Master Sourcing Strategies for L Channel Aluminum: A B2B

Introduction: Navigating the Global Market for l channel aluminum

In today’s interconnected global marketplace, L-channel aluminum has become a vital element across diverse sectors, from construction and manufacturing to electronics and aerospace. Its unique L-shape not only provides structural integrity but also enhances aesthetic appeal, making it a preferred choice for innovative applications. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing L-channel aluminum is essential for optimizing procurement strategies and ensuring project success.

This comprehensive guide covers everything you need to know about L-channel aluminum, including an exploration of various types and designs, the aluminum alloys used in production, and insights into manufacturing processes and quality control measures. Additionally, it offers an overview of cost considerations, emerging market trends, and potential suppliers across key regions.

By addressing frequently asked questions, this guide empowers buyers to make well-informed decisions that align with their project specifications and budget constraints. As the global aluminum market continues to expand, leveraging the insights provided here will enable you to navigate the complexities of sourcing L-channel aluminum effectively. This ensures that you capitalize on opportunities while mitigating risks in an increasingly competitive landscape.

Understanding l channel aluminum Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| L-shaped Profiles with Even Sides | Equal-length sides forming a 90° angle | Electronics, Robotics, Furnishing | Pros: Versatile, cost-effective; Cons: Limited to applications requiring uniformity. |

| L-shaped Profiles with Uneven Sides | Different length sides, providing flexibility | Mechanics, Electromechanics, Construction | Pros: High strength, shock resistance; Cons: May require custom orders for specific applications. |

| L-shaped Profiles with Special Cross Section | Unique shapes (e.g., knurled surfaces) for specific functions | Finishing elements for panels, steps | Pros: Tailored solutions for unique applications; Cons: Potentially higher costs for custom designs. |

| Customized L-shaped Profiles | Tailored designs based on specific client requirements | Specialized machinery, bespoke structures | Pros: Exact fit for unique needs; Cons: Longer lead times and higher initial costs. |

| Standard L-shaped Aluminum Bars | Simple, uniform bars available in standard sizes | General construction, framing | Pros: Readily available, easy to source; Cons: Limited functionality compared to specialized profiles. |

L-shaped Profiles with Even Sides

These profiles feature equal-length sides that form a standard 90° angle, making them ideal for applications requiring uniformity. Commonly made from alloys like 6060, they are particularly suited for electronics and robotics, where precision is crucial. When sourcing, buyers should be mindful of minimum order quantities and ensure that the chosen alloy meets their specific performance requirements.

L-shaped Profiles with Uneven Sides

Uneven-sided profiles offer enhanced flexibility, making them suitable for mechanical and construction applications where strength and shock resistance are vital. These profiles can be manufactured from various aluminum alloys to suit specific needs. Buyers should consider the potential for custom designs, which may involve longer lead times and additional costs, but can provide significant advantages in specialized applications.

L-shaped Profiles with Special Cross Section

Profiles with special cross sections, such as knurled or textured surfaces, cater to unique functional requirements in applications like panel finishes or stair treads. These tailored solutions often come at a higher cost, so it is essential for buyers to evaluate the trade-off between enhanced functionality and budget constraints. Customization can lead to innovative design solutions, but careful planning is necessary to manage expenses.

Customized L-shaped Profiles

For businesses with specific design needs, customized L-shaped profiles provide the flexibility to meet exact specifications. While these profiles ensure a perfect fit for specialized machinery or bespoke structures, they typically involve longer lead times and higher initial costs. B2B buyers should weigh the benefits of tailored solutions against potential delays in delivery and assess their project timelines accordingly.

Standard L-shaped Aluminum Bars

Standard L-shaped aluminum bars are readily available and commonly used in general construction and framing projects. Their simplicity and uniformity make them easy to source, providing a practical solution for many applications. However, buyers should evaluate whether these profiles will meet their specific project requirements, as they may lack the versatility and functionality of more specialized options.

