Master the Art of Sourcing Spring Loaded Hinges for Global

Introduction: Navigating the Global Market for spring loaded hinges

In an increasingly interconnected global market, the role of spring-loaded hinges cannot be understated. These mechanical devices are essential for ensuring seamless operations across diverse industries, including manufacturing, construction, and furniture design. Their ability to provide automatic opening and closing actions enhances efficiency and safety, making them indispensable in environments that require frequent access or secure closures. For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, understanding the nuances of spring-loaded hinges is critical to maintaining competitive advantage.

This comprehensive guide is designed to equip procurement professionals with actionable insights into the world of spring-loaded hinges. It delves into various types, such as concealed and adjustable spring-loaded hinges, and examines key materials and their properties, including corrosion resistance and load capacity. Furthermore, it explores manufacturing quality control standards that ensure product reliability, alongside strategies for selecting reputable suppliers and optimizing costs.

With region-specific insights, this guide empowers buyers to make informed sourcing decisions tailored to their unique market conditions. Whether navigating the complexities of local regulations or adapting to evolving customer expectations, this resource serves as a vital tool for enhancing operational excellence and driving business growth. By leveraging the knowledge presented herein, B2B buyers can confidently engage with the global hinge market, securing components that align with their strategic objectives.

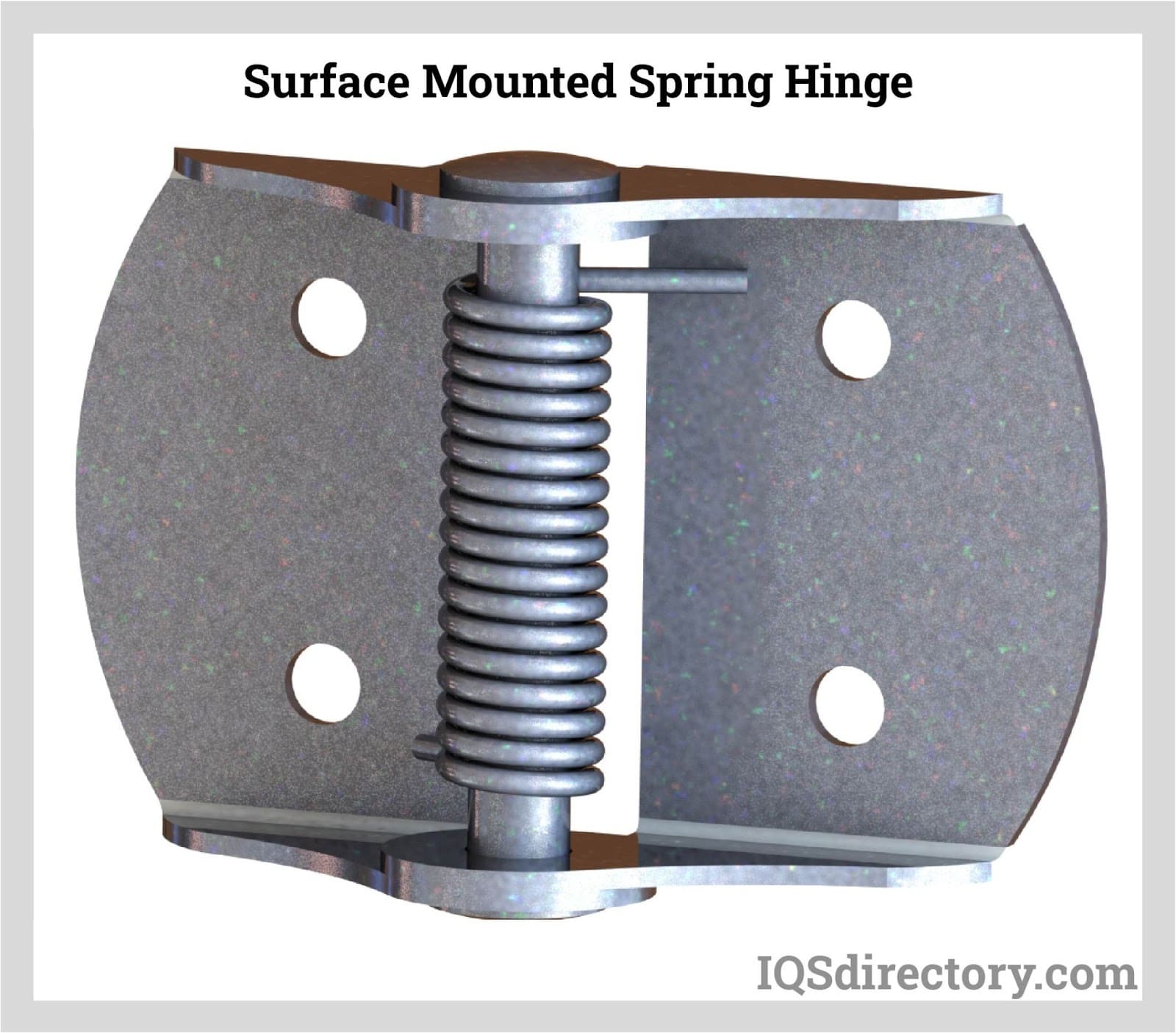

Understanding spring loaded hinges Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Adjustable Spring-Loaded Hinge | Allows tension adjustment for customized operation | Heavy doors, industrial applications | Flexible performance; requires careful calibration during setup. |

| Concealed Spring-Loaded Hinge | Hidden installation for aesthetic appeal | High-end cabinetry, commercial spaces | Sleek design; may require precise installation and alignment. |

| Heavy-Duty Spring-Loaded Hinge | Built for high load capacity and durability | Warehouse doors, loading docks | Robust performance; often more expensive and heavier. |

| Self-Closing Spring-Loaded Hinge | Automatically closes after opening | Public restrooms, fire doors | Enhances safety and convenience; potential for wear over time. |

| Pneumatic Spring-Loaded Hinge | Uses air pressure for operation | Machinery, automated systems | Smooth operation; requires a compressed air source and maintenance. |

