Your Ultimate Guide to Sourcing Industrial Dryers

Introduction: Navigating the Global Market for industrial dryers

Navigating the global market for industrial dryers is crucial for businesses aiming to optimize their production processes and ensure product integrity. Industrial dryers play a pivotal role across diverse sectors, including food processing, pharmaceuticals, textiles, and chemical manufacturing, by effectively removing moisture from materials. This not only preserves quality but also complies with stringent regulatory standards.

In this comprehensive guide, we delve into the multifaceted world of industrial dryers, offering insights into the various types available—such as air dryers, rotary dryers, and fluid bed dryers—each tailored to specific applications and materials. We will explore essential factors including manufacturing processes, quality control measures, and supplier selection to empower international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe (with a special focus on markets like Turkey and Spain).

Understanding the complexities of industrial dryers is vital for informed sourcing decisions. Buyers will gain knowledge about cost considerations, market trends, and frequently asked questions, enabling them to navigate procurement with confidence. With this guide, you will be equipped to select the right industrial drying technology, ensuring operational efficiency and product excellence in your business endeavors.

Understanding industrial dryers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Air Dryers | Utilize heated air for direct moisture removal; simple design. | Food processing, textiles, and plastics. | Pros: Cost-effective, easy maintenance. Cons: Less suitable for heat-sensitive materials. |

| Rotary Dryers | Large cylindrical drