Master Sourcing High Density Closed Cell Foam: Your

Introduction: Navigating the Global Market for high density closed cell foam

In today’s competitive global marketplace, high density closed cell foam stands out as a critical material across a myriad of industries, including automotive, construction, healthcare, and packaging. Renowned for its durability, moisture resistance, and excellent insulation properties, this versatile foam is increasingly sought after by businesses looking to enhance product performance and longevity. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of high density closed cell foam is paramount for making informed sourcing decisions.

This comprehensive guide delves into the essential aspects of high density closed cell foam, covering various types and materials, along with insights into manufacturing processes and quality control measures. It also highlights key suppliers and provides a detailed analysis of cost considerations and market trends. By addressing frequently asked questions, the guide aims to empower buyers with actionable insights that facilitate strategic procurement and ensure the selection of the most suitable foam products for their specific applications.

Illustrative Image (Source: Google Search)

Navigating the complexities of the global foam market can be challenging, but this guide serves as an invaluable resource. It equips B2B buyers with the knowledge necessary to enhance their supply chain efficiency, optimize product quality, and ultimately drive business success in their respective sectors.

Understanding high density closed cell foam Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Polyethylene Foam | Lightweight, water-resistant, excellent shock absorption | Packaging, automotive, sports equipment | Pros: Cost-effective, versatile. Cons: Less durable under extreme temperatures. |

| Cross-Linked Polyethylene | Higher density, resistant to moisture and chemicals | Industrial, construction, flotation devices | Pros: Durable, excellent insulation properties. Cons: Higher cost compared to standard polyethylene. |

| Polystyrene Foam | Rigid structure, various densities available | Packaging, insulation, crafts | Pros: Strong and lightweight. Cons: Less flexible, can be brittle. |

| Neoprene Rubber | Flexible, resistant to oil, water, and ozone | Medical, flooring, sports equipment | Pros: High durability, good insulation. Cons: More expensive than other foams. |

| Gym Rubber Foam | High density, shock absorbent, slight bounce | Gym flooring, daycare centers, insulation | Pros: Excellent durability, easy to clean. Cons: Heavier, may require more robust support structures. |

Polyethylene Foam

Polyethylene foam is a widely used closed cell foam known for its lightweight and water-resistant properties. It is particularly suitable for applications requiring shock absorption, such as packaging and protective cases for automotive parts. B2B buyers should consider the foam’s cost-effectiveness and versatility; however, its performance may degrade under extreme temperatures, which is a critical factor for industries operating in varied climates.

Cross-Linked Polyethylene

Cross-linked polyethylene foam offers enhanced durability and resistance to moisture, making it ideal for industrial applications, construction, and flotation devices. Its higher density provides superior insulation properties, which can be beneficial in energy-efficient building projects. While the initial cost is higher than standard polyethylene, the long-term savings in durability and performance can justify the investment for B2B buyers focused on quality and sustainability.

Polystyrene Foam

With a rigid structure and a variety of densities, polystyrene foam is commonly used in packaging and insulation applications. Its strength and lightweight nature make it a preferred choice for storage solutions. However, buyers should be aware that while polystyrene offers excellent protection, it can be brittle and less flexible, which may limit its use in applications requiring more adaptability.

Neoprene Rubber

Neoprene rubber is celebrated for its flexibility and resistance to oil, water, and ozone, making it suitable for medical applications and flooring in sports facilities. Its durability and insulation properties are significant advantages for B2B buyers looking for reliable materials. However, the higher price point compared to other foam types may be a consideration for budget-sensitive projects.

Gym Rubber Foam

Gym rubber foam is characterized by its high density and shock-absorbing qualities, making it an excellent choice for gym flooring and daycare centers. Its durability and ease of cleaning are key benefits for facilities that require hygienic environments. However, its heavier weight may necessitate additional support, which buyers should factor into their purchasing decisions to ensure compatibility with existing structures.

Related Video: Understanding Foam Types: Density, Firmness, and Best Uses

Key Industrial Applications of high density closed cell foam

| Industry/Sector | Specific Application of high density closed cell foam | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Sound dampening and insulation in vehicle interiors | Enhances passenger comfort by reducing noise and vibration. | Ensure compliance with automotive industry standards and fire safety regulations. |

| Construction | Insulation for walls and roofs | Improves energy efficiency, reducing heating and cooling costs. | Look for materials with high thermal resistance and moisture resistance. |

| Marine | Buoyancy aids and flotation devices | Provides safety and reliability in watercraft applications. | Verify UV and saltwater resistance, especially for tropical climates. |

| Healthcare | Protective padding for medical equipment | Ensures safety and comfort for patients and staff. | Source materials that are hypoallergenic and easy to clean. |

| Packaging | Custom-fit protective packaging | Reduces damage during shipping, lowering replacement costs. | Consider sourcing options that allow for customization and rapid prototyping. |

High density closed cell foam plays a vital role in the automotive industry by providing sound dampening and insulation for vehicle interiors. This application enhances passenger comfort by significantly reducing noise and vibration, which is especially crucial for luxury vehicles. International buyers should ensure that the materials sourced comply with automotive industry standards, including fire safety regulations, as these are critical for both safety and performance.

In the construction sector, high density closed cell foam is widely used for insulation in walls and roofs. This application improves energy efficiency, leading to lower heating and cooling costs, which is particularly beneficial in regions with extreme climates. Buyers should prioritize materials with high thermal resistance and moisture resistance to ensure long-term performance and compliance with local building codes.

The marine industry utilizes high density closed cell foam for buoyancy aids and flotation devices. This application is essential for ensuring safety and reliability in various watercraft, particularly in regions with challenging maritime conditions. Buyers should verify that the foam is resistant to UV rays and saltwater, especially in tropical climates, to guarantee durability and functionality.

In the healthcare sector, high density closed cell foam serves as protective padding for medical equipment, ensuring safety and comfort for both patients and staff. This application is critical in hospitals and clinics where equipment must be both functional and user-friendly. Buyers should focus on sourcing hypoallergenic materials that are easy to clean and maintain, as hygiene is a top priority in healthcare settings.

Lastly, in packaging, high density closed cell foam is employed for custom-fit protective packaging solutions. This application significantly reduces damage during shipping, thereby lowering replacement costs and enhancing customer satisfaction. B2B buyers should consider sourcing options that allow for customization and rapid prototyping, which can help in developing tailored solutions for specific products and shipping needs.

Related Video: Insulating Metal Buildings With Closed Cell Spray Foam

Strategic Material Selection Guide for high density closed cell foam

When selecting high-density closed cell foam for various applications, international B2B buyers must consider the specific properties, advantages, and limitations of different materials. Below is an analysis of four common materials used in high-density closed cell foam, focusing on their performance characteristics, application impact, and considerations for buyers from regions such as Africa, South America, the Middle East, and Europe.

Polyethylene Foam

Key Properties: Polyethylene foam is known for its excellent buoyancy, shock absorption, and sound dampening capabilities. It typically operates effectively in temperature ranges from -40°F to 180°F (-40°C to 82°C) and has good resistance to moisture and chemicals.

Pros & Cons: This material is lightweight and cost-effective, making it suitable for a wide range of applications, including packaging and insulation. However, it has lower durability compared to some other materials, which may limit its use in high-stress environments.

Impact on Application: Polyethylene foam is particularly effective in applications where moisture resistance is critical, such as in marine or outdoor settings. Its compatibility with various media makes it a versatile choice for packaging sensitive equipment.

Considerations for Buyers: Buyers should ensure that the polyethylene foam meets local compliance standards, such as ASTM or ISO certifications. In regions like Turkey and the UK, preferences may lean towards materials that are environmentally friendly and recyclable.

Cross-Linked Polyethylene Foam

Key Properties: Cross-linked polyethylene foam exhibits superior strength and durability, with a temperature rating from -40°F to 200°F (-40°C to 93°C). It is resistant to mildew, water, and chemicals.

Pros & Cons: The enhanced durability makes it suitable for demanding applications, such as automotive and industrial uses. However, it tends to be more expensive than standard polyethylene foam, which could impact budget considerations.

