances

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, it is important to understand the nuances of quality control and certification:

- Regional Regulations: Different regions may have specific regulations and standards that must be adhered to, influencing the choice of suppliers.

- Cultural Considerations: Understanding cultural differences in business practices can facilitate better communication and negotiation regarding quality expectations.

- Documentation: Ensuring that suppliers provide all necessary documentation, such as compliance certificates and test results, is essential for transparent transactions.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for closed cell foam is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control measures, buyers can ensure they source high-quality products tailored to their specific needs.

Related Video: Inside the Molded Foam Manufacturing Process

Comprehensive Cost and Pricing Analysis for close cell foam Sourcing

Closed Cell Foam Sourcing: Cost Structure and Pricing Analysis

When sourcing closed cell foam, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis outlines the key cost components, price influencers, and provides actionable tips for buyers, particularly those in Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary cost driver in closed cell foam production is the raw materials used. Variations in material types—such as polyethylene, cross-linked polyethylene, neoprene, and polystyrene—affect pricing significantly. Higher-quality materials generally command a premium but also provide better performance characteristics.

-

Labor: Labor costs can vary greatly depending on the region and the complexity of the manufacturing process. Skilled labor is essential for quality production, particularly in custom applications. In regions with higher labor costs, it may be beneficial to source from countries with lower labor costs, while still ensuring quality standards.

-

Manufacturing Overhead: This includes costs associated with facilities, machinery, and utilities. Efficient production processes can lower overhead costs. Investing in technology and automation can enhance efficiency but may require higher upfront capital.

-

Tooling: Custom tooling for specific applications can add to the initial costs. For large orders, buyers may negotiate tooling costs into the overall pricing, which can help spread out the expense over larger volumes.

-

Quality Control (QC): Implementing a robust QC process is vital to ensure product consistency and compliance with industry standards. This may involve additional costs, but the long-term benefits of minimizing defects and returns outweigh the initial investment.

-

Logistics: Transportation and shipping costs are significant, especially for international buyers. Factors such as distance, shipping method, and Incoterms can heavily influence overall logistics costs. Buyers should account for potential tariffs and duties when estimating total logistics expenses.

-

Margin: Supplier margins can vary widely based on market conditions, competition, and the specific value-added services provided. Buyers should be aware of typical margins within the industry to assess fair pricing.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQ) play a critical role in pricing. Larger orders typically result in better pricing due to economies of scale. However, buyers should balance their inventory needs against storage costs.

-

Specifications/Customization: Custom specifications such as thickness, density, and chemical resistance can increase costs. Buyers should clearly define their requirements to receive accurate quotes.

-

Materials Quality/Certifications: High-quality materials with relevant certifications (e.g., ISO, ASTM) may come at a premium. However, investing in certified materials can enhance product reliability and compliance.

-

Supplier Factors: The supplier’s reputation, experience, and production capabilities can influence pricing. Established suppliers with proven track records may charge more, but they often provide superior quality and service.

-

Incoterms: Understanding Incoterms is essential for international transactions. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) determine who bears shipping costs and risks, impacting the overall price.

Buyer Tips

-

Negotiation: Always negotiate pricing, especially for larger orders. Suppliers may be willing to offer discounts or better terms based on volume commitments.

-

Cost-Efficiency: Analyze the total cost of ownership (TCO) rather than just the purchase price. Consider factors such as durability, maintenance, and potential waste reduction when evaluating options.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and geopolitical factors that can impact pricing. Establish contracts that account for potential changes in costs over time.

-

Due Diligence: Research and vet potential suppliers thoroughly. Assess their production capabilities, quality assurance processes, and customer feedback to ensure you are partnering with a reliable source.

By understanding these cost components, price influencers, and strategic negotiation tactics, international B2B buyers can make informed decisions that align with their business objectives while optimizing their sourcing of closed cell foam products.

Spotlight on Potential close cell foam Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘close cell foam’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for close cell foam

Key Technical Properties of Closed Cell Foam

Understanding the essential technical properties of closed cell foam is crucial for international B2B buyers. These specifications help in selecting the appropriate foam for specific applications, ensuring optimal performance and cost-effectiveness.

1. Material Grade

Material grade refers to the quality and type of foam used, often influenced by the manufacturing process and chemical composition. Common grades include polyethylene, cross-linked polyethylene (XLPE), and neoprene. For B2B buyers, selecting the right material grade is vital as it affects durability, resistance to environmental factors, and overall performance in specific applications.