Related Video: How Die Casting Aluminum Works – How It’s Made

Key Industrial Applications of l channel aluminum

| Industry/Sector | Specific Application of l channel aluminum | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural support in high-rise buildings and bridges | Provides lightweight strength and corrosion resistance | Assess local supply availability and compliance with building codes |

| Transportation | Chassis construction for vehicles and aircraft | Enhances fuel efficiency through weight reduction | Verify alloy specifications and weight tolerances for safety standards |

| Medical Equipment | Frames for hospital beds and dialysis machines | Ensures hygiene and easy maintenance due to corrosion resistance | Evaluate custom design capabilities for specific medical applications |

| Electronics | Housing and structural supports for electronic devices | Offers excellent heat dissipation and lightweight design | Consider thermal conductivity and electromagnetic shielding properties |

| Manufacturing | Ramps and loading equipment in logistics | Improves operational efficiency and safety | Ensure compliance with international safety standards and durability requirements |

Construction

In the construction industry, L channel aluminum is widely utilized for structural support in high-rise buildings and bridges. Its lightweight yet strong properties allow for easier handling and installation, reducing labor costs and time on-site. Additionally, the corrosion resistance of aluminum ensures longevity, which is crucial for infrastructures exposed to various environmental conditions. For international buyers, it is essential to consider local supply chains and compliance with regional building codes to avoid project delays.

Transportation

In the transportation sector, L channel aluminum plays a pivotal role in the chassis construction of vehicles and aircraft. The material’s high strength-to-weight ratio contributes to improved fuel efficiency, a critical factor for reducing operational costs. Buyers should verify the specific alloy grades used to ensure they meet safety standards and performance requirements. Understanding local regulations regarding transportation materials is also vital for international sourcing.

Medical Equipment

L channel aluminum is essential in the medical equipment sector, particularly for frames in hospital beds and dialysis machines. Its non-corrosive nature helps maintain hygiene standards, making it suitable for sterile environments. Buyers in this sector should assess the custom design capabilities of suppliers to meet specific medical requirements, ensuring compliance with health and safety regulations. Additionally, sourcing from reliable manufacturers can mitigate risks associated with equipment failure.

Electronics

In the electronics industry, L channel aluminum is used for housing and structural supports in various devices. The material’s excellent heat dissipation properties help maintain optimal operating temperatures, thereby enhancing device performance and longevity. When sourcing, international buyers should consider the need for electromagnetic shielding, as well as the thermal conductivity of the chosen aluminum alloy. This ensures that the components can operate efficiently in diverse environments.

Manufacturing

L channel aluminum is commonly employed in manufacturing settings for ramps and loading equipment, facilitating the movement of goods and enhancing operational efficiency. The lightweight nature of aluminum reduces the risk of injury during manual handling and improves safety protocols. Buyers should ensure that the sourced products comply with international safety standards and durability requirements to withstand industrial use. Understanding local market conditions can also aid in optimizing logistics and supply chain management.

Related Video: Extrusion 101: Aluminum Extrusion Process Explained by ILSCO Extrusions Inc.

Strategic Material Selection Guide for l channel aluminum

When selecting materials for L-channel aluminum, it is essential to consider various aluminum alloys, as their properties significantly influence the performance and suitability for specific applications. Below are analyses of four common materials used in L-channel aluminum, focusing on their key properties, advantages and disadvantages, application impacts, and considerations for international B2B buyers.

1. Aluminum Alloy 6061

Key Properties:

Aluminum Alloy 6061 is known for its excellent mechanical properties, including high strength-to-weight ratio and good corrosion resistance. It can withstand temperatures up to 150°C (302°F) and is suitable for welding.

Pros & Cons:

Pros: Durable, versatile, and easy to machine. It offers good resistance to stress corrosion cracking.

Cons: Moderate cost compared to other alloys; may require additional surface treatments for enhanced corrosion resistance in harsh environments.

Impact on Application:

6061 is commonly used in structural applications, including frames and supports in construction and automotive industries. Its compatibility with various media makes it suitable for both indoor and outdoor applications.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with EN standards for structural aluminum. In Africa and South America, local sourcing may affect availability and lead times.

2. Aluminum Alloy 6063

Key Properties:

6063 aluminum alloy is characterized by excellent extrudability and a smooth surface finish. It has good corrosion resistance and can handle temperatures up to 100°C (212°F).

Pros & Cons:

Pros: Ideal for architectural applications due to its aesthetic finish; lightweight yet strong.

Cons: Lower strength compared to 6061; may not be suitable for heavy-load applications.

Impact on Application:

This alloy is often used in window frames, door frames, and other architectural elements. Its aesthetic properties make it a preferred choice in construction and design.

Considerations for International Buyers:

European buyers should reference EN 573 standards, while Middle Eastern buyers may need to consider local building codes that emphasize aesthetic qualities.

3. Aluminum Alloy 5052

Key Properties:

5052 aluminum alloy is known for its excellent corrosion resistance, particularly in marine environments, and has a high fatigue strength. It can withstand temperatures up to 65°C (149°F).

Pros & Cons:

Pros: Exceptional corrosion resistance and weldability; suitable for marine and chemical applications.

Cons: Higher cost compared to 6061 and 6063; limited availability in some regions.

Impact on Application:

This alloy is ideal for applications in marine environments, such as boat hulls and chemical storage tanks, where corrosion resistance is critical.

Considerations for International Buyers:

Buyers in coastal regions of Africa and South America should prioritize 5052 for marine applications. Compliance with ASTM standards is crucial for ensuring quality and performance.

4. Aluminum Alloy 7075

Key Properties:

7075 aluminum alloy is one of the strongest aluminum alloys, with high strength and good fatigue resistance. It can withstand temperatures up to 120°C (248°F).

Pros & Cons:

Pros: High strength-to-weight ratio; excellent for aerospace and military applications.

Cons: More expensive than other alloys; less corrosion resistant, requiring protective coatings.

Impact on Application:

7075 is primarily used in aerospace and defense applications where strength is critical. It is also suitable for high-stress structural components.

Considerations for International Buyers:

International buyers, particularly in the aerospace sector in Europe and the Middle East, should ensure compliance with stringent aerospace standards (e.g., AMS specifications).

Summary Table

| Material | Typical Use Case for l channel aluminum | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy 6061 | Structural frames, automotive parts | High strength-to-weight ratio | Moderate cost; requires treatments | Medium |

| Aluminum Alloy 6063 | Architectural elements, window frames | Excellent extrudability | Lower strength than 6061 | Medium |

| Aluminum Alloy 5052 | Marine applications, chemical storage tanks | Exceptional corrosion resistance | Higher cost; limited availability | High |

| Aluminum Alloy 7075 | Aerospace and military applications | Very high strength | Expensive; less corrosion resistant | High |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for l channel aluminum

In the world of L-channel aluminum, understanding the manufacturing processes and quality assurance protocols is essential for B2B buyers looking to source high-quality materials. This section delves into the key stages of manufacturing, relevant quality control standards, and actionable insights for verifying supplier quality.

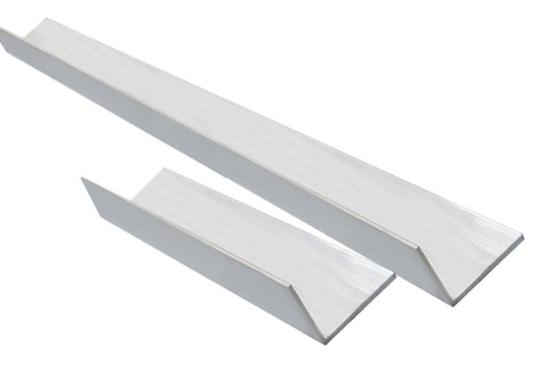

Illustrative Image (Source: Google Search)

Manufacturing Process of L-Channel Aluminum

The production of L-channel aluminum involves several critical stages, each designed to ensure the final product meets specific performance and aesthetic criteria. Here’s a breakdown of the primary stages:

1. Material Preparation

The journey begins with the selection of aluminum alloys, which are crucial for achieving desired properties such as strength, corrosion resistance, and lightweight characteristics. Common alloys include 6060, 6061, and 6082, which are favored for their balance of strength and workability.

- Billet Selection: High-quality aluminum billets are selected based on their chemical composition and mechanical properties.

- Cleaning and Inspection: The billets undergo cleaning to remove any contaminants that could affect extrusion quality.

2. Forming

The actual shaping of L-channel aluminum is accomplished through an extrusion process, which can be either hot, cold, or warm, depending on the alloy and desired characteristics.

- Hot Extrusion: Typically used for softer alloys, the aluminum is heated to a temperature that allows it to be forced through a channel-shaped die. This process enhances the material’s ductility, enabling complex shapes.

- Cold Extrusion: This method is employed for harder alloys and involves extruding at or near room temperature, resulting in a denser final product with improved mechanical properties.

- Die Design: The design of the extrusion die plays a vital role in determining the final profile’s accuracy, surface finish, and tolerances.

