Your Ultimate Guide to Sourcing Wire Cloth Suppliers

Introduction: Navigating the Global Market for wire cloth suppliers

In today’s interconnected global economy, sourcing quality wire cloth is paramount for B2B buyers across diverse industries. Wire cloth, an essential component in applications ranging from filtration to structural support, plays a critical role in ensuring operational efficiency and product integrity. For international buyers from regions such as Africa, South America, the Middle East, and Europe, identifying reliable wire cloth suppliers is not just about procurement; it’s about forging partnerships that can enhance competitive advantage.

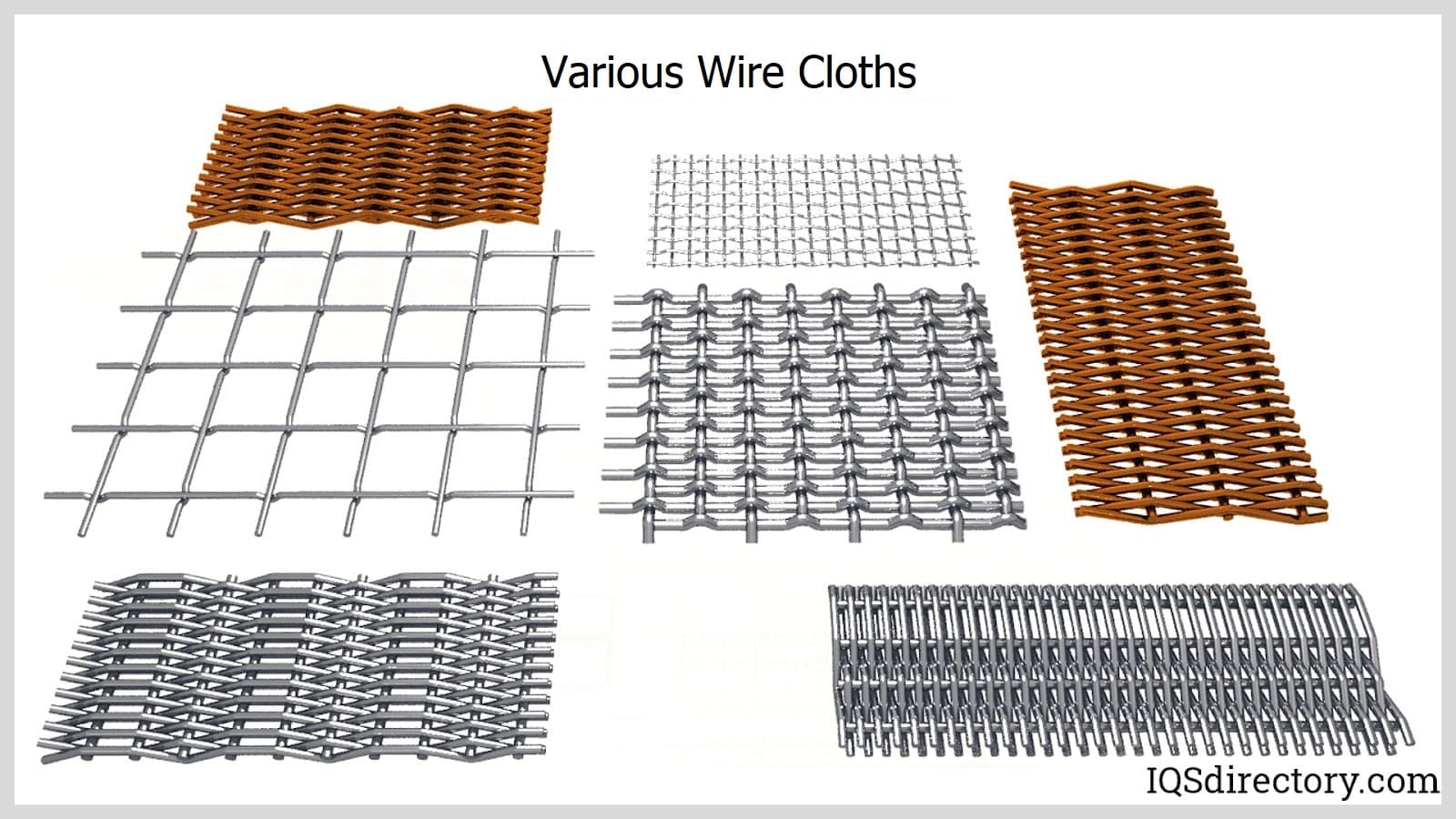

This comprehensive guide is designed to empower you with the insights needed to make informed sourcing decisions. We delve into the various types of wire cloth, including woven and welded options, and explore the materials used—ranging from stainless steel to galvanized wire. Understanding manufacturing processes and quality control measures is crucial for selecting suppliers who meet your specifications.

Moreover, we provide an overview of cost factors, market trends, and supplier evaluation criteria, ensuring that you have the tools necessary to navigate the complexities of the wire cloth market. With FAQs addressing common concerns, this guide serves as a vital resource for B2B buyers seeking to optimize their supply chains and enhance product offerings. By leveraging the information within, you can confidently engage with suppliers, ensuring that your wire cloth needs are met with precision and reliability.

Understanding wire cloth suppliers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Woven Wire Mesh | Interlocking pattern, high precision, labor-intensive | Filtration, sieving, architectural applications | Pros: High quality, precise apertures; Cons: Higher cost due to manufacturing complexity. |

| Welded Wire Mesh | Automated welding, exceptional strength and rigidity | Fencing, reinforcement, cages | Pros: Strong, versatile; Cons: Less flexibility in design compared to woven. |

| Galvanized Hardware Cloth | Zinc-coated for corrosion resistance | Outdoor applications, agricultural uses | Pros: Durable in harsh environments; Cons: Limited aesthetic options. |

| Refinery-Grade Wire Mesh | Engineered for high-performance, corrosion-resistant | Petrochemical, refinery applications | Pros: Reliable in extreme conditions; Cons: Higher price point due to specialized materials. |

| Market-Grade Wire Cloth | Standard wire diameter and mesh size combinations | General-purpose screening, food processing | Pros: Economical, readily available; Cons: May not meet specific high-performance needs. |

Woven Wire Mesh