2. Density

Density is a critical specification that indicates the mass of foam per unit volume, typically measured in pounds per cubic foot (lb/ft³). Higher density foams tend to offer better durability, shock absorption, and insulation properties. For buyers, understanding density helps in assessing the foam’s suitability for applications such as packaging, insulation, or cushioning.

3. Compression Set

Compression set measures the foam’s ability to return to its original thickness after being compressed. A lower compression set value indicates better resilience and longevity. For businesses, this property is essential in applications where repeated loading and unloading occur, such as in automotive gaskets or cushioning materials.

4. Water Absorption

Water absorption quantifies the foam’s ability to resist moisture penetration. Closed cell foams generally have low water absorption, making them ideal for applications requiring water resistance, such as marine and outdoor products. For international buyers, this property is crucial for ensuring the reliability and longevity of products exposed to moisture.

5. Thermal Conductivity

Thermal conductivity measures the foam’s ability to conduct heat, which is essential for insulation applications. Lower thermal conductivity values indicate better insulating properties. B2B buyers in sectors like construction or HVAC must consider this property to ensure energy efficiency and compliance with building standards.

Common Trade Terminology

Familiarity with industry-specific jargon is essential for effective communication and negotiation in B2B transactions involving closed cell foam.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the foam industry, understanding OEM relationships helps buyers identify reliable suppliers that provide high-quality components tailored to their specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For international buyers, knowing the MOQ is crucial for budget planning and inventory management, especially when dealing with specialized closed cell foam products that may have higher production costs.

3. RFQ (Request for Quote)

An RFQ is a formal document issued by a buyer to solicit price quotes from suppliers. It typically includes specifications, quantities, and terms of delivery. For B2B buyers, submitting an RFQ can streamline the procurement process, ensuring that they receive competitive pricing and suitable materials for their needs.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), is vital for B2B buyers to clarify shipping costs, insurance, and risk management during transportation.

5. Lead Time

Lead time refers to the time taken from placing an order to its delivery. For buyers, understanding lead times is essential for effective project planning and inventory management, particularly in industries with tight deadlines.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions, ensuring they select the best closed cell foam products for their specific needs while navigating the complexities of global trade.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the close cell foam Sector

Market Overview & Key Trends

The closed cell foam market is experiencing robust growth driven by increasing demand across various sectors, including automotive, construction, healthcare, and packaging. Factors such as enhanced product durability, moisture resistance, and thermal insulation properties are propelling the adoption of closed cell foam solutions. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these dynamics is essential for strategic sourcing decisions.

Emerging technologies such as advanced manufacturing processes and automation are reshaping the sourcing landscape. Buyers are increasingly leveraging digital platforms to connect with manufacturers, ensuring transparency and efficiency in procurement. Moreover, the rise of customized solutions tailored to specific industry needs allows companies to enhance product performance while reducing waste.

Current market dynamics also reflect a shift toward sustainable materials. Buyers are increasingly prioritizing suppliers who offer eco-friendly alternatives, reflecting a broader global trend towards sustainability. This trend is particularly pronounced in regions like Europe, where regulatory frameworks encourage environmentally responsible sourcing practices. Consequently, international buyers must stay abreast of these trends to align their procurement strategies with market demands.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration for B2B buyers in the closed cell foam sector. The environmental impact of foam production, particularly concerning raw material sourcing and waste management, necessitates a focus on ethical supply chains. Buyers are urged to engage with manufacturers who prioritize sustainability in their operations, such as those utilizing recyclable materials or implementing waste reduction initiatives.

Certifications such as ISO 14001 (Environmental Management) and other ‘green’ certifications signify a commitment to sustainable practices within the supply chain. These certifications assure buyers that the materials used in closed cell foam production have been sourced responsibly and are compliant with environmental regulations.

Furthermore, exploring bio-based or recycled materials for closed cell foam can significantly reduce the carbon footprint associated with traditional foam manufacturing. By prioritizing suppliers that adopt sustainable practices, B2B buyers can contribute to a circular economy while enhancing their brand’s reputation in increasingly eco-conscious markets.

Brief Evolution/History

Closed cell foam has evolved significantly since its inception, originating from basic rubber and plastic compounds. Initially used primarily in packaging and insulation, advancements in technology have expanded its applications across various industries. The introduction of cross-linked polyethylene and other innovative formulations has enhanced the material’s performance, making it suitable for high-demand environments such as automotive interiors and medical devices.