Adjustable Spring-Loaded Hinge

Adjustable spring-loaded hinges are designed to allow users to modify the spring tension according to specific needs, making them ideal for applications involving heavy doors or panels. This flexibility is particularly beneficial in industrial settings where load requirements may vary. When purchasing, B2B buyers should assess the hinge’s load capacity and ensure compatibility with existing door systems. Proper installation is critical, as incorrect tension settings can lead to functionality issues or premature wear.

Concealed Spring-Loaded Hinge

Concealed spring-loaded hinges are installed within the door or frame, providing a clean and modern appearance without visible hardware. This type of hinge is commonly used in high-end cabinetry and commercial spaces where aesthetics are paramount. B2B buyers should consider the hinge’s adjustability and load capacity, as these factors are crucial for maintaining the desired door alignment. The installation process requires precision, making it essential to partner with experienced suppliers to ensure optimal performance.

Heavy-Duty Spring-Loaded Hinge

Heavy-duty spring-loaded hinges are engineered to withstand significant weight and frequent use, making them suitable for environments such as warehouses and loading docks. Their robust construction ensures durability and reliability in high-traffic applications. Buyers should evaluate load ratings and material composition, as these factors directly influence performance and lifespan. While they may come at a higher cost, the investment is justified by their long-term reliability and reduced maintenance needs.

Self-Closing Spring-Loaded Hinge

Self-closing spring-loaded hinges automatically close doors after opening, enhancing safety and convenience in various applications, including public restrooms and fire doors. This feature is particularly valuable in environments where maintaining security and hygiene is essential. Buyers should assess the durability of the spring mechanism and consider potential wear over time. Additionally, compliance with safety regulations is crucial when selecting these hinges for commercial use.

Pneumatic Spring-Loaded Hinge

Pneumatic spring-loaded hinges utilize air pressure to facilitate their operation, offering smooth and controlled movement. These hinges are often found in machinery and automated systems, where precision and reliability are critical. B2B buyers must ensure access to a compressed air source and consider the maintenance requirements associated with pneumatic systems. Evaluating the operational environment and potential exposure to contaminants is essential for selecting the right hinge type to ensure longevity and efficiency.