3. Assembly

Post-extrusion, the L-channel aluminum may undergo additional processing, depending on the application.

- Cutting: The extruded lengths are cut to specified dimensions.

- Fabrication: Additional machining operations, such as drilling or milling, may be performed to meet specific customer requirements.

4. Finishing

The finishing stage enhances both the aesthetic appeal and functional properties of the aluminum.

- Surface Treatments: Techniques such as anodizing, powder coating, or painting can be applied to improve corrosion resistance and provide a decorative finish.

- Straightening: After extrusion, sections are often straightened to ensure they meet dimensional tolerances before shipping.

Quality Assurance in L-Channel Aluminum Production

Quality assurance is a cornerstone of manufacturing processes, ensuring that products meet both international standards and customer specifications. Here are the key components of quality control:

Relevant International Standards

B2B buyers should look for suppliers that comply with recognized international quality management standards, such as:

- ISO 9001: This standard specifies requirements for a quality management system (QMS), ensuring consistent quality in products and services.

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with safety, health, and environmental protection standards.

- API Standards: For applications in the oil and gas industry, compliance with American Petroleum Institute standards ensures reliability and safety.

Quality Control Checkpoints

Effective quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspecting raw materials upon receipt to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring production processes to detect deviations in real-time, which helps maintain quality throughout manufacturing.

- Final Quality Control (FQC): Conducting comprehensive inspections of finished products to verify they meet design specifications and quality standards.

Common Testing Methods

To ensure the integrity and performance of L-channel aluminum, various testing methods may be employed:

- Mechanical Testing: Tensile tests, hardness tests, and impact tests assess the material’s mechanical properties.

- Chemical Analysis: Spectrometric analysis verifies the composition of aluminum alloys, ensuring compliance with specified grades.

- Dimensional Inspection: Utilizing tools such as calipers and gauges to confirm that the final product meets specified dimensions and tolerances.

Verifying Supplier Quality Control

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are actionable steps:

- Supplier Audits: Conducting on-site audits can provide insight into the supplier’s manufacturing processes, quality control measures, and overall operational standards.

- Request Quality Reports: Suppliers should be able to provide detailed quality reports, including inspection results, testing certifications, and compliance with industry standards.

- Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s quality control processes, ensuring adherence to international standards.

Quality Control Considerations for International Buyers

When sourcing L-channel aluminum, international buyers should be aware of specific nuances in quality control:

- Documentation Requirements: Ensure that suppliers provide all necessary documentation, including certificates of compliance, material test reports, and warranties.

- Cultural and Regulatory Differences: Be mindful of varying regulations and quality expectations across different regions. For example, suppliers in Europe may have more stringent compliance requirements than those in other regions.

- Communication: Establish clear communication channels with suppliers to address quality concerns promptly. Regular updates and feedback can help maintain quality standards throughout the supply chain.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for L-channel aluminum is crucial for B2B buyers looking to make informed sourcing decisions. By focusing on material preparation, forming techniques, and robust quality control measures, buyers can ensure they partner with suppliers who deliver reliable and high-quality products. With this knowledge, companies can navigate the complexities of international sourcing, ensuring their projects meet the highest standards of quality and performance.

Related Video: Most Amazing Factory Manufacturing Process Videos | Factory Mass Production

Comprehensive Cost and Pricing Analysis for l channel aluminum Sourcing

Understanding the cost structure and pricing dynamics of L channel aluminum sourcing is essential for international B2B buyers looking to optimize their procurement strategies. This analysis will break down the key components of cost, the factors influencing prices, and provide actionable tips for negotiating better deals.

Cost Components of L Channel Aluminum

-

Materials: The cost of aluminum alloys is a significant portion of the total price. Common alloys used for L channel aluminum include 6060, 6061, and 6082, each with distinct properties affecting their price. Prices fluctuate based on market demand and global aluminum prices, which are influenced by economic conditions and production levels.

-

Labor: Labor costs vary significantly by region. For instance, manufacturing in Europe may incur higher labor costs compared to facilities in Africa or South America. Understanding local labor rates is crucial for assessing total costs.

-

Manufacturing Overhead: This includes costs associated with factory operations such as utilities, maintenance, and administrative expenses. Efficient manufacturing processes can lower overhead, impacting the final price.