Woven wire mesh is characterized by its intricate interlocking pattern, created through a meticulous weaving process. This type is ideal for applications requiring precision, such as filtration and separation in various industries, including food processing and pharmaceuticals. When purchasing woven wire mesh, buyers should consider the required mesh size and wire diameter, as these factors directly impact performance and filtration efficiency. While it offers superior quality and reliability, the higher manufacturing costs may be a consideration for budget-conscious businesses.

Welded Wire Mesh

Welded wire mesh is known for its robust structure, achieved through automated welding techniques. This type is commonly used in applications such as fencing, reinforcement, and cages due to its strength and ease of customization. Buyers should assess the mesh’s gauge and spacing based on their specific application needs. While welded wire mesh provides excellent strength and versatility, it may lack the flexibility offered by woven alternatives, which could limit its use in certain designs.

Galvanized Hardware Cloth

Galvanized hardware cloth is treated with a zinc coating to enhance its corrosion resistance, making it suitable for outdoor and agricultural applications. It is often used for garden fencing, animal enclosures, and pest control barriers. Buyers should consider the gauge and mesh size to ensure it meets the specific demands of their project. Although it is cost-effective and durable, galvanized hardware cloth may not provide the aesthetic appeal needed for certain architectural applications.

Refinery-Grade Wire Mesh

Refinery-grade wire mesh is specially designed for high-performance environments, such as petrochemical plants and refineries. Its construction ensures durability and corrosion resistance, making it ideal for critical applications like catalyst support and sand control. When selecting refinery-grade mesh, buyers should focus on material specifications and compliance with industry standards. While this type offers enhanced reliability under extreme conditions, it typically comes at a higher price point, reflecting its specialized nature.

Market-Grade Wire Cloth

Market-grade wire cloth features standard wire diameter and mesh size combinations, making it a versatile option for general-purpose applications. Commonly utilized in industries like construction and food processing, this type is valued for its predictable performance and availability. Buyers should evaluate the specific requirements of their application, including material type and mesh count. While market-grade wire cloth is economical and easily accessible, it may not suffice for specialized tasks requiring high precision or durability.

Related Video: Lecture 1 Two compartment models

Key Industrial Applications of wire cloth suppliers

| Industry/Sector | Specific Application of wire cloth suppliers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Filtration in food processing | Ensures product purity and compliance with health standards | Material safety certifications; resistance to corrosion and high temperatures |

| Construction | Reinforcement in concrete and masonry | Increases structural integrity and durability | Mesh strength and gauge; compliance with local building codes |

| Agriculture | Pest control and animal enclosures | Protects crops and livestock, improving yields | Weather resistance; appropriate mesh size for specific pests |

| Mining and Mineral Processing | Screening and sizing of aggregates | Enhances efficiency in material separation | Custom mesh sizes; durability against abrasive materials |

| Oil and Gas | Catalyst support in refining processes | Optimizes flow rates and reduces downtime | High-temperature and corrosion-resistant materials; compliance with industry standards |

Food and Beverage

In the food and beverage industry, wire cloth suppliers provide critical filtration solutions that ensure product purity. Applications include strainers and filters that prevent contaminants from entering the production line. For international buyers, particularly in regions like Africa and South America, sourcing materials that meet safety certifications and health regulations is essential. Additionally, wire cloth must withstand high temperatures and corrosive environments, which necessitates a focus on material properties such as stainless steel or specialized alloys.

Construction

Wire cloth is widely used in the construction sector for reinforcement applications, particularly in concrete and masonry. By integrating wire mesh into structures, businesses can significantly enhance their durability and structural integrity. Buyers must consider the mesh strength and gauge to ensure compliance with local building codes, especially in regions with stringent regulations, such as Europe. Suppliers should provide documentation proving the material’s compliance and performance standards.

Agriculture

In agriculture, wire cloth serves as a vital tool for pest control and creating animal enclosures. By utilizing wire mesh, farmers can effectively protect crops from pests and ensure the safety of livestock, ultimately improving yield. For buyers in Africa and the Middle East, it is crucial to source weather-resistant materials that can withstand harsh climates. Additionally, selecting the appropriate mesh size is important to prevent unwanted animals while allowing beneficial species to thrive.

Mining and Mineral Processing

Wire cloth suppliers play a significant role in the mining industry by providing screening and sizing solutions for aggregates. This application enhances efficiency in material separation, which is critical for optimizing processing operations. International buyers, particularly from South America and Africa, should focus on custom mesh sizes that align with specific material requirements. Durability against abrasive materials is also a key consideration, necessitating robust materials that can endure harsh operational environments.

Oil and Gas

In the oil and gas sector, wire cloth is essential for applications such as catalyst support in refining processes. By optimizing flow rates and reducing downtime, businesses can significantly enhance operational efficiency. Buyers from the Middle East and Europe must prioritize sourcing high-temperature and corrosion-resistant materials that comply with industry standards. Additionally, thorough supplier vetting for quality assurance and performance reliability is critical to maintaining operational integrity in demanding environments.

Related Video: Fencing 101 – Woven Wire Basics

Strategic Material Selection Guide for wire cloth suppliers

When selecting wire cloth materials for various applications, international B2B buyers must consider several factors, including the specific properties of the materials, their advantages and disadvantages, and how they align with the intended application. Below, we analyze four common materials used in wire cloth manufacturing: Stainless Steel, Carbon Steel, Aluminum, and Galvanized Steel.

Stainless Steel

Key Properties:

Stainless steel wire cloth is renowned for its excellent corrosion resistance, high tensile strength, and ability to withstand extreme temperatures. It typically has a temperature rating up to 1,500°F (815°C) and can handle high-pressure environments, making it suitable for demanding industrial applications.

Pros & Cons:

The primary advantage of stainless steel is its durability and resistance to rust and corrosion, which extends its service life. However, it is generally more expensive than other materials, and its manufacturing process can be complex, requiring specialized equipment.

Impact on Application:

Stainless steel wire cloth is ideal for applications in food processing, pharmaceuticals, and petrochemical industries, where hygiene and resistance to corrosive substances are critical.