Related Video: Difference Between Loaded to Open & Loaded to Close Spring Hinges

Key Industrial Applications of spring loaded hinges

| Industry/Sector | Specific Application of spring loaded hinges | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automatic doors in production lines | Enhances workflow efficiency and safety by ensuring doors close automatically | Load capacity, material durability, and environmental resistance |

| Hospitality | Self-closing doors in hotels and restaurants | Improves guest experience and safety, reducing noise and ensuring privacy | Aesthetic design, ease of installation, and maintenance needs |

| Healthcare | Doors in clinics and hospitals that require controlled access | Maintains hygiene and safety by ensuring doors close after use | Compliance with health regulations, corrosion resistance, and ease of cleaning |

| Transportation | Cargo doors on freight vehicles and shipping containers | Increases operational efficiency by ensuring secure closure during transit | Load rating, resistance to environmental conditions, and ease of operation |

| Construction | Entry doors in commercial buildings | Enhances security and energy efficiency, maintaining climate control | Compliance with building codes, durability, and warranty terms |

Manufacturing

In the manufacturing sector, spring-loaded hinges are often utilized in automatic doors on production lines. These hinges facilitate seamless movement, allowing doors to close automatically after passing through, which enhances workflow efficiency and safety. Buyers must consider the load capacity of the hinges to ensure they can withstand the weight of heavy doors, as well as the material’s durability to cope with industrial environments, including exposure to dust and moisture.

Hospitality

In the hospitality industry, self-closing doors equipped with spring-loaded hinges are widely used in hotels and restaurants. These hinges not only enhance the guest experience by providing privacy and reducing noise but also ensure that doors close securely behind patrons. B2B buyers should focus on aesthetic design to match the establishment’s decor, while also considering ease of installation and maintenance requirements to ensure longevity and functionality.

Healthcare

Spring-loaded hinges play a critical role in healthcare facilities, particularly in clinics and hospitals where controlled access is necessary. These hinges ensure that doors close automatically, helping to maintain hygiene and safety standards by minimizing the risk of contamination. Buyers in this sector must prioritize compliance with health regulations, selecting hinges made from materials that are resistant to corrosion and easy to clean, ensuring they meet the stringent requirements of healthcare environments.

Transportation

In the transportation sector, spring-loaded hinges are essential for cargo doors on freight vehicles and shipping containers. These hinges secure the doors during transit, preventing accidental openings that could compromise cargo safety. When sourcing these hinges, businesses should evaluate the load rating to ensure they can handle heavy cargo, as well as the resistance to environmental conditions, such as moisture and temperature fluctuations, to ensure reliability during transport.

Construction

In construction, spring-loaded hinges are frequently installed on entry doors in commercial buildings. These hinges contribute to enhanced security and energy efficiency by ensuring doors close tightly, maintaining climate control within the building. Buyers must ensure compliance with local building codes, considering the durability of the hinges to withstand heavy use, and reviewing warranty terms to protect their investment in quality hardware.

Strategic Material Selection Guide for spring loaded hinges

When selecting spring-loaded hinges, the choice of material significantly influences performance, durability, and overall application suitability. Below is an analysis of four common materials used in the manufacturing of spring-loaded hinges, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Stainless Steel

Key Properties:

Stainless steel is renowned for its excellent corrosion resistance and strength. It typically withstands high temperatures and pressures, making it suitable for various industrial applications. Its non-reactive nature also ensures compatibility with a wide range of media, including chemicals.

Pros & Cons:

Stainless steel hinges are highly durable and can endure harsh environmental conditions, which is vital for outdoor or industrial settings. However, they tend to be more expensive than other materials, and their manufacturing process can be complex due to the need for specialized tooling.

Impact on Application:

These hinges are ideal for applications exposed to moisture or corrosive substances, such as in food processing or marine environments. Their robustness ensures longevity, reducing the need for frequent replacements.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM and DIN for quality assurance. In Africa and South America, sourcing from reputable manufacturers is crucial to avoid substandard products.

Brass

Key Properties:

Brass is a metal alloy made primarily of copper and zinc. It exhibits good corrosion resistance, particularly in non-humid environments, and has a moderate strength-to-weight ratio, making it suitable for lighter applications.

Pros & Cons:

Brass hinges are aesthetically pleasing and provide a classic look, often favored in decorative applications. However, they are less durable than stainless steel, particularly in outdoor settings, and can tarnish over time, requiring maintenance.

Impact on Application:

These hinges are commonly used in residential and commercial furniture, cabinetry, and decorative doors. Their lightweight nature makes them suitable for applications where heavy-duty performance is not critical.

Considerations for International Buyers:

Buyers should be aware of local preferences for aesthetics and ensure that brass products meet regional standards for quality and performance. Compliance with JIS standards may be particularly relevant for buyers in Japan and other parts of Asia.

Plastic

Key Properties:

Plastic hinges are lightweight and resistant to corrosion and chemicals, making them suitable for various environments. They can operate effectively within a wide temperature range, although they may have lower load-bearing capabilities compared to metal hinges.

Pros & Cons:

Plastic hinges are cost-effective and easy to install, making them attractive for budget-conscious projects. However, they may not provide the same level of durability or strength as metal options, limiting their use in heavy-duty applications.

Impact on Application:

These hinges are often used in applications such as lightweight doors, cabinets, and equipment enclosures. Their resistance to chemicals makes them suitable for laboratories and food processing environments.

Considerations for International Buyers:

When sourcing plastic hinges, buyers should consider the specific types of plastics used, as not all plastics offer the same level of performance. Compliance with environmental regulations, such as REACH in Europe, is also essential.

Aluminum

Key Properties:

Aluminum is lightweight yet strong, with good corrosion resistance. It can withstand moderate temperatures and is often treated with coatings to enhance its durability in various environments.

Pros & Cons:

Aluminum hinges are versatile and can be used in a wide range of applications, from residential to industrial. However, they may not be suitable for extremely high-load applications, and their cost can vary significantly based on the alloy used.

Impact on Application:

These hinges are ideal for applications requiring a balance of strength and weight, such as in aircraft, automotive, and high-end furniture. Their corrosion resistance makes them suitable for both indoor and outdoor use.

Considerations for International Buyers:

Buyers should ensure that aluminum hinges meet relevant standards, such as ASTM for strength and durability. In regions like Africa and South America, it is essential to source from manufacturers with a proven track record to ensure product reliability.

| Material | Typical Use Case for spring loaded hinges | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial doors, marine applications | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Brass | Decorative furniture, cabinetry | Aesthetic appeal | Less durable in outdoor settings | Medium |

| Plastic | Lightweight doors, equipment enclosures | Cost-effective and lightweight | Lower load-bearing capacity | Low |

| Aluminum | Aircraft, automotive, high-end furniture | Lightweight and corrosion-resistant | May not handle extreme loads | Medium |

This analysis provides a clear overview of material options for spring-loaded hinges, helping international B2B buyers make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for spring loaded hinges

Manufacturing Processes for Spring Loaded Hinges

The production of spring-loaded hinges involves several key stages, each critical to ensuring the final product meets performance and quality standards. The primary phases include material preparation, forming, assembly, and finishing.

Illustrative Image (Source: Google Search)

Material Preparation

The first step in manufacturing spring-loaded hinges is selecting the right materials. Common materials include stainless steel, carbon steel, and brass, chosen for their strength, durability, and resistance to corrosion. The materials undergo thorough inspections to verify their quality and compliance with specifications. This often involves checking for defects, measuring thickness, and assessing mechanical properties.

Once the materials are verified, they are cut to size using precision machinery. Laser cutting or water jet cutting is commonly employed to achieve clean edges and precise dimensions, which are crucial for the hinge’s functionality.

Forming

The forming stage shapes the material into the desired hinge components. This typically involves stamping, bending, or forging processes. For spring-loaded hinges, the spring mechanism is a critical component, and the manufacturing process must ensure that the springs are produced with the right tension and size.

Key Techniques in Forming:

– Stamping: Used for creating flat components of the hinge. High-speed stamping machines can produce large quantities with uniform quality.

– Bending: Involves shaping the metal parts to fit the hinge design, ensuring that they can operate smoothly.

– Forging: Often used for heavy-duty hinges, forging enhances the strength of the material through deformation under heat and pressure.

Assembly

The assembly phase combines all the individual components into a complete hinge. This process may involve:

– Inserting the spring mechanism into the hinge body.

