Your Ultimate Guide to Sourcing Shot Peening Equipment

Introduction: Navigating the Global Market for shot peening equipment

In today’s competitive landscape, the importance of shot peening equipment cannot be overstated. This innovative process is essential for enhancing the durability and fatigue resistance of metal components across various industries, including aerospace, automotive, and manufacturing. By inducing compressive stresses, shot peening not only strengthens materials but also extends the lifespan of critical components, making it a vital consideration for manufacturers worldwide.

This comprehensive guide serves as a valuable resource for international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe. Within its pages, you will find an in-depth exploration of the different types of shot peening equipment, the materials utilized in the process, and the quality control measures necessary to ensure compliance with global standards. We also delve into the landscape of suppliers, examine cost factors, and provide insights into market trends that can influence purchasing decisions.

Furthermore, this guide addresses common FAQs and offers actionable insights to empower informed sourcing decisions. By understanding the intricacies of shot peening equipment, buyers can effectively navigate the global market, ensuring they select the right solutions tailored to their specific needs. Ultimately, this guide aims to enhance your procurement strategy, helping you achieve operational excellence while minimizing risk in your supply chain.

Understanding shot peening equipment Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Air Blast Shot Peening | Utilizes compressed air to propel media through a nozzle | Aerospace, automotive, general manufacturing | Pros: Versatile, suitable for various applications. Cons: Higher operational costs due to air consumption. |

| Centrifugal Blast Shot Peening | Employs a high-speed paddle wheel to launch media | Foundries, automotive, heavy machinery | Pros: High efficiency, suitable for large volumes. Cons: Initial investment can be significant. |

| Automated Shot Peening | Incorporates robotics and sensors for process control | Aerospace, automotive, precision engineering | Pros: Consistent quality, reduced labor costs. Cons: Complexity may require specialized training. |

| Wet Shot Peening | Uses a liquid medium to enhance media effectiveness | Aerospace, marine applications | Pros: Reduces dust and environmental impact. Cons: Equipment maintenance can be more demanding. |

| Laser Peening | Non-traditional method using laser technology | Aerospace, high-performance automotive components | Pros: Precise control, less surface damage. Cons: High cost, limited to specific applications. |

Air Blast Shot Peening

Air blast shot peening is a widely used method that propels peening media through a nozzle using compressed air. This type is adaptable for various surface profiles and can handle intricate geometries, making it suitable for industries like aerospace and automotive. When considering this option, buyers should evaluate the air supply infrastructure and the potential for higher operational costs due to air consumption.

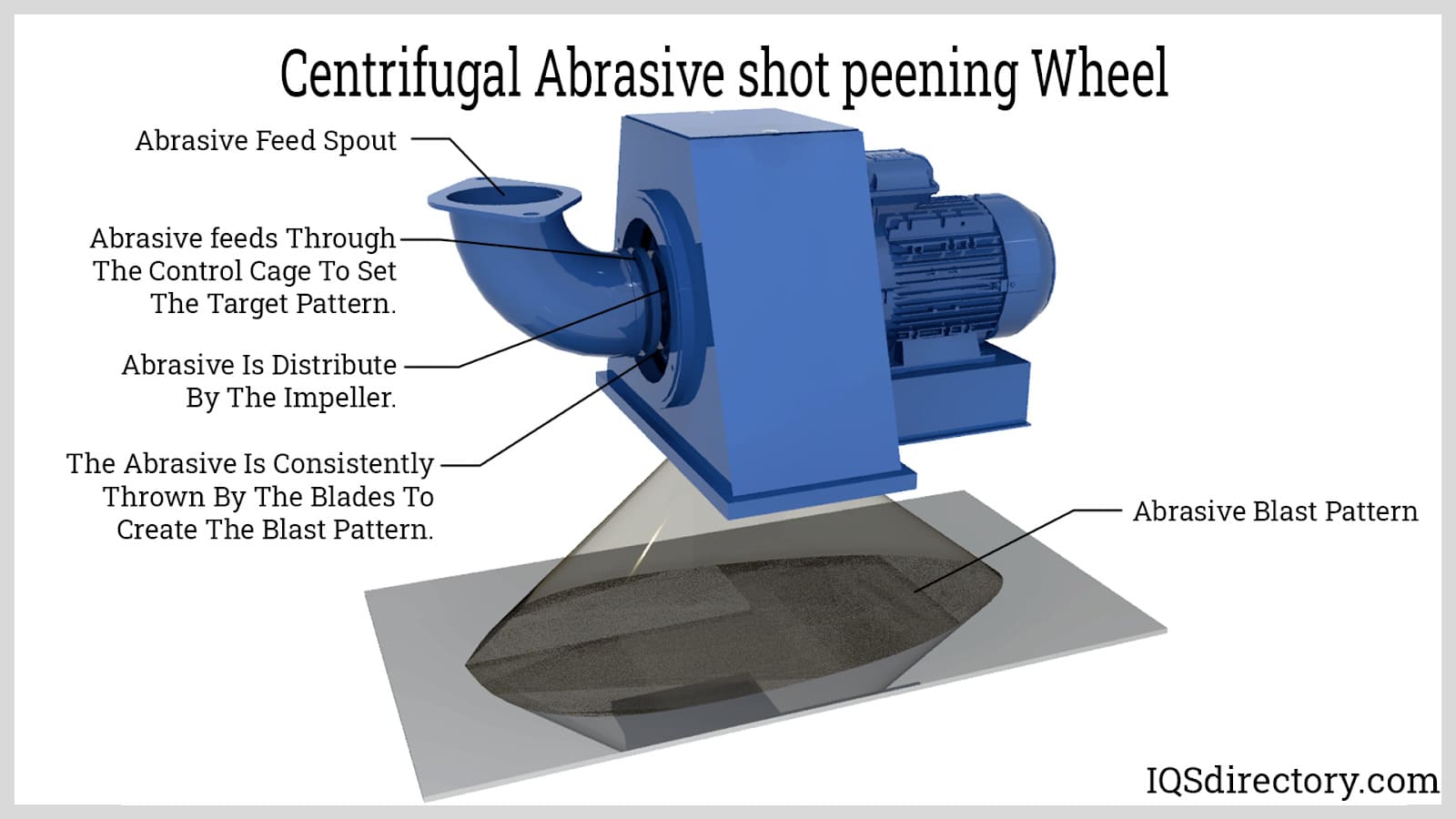

Centrifugal Blast Shot Peening

Centrifugal blast shot peening employs a high-speed paddle wheel to propel media towards the workpiece. This method is particularly efficient for large production volumes, making it ideal for foundries and heavy machinery applications. Buyers should consider the initial investment required for centrifugal systems and the potential for high throughput, which can lead to reduced processing times.

Automated Shot Peening

Automated shot peening incorporates robotics and advanced sensors to monitor and control the peening process. This technology is especially beneficial in industries requiring high precision, such as aerospace and automotive. While it offers consistent quality and reduced labor costs, the complexity of automated systems may necessitate specialized training for operators. Buyers should weigh the benefits of automation against the initial setup costs.