-

Tooling: Tooling costs depend on the complexity of the extrusion process. Customized profiles require specialized dies, which can significantly increase initial costs. However, these costs can be amortized over large production runs.

-

Quality Control (QC): Investments in quality assurance processes ensure that the aluminum profiles meet industry standards. Enhanced QC measures may raise costs but are critical for maintaining product integrity, especially in sectors like aerospace or construction.

-

Logistics: Shipping costs can vary widely based on the distance from the supplier to the buyer, the mode of transport, and any tariffs or duties applicable. International buyers must consider these logistics costs when evaluating total procurement expenses.

-

Margin: Suppliers typically build in a profit margin, which can vary based on their business model and market competition. Understanding the market dynamics can aid in negotiating better terms.

Price Influencers

Several factors significantly influence the pricing of L channel aluminum:

-

Volume/MOQ: Larger orders often lead to lower per-unit prices due to economies of scale. Understanding minimum order quantities (MOQ) is vital for cost efficiency.

-

Specifications/Customization: Customized profiles generally command a premium price. Buyers should evaluate whether the benefits of customization justify the additional costs.

-

Materials: The choice of alloy impacts pricing. Higher-grade materials may be more expensive but offer enhanced performance and durability.

-

Quality/Certifications: Products meeting specific industry certifications may be priced higher. Buyers should assess the importance of these certifications for their applications.

-

Supplier Factors: Supplier reputation, reliability, and service levels can influence pricing. Established suppliers may charge more for their expertise and assurance of quality.

-

Incoterms: The terms of shipping can affect pricing significantly. Understanding Incoterms (International Commercial Terms) will help buyers clarify responsibilities regarding shipping costs, risks, and insurance.

Buyer Tips

-

Negotiation: Leverage knowledge of the cost structure and price influencers to negotiate better terms. Engaging multiple suppliers can provide leverage in discussions.

-

Cost-Efficiency: Evaluate all components of the Total Cost of Ownership (TCO), including logistics and QC, rather than just the upfront price. This holistic view can lead to more informed purchasing decisions.

-

Pricing Nuances: Be aware of regional pricing trends. For example, prices may vary between suppliers in Europe and those in Africa or South America due to different economic conditions and market dynamics.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and service. Regular communication and feedback can foster trust and collaboration.

-

Market Research: Stay informed about global aluminum market trends and forecasts to anticipate price changes and adjust sourcing strategies accordingly.

Disclaimer: Prices for L channel aluminum can fluctuate based on a variety of factors, including market conditions and supplier dynamics. Always seek updated quotes and conduct thorough market research to inform your purchasing decisions.

Spotlight on Potential l channel aluminum Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘l channel aluminum’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for l channel aluminum

Understanding the essential technical properties and trade terminology associated with L channel aluminum is crucial for international B2B buyers. This knowledge not only aids in making informed purchasing decisions but also helps in establishing effective communication with suppliers and manufacturers.

Key Technical Properties of L Channel Aluminum

-

Material Grade

– Definition: Material grade refers to the specific alloy used in the aluminum profile, which affects its strength, corrosion resistance, and other mechanical properties. Common grades include 6060, 6061, and 7075.

– B2B Importance: Selecting the appropriate material grade is vital for ensuring the L channel meets the specific requirements of the intended application, whether it be structural integrity in construction or lightweight performance in aerospace. -

Tolerance

– Definition: Tolerance denotes the permissible limit of variation in the dimensions of the aluminum profiles. It is typically expressed in millimeters or inches.

– B2B Importance: Understanding tolerance is crucial for ensuring that the L channel fits precisely within the assembly it is intended for. High precision can prevent costly adjustments during installation. -

Surface Finish

– Definition: Surface finish refers to the treatment applied to the aluminum, such as anodizing or powder coating, which enhances aesthetics and protects against corrosion.

– B2B Importance: Buyers should consider surface finish to ensure durability and maintain the desired appearance of their products, especially in industries where visual appeal is critical, like interior design and architecture.

Illustrative Image (Source: Google Search)

-

Weight Capacity

– Definition: Weight capacity indicates the maximum load that an L channel can support without bending or failing.

– B2B Importance: Knowing the weight capacity is essential for applications in construction or manufacturing, as it directly impacts safety and performance standards. -

Length and Customization Options

– Definition: This refers to the standard lengths available and the ability to customize lengths to meet specific project requirements.