– Attaching the hinge leaves and ensuring proper alignment.

– Applying any necessary lubricants to facilitate smooth operation.

During assembly, manufacturers often utilize jigs and fixtures to maintain precision and reduce variability, ensuring that each hinge meets stringent specifications.

Finishing

The final stage is the finishing process, which enhances the hinge’s appearance and resistance to environmental factors. Common finishing techniques include:

– Electroplating: Adds a protective layer to prevent corrosion and improve aesthetics.

– Powder Coating: Provides a durable, colored finish that can withstand harsh conditions.

– Polishing: Enhances the visual appeal of the hinge, especially for decorative applications.

This stage also includes rigorous quality checks to ensure that the finished product meets all design specifications and performance criteria.

Quality Assurance in Manufacturing

Quality assurance (QA) is a critical component of the manufacturing process for spring-loaded hinges. It encompasses a series of standards and checkpoints to ensure that every hinge produced meets both international and industry-specific requirements.

International Standards

International standards such as ISO 9001 are pivotal for ensuring quality management systems are in place. These standards require manufacturers to establish processes that consistently produce products that meet customer and regulatory requirements. Other certifications that may be relevant include:

– CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

– API Certification: Relevant for hinges used in the oil and gas industry, ensuring products meet specific quality and safety criteria.

Quality Control Checkpoints

Quality control (QC) is typically structured around several critical checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC):

– This involves inspecting raw materials upon delivery to ensure they meet required specifications.

– Common tests include dimensional checks and material property assessments. -

In-Process Quality Control (IPQC):

– Continuous monitoring during the manufacturing process helps catch defects early.

– Techniques include visual inspections and measurements at various stages of production. -

Final Quality Control (FQC):

– The final inspection ensures that the assembled product functions correctly and meets all design criteria.

– Common tests include load testing, cycle testing, and performance assessments.

Common Testing Methods

Testing methods vary but typically include:

– Load Testing: Ensures that the hinge can withstand specified weight and pressure without failure.

– Durability Testing: Simulates real-world usage to assess the longevity of the hinge under operational conditions.

– Corrosion Resistance Testing: Evaluates how well the hinge withstands exposure to moisture and chemicals.

Verifying Supplier Quality Control

For B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are actionable strategies:

-

Supplier Audits: Regular audits can help assess compliance with international standards and internal processes. This includes evaluating manufacturing facilities, QA protocols, and employee training.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed QC reports, including results from testing and inspections. These documents provide transparency and assurance about product quality.

-

Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased assessment of product quality and compliance with specifications. This is particularly important for buyers in regions with varying regulatory standards.

Navigating Quality Control Nuances for International Buyers

B2B buyers must also be aware of the nuances in quality control when sourcing spring-loaded hinges internationally. Factors to consider include:

-

Regional Compliance: Different regions may have specific regulations and standards that need to be adhered to. For instance, European markets may have stricter environmental and safety regulations than those in other regions.

-

Cultural Differences in Manufacturing: Understanding cultural practices in manufacturing can help buyers anticipate potential issues. For example, communication styles and decision-making processes may vary significantly.

-

Supply Chain Logistics: Buyers should consider how logistics and transportation can impact product quality, especially for sensitive components like spring-loaded hinges that may require careful handling.

By thoroughly understanding the manufacturing processes and quality assurance measures for spring-loaded hinges, B2B buyers can make informed decisions that enhance their procurement strategies and ensure they source reliable, high-quality components.

Related Video: How Millions of Door Hinges are Produced in a Chinese Stainless Steel Factory

Comprehensive Cost and Pricing Analysis for spring loaded hinges Sourcing

Navigating the cost structure and pricing for spring-loaded hinges is crucial for international B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe. Understanding the components that contribute to the overall cost and identifying the key price influencers can empower buyers to make informed decisions and negotiate effectively.

Cost Components

-

Materials: The primary materials used in spring-loaded hinges include stainless steel, brass, and specialized alloys. Stainless steel is often preferred for its corrosion resistance and durability, especially in humid or industrial environments. The choice of material significantly influences pricing, with higher-quality materials commanding a premium.

-

Labor: Labor costs can vary widely based on the manufacturing location. Regions with lower labor costs can produce hinges more economically, but this may come at the expense of quality. In contrast, manufacturers in Europe may offer higher labor costs but often provide superior craftsmanship and compliance with strict quality standards.

-

Manufacturing Overhead: This includes costs associated with factory operations such as utilities, equipment depreciation, and administrative expenses. Manufacturers with advanced technology and efficient processes may have lower overhead costs, which can reflect in the pricing of their products.

-

Tooling: The initial investment in tooling for custom or specialized hinges can be significant. Tooling costs are often amortized over the production volume, meaning larger orders can help reduce the per-unit cost.

-

Quality Control (QC): Rigorous QC processes ensure that hinges meet industry standards and specifications. Enhanced QC measures can increase production costs but are essential for ensuring reliability and safety, particularly in critical applications.

-

Logistics: Shipping and transportation costs can vary based on the distance from the manufacturing site to the buyer’s location. Incoterms play a crucial role in determining who bears these costs, affecting the total landed price of the hinges.

-

Margin: Supplier profit margins can vary based on market competition, brand reputation, and product differentiation. Understanding the typical margins in the hinge market can help buyers gauge whether a price is reasonable.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer discounts for larger orders. Buyers should assess their needs to negotiate the best pricing based on volume.

-

Specifications/Customization: Custom specifications or unique design requirements can increase costs. It’s essential for buyers to clearly define their needs to avoid unexpected expenses.

-

Materials: As mentioned, material quality directly impacts pricing. Buyers should consider not just the initial cost but also the longevity and performance of the materials in their specific applications.

-

Quality/Certifications: Products that meet international quality standards or possess certifications (e.g., ISO, CE) may come at a higher price but can provide added assurance of reliability and safety.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a history of quality and service may charge more but offer peace of mind.

-

Incoterms: Understanding the agreed-upon Incoterms is crucial for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the total cost and responsibilities in the shipping process.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Leverage competitive quotes from multiple suppliers to secure better deals.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider factors like maintenance, lifespan, and operational efficiency when evaluating hinge options.

-

Pricing Nuances: Be aware of regional pricing differences. For example, buyers from Africa and South America may face higher logistics costs due to distance, whereas European buyers may benefit from closer proximity to suppliers.

-

Research and Benchmarking: Conduct thorough market research to understand typical pricing and quality levels within the hinge market. This knowledge can enhance negotiation strategies and help identify reputable suppliers.

Disclaimer

Prices for spring-loaded hinges can vary significantly based on the aforementioned factors. This analysis provides indicative insights but does not reflect specific pricing, which may fluctuate based on market conditions and supplier negotiations.

Spotlight on Potential spring loaded hinges Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘spring loaded hinges’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for spring loaded hinges

Understanding the technical specifications and trade terminology related to spring-loaded hinges is crucial for international B2B buyers. This knowledge not only aids in selecting the right products but also enhances communication with suppliers and ensures compliance with regional standards.

Key Technical Properties of Spring-Loaded Hinges

-

Material Grade

– The material from which the hinge is made significantly affects its durability, corrosion resistance, and overall performance. Common materials include stainless steel, brass, and zinc-coated steel. For applications in humid or corrosive environments, stainless steel is often preferred due to its superior resistance to rust and oxidation. -

Load Capacity

– This specification indicates the maximum weight the hinge can support without compromising functionality. Load capacity is vital in ensuring that the hinge can handle the demands of heavy doors or industrial applications. Buyers must verify the load ratings provided by manufacturers to prevent premature failure. -

Spring Tension

– Spring tension determines the force with which the hinge will return to its closed position. Adjustable spring tension allows customization based on specific application needs, enhancing user satisfaction and operational efficiency. Proper tension settings can reduce wear and extend the hinge’s lifespan. -

Tolerance

– Tolerance refers to the permissible limits of variation in a hinge’s dimensions. Tight tolerances are crucial for ensuring a proper fit and function, especially in precision applications. Inaccurate tolerances can lead to misalignment, increased wear, and operational failure, making it an essential consideration during procurement. -

Finish

– The finish of a hinge not only affects its aesthetic appeal but also its resistance to environmental factors. Options such as powder coating, anodizing, or plating can enhance corrosion resistance and surface durability. Selecting the right finish is particularly important for projects in regions with extreme weather conditions.