Impact on Application: This foam is ideal for applications requiring high resilience and protection against harsh conditions, such as in construction or as insulation in HVAC systems.

Considerations for Buyers: Buyers from Africa and South America may need to consider the availability and import regulations for cross-linked polyethylene. Compliance with international standards is essential, especially in industries like automotive where safety regulations are stringent.

Neoprene Rubber Foam

Key Properties: Neoprene foam offers excellent thermal insulation and is resistant to oils, chemicals, and weather conditions. It typically performs well in temperatures ranging from -40°F to 200°F (-40°C to 93°C).

Pros & Cons: Its durability and resistance to various environmental factors make it suitable for medical and industrial applications. However, neoprene can be pricier than other foam types, which may deter cost-sensitive buyers.

Impact on Application: Neoprene foam is particularly valuable in applications requiring cleanliness and insulation, such as in hospitals or laboratories. Its compatibility with various media, including oils and chemicals, enhances its applicability.

Considerations for Buyers: Buyers should be aware of the environmental regulations surrounding neoprene in their regions. In Europe, for instance, there may be stricter regulations on the use of synthetic materials, prompting buyers to seek compliant products.

Expanded Polypropylene Foam

Key Properties: Expanded polypropylene (EPP) foam is lightweight yet strong, with a temperature resistance ranging from -40°F to 200°F (-40°C to 93°C). It is also resistant to moisture and chemicals.

Pros & Cons: EPP is highly durable and provides excellent cushioning, making it ideal for protective packaging. However, its manufacturing process can be complex, potentially leading to higher costs.

Impact on Application: This foam is particularly effective in applications requiring significant impact resistance, such as in automotive components or protective packaging for fragile items.

Considerations for Buyers: Buyers should evaluate the supply chain for EPP foam, especially in regions with less established manufacturing capabilities. Compliance with international standards is crucial, particularly in sectors like aerospace and automotive.

| Material | Typical Use Case for high density closed cell foam | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene Foam | Packaging, insulation | Cost-effective, lightweight | Lower durability | Low |

| Cross-Linked Polyethylene Foam | Automotive, industrial insulation | High durability, chemical resistance | Higher cost | Med |

| Neoprene Rubber Foam | Medical applications, flooring | Excellent thermal insulation | Higher cost | High |

| Expanded Polypropylene Foam | Protective packaging, automotive components | Strong, impact-resistant | Complex manufacturing | Med |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on the unique requirements of their applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for high density closed cell foam

The manufacturing of high-density closed cell foam involves a series of meticulously controlled processes designed to ensure the final product meets specific performance criteria. Understanding these processes, as well as the quality assurance measures implemented, is crucial for B2B buyers seeking reliable suppliers. This guide provides an in-depth look into the typical manufacturing stages, techniques, and quality assurance standards relevant to the production of high-density closed cell foam.

Manufacturing Processes

1. Material Preparation

The first stage in the manufacturing process involves selecting and preparing raw materials. High-density closed cell foam is primarily made from materials such as polyethylene, polystyrene, or neoprene rubber. Each material is chosen based on the desired characteristics of the final product, such as density, flexibility, and resistance to moisture.

- Material Sourcing: B2B buyers should verify that suppliers source high-quality raw materials from reputable manufacturers. This can impact the foam’s durability and performance.

- Batch Testing: Before production, materials are often subjected to batch testing to ensure they meet specific chemical and physical properties.

2. Forming

Once the materials are prepared, they undergo the forming process. This involves mixing the chosen polymer with additives, such as blowing agents, which create gas bubbles within the foam structure.

- Foaming Techniques: Common methods include:

- Extrusion: The material is melted and forced through a die to form sheets or rolls of foam.

- Molding: Liquid foam is poured into molds to create specific shapes. This method is often used for customized applications.

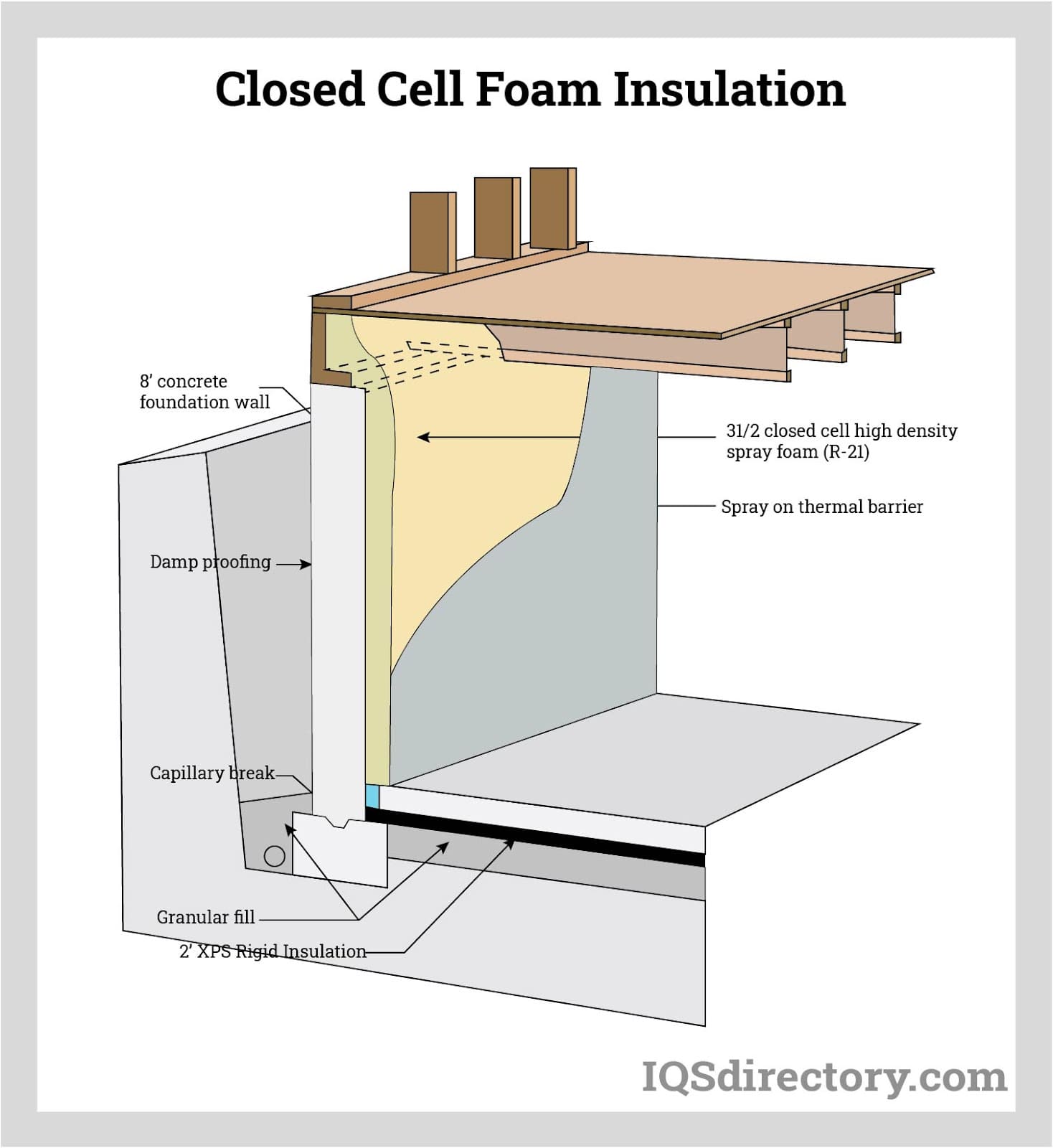

- Spray Application: Closed-cell spray foam is applied directly to surfaces for insulation purposes.

3. Assembly

After forming, the foam may require further processing, such as cutting, laminating, or adhering layers together to enhance performance characteristics.

- Cutting Techniques: Precision cutting ensures that the foam meets the required dimensions. Techniques include:

- Die Cutting: For high-volume production of specific shapes.

- Water Jet Cutting: For intricate designs without damaging the foam structure.

4. Finishing

The final stage involves finishing processes that enhance the foam’s properties, such as surface treatments for added durability or aesthetics.

- Surface Treatments: These can include coatings to improve UV resistance, water repellency, or flame retardancy.

- Quality Checks: Each batch undergoes inspection to ensure it meets the specified standards before packaging.

Quality Assurance

Quality assurance is a critical component of the manufacturing process for high-density closed cell foam. It ensures that the final product is safe, reliable, and meets the expectations of international buyers.

Relevant International Standards

B2B buyers should be aware of the various international standards that govern quality assurance in foam manufacturing, including:

- ISO 9001: This standard outlines the criteria for a quality management system, ensuring that products consistently meet customer and regulatory requirements.

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Standards: Relevant for applications in the oil and gas industry, focusing on quality and safety.

Quality Control Checkpoints

Quality control (QC) is implemented at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to detect any deviations from standards.

- Final Quality Control (FQC): A thorough inspection of the finished product, including dimensional checks and performance testing.

Common Testing Methods

To ensure compliance with quality standards, several testing methods are employed:

- Density Testing: Measures the foam’s density to confirm it meets specifications.

- Compression Testing: Assesses the foam’s ability to withstand compressive forces.

- Water Absorption Tests: Evaluates the foam’s resistance to moisture.

- Flame Retardancy Tests: Ensures compliance with safety standards regarding fire resistance.

Verifying Supplier Quality Control

B2B buyers must adopt a proactive approach to verify the quality control practices of potential suppliers:

- Supplier Audits: Conduct regular audits of suppliers to assess their manufacturing processes and quality control measures. This can include on-site visits to observe production and QC practices firsthand.

- Quality Reports: Request documentation on quality control processes, including test results and certifications. This transparency can help build trust in the supplier’s capabilities.

- Third-Party Inspections: Engage independent inspection agencies to verify compliance with relevant standards and conduct random sampling of products.

QC and Certification Nuances for International Buyers

When dealing with suppliers from diverse regions, international buyers must be aware of the nuances in quality control and certification practices:

- Regional Standards: Different regions may have varying standards and regulations. For instance, the European market may demand stricter compliance compared to other regions.

- Language Barriers: Ensure that documentation and communication are clear and understandable, potentially requiring translation services.

- Cultural Considerations: Building relationships with suppliers from different cultures may require an understanding of local business practices and negotiation styles.

By thoroughly understanding the manufacturing processes and quality assurance measures for high-density closed cell foam, international B2B buyers can make informed decisions, ensuring they partner with reliable suppliers capable of delivering high-quality products tailored to their specific needs.

Related Video: Inside the Molded Foam Manufacturing Process

Comprehensive Cost and Pricing Analysis for high density closed cell foam Sourcing

When sourcing high density closed cell foam, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. The cost components can be broadly categorized into several key areas, each influencing the overall price and decision-making process.

Cost Components

-

Materials: The primary cost driver in closed cell foam sourcing is the raw materials used. Different types of foam, such as polyethylene, neoprene, or cross-linked polyethylene, have varying price points based on their properties and availability. Material costs can fluctuate based on market demand, availability, and geographical factors.

-

Labor: Labor costs are incurred during the production process. This includes wages for skilled workers involved in manufacturing and quality control. In regions with higher labor costs, such as Europe, this may significantly impact the final product price.

-

Manufacturing Overhead: This includes costs associated with maintaining manufacturing facilities, utilities, and administrative expenses. Efficient operations can help reduce these overheads, thus lowering the overall cost of the foam.

-

Tooling: Custom tooling for specific applications can lead to higher initial costs. Buyers should consider whether the investment in custom tooling is justified based on the expected volume and long-term usage.

-

Quality Control (QC): Ensuring that the foam meets specific quality standards requires investment in QC processes. This is particularly important for applications in industries like aerospace or medical, where compliance with certifications can add to costs.

-

Logistics: Transporting foam materials from the manufacturer to the buyer involves logistical costs, which can vary significantly depending on distance, shipping methods, and international trade regulations.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure profitability. This margin can vary based on the supplier’s market position, reputation, and service offerings.

Price Influencers

Several factors can influence the pricing of high density closed cell foam:

-

Volume/MOQ: Larger order volumes typically result in lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) to leverage better pricing.

-

Specifications/Customization: Custom specifications can increase costs due to the need for specialized materials or production processes. Buyers should weigh the benefits of customization against the associated costs.

-

Quality/Certifications: Higher quality materials or certifications (such as ISO standards) can lead to increased costs. Buyers should assess whether the additional investment aligns with their project requirements.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their products but often provide added value in terms of service and reliability.

-

Incoterms: The chosen Incoterm can significantly affect the total landed cost of the foam. Buyers should understand the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) when negotiating contracts.

Buyer Tips

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, here are actionable insights to optimize sourcing:

-

Negotiation: Always negotiate pricing with suppliers. Leverage your purchasing power by discussing future volume commitments to secure better rates.

-

Cost-Efficiency: Look beyond initial pricing. Consider total cost of ownership, including logistics, storage, and disposal costs, which can significantly affect the overall expenditure.

-

Pricing Nuances: Be aware that pricing can vary widely based on geographical factors, market conditions, and exchange rates. It is advisable to obtain multiple quotes to understand the market better.

-

Research Suppliers: Conduct thorough research on potential suppliers to understand their capabilities, quality assurance processes, and customer service reputation.

-

Stay Informed: Keep abreast of industry trends and market dynamics that may influence foam prices, such as shifts in raw material costs or changes in manufacturing technologies.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on market conditions and specific buyer requirements. Always seek updated quotes directly from suppliers to obtain the most accurate pricing.

Spotlight on Potential high density closed cell foam Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘high density closed cell foam’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for high density closed cell foam

High density closed cell foam is a versatile material widely used across various industries, thanks to its unique properties and applications. Understanding its technical specifications and trade terminology is crucial for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

Key Technical Properties

-

Material Grade

– Definition: Material grade refers to the quality and type of foam, which can include polyethylene, polystyrene, neoprene, or polypropylene.

– Importance: Selecting the correct material grade ensures the foam meets specific performance requirements for durability, resistance to moisture, and insulation properties, impacting overall project success. -

Density

– Definition: Density is measured in pounds per cubic foot (lb/ft³) and indicates the mass of the foam. High-density closed cell foam typically ranges from 2 to 20 lb/ft³.

– Importance: Higher density foams provide better structural integrity, sound dampening, and resistance to compression. For buyers, understanding density helps in choosing the right foam for applications such as packaging, insulation, or protective cushioning. -

Compression Set

– Definition: Compression set is the percentage of deformation remaining after a foam has been compressed over time.

– Importance: A low compression set indicates that the foam will retain its original shape after being compressed, which is critical for applications requiring long-term performance, such as in construction or automotive sectors. -

Water Absorption Rate

– Definition: This measures how much water the foam can absorb over a specified period.

– Importance: For applications in humid environments or exposure to water, a low water absorption rate is essential to prevent degradation of foam properties and maintain insulation effectiveness. -

Thermal Conductivity

– Definition: Thermal conductivity measures the foam’s ability to conduct heat, typically expressed in units of W/m·K.

– Importance: Understanding thermal conductivity is vital for insulation applications. Lower thermal conductivity values indicate better insulating properties, which can significantly affect energy efficiency in buildings. -

Flame Retardancy

– Definition: This property indicates how well the foam resists ignition and the spread of flames.

– Importance: For many industrial applications, especially in construction and transportation, flame retardancy is a key factor in compliance with safety regulations and standards.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships is crucial for buyers who need custom foam solutions that integrate with existing products. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ helps buyers plan their budgets and inventory, ensuring they can meet their production needs without overcommitting financially. -

RFQ (Request for Quote)

– Definition: A document issued by a buyer to solicit price bids from suppliers for specific products or services.