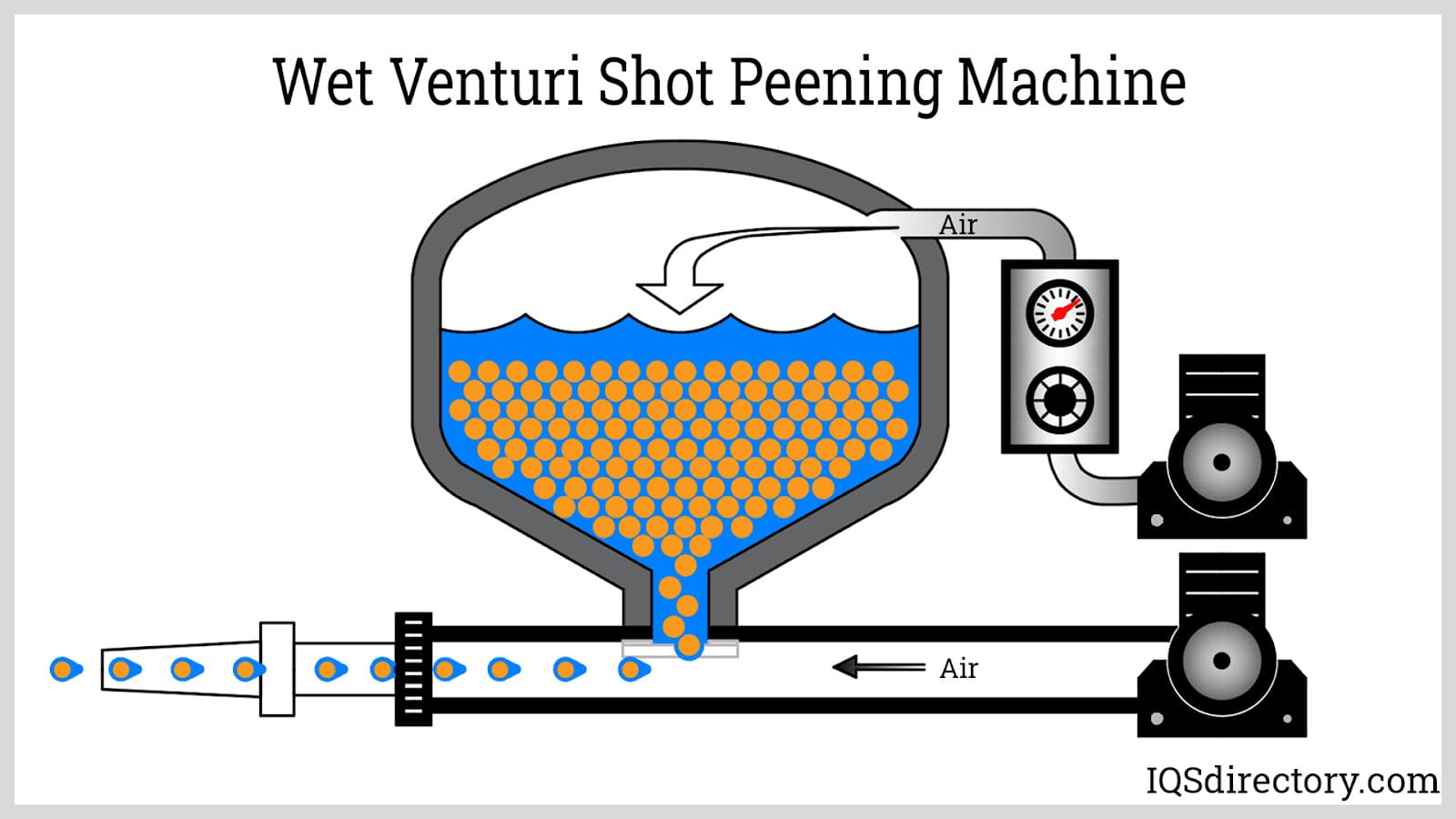

Wet Shot Peening

Wet shot peening combines peening media with a liquid medium, enhancing the effectiveness of the process while minimizing dust and environmental impact. This method is particularly useful in aerospace and marine applications where surface integrity is paramount. Buyers should consider the additional maintenance required for wet systems, as well as the need for proper waste management to comply with environmental regulations.

Laser Peening

Laser peening represents a cutting-edge approach that uses laser technology to induce compressive stresses in materials. This method is advantageous for high-performance components in aerospace and automotive sectors, where precision is critical. While laser peening offers less surface damage and precise control, its high costs and limited applicability may pose challenges for some buyers. Consideration of the specific application and budget constraints is essential when exploring this technology.

Related Video: Lecture 1 Two compartment models

Key Industrial Applications of shot peening equipment

| Industry/Sector | Specific Application of shot peening equipment | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Surface treatment of turbine blades to enhance fatigue resistance | Extends component life, improves safety, reduces maintenance costs | Compliance with strict aerospace standards (e.g., AS9100) |

| Automotive | Strengthening of clutch springs and suspension components | Increases durability and performance, reduces failure rates | Compatibility with various media types and sizes |

| Oil & Gas | Treatment of drilling components to withstand harsh environments | Enhances reliability and longevity in extreme conditions | Need for specialized media and equipment for corrosive environments |

| Manufacturing & Fabrication | Descaling and surface finishing of metal parts | Improves surface quality, enhances product lifespan | Equipment flexibility to handle diverse part shapes and sizes |

| Defense | Preparation of components for stress relief in military equipment | Ensures operational reliability and safety under stress | Adherence to international defense standards and specifications |

Aerospace

In the aerospace industry, shot peening is primarily utilized for the surface treatment of turbine blades. This application enhances fatigue resistance, which is critical given the high-stress environments these components operate in. Shot peening induces compressive stresses that counteract tensile stresses, thereby extending the life of turbine blades and improving safety. For international buyers, particularly those from Europe and the Middle East, ensuring compliance with stringent aerospace standards such as AS9100 is essential when sourcing shot peening equipment.

Automotive

The automotive sector employs shot peening extensively for strengthening components such as clutch springs and suspension parts. This process significantly increases the durability and performance of these components, which is vital for vehicle safety and reliability. Buyers in South America and Africa should consider the compatibility of shot peening equipment with various media types and sizes, as this can affect the effectiveness of the process and the quality of the end product.