Common Trade Terms in the Hinge Industry

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that manufacture products that are used as components in another company’s product. In the hinge market, many suppliers offer OEM services, allowing buyers to customize products to fit their specific needs. Understanding OEM agreements is essential for ensuring product quality and compatibility. -

MOQ (Minimum Order Quantity)

– MOQ is the minimum number of units a supplier is willing to sell in a single order. This term is critical for buyers as it affects budgeting and inventory management. Buyers must negotiate MOQs that align with their project requirements to avoid excess inventory or stockouts. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. It allows buyers to compare offers and negotiate better deals. Crafting a clear and detailed RFQ can lead to more accurate quotations and better supplier relationships. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for understanding shipping responsibilities, risk management, and cost implications in cross-border trade. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is crucial for planning and scheduling, particularly in industries where timing is critical. Buyers should always inquire about lead times to align their procurement processes with project deadlines.

By mastering these technical specifications and trade terms, B2B buyers can enhance their purchasing decisions, improve supplier negotiations, and ultimately drive better outcomes in their operations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the spring loaded hinges Sector

Market Overview & Key Trends

The global market for spring-loaded hinges is experiencing significant growth, driven by increasing demand across various industries such as manufacturing, construction, and automotive. Key market dynamics include the push for automation, which enhances operational efficiency and improves safety in industrial settings. Emerging technologies such as IoT-enabled hinges are gaining traction, allowing for real-time monitoring and predictive maintenance, which can significantly reduce downtime and maintenance costs.

International B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of the distinct sourcing trends in their respective markets. For example, buyers in Europe are increasingly prioritizing high-quality materials and innovative designs that meet stringent safety standards, while those in Africa and South America may focus on cost-effective solutions that can withstand diverse environmental conditions. Additionally, the shift towards digital procurement processes is streamlining sourcing operations, enabling buyers to access a wider range of suppliers and products online, thereby improving competitiveness.

Another notable trend is the growing emphasis on customizable solutions. As industries evolve, the need for specialized hinge configurations that cater to specific applications is becoming more prevalent. This demand for tailored products is encouraging manufacturers to invest in R&D to enhance their offerings, creating opportunities for buyers to negotiate better terms and innovative solutions.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly becoming a cornerstone in the sourcing of spring-loaded hinges, reflecting a broader commitment to reducing environmental impact. B2B buyers must consider the environmental footprint of the products they procure, including the materials used and the manufacturing processes employed. The use of recycled metals and sustainable materials can significantly mitigate the negative environmental effects associated with hinge production.

Ethical sourcing is also gaining prominence, as businesses recognize the importance of transparent supply chains. Buyers should prioritize suppliers who demonstrate commitment to fair labor practices and sustainable production methods. Certifications such as ISO 14001 for environmental management and FSC (Forest Stewardship Council) for wood products are indicators of responsible sourcing practices. By choosing suppliers with these certifications, buyers not only contribute to environmental sustainability but also enhance their corporate reputation.

Moreover, integrating sustainability into procurement strategies can lead to cost savings over time. Products designed for longevity and energy efficiency reduce the need for frequent replacements and maintenance, ultimately benefiting the bottom line while supporting a greener planet.

Brief Evolution/History

The evolution of spring-loaded hinges dates back to their inception in the early 20th century, primarily used in industrial applications for their self-closing functionality. Initially, they were designed for heavy doors in factories and warehouses, where the need for efficiency and safety was paramount. Over the decades, advancements in materials science and engineering have led to the development of more sophisticated hinge designs that incorporate adjustable spring mechanisms and corrosion-resistant materials.

Today, spring-loaded hinges are not only vital in industrial settings but also find applications in residential and commercial furniture, showcasing their versatility. The historical progression from basic designs to modern, customizable options reflects the growing demands of various sectors, emphasizing the importance of innovation in maintaining competitive advantages in the B2B marketplace.

Related Video: What global trade deals are really about (hint: it’s not trade) | Haley Edwards | TEDxMidAtlantic

Frequently Asked Questions (FAQs) for B2B Buyers of spring loaded hinges

-

What should I consider when vetting suppliers for spring-loaded hinges?