Considerations for International Buyers:

Compliance with international standards such as ASTM and DIN is essential, particularly in Europe and the Middle East. Buyers should ensure that the stainless steel grades meet the specific requirements of their industry.

Carbon Steel

Key Properties:

Carbon steel wire cloth offers good strength and rigidity, with a temperature rating typically around 400°F (204°C). It is less resistant to corrosion compared to stainless steel, but it can be treated to improve its durability.

Pros & Cons:

The main advantage of carbon steel is its cost-effectiveness, making it a popular choice for applications where budget constraints are a factor. However, its susceptibility to rust and corrosion limits its use in harsh environments.

Impact on Application:

Carbon steel is commonly used in construction, fencing, and agricultural applications. It is suitable for environments where exposure to moisture is limited.

Considerations for International Buyers:

Buyers from regions with high humidity, such as parts of Africa and South America, should consider additional protective coatings to enhance corrosion resistance. Compliance with local standards is also necessary.

Aluminum

Key Properties:

Aluminum wire cloth is lightweight, resistant to corrosion, and has a temperature rating of up to 600°F (316°C). Its low density makes it easy to handle and install.

Pros & Cons:

The key advantage of aluminum is its excellent resistance to corrosion and lightweight nature, which simplifies installation. However, it is less strong than stainless or carbon steel, making it unsuitable for high-load applications.

Impact on Application:

Aluminum wire cloth is often used in architectural applications, ventilation systems, and as insect screens. Its aesthetic appeal makes it a preferred choice in design-oriented projects.

Considerations for International Buyers:

International buyers should be aware of the specific aluminum grades and their properties, ensuring they meet local regulations and standards, particularly in the construction industry in Europe and the Middle East.

Galvanized Steel

Key Properties:

Galvanized steel wire cloth is coated with zinc to enhance its corrosion resistance, withstanding moisture and environmental elements. Its temperature rating is similar to carbon steel, around 400°F (204°C).

Pros & Cons:

The primary advantage of galvanized steel is its affordability combined with decent corrosion resistance. However, the zinc coating can wear off over time, especially in harsh environments, leading to potential rust issues.

Impact on Application:

This material is widely used in outdoor applications, such as fencing, animal enclosures, and construction reinforcement, where durability against the elements is required.

Considerations for International Buyers:

Buyers should ensure that the galvanization process meets international standards to guarantee longevity. Awareness of local environmental conditions is crucial, particularly in humid climates prevalent in parts of Africa and South America.

Summary Table

| Material | Typical Use Case for wire cloth suppliers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Carbon Steel | Construction, fencing | Cost-effective | Susceptible to rust and corrosion | Low |

| Aluminum | Architectural applications, insect screens | Lightweight and corrosion-resistant | Less strength than steel | Medium |

| Galvanized Steel | Outdoor fencing, animal enclosures | Affordable with decent corrosion resistance | Zinc coating can wear off | Low |

This guide provides an overview of the key materials used in wire cloth manufacturing, offering insights that can assist international B2B buyers in making informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for wire cloth suppliers

The manufacturing processes and quality assurance mechanisms for wire cloth suppliers are crucial elements that directly impact the reliability and performance of the final product. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes can enhance purchasing decisions and ensure compliance with industry standards.

Manufacturing Processes

The manufacturing of wire cloth typically involves several key stages, each critical to ensuring the product’s quality and suitability for specific applications.

1. Material Preparation

The first step in the manufacturing process involves selecting the appropriate metal or alloy, which can include stainless steel, aluminum, copper, or galvanized steel. The choice of material depends on the intended use, such as corrosion resistance for food processing or strength for construction applications. After selecting the material, it is drawn into wire of specific diameters, which is essential for achieving the desired mesh characteristics.

Illustrative Image (Source: Google Search)

2. Forming

The forming stage is where the wires are woven or welded into mesh. There are two primary techniques:

- Woven Wire Mesh: This process uses a loom to interlace the wires in a specific pattern, such as plain weave or twill weave. The precision of the weaving technique is crucial for applications requiring exact aperture sizes, such as filtration.