Oil & Gas

In the oil and gas industry, shot peening is used to treat drilling components, enhancing their ability to withstand harsh environmental conditions. This application is critical for ensuring the reliability and longevity of equipment that operates under extreme stress. International buyers need to focus on sourcing specialized media and equipment capable of withstanding corrosive environments, which is a common challenge in this sector.

Manufacturing & Fabrication

Manufacturing and fabrication sectors utilize shot peening for descaling and surface finishing of metal parts. This process improves surface quality, which is essential for product lifespan and performance. Buyers should look for equipment that offers flexibility to handle diverse part shapes and sizes, ensuring that they can meet varying production requirements and quality standards.

Defense

In defense applications, shot peening prepares components for stress relief, ensuring operational reliability and safety under high-stress conditions. This is particularly crucial for military equipment that must perform flawlessly in critical situations. Buyers must ensure that their sourcing aligns with international defense standards and specifications to maintain compliance and quality assurance in their operations.

Related Video: Shot Peening Process Optimization – Critical Applications

Strategic Material Selection Guide for shot peening equipment

When selecting materials for shot peening equipment, international B2B buyers must consider various factors that affect performance, durability, and compliance with industry standards. Below is an analysis of four common materials used in shot peening equipment, focusing on their properties, advantages, disadvantages, and specific considerations for international markets.

1. Cast Steel

Key Properties:

Cast steel is known for its excellent toughness and strength, making it suitable for high-impact applications. It can withstand significant temperature and pressure variations, which is critical in shot peening processes.

Pros & Cons:

The durability of cast steel is a significant advantage, as it can endure repeated impacts without significant wear. However, it may be more expensive than other materials, and its manufacturing process can be complex, potentially leading to longer lead times.

Impact on Application:

Cast steel is compatible with various media types, including cut wire and ceramic beads. Its robustness makes it ideal for heavy-duty applications in industries like aerospace and automotive.

Considerations for International Buyers:

Buyers from regions such as Africa and South America should ensure that suppliers comply with ASTM standards for cast steel. Additionally, understanding local sourcing options can help mitigate costs.

2. Ceramic Beads

Key Properties:

Ceramic beads are lightweight and exhibit high hardness, providing excellent resistance to wear and corrosion. They can operate effectively at elevated temperatures, making them suitable for specific applications.

Pros & Cons:

The primary advantage of ceramic beads is their ability to produce a fine finish on metal surfaces without damaging them. However, they are more fragile than metal media and can break under excessive impact, leading to higher replacement costs.

Impact on Application:

Ceramic beads are particularly effective for delicate components that require a gentle peening process. They are often used in the aerospace industry for finishing turbine blades.

Considerations for International Buyers:

Buyers should confirm compliance with JIS standards for ceramic materials, especially in regions like Europe, where regulations may be stricter. Understanding local availability can also help in managing costs.

3. Glass Beads

Key Properties:

Glass beads are non-metallic and offer excellent corrosion resistance. They are lightweight and can operate effectively in lower-temperature environments, making them versatile for various applications.

Pros & Cons:

The key advantage of glass beads is their ability to produce a smooth surface finish without altering the material’s properties significantly. However, they are less durable than metal media and may require more frequent replacement.

Impact on Application:

Glass beads are ideal for applications requiring a gentle cleaning or finishing process, such as in the automotive and electronics industries.

Considerations for International Buyers:

For buyers in the Middle East, it is essential to ensure that glass beads meet local environmental regulations regarding silica content. Certification to relevant industry standards can also enhance credibility.

4. Cut Wire Shot

Key Properties:

Cut wire shot is made from high-quality steel and retains its round shape longer than cast shot, providing consistent performance. It is resistant to breakage and can withstand high-intensity peening processes.

Pros & Cons:

The main advantage of cut wire shot is its longevity, allowing for extended use before replacement. However, it can be more expensive than cast shot, which might deter some budget-conscious buyers.

Impact on Application:

Cut wire shot is widely used in heavy-duty applications, including automotive and aerospace components, where durability and performance are critical.

Considerations for International Buyers:

International buyers should ensure that cut wire shot complies with ISO standards and local regulations, particularly in Europe and South America, where quality assurance is paramount.