– Relevance: Utilizing RFQs allows buyers to compare pricing and terms from multiple suppliers, facilitating better purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms used to clarify the responsibilities of buyers and sellers.

– Relevance: Familiarity with Incoterms is essential for understanding shipping costs, risks, and responsibilities, particularly in cross-border transactions. -

Lead Time

– Definition: The amount of time from placing an order until it is delivered.

– Relevance: For project planning, understanding lead times can help buyers schedule their operations effectively and avoid delays in production. -

Custom Fabrication

– Definition: The process of creating customized foam products tailored to specific requirements.

– Relevance: Buyers often require custom solutions to meet unique specifications, making it vital to engage with suppliers who offer these services.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right high density closed cell foam for their applications while navigating the complexities of international trade effectively.

Illustrative Image (Source: Google Search)

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the high density closed cell foam Sector

Market Overview & Key Trends

The high-density closed cell foam market is witnessing robust growth, driven by increasing demand across various sectors such as automotive, construction, and healthcare. The global shift towards lightweight materials that offer superior insulation properties is propelling the adoption of closed cell foams. In regions like Africa and South America, infrastructure development is a significant driver, while in Europe and the Middle East, energy efficiency regulations are influencing procurement decisions.

Emerging technologies such as advanced manufacturing processes, including 3D printing and automated cutting, are reshaping sourcing strategies. Buyers are increasingly leveraging digital platforms for procurement, enabling streamlined supply chains and enhanced visibility into product offerings. Additionally, the rise of e-commerce is facilitating easier access to suppliers, particularly for small and medium enterprises that may struggle with traditional sourcing methods.

Moreover, the trend towards customization is gaining traction, with buyers seeking tailored solutions that meet specific application needs. As a result, suppliers are investing in R&D to develop innovative foam formulations that enhance performance characteristics, such as enhanced fire resistance and acoustic dampening. For international B2B buyers, understanding these dynamics will be crucial for making informed sourcing decisions that align with market demands.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a pivotal concern in the high-density closed cell foam sector. The environmental impact of foam production, particularly in terms of greenhouse gas emissions and waste generation, has prompted a shift towards more sustainable practices. Buyers are increasingly prioritizing suppliers that adhere to eco-friendly manufacturing processes, use recycled materials, or offer biodegradable options.

Ethical sourcing is also gaining importance, with businesses focusing on transparency in their supply chains. Buyers should seek suppliers that can provide certifications indicating compliance with environmental standards, such as ISO 14001 for environmental management systems or the Global Recycle Standard (GRS) for recycled materials. Additionally, certifications like Greenguard, which ensures low chemical emissions, are valuable for buyers in sectors like healthcare and education where indoor air quality is critical.

Incorporating sustainability into procurement strategies not only enhances a company’s brand reputation but also aligns with global trends towards corporate social responsibility. By selecting suppliers committed to sustainable practices, buyers can contribute to a greener economy while meeting regulatory requirements and consumer expectations.

Brief Evolution/History

The development of closed cell foam can be traced back to the mid-20th century, originally used in military applications due to its durability and insulation properties. Over the decades, advancements in polymer chemistry have led to the formulation of various types of closed cell foams, each tailored for specific applications.

The commercial sector began to adopt these materials for diverse uses, from packaging to insulation in construction, as their benefits became widely recognized. Today, the market has evolved to include a variety of formulations, such as polyethylene and neoprene, that cater to specific industry needs. This evolution reflects a growing understanding of material performance, sustainability, and the importance of ethical sourcing in the global supply chain, making high-density closed cell foam a vital component across multiple industries.

Related Video: Revitalizing Global Trade | Presented by Verizon Business

Frequently Asked Questions (FAQs) for B2B Buyers of high density closed cell foam

-

What should I consider when vetting suppliers for high-density closed cell foam?

When vetting suppliers, prioritize those with a proven track record in the closed cell foam industry. Look for certifications such as ISO 9001 for quality management and ISO 14001 for environmental management. Review their production capacity, lead times, and customer reviews. Engage in direct communication to assess responsiveness and willingness to provide samples. Additionally, inquire about their experience with international shipping and compliance with local regulations in your region, particularly in Africa, South America, the Middle East, and Europe. -

Can I customize high-density closed cell foam products?