- Welded Wire Mesh: In this method, parallel wires are joined at their intersections using automated welding techniques. This results in a robust mesh that can withstand significant stress and is easier to manipulate into various shapes.

3. Assembly

Once the wire cloth is formed, it may undergo additional processes such as cutting, bending, or shaping to meet specific customer requirements. This stage may also involve combining different types of wire cloth or integrating additional features like coatings for enhanced durability or aesthetic finishes.

4. Finishing

The finishing stage includes treatments such as galvanization, which involves applying a zinc coating to protect against corrosion. Other finishing processes may include powder coating, painting, or passivation, depending on the intended application and environmental conditions the wire cloth will face.

Quality Assurance

Quality assurance is a critical component of the manufacturing process, ensuring that the wire cloth meets international standards and customer expectations.

International Standards

Many wire cloth suppliers adhere to internationally recognized standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards ensures that the manufacturing processes are documented, controlled, and continuously improved. Additionally, industry-specific certifications like CE marking for products sold in Europe or API standards for oil and gas applications are also significant.

Quality Control Checkpoints

Quality control is typically divided into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): During manufacturing, periodic checks are performed to monitor processes and detect any deviations from standards.

- Final Quality Control (FQC): Before shipping, the finished wire cloth is thoroughly inspected for defects, dimensions, and performance characteristics.

Common Testing Methods

B2B buyers should be aware of common testing methods used in the industry, including:

- Mesh Count Testing: To verify the number of openings per unit length.

- Aperture Size Measurement: Ensures that the openings meet specifications.

- Tensile Strength Testing: Assesses the strength of the wire under stress.

- Corrosion Resistance Testing: Evaluates the mesh’s performance under harsh environmental conditions.

Verifying Supplier Quality Control

For international B2B buyers, especially in regions like Africa and South America where supply chain complexities may arise, verifying a supplier’s quality control processes is essential.

Audits and Reports

Buyers can request audits of the supplier’s quality management system, which should detail their compliance with relevant standards. Regular reports on quality metrics, defect rates, and corrective actions taken are also valuable.

Third-Party Inspections

Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality processes. These inspections can occur at various stages of production and are particularly useful for buyers unfamiliar with local manufacturing practices.

Quality Control and Certification Nuances

When dealing with international suppliers, B2B buyers should consider the following nuances:

- Cultural and Regulatory Differences: Understand that quality standards may vary significantly across regions. What is acceptable in one market may not be in another.

- Documentation Practices: Ensure that suppliers maintain detailed documentation of quality control processes and test results, which can facilitate smoother cross-border transactions.

- Local Certifications: Some regions may require specific local certifications or compliance with regional regulations, which should be confirmed prior to procurement.

Conclusion

A comprehensive understanding of the manufacturing processes and quality assurance practices of wire cloth suppliers is vital for international B2B buyers. By focusing on material selection, production techniques, and stringent quality control measures, buyers can ensure they procure reliable products that meet their specific needs. Engaging with suppliers who prioritize quality and comply with international standards not only safeguards investments but also enhances operational efficiencies across various applications.

Related Video: Garments Full Production Process | Order receive to Ex-Factory | Episode 2

Comprehensive Cost and Pricing Analysis for wire cloth suppliers Sourcing

When sourcing wire cloth, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. The costs associated with wire cloth suppliers can be broken down into several key components, each influencing the final price.

Cost Components

-

Materials: The choice of raw materials significantly impacts pricing. Common materials include stainless steel, aluminum, brass, and galvanized steel. Stainless steel, known for its durability and corrosion resistance, is often the most expensive option. Buyers should evaluate the specific requirements of their application to choose the most cost-effective material without compromising quality.

-

Labor: Labor costs vary by region and are influenced by the complexity of the manufacturing process. For instance, woven wire mesh, which requires meticulous weaving techniques, typically incurs higher labor costs compared to welded wire mesh, which is produced through more automated processes.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, factory rent, and equipment maintenance. Efficient operations can reduce overhead, allowing suppliers to offer more competitive prices.

-

Tooling: Investment in specialized tooling and machinery can affect pricing. Suppliers with advanced technology may have higher initial costs but can achieve economies of scale, resulting in lower prices for bulk orders.