When vetting suppliers, prioritize their experience in manufacturing spring-loaded hinges and their track record in international trade. Check for certifications such as ISO or ASTM that indicate adherence to quality standards. Request references from previous clients and assess their responsiveness to inquiries. It’s also beneficial to visit the supplier’s manufacturing facility, if possible, to evaluate their production capabilities and quality control processes firsthand. -

Can I customize spring-loaded hinges to fit my specific needs?

Yes, many manufacturers offer customization options for spring-loaded hinges. You can request specific dimensions, materials, finishes, and spring tension adjustments to meet your application requirements. Ensure you communicate your needs clearly and confirm that the supplier has the capability to deliver customized products. Consider requesting prototypes or samples before placing a bulk order to verify that the customization meets your expectations. -

What are the typical minimum order quantities (MOQ) and lead times for spring-loaded hinges?

MOQs for spring-loaded hinges can vary significantly by supplier, but they typically range from 100 to 1,000 units. Lead times can also differ based on customization and manufacturing location, usually spanning from 4 to 12 weeks. It’s crucial to discuss these factors upfront with your supplier to ensure that their production capabilities align with your project timelines and budget constraints. -

What quality assurance measures should I look for in spring-loaded hinges?

Quality assurance measures should include rigorous testing protocols, such as load capacity tests and corrosion resistance evaluations. Ask suppliers for documentation of their QA processes, including any certifications they hold. Additionally, inquire about their warranty policies and procedures for handling defective products. Regular audits and compliance with international standards will enhance your confidence in their product quality. -

How do I handle logistics and shipping for international orders of spring-loaded hinges?

Effective logistics management is essential when sourcing internationally. Work with suppliers who have experience in exporting to your region and understand local import regulations. Discuss shipping options, including freight forwarding and insurance, to safeguard your order during transit. Tracking shipments and establishing clear communication channels with your supplier can help mitigate delays and ensure timely delivery. -

What steps should I take if there is a dispute with my supplier?

In the event of a dispute, begin by reviewing the contract terms, including payment terms and delivery timelines. Open a line of communication with the supplier to discuss the issue and seek a resolution. If necessary, involve a third-party mediator to facilitate discussions. Document all communications and agreements to maintain a clear record. If resolution fails, consider legal options as per the terms outlined in your contract. -

Are there specific certifications I should request for spring-loaded hinges?

Yes, certain certifications can indicate the quality and reliability of spring-loaded hinges. Look for ISO 9001 for quality management systems, as well as certifications like CE marking, which ensures compliance with European standards. Depending on your industry, additional certifications such as UL or RoHS might also be relevant, especially in sectors where safety and environmental considerations are paramount. -

How can I ensure the longevity of spring-loaded hinges in different environments?

To ensure longevity, select hinges made from corrosion-resistant materials such as stainless steel or coated options suitable for specific environmental conditions. Consider the installation location—high humidity or extreme temperatures can impact performance. Regular maintenance, including lubrication and inspections, can also extend the life of the hinges. Consult with your supplier for best practices tailored to the specific conditions in which the hinges will be used.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for spring loaded hinges

In conclusion, effective strategic sourcing of spring-loaded hinges is critical for international B2B buyers aiming to enhance operational efficiency and product durability. By understanding the various types and applications of these hinges, businesses can select solutions that meet their specific operational demands while also considering environmental factors and load capacities. Key takeaways include the importance of evaluating supplier capabilities, ensuring compliance with regional standards, and prioritizing quality materials to mitigate long-term costs.

For buyers from Africa, South America, the Middle East, and Europe, the strategic approach to sourcing hinges can significantly impact project execution and customer satisfaction. Emphasizing quality and adaptability in hinge selection not only enhances product performance but also strengthens competitive positioning in diverse markets.

As the global market continues to evolve, staying informed about innovations in hinge technology and industry trends will be paramount. B2B buyers are encouraged to engage with reputable suppliers, attend industry events, and leverage expert resources to refine their sourcing strategies. By doing so, they can ensure their procurement practices not only meet current needs but also align with future market developments.