Summary Table

| Material | Typical Use Case for shot peening equipment | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Steel | Heavy-duty applications in aerospace | Excellent toughness and durability | Higher cost and complex manufacturing | High |

| Ceramic Beads | Delicate components in aerospace | Produces fine finishes without damage | Fragility under impact | Medium |

| Glass Beads | Cleaning and finishing in automotive | Smooth surface finish | Less durable, frequent replacement | Low |

| Cut Wire Shot | Heavy-duty applications in automotive | Longevity and consistent performance | Higher initial cost | Medium |

This guide provides a comprehensive overview of material selection for shot peening equipment, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for shot peening equipment

Manufacturing Processes for Shot Peening Equipment

The manufacturing of shot peening equipment involves several critical stages that ensure the machinery is capable of delivering precise and effective shot peening processes. Understanding these stages can help B2B buyers assess the quality and reliability of potential suppliers.

1. Material Preparation

The first stage in manufacturing shot peening equipment is material preparation. This involves sourcing high-quality raw materials that meet specific performance standards. Common materials include various grades of steel for structural components, as well as specialized alloys for parts that endure high stress or wear.

- Key Considerations:

- Material Certification: Ensure that the supplier provides certifications that verify the quality of raw materials, such as ASTM standards.

- Sourcing: Evaluate suppliers based on their ability to source materials locally, which can reduce costs and lead times, particularly important for buyers in Africa and South America.

2. Forming

In the forming stage, raw materials are shaped into components using techniques such as machining, welding, and casting.

- Techniques:

- CNC Machining: Utilizes computer-controlled machines to achieve precise dimensions and tolerances, which are crucial for the performance of shot peening equipment.

- Welding: Often used to assemble larger components or frameworks. The integrity of welds is critical and should be inspected through non-destructive testing (NDT) methods.

3. Assembly

The assembly phase involves integrating all components into a cohesive unit. This stage requires skilled labor and precise handling to ensure that each part fits correctly and functions as intended.

- Key Considerations:

- Assembly Procedures: Documented procedures should be in place to guide assembly, ensuring consistency across production lots.

- Quality Assurance Checks: Regular checks during assembly can catch defects early, reducing rework and enhancing overall product quality.

4. Finishing

Finishing processes enhance the durability and appearance of shot peening equipment. Techniques may include surface treatment, painting, or coating to protect against corrosion and wear.

- Importance of Finishing:

- Surface Preparation: Ensures that surfaces are free from contaminants before any coatings are applied. This is vital for ensuring the longevity of the equipment, especially in environments typical of the Middle East or South America.

- Testing for Coating Integrity: Buyers should inquire about the testing methods used to ensure coatings meet industry standards.

Quality Assurance Practices

Quality assurance (QA) is essential in the manufacturing of shot peening equipment. This includes adhering to international and industry-specific standards to ensure that the equipment meets performance expectations.

Relevant International Standards

B2B buyers should familiarize themselves with the following standards:

- ISO 9001: This standard outlines the requirements for a quality management system and is applicable to all organizations, regardless of size or industry.

- CE Marking: For equipment sold in Europe, CE marking signifies compliance with health, safety, and environmental protection standards.

- API Standards: Relevant for buyers in the oil and gas sector, API standards ensure that equipment meets specific industry requirements.

QC Checkpoints

Quality control checkpoints are critical throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspects raw materials and components upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing to monitor the production process and identify any deviations.

- Final Quality Control (FQC): Comprehensive testing of the final product before shipment, ensuring it meets all specifications.

Common Testing Methods

Testing is an integral part of quality assurance in shot peening equipment manufacturing. Common methods include:

- Dimensional Inspection: Using tools like calipers and gauges to verify that components meet specified dimensions.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic or magnetic particle testing to detect defects without damaging the equipment.

- Performance Testing: Simulating actual operating conditions to ensure the equipment performs as expected under stress.

Verifying Supplier Quality Control

B2B buyers can take several steps to verify the quality control processes of their suppliers:

- Conduct Audits: Regular audits can help assess the effectiveness of a supplier’s quality management system and compliance with standards.

- Request Documentation: Suppliers should provide detailed reports on quality inspections, testing results, and any certifications they hold.

- Engage Third-Party Inspectors: Utilizing independent inspectors can provide an unbiased assessment of the supplier’s quality practices.

QC/Cert Nuances for International Buyers

International B2B buyers must navigate various nuances in quality certification and assurance:

- Cultural and Regulatory Differences: Understanding local regulations and cultural expectations can help buyers select suppliers that align with their operational norms.

- Supply Chain Considerations: Buyers should consider suppliers’ logistics capabilities, especially for regions like Africa and South America, where infrastructure may impact delivery times.

- Language Barriers: Clear communication is essential. Buyers should ensure that suppliers can provide documentation and support in languages they understand, particularly when dealing with complex specifications.

In summary, a thorough understanding of the manufacturing processes and quality assurance measures for shot peening equipment is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with robust QA practices, buyers can make informed decisions that enhance their procurement strategies and ensure they select reliable suppliers.

Related Video: Shot peening to consolidate the surfaces of workpieces.

Comprehensive Cost and Pricing Analysis for shot peening equipment Sourcing

Cost Structure of Shot Peening Equipment

When sourcing shot peening equipment, buyers must understand the various cost components involved in its production and procurement.

-

Materials: The cost of raw materials, such as steel, ceramic beads, or glass beads, constitutes a significant portion of the overall expense. The choice of media directly affects performance and longevity, impacting the long-term cost-effectiveness of the equipment.

-

Labor: Labor costs include not just assembly but also skilled technicians for setup and maintenance. As labor rates vary significantly across regions, understanding local wage standards can help buyers make more informed decisions.

-

Manufacturing Overhead: This includes costs related to utilities, equipment depreciation, and facility maintenance. Efficient manufacturing processes can mitigate overhead costs, leading to better pricing for buyers.

-

Tooling: Custom tooling may be necessary for specific applications, adding to initial costs. However, investing in the right tooling can enhance the quality and consistency of shot peening outcomes.

-

Quality Control (QC): Quality assurance processes are crucial, especially for industries like aerospace and automotive, where compliance with strict standards is mandatory. QC expenses can vary based on the certification requirements of the end user.

-

Logistics: Transportation and shipping costs depend on the distance from the supplier and the mode of transport. Incoterms play a crucial role in defining these costs and responsibilities.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and ensure profitability. This can range widely based on market competition and supplier reputation.

Price Influencers

Several factors influence the pricing of shot peening equipment:

-

Volume/MOQ: Larger orders often result in discounts, as suppliers benefit from economies of scale. Understanding the minimum order quantity (MOQ) is essential for negotiating better prices.

-

Specifications/Customization: Custom-built equipment tailored to specific needs can significantly increase costs. Buyers should weigh the benefits of customization against the added expense.

-

Materials Quality/Certifications: Higher quality materials and certifications, such as ISO or Nadcap, can increase initial costs but result in better performance and lower maintenance costs in the long run.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the implications of different Incoterms (e.g., FOB, CIF) is crucial for international buyers, as they dictate shipping responsibilities and costs.

Buyer Tips

International B2B buyers, especially from Africa, South America, the Middle East, and Europe, should consider the following strategies to optimize their sourcing:

-

Negotiation: Engage suppliers in discussions about pricing, especially if you can commit to larger orders. Leverage competitive quotes from multiple suppliers to strengthen your position.

-

Cost-Efficiency: Evaluate the total cost of ownership rather than just the purchase price. Consider factors such as maintenance, energy consumption, and the longevity of equipment when making decisions.

-

Pricing Nuances: Be aware of regional pricing variations due to differences in labor costs, regulations, and market demand. This understanding can help you identify opportunities for cost savings.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and service. Regular communication and feedback can foster trust and lead to more favorable terms.

Disclaimer

The prices and cost structures outlined here are indicative and can vary widely based on specific circumstances, including market conditions and supplier negotiations. Always conduct thorough market research and supplier assessments to obtain the most accurate and relevant pricing information for your needs.

Spotlight on Potential shot peening equipment Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘shot peening equipment’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for shot peening equipment

Key Technical Properties of Shot Peening Equipment

When evaluating shot peening equipment, several technical properties are critical to ensure optimal performance and compliance with industry standards. Understanding these properties can help international B2B buyers make informed decisions.

- Media Type and Size

– The media used in shot peening can significantly influence the outcome. Common types include cast steel, glass beads, and ceramic beads. The size of the media affects the intensity and coverage of the peening process. For instance, larger media can impart greater energy but may also increase the risk of surface damage. Selecting the appropriate media type and size based on the specific application is essential for achieving the desired surface finish and fatigue resistance.

Illustrative Image (Source: Google Search)

-

Peening Intensity

– Measured through Almen strips, peening intensity indicates the energy of the shot stream impacting the surface. This property is vital because it directly correlates with the compressive stress imparted on the workpiece. The intensity can be adjusted by varying the media size, velocity, and impingement angle. For B2B buyers, understanding the required intensity is crucial to meet the performance specifications of their components, especially in high-stress applications like aerospace or automotive. -

Coverage

– Coverage refers to the percentage of the surface area that has been affected by the peening process. A minimum coverage of 100% is essential to prevent fatigue and stress corrosion cracking. In certain applications, higher coverage percentages (e.g., 150% or 200%) may be specified to enhance durability. For buyers, ensuring complete coverage is a critical factor in maintaining product integrity and longevity. -

Control Systems

– Automated shot peening equipment often includes advanced control systems that monitor and document the peening process. Features such as Computer Monitored Shot Peening (CMSP) enhance repeatability and ensure compliance with industry standards. Buyers should prioritize equipment that offers robust control systems for quality assurance and traceability, particularly in regulated industries. -

Durability and Maintenance

– The construction quality and materials used in the equipment itself determine its durability and maintenance requirements. Robust designs minimize downtime and maintenance costs, which can be particularly beneficial for businesses aiming to maintain high production levels. Buyers should evaluate the long-term operational costs against initial investment to ensure a favorable return on investment.

Common Trade Terms in Shot Peening

Understanding industry jargon is crucial for effective communication and negotiation in the procurement of shot peening equipment. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

– Refers to companies that produce parts or equipment that may be marketed by another manufacturer. For B2B buyers, sourcing from reputable OEMs ensures quality and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– This term indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory and cash flow effectively. -

RFQ (Request for Quotation)

– A formal document requesting pricing and terms from suppliers for specific products or services. Buyers should prepare a comprehensive RFQ to ensure they receive competitive bids and accurately compare offerings. -

Incoterms (International Commercial Terms)

– A set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, insurance, and risk management. -

CNC (Computer Numerical Control)

– Refers to automated machine tools controlled by a computer. In shot peening, CNC technology can enhance precision and consistency in the peening process, making it a valuable feature for buyers looking for advanced equipment.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can navigate the complexities of the shot peening market more effectively, ensuring they make informed purchasing decisions that align with their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shot peening equipment Sector

Market Overview & Key Trends

The shot peening equipment market is witnessing robust growth driven by the increasing demand for enhanced durability and fatigue resistance in metal components across various industries, including aerospace, automotive, and construction. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, should note the following key trends shaping the sector:

-

Technological Advancements: The integration of automation and computer-controlled systems in shot peening equipment is enhancing precision and efficiency. Buyers are increasingly seeking suppliers who offer equipment with advanced monitoring capabilities, such as Computer Monitored Shot Peening (CMSP), which ensures consistent quality and reduces material waste.

-

Customization and Flexibility: As industries evolve, the need for tailored solutions becomes paramount. B2B buyers should look for manufacturers that can provide customizable shot peening systems adaptable to specific production processes and materials.

Illustrative Image (Source: Google Search)

-

Global Supply Chain Dynamics: With the ongoing shifts in global trade policies and supply chain logistics, international buyers must remain vigilant about sourcing trends. Companies that can offer localized support or flexible shipping options are more attractive to buyers in regions with unique logistical challenges.

-

Rising Demand in Emerging Markets: Regions like Africa and South America are experiencing industrial growth, leading to an increased need for shot peening services. B2B buyers in these areas should actively seek partnerships with equipment suppliers who have a proven track record in similar markets.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical focus for international B2B buyers in the shot peening equipment sector. The environmental impact of manufacturing processes, including the use of energy-intensive equipment and materials, necessitates a shift towards greener practices. Buyers should consider the following aspects:

-

Eco-friendly Materials: Opting for shot peening media that is recyclable or made from sustainable sources can significantly reduce environmental footprints. For instance, cut wire shot is preferable to cast shot due to its longer life cycle and minimal waste generation.

-

Energy Efficiency: Equipment that incorporates energy-saving technologies not only reduces operational costs but also aligns with global sustainability goals. Buyers should inquire about the energy consumption ratings of the shot peening equipment they are considering.

-

Ethical Supply Chains: Transparency in sourcing practices is essential. Buyers should prioritize suppliers who adhere to ethical labor practices and can demonstrate compliance with environmental regulations. Certifications such as ISO 14001 for environmental management systems can be indicative of a supplier’s commitment to sustainability.

-

Waste Reduction Initiatives: Suppliers that implement waste reduction programs and recycling initiatives can offer significant value to B2B buyers. Understanding a supplier’s approach to waste management can be a critical factor in decision-making.

Brief Evolution/History

The shot peening process has evolved significantly since its inception in the early 20th century. Initially developed as a method to improve the fatigue life of aircraft components, shot peening has expanded into various industries, including automotive and manufacturing. Over the decades, advancements in technology have transformed the equipment used, moving from manual systems to highly automated and computer-controlled machines. This evolution reflects the growing emphasis on precision, efficiency, and sustainability in manufacturing processes, which are now crucial considerations for international B2B buyers. As the industry continues to innovate, understanding these historical shifts can provide valuable context for making informed purchasing decisions.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of shot peening equipment

-

What criteria should I use to vet suppliers of shot peening equipment?