-

Quality Control (QC): Rigorous QC processes ensure that the wire cloth meets specific standards. While implementing these processes adds to the cost, they are essential for maintaining product integrity, particularly in industries with strict regulations, such as food processing and pharmaceuticals.

-

Logistics: Shipping and handling costs can vary widely based on the destination and shipping method. International buyers should consider these costs, especially for bulk orders, as they can significantly impact the total cost.

-

Margin: Suppliers typically apply a markup to cover their costs and ensure profitability. This margin can vary depending on market demand, competition, and the supplier’s pricing strategy.

Price Influencers

Several factors can influence the pricing of wire cloth:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract discounts due to economies of scale. Buyers should negotiate MOQs to benefit from lower unit prices.

-

Specifications/Customization: Custom orders involving specific mesh sizes, materials, or coatings usually incur higher costs. It’s advisable to standardize specifications where possible to minimize expenses.

-

Quality/Certifications: Certifications, such as ISO or ASTM standards, can add to the cost but are often necessary for compliance in regulated industries. Buyers should weigh the benefits of certification against the additional cost.

-

Supplier Factors: Supplier reputation, experience, and geographical location can impact pricing. Established suppliers may charge a premium for their reliability and quality.

-

Incoterms: The terms of delivery (e.g., FOB, CIF) dictate responsibilities for shipping and insurance, influencing overall costs. Understanding these terms is crucial for accurate budgeting.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing, especially if you can commit to larger volumes. Leverage competition by obtaining quotes from multiple suppliers.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO), which includes not just the purchase price but also shipping, installation, and potential maintenance costs. A lower initial price may not always equate to better value.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and tariffs that can affect the final cost. Buyers from Africa, South America, the Middle East, and Europe should also consider the implications of geopolitical factors on supply chains.

-

Disclaimer for Indicative Prices: Pricing can vary based on market conditions, supplier negotiations, and specific order requirements. Always request detailed quotes tailored to your needs to ensure clarity and avoid unexpected costs.

By understanding these components and influencers, international B2B buyers can make informed decisions when sourcing wire cloth, optimizing their purchasing strategies for better cost efficiency and value.

Spotlight on Potential wire cloth suppliers Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘wire cloth suppliers’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for wire cloth suppliers

Understanding the technical properties and trade terminology related to wire cloth is crucial for B2B buyers. This knowledge enables informed decision-making and effective communication with suppliers, particularly in diverse markets across Africa, South America, the Middle East, and Europe.

Illustrative Image (Source: Google Search)

Key Technical Properties of Wire Cloth

-

Material Grade

– The material grade of wire cloth, such as stainless steel, carbon steel, or aluminum, significantly impacts its performance and suitability for specific applications. For example, stainless steel is preferred in corrosive environments, while carbon steel is often chosen for its strength and cost-effectiveness. Understanding material grades helps buyers select wire cloth that meets their durability and corrosion resistance requirements. -

Mesh Count

– Mesh count refers to the number of openings per linear inch in the wire cloth. A higher mesh count indicates smaller openings, making it ideal for applications requiring fine filtration or separation. Conversely, a lower mesh count is suitable for larger particles. Buyers should consider mesh count to ensure the wire cloth meets their specific filtration or screening needs. -

Wire Diameter

– The diameter of the wire used in the cloth affects its strength, flexibility, and overall durability. Thicker wires provide greater strength and rigidity, making them suitable for demanding applications, while thinner wires may offer better flexibility for certain uses. Buyers should assess wire diameter in relation to the intended application and environmental conditions. -

Tolerance

– Tolerance refers to the allowable variation in dimensions and openings of the wire cloth. Tight tolerances are essential for applications requiring precise filtration or structural integrity, while looser tolerances may be acceptable for general-purpose uses. Understanding tolerance specifications is crucial for ensuring that the wire cloth will function as intended in its application. -