– B2B Importance: Custom lengths can minimize waste and reduce installation time, making it an attractive option for large-scale projects. -

Corrosion Resistance

– Definition: This property indicates how well the aluminum can withstand environmental factors that lead to degradation.

– B2B Importance: In regions with high humidity or exposure to chemicals, corrosion resistance is a critical factor for long-term performance and maintenance costs.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify reliable suppliers who adhere to industry standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest amount of product a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers assess the feasibility of placing orders and managing inventory effectively. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products.

– Importance: RFQs are essential for comparing offers and negotiating terms, ensuring buyers get the best value. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities associated with international transactions. -

Lead Time

– Definition: The time it takes from placing an order to the delivery of the product.

– Importance: Understanding lead times is crucial for project planning and inventory management, allowing buyers to align procurement with production schedules. -

Certification Standards

– Definition: Specifications that products must meet to comply with industry regulations (e.g., ISO, ASTM).

– Importance: Certifications assure buyers of quality and safety, which is particularly important in regulated industries like construction and aerospace.

By grasping these technical properties and trade terms, international B2B buyers can enhance their procurement strategies, ensuring they select the right L channel aluminum for their specific needs while maintaining effective supplier relationships.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the l channel aluminum Sector

In the rapidly evolving landscape of global trade, the L channel aluminum sector is witnessing significant transformations driven by various market dynamics. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must stay attuned to these changes to optimize their sourcing strategies.

Market Overview & Key Trends

The demand for L channel aluminum is primarily driven by its versatility and lightweight characteristics, making it a preferred choice in construction, automotive, and electronics sectors. Emerging trends include the increasing adoption of digital sourcing platforms that facilitate streamlined procurement processes. Buyers are now leveraging data analytics and AI to forecast demand more accurately and identify reliable suppliers. Additionally, just-in-time (JIT) inventory practices are gaining traction, enabling companies to minimize holding costs while ensuring timely project execution.

The global aluminum market is also influenced by geopolitical factors, fluctuating raw material prices, and supply chain disruptions. For instance, trade policies and tariffs can significantly impact sourcing strategies, particularly for buyers in regions like Europe and the Middle East. Understanding local market conditions and potential trade barriers is crucial for making informed purchasing decisions. Furthermore, the shift towards local sourcing is gaining momentum, as companies aim to reduce lead times and mitigate risks associated with international logistics.

Sustainability & Ethical Sourcing in B2B

As environmental concerns become increasingly paramount, sustainability in the sourcing of L channel aluminum is a critical consideration for international buyers. The aluminum industry is known for its significant carbon footprint during production; however, advancements in recycling technologies are helping to mitigate this impact. Aluminum is 100% recyclable, and utilizing recycled materials can drastically reduce energy consumption and emissions.

Ethical supply chains are also essential, as buyers are encouraged to prioritize suppliers that adhere to responsible sourcing practices. This includes obtaining green certifications such as ISO 14001, which signifies an organization’s commitment to effective environmental management. Additionally, sourcing from manufacturers that utilize sustainable energy sources in their production processes can enhance a company’s environmental credentials. Buyers should also consider the entire lifecycle of aluminum products, from extraction to disposal, to ensure they are making choices that support sustainability goals.

Brief Evolution/History

The use of aluminum channels, including L channel profiles, has evolved significantly since the mid-20th century when aluminum became widely recognized for its lightweight and corrosion-resistant properties. Initially utilized in aerospace applications, the material’s versatility soon expanded to include construction and automotive sectors. Over the decades, advancements in extrusion techniques and alloy formulations have enhanced the performance and applications of aluminum, making it a staple in modern manufacturing. Today, the focus on sustainability and ethical sourcing is shaping the future of the L channel aluminum market, with buyers increasingly seeking suppliers that prioritize environmental responsibility.

By staying informed about these market dynamics and trends, B2B buyers can navigate the complexities of sourcing L channel aluminum, ensuring they make strategic decisions that align with their business objectives and sustainability commitments.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of l channel aluminum

-

What should I look for when vetting suppliers of L channel aluminum?