As industries continue to evolve, the emphasis on customization and sustainability within the closed cell foam sector underscores the importance of staying informed about market changes. This evolution not only reflects advancements in material science but also the growing expectations from B2B buyers for ethical sourcing and high-performance solutions. By understanding this historical context, international buyers can make more informed decisions that align with current trends and future needs.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of close cell foam

-

What criteria should I use to vet suppliers of closed cell foam?

When vetting suppliers, consider their industry experience, production capabilities, and quality certifications (e.g., ISO 9001). Request samples to evaluate foam properties and ensure they meet your specifications. Additionally, check customer testimonials and case studies to gauge reliability and service quality. For international suppliers, ensure they have a robust logistics framework to handle shipping and customs efficiently, particularly for regions like Africa and South America, where logistical challenges may arise. -

Can closed cell foam be customized to meet specific requirements?

Yes, many suppliers offer customization options for closed cell foam, including variations in density, thickness, and color. You can also specify unique properties such as flame resistance, UV stability, or enhanced thermal insulation. It’s crucial to communicate your exact needs during initial discussions with suppliers. Ensure they have the capabilities to produce custom formulations and provide a timeline for prototyping and production. -

What are the typical minimum order quantities (MOQs) and lead times for closed cell foam?

MOQs for closed cell foam can vary widely depending on the supplier and the complexity of the order. Generally, MOQs can range from 100 square meters for standard products to several thousand for custom formulations. Lead times may also differ based on order size and customization requirements, typically ranging from 2-6 weeks. It’s advisable to confirm these details upfront to align production schedules with your project timelines. -

What payment terms should I expect when sourcing closed cell foam internationally?

Payment terms can vary by supplier and region, but typical arrangements include upfront payments, letters of credit, or payment upon delivery. For international transactions, it’s essential to agree on currency, payment method, and any applicable taxes or tariffs. Ensure that the payment structure is clearly outlined in the purchase agreement to avoid any misunderstandings or disputes later. -

How can I ensure quality assurance and certifications for closed cell foam products?

Request documentation of quality control processes and certifications from your supplier, such as ISO, ASTM, or other relevant industry standards. Ask for test reports verifying material properties like density, tensile strength, and thermal resistance. Engaging third-party inspection services can also provide additional assurance, especially for large orders, ensuring that the products received meet your specified criteria. -

What logistics considerations should I keep in mind when importing closed cell foam?

Logistics for importing closed cell foam require careful planning. Consider factors such as shipping methods (air vs. sea), customs clearance, and potential duties or tariffs. It’s advisable to work with a freight forwarder experienced in handling foam products to navigate international regulations efficiently. Additionally, ensure the supplier can provide proper documentation, including bills of lading and safety data sheets, to facilitate smooth customs processing. -

How should disputes or issues with suppliers be managed?

Disputes can arise over quality, delivery times, or contractual obligations. To mitigate issues, establish clear communication channels and document all agreements in writing. If a dispute occurs, try to resolve it amicably through direct discussions. If necessary, refer to the terms of your contract regarding dispute resolution mechanisms, such as mediation or arbitration. Maintaining a professional relationship with suppliers can often lead to quicker and more satisfactory resolutions. -

What are the common applications for closed cell foam in various industries?

Closed cell foam is utilized across multiple industries, including automotive for insulation and sound dampening, medical for cushioning and protective packaging, and construction for thermal insulation and expansion joint fillers. In marine applications, it serves as buoyancy aids, while in sports, it provides shock absorption. Understanding these applications can help you identify the best type of foam for your specific needs and enhance your product offerings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for close cell foam

In conclusion, strategic sourcing of closed cell foam is paramount for international B2B buyers seeking high-performance materials tailored to diverse applications. This versatile foam type, recognized for its durability, moisture resistance, and sound dampening properties, is essential in industries ranging from automotive to healthcare. By understanding the various types—such as polyethylene, cross-linked polyethylene, and neoprene—buyers can make informed decisions that align with their specific project needs.

Key takeaways include the importance of evaluating suppliers based on their capabilities in custom fabrication and the variety of foam grades available. Engaging with reputable manufacturers ensures that businesses receive materials that meet their quality standards and performance specifications.

As global demand for closed cell foam continues to rise, buyers from Africa, South America, the Middle East, and Europe should proactively explore partnerships with reliable suppliers. This not only enhances supply chain resilience but also opens avenues for innovation and growth in their respective markets. Now is the time to leverage strategic sourcing for closed cell foam to stay competitive and meet the evolving needs of your customers.

Illustrative Image (Source: Google Search)