Yes, many suppliers offer customization options for high-density closed cell foam, including variations in thickness, density, color, and cutting shapes. When discussing customization, provide detailed specifications to ensure the supplier understands your requirements. Be aware that custom orders may have minimum order quantities (MOQs) and longer lead times. It is advisable to collaborate closely with the supplier during the design phase to avoid miscommunication and ensure the final product meets your expectations. -

What are typical minimum order quantities (MOQs) and lead times for high-density closed cell foam?

MOQs can vary significantly by supplier and product type, often ranging from 100 to 1,000 square meters. Lead times typically span from 2 to 8 weeks, depending on the complexity of the order and the supplier’s location. For international buyers, consider potential delays in customs clearance and logistics. Always confirm the specifics with your supplier before placing an order, and factor in additional time for shipping when planning your project timelines. -

What payment terms should I expect when sourcing high-density closed cell foam internationally?

Payment terms can vary based on the supplier’s policies and your relationship with them. Common terms include advance payments, partial payments upon order confirmation, and balance payment before shipment. For first-time transactions, suppliers may require upfront payment or a letter of credit to mitigate risks. It is advisable to negotiate terms that suit your cash flow while ensuring security for both parties. Always document payment agreements clearly in your contracts. -

How can I ensure quality assurance (QA) and certifications for high-density closed cell foam products?

Request documentation of quality assurance processes and relevant certifications from your supplier. Common certifications include ISO 9001 and ASTM standards, which can provide assurance of product quality and safety. Ask for samples to conduct your own quality testing, and consider third-party inspection services if the order volume justifies the cost. Establish clear quality expectations in your purchase agreement to address any potential discrepancies before they arise. -

What logistics considerations should I keep in mind when importing high-density closed cell foam?

Logistics is crucial when importing closed cell foam. Evaluate shipping methods (air vs. sea) based on your budget and urgency. Be aware of potential customs duties, tariffs, and import regulations specific to your region. Ensure your supplier provides all necessary documentation, such as bills of lading and certificates of origin, to facilitate smooth customs clearance. Collaborate with a logistics provider experienced in handling foam products to optimize shipping routes and minimize costs. -

How can I handle disputes with suppliers effectively?

To handle disputes, maintain open communication with your supplier and document all interactions. Establish a clear dispute resolution process in your contract, which may include mediation or arbitration clauses. If issues arise, address them promptly, presenting evidence and seeking a mutually agreeable solution. Consider involving a third-party mediator if direct discussions stall. Building a strong relationship with your supplier can often prevent disputes from escalating. -

What are the key applications of high-density closed cell foam that I should consider for my business?

High-density closed cell foam is widely used in various industries, including packaging, automotive, healthcare, and construction. Its water resistance and durability make it ideal for insulation, shock absorption, and flotation devices. For businesses in these sectors, leveraging the unique properties of closed cell foam can enhance product performance and safety. Evaluate specific applications within your industry to determine how high-density closed cell foam can meet your operational needs and improve your product offerings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for high density closed cell foam

In summary, high density closed cell foam presents a wealth of opportunities for international B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. Its exceptional durability, moisture resistance, and versatility make it ideal for applications ranging from insulation to packaging and automotive uses.

Strategic sourcing of this material not only ensures quality and reliability but also enhances supply chain efficiency. Buyers should prioritize establishing strong relationships with reputable suppliers who can provide tailored solutions that meet specific industry needs. Leveraging local suppliers can also reduce lead times and transportation costs, which is crucial in today’s fast-paced market.

Looking ahead, the demand for high density closed cell foam is expected to rise, driven by advancements in manufacturing processes and an increasing focus on sustainability. B2B buyers are encouraged to stay informed about emerging trends and innovations within the foam industry. By doing so, they can position themselves to capitalize on new opportunities and maintain a competitive edge. Embrace the potential of high density closed cell foam—strategically source your materials to drive growth and success in your operations.