When vetting suppliers, consider their manufacturing capabilities, certifications, and reputation in the market. Check for ISO certifications, as they indicate adherence to international quality standards. Evaluate their experience with international trade, particularly in your region, to ensure they understand local regulations and market dynamics. Request samples of their products to assess quality, and look for customer testimonials or case studies that demonstrate their reliability and service. Additionally, inquire about their production capacity to ensure they can meet your order volumes. -

Can I customize L channel aluminum profiles to meet specific project needs?

Yes, many suppliers offer customization options for L channel aluminum profiles. You can specify dimensions, alloys, and even special features such as surface treatments or finishes. When requesting customization, be clear about your project requirements and provide detailed specifications. Keep in mind that custom orders may require longer lead times and higher costs, so factor this into your project timeline and budget. Ensure that the supplier has experience with custom designs and can provide examples of past projects. -

What are the typical minimum order quantities (MOQs) and lead times for L channel aluminum?

Minimum order quantities for L channel aluminum can vary widely depending on the supplier and the complexity of the order. Standard profiles typically have lower MOQs, often around 300 kg, while custom profiles may have higher MOQs. Lead times also vary; standard orders may take a few weeks, while custom profiles could take several weeks to months. It’s essential to discuss these details upfront with potential suppliers to align your project timelines and avoid unexpected delays. -

What payment options are commonly available for international B2B transactions?

Payment options for international B2B transactions typically include wire transfers, letters of credit, and payment platforms like PayPal. Wire transfers are the most common due to their simplicity and speed, but they may not offer buyer protection. Letters of credit provide a secure option, ensuring that payment is made only when certain conditions are met. Discuss payment terms with your supplier early in negotiations and consider using escrow services for larger transactions to mitigate risks. -

How can I ensure quality assurance and certifications for L channel aluminum?

To ensure quality assurance, request that suppliers provide documentation of their quality control processes and any relevant certifications, such as ISO 9001. Ask about their testing procedures, including tensile strength, corrosion resistance, and dimensional accuracy. A reputable supplier should be willing to share test reports and quality assurance certifications upon request. Additionally, consider conducting periodic audits or inspections of the manufacturing facility if the order volume justifies it. -

What logistics considerations should I keep in mind when sourcing L channel aluminum?

Logistics is a critical aspect of sourcing L channel aluminum internationally. Consider the shipping methods, costs, and transit times to your location. Understand the import regulations and duties in your country, as these can significantly impact the total cost. Collaborate with the supplier to choose the best shipping option, whether it’s air freight for speed or sea freight for cost-effectiveness. Ensure that the supplier has a reliable logistics partner and can provide tracking information throughout the shipping process. -

What should I do if there is a dispute with my supplier?

In case of a dispute, first, attempt to resolve the issue through direct communication with the supplier. Clearly outline your concerns and provide any supporting documentation. If informal discussions do not lead to a resolution, refer to the contract terms, which should detail dispute resolution processes, such as mediation or arbitration. Keeping a record of all communications can be beneficial. If necessary, seek legal advice, especially when international laws and regulations are involved. -

How can I keep up with market trends in L channel aluminum sourcing?

Staying informed about market trends requires proactive engagement with industry publications, trade shows, and online forums. Subscribe to industry newsletters and follow relevant organizations on social media to receive updates on market conditions, pricing fluctuations, and new technologies. Networking with other B2B buyers and suppliers can provide insights into best practices and emerging trends. Additionally, consider leveraging market research reports for in-depth analyses tailored to your specific regions of interest.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for l channel aluminum

The strategic sourcing of L-shaped aluminum profiles is essential for international B2B buyers aiming to optimize their supply chains and enhance project outcomes. Understanding the diverse types of L-shaped aluminum, including their unique applications and benefits, allows buyers to make informed decisions that align with their specific needs. Prioritizing suppliers who demonstrate strong quality control measures and a commitment to using high-grade aluminum alloys can significantly impact the performance and longevity of the products.

As the global demand for aluminum continues to rise, particularly in construction, aerospace, and electronics, strategic sourcing will play a pivotal role in securing competitive pricing and reliable delivery timelines. Buyers from Africa, South America, the Middle East, and Europe should leverage regional advantages while exploring partnerships with manufacturers that offer both standard and customized profiles.

Looking ahead, embracing innovative sourcing strategies and staying abreast of market trends will empower buyers to navigate challenges and seize opportunities in this dynamic industry. Engage with suppliers proactively, evaluate your sourcing strategies regularly, and prioritize quality to ensure your projects succeed in an increasingly competitive global marketplace.