Open Area Percentage

– Open area percentage indicates the proportion of the wire cloth that is open space compared to the total area. This property is vital for applications involving airflow, drainage, or material passage. A higher open area percentage allows for better fluid flow, while a lower percentage may be necessary for more substantial filtration tasks. Buyers should evaluate open area percentage based on their operational requirements.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of wire cloth, buyers may deal with OEMs that supply components for machinery or filtration systems. Understanding OEM relationships can help buyers navigate their supply chains effectively. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to know, as it can affect purchasing decisions and inventory management. Understanding MOQ helps in budgeting and planning for procurement. -

RFQ (Request for Quotation)

– An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. It typically includes detailed specifications, quantities, and delivery requirements. Submitting an RFQ can streamline the procurement process and ensure competitive pricing. -

Incoterms (International Commercial Terms)

– Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They cover aspects such as shipping, insurance, and risk transfer. Familiarity with Incoterms is essential for buyers engaging in cross-border trade, as it clarifies obligations and reduces potential disputes. -

Lead Time

– Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is vital for effective project planning and inventory management, as delays can impact production schedules and overall business operations.

By grasping these essential technical properties and trade terminologies, international B2B buyers can enhance their procurement strategies, foster better supplier relationships, and ensure they select the most appropriate wire cloth products for their needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the wire cloth suppliers Sector

Global demand for wire cloth is being driven by a variety of factors, including industrial growth, technological advancements, and the increasing need for efficient filtration and separation solutions. In recent years, the rise of automation and smart manufacturing has also influenced sourcing trends, with B2B buyers increasingly relying on digital platforms for procurement. This shift toward e-commerce is particularly significant for international buyers from regions like Africa, South America, the Middle East, and Europe, where access to comprehensive product catalogs and supplier reviews can enhance decision-making.

Emerging trends include a growing preference for customized wire cloth solutions tailored to specific industrial applications. Buyers are now seeking suppliers who can offer diverse weave types, materials, and mesh sizes, ensuring that products meet precise performance criteria. Additionally, the integration of Industry 4.0 technologies—such as IoT and AI—enables suppliers to provide real-time data analytics, enhancing transparency and fostering trust in supply chains.

Moreover, the push for sustainability is reshaping market dynamics. Buyers are increasingly prioritizing suppliers who demonstrate environmentally responsible practices, leading to a higher demand for recycled materials and eco-friendly production methods. This trend is particularly pronounced in Europe, where stringent regulations and consumer preferences favor sustainable products.

Sustainability & Ethical Sourcing in B2B

The environmental impact of wire cloth manufacturing is a critical consideration for B2B buyers. Traditional production processes can lead to significant waste and pollution, prompting an urgent need for sustainable practices. Ethical sourcing is not just a trend; it is becoming a necessity for businesses looking to maintain competitive advantage and meet regulatory standards.

Buyers should look for suppliers who utilize green certifications such as ISO 14001, which denotes effective environmental management systems. Additionally, suppliers offering recyclable materials, such as stainless steel or aluminum, contribute positively to sustainability goals. The demand for galvanized wire cloth—which provides enhanced corrosion resistance and durability—also supports longer product life cycles, reducing the frequency of replacements and waste.

Investing in suppliers that emphasize sustainability can also enhance brand reputation and customer loyalty, particularly among environmentally-conscious consumers. By fostering relationships with ethical suppliers, businesses can ensure compliance with international standards while simultaneously contributing to a more sustainable future.

Brief Evolution/History

The wire cloth industry has evolved significantly over the past century, transitioning from manual weaving techniques to advanced automated processes. Initially used primarily for agricultural and construction purposes, wire cloth has diversified into various sectors, including food processing, pharmaceuticals, and environmental management. The advent of new materials and weaving techniques has further expanded its applications, making it an indispensable resource across multiple industries.

Today, innovations in wire cloth manufacturing focus on enhancing durability and performance, with a strong emphasis on sustainability. As global demand continues to rise, suppliers are adapting to meet the evolving needs of B2B buyers, ensuring that wire cloth remains a vital component in industrial applications worldwide.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of wire cloth suppliers

-

How do I vet potential wire cloth suppliers for international trade?