When vetting suppliers, consider their industry experience, certifications (e.g., ISO 9001, Nadcap), and compliance with international quality standards. Request references from other clients, especially those in your region, to assess reliability and service quality. Evaluate their ability to provide customization options, as well as their technical support and after-sales service. A supplier’s responsiveness to inquiries can also indicate their commitment to customer service, which is vital for ongoing support. -

Can shot peening equipment be customized to meet specific production needs?

Yes, many manufacturers offer customization options for shot peening equipment to align with your specific operational requirements. This may include adjustments to machine size, media type, intensity settings, and control systems. Engage with suppliers early in the negotiation process to discuss your needs and ensure they can accommodate them. Customization can enhance efficiency and effectiveness, ultimately improving the quality of your products. -

What is the typical minimum order quantity (MOQ) for shot peening equipment, and how do lead times vary?

The MOQ for shot peening equipment can vary significantly between suppliers and is often influenced by the complexity of the machinery. Generally, MOQs may range from one unit for standard equipment to larger quantities for custom solutions. Lead times can also differ based on the supplier’s production capacity and your location; expect anywhere from a few weeks to several months. Always clarify these details upfront to avoid unexpected delays in your production schedule. -

What payment terms are commonly offered by suppliers, and how can I protect my investment?

Payment terms typically range from advance payments to net 30 or 60 days, depending on the supplier’s policies and your negotiation leverage. To protect your investment, consider using an escrow service or letters of credit, especially for high-value transactions. Ensure that payment terms are clearly outlined in the contract, along with conditions for refunds or replacements in case of equipment defects or non-compliance with specifications. -

What quality assurance measures should I expect from shot peening equipment suppliers?

Reputable suppliers should adhere to stringent quality assurance measures, including routine inspections and testing of their equipment. Look for suppliers who provide documentation of quality certifications and who perform tests such as Almen strip measurements to verify shot peening intensity. Request information about their quality control processes and whether they can provide traceability documentation for the materials used in the equipment. -

How do suppliers handle logistics and shipping for international buyers?

Suppliers typically coordinate logistics based on your location and shipping preferences. They should provide options for shipping methods (air, sea, or land), along with estimated costs and delivery times. Ensure that your supplier is familiar with customs regulations in your country and can assist with necessary paperwork. It’s advisable to confirm who is responsible for duties and taxes to avoid unexpected costs upon delivery. -

What steps can I take if there is a dispute with a supplier regarding shot peening equipment?

In the event of a dispute, first try to resolve the issue directly with the supplier through open communication. Refer to your contract for dispute resolution clauses, which may include mediation or arbitration. If a resolution cannot be reached, consider escalating the matter through legal channels based on the jurisdiction specified in your agreement. Document all communications and retain copies of contracts and related documents as evidence. -

Are there specific certifications that shot peening equipment should have for international trade?

Yes, certain certifications are crucial for ensuring that shot peening equipment meets international quality and safety standards. Look for ISO certifications (like ISO 9001 for quality management) and industry-specific certifications such as Nadcap for aerospace applications. These certifications not only validate the equipment’s performance but also facilitate smoother customs clearance and acceptance in various markets, particularly in Europe and North America.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for shot peening equipment

In conclusion, strategic sourcing of shot peening equipment presents a significant opportunity for international B2B buyers to enhance manufacturing processes across diverse industries such as aerospace, automotive, and construction. By understanding the critical factors—such as media quality, intensity, and coverage—buyers can ensure that the equipment they select meets the stringent demands of their specific applications.

Key Takeaways:

- Quality Assurance: Prioritize suppliers who maintain compliance with quality standards like ISO9001 and Nadcap certifications to guarantee reliable performance.

- Technology Adoption: Consider advanced technologies like Computer Monitored Shot Peening (CMSP) for enhanced process control and documentation, ensuring repeatability and precision.

- Material Selection: Choose the appropriate media type to maximize equipment lifespan and performance, with a preference for rounded cut wire shot for its durability.

As global markets evolve, the need for robust and efficient shot peening solutions will only increase. B2B buyers from Africa, South America, the Middle East, and Europe should leverage this moment to partner with reputable suppliers who can meet their specific needs and contribute to their competitive edge. Engage in strategic sourcing today to secure the future of your manufacturing excellence.