Vetting suppliers is crucial for ensuring product quality and reliability. Start by checking their certifications, such as ISO 9001 for quality management systems. Look for reviews or testimonials from previous clients and request samples of their wire cloth products. It’s also beneficial to engage with suppliers through video calls to assess their operations and capabilities. Finally, consider suppliers who have experience exporting to your region, as they will be familiar with local regulations and logistics. -

Can I customize my wire cloth orders, and what are the limitations?

Most reputable wire cloth suppliers offer customization options, including variations in mesh size, wire diameter, and material type. However, customization may be subject to minimum order quantities (MOQs) and specific lead times. It’s essential to discuss your requirements upfront with the supplier and clarify any limitations regarding design, material availability, and production capabilities. Keep in mind that highly specialized requests may incur additional costs and longer delivery times. -

What should I know about minimum order quantities (MOQs) and lead times?

MOQs vary by supplier and can depend on the type of wire cloth and customization requested. Standard products typically have lower MOQs, while customized orders may require larger quantities to justify production costs. Lead times can also fluctuate based on the complexity of your order and the supplier’s current production schedule. Always inquire about lead times before placing an order, and consider potential delays in shipping, especially for international transactions. -

What payment terms should I expect when sourcing wire cloth internationally?

Payment terms can vary widely among suppliers. Common options include advance payment, letter of credit, or payment upon delivery. It’s advisable to negotiate terms that protect your interests, particularly for larger orders. Research the supplier’s payment history and consider using secure payment methods to minimize risks. Additionally, ensure that the payment terms align with your cash flow needs and project timelines to avoid disruptions. -

What quality assurance measures should I look for in wire cloth suppliers?

Quality assurance (QA) is vital when sourcing wire cloth. Suppliers should have a robust QA process that includes material inspection, in-process checks, and final product testing. Request certifications that demonstrate compliance with relevant industry standards, such as ASTM or ISO. Additionally, inquire about their return policy and warranty terms, as these can provide insights into their commitment to product quality and customer satisfaction. -

How can I effectively manage logistics when sourcing wire cloth from international suppliers?

Logistics can be complex, especially for international shipments. Collaborate with suppliers who have experience in your region to streamline the process. Discuss shipping methods, estimated delivery times, and customs clearance procedures upfront. It’s also wise to work with a reliable freight forwarder who understands import/export regulations and can assist with documentation. Keeping communication open with your supplier throughout the logistics process can help mitigate potential issues. -

What steps should I take if there’s a dispute with my wire cloth supplier?

In the event of a dispute, start by addressing the issue directly with the supplier through clear and open communication. Document all correspondence and agreements to provide evidence if needed. If the issue remains unresolved, consider mediation or arbitration as alternative dispute resolution methods, which are often less costly and faster than legal action. Always refer to the terms outlined in your contract regarding dispute resolution to guide your actions. -

Are there any specific certifications or standards I should look for in wire cloth products?

Yes, certain certifications can indicate the quality and suitability of wire cloth for your applications. Look for suppliers with ISO certifications, which demonstrate adherence to international quality management standards. Additionally, industry-specific certifications, such as FDA compliance for food-grade applications or API standards for oil and gas, may be necessary depending on your industry. Ensure that the supplier can provide documentation proving compliance with these standards to avoid issues with product performance and safety.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for wire cloth suppliers

In navigating the complexities of sourcing wire cloth, international B2B buyers from Africa, South America, the Middle East, and Europe must prioritize strategic partnerships that align with their specific industry needs. Understanding the distinctions between woven, welded, and market-grade wire cloth is essential for ensuring that the selected products meet performance requirements in various applications, from construction to food processing.

Key takeaways for buyers include evaluating suppliers based on their material offerings, customization capabilities, and adherence to international standards. This strategic sourcing approach not only mitigates risks associated with quality and reliability but also fosters long-term relationships that can enhance supply chain efficiency.

Looking ahead, the demand for innovative wire cloth solutions will continue to grow, driven by advancements in manufacturing technologies and evolving industry standards. Buyers are encouraged to actively engage with suppliers who demonstrate a commitment to sustainability and innovation. By doing so, they can secure a competitive edge in their respective markets.

Take action today by reaching out to reputable wire cloth suppliers to explore tailored solutions that will drive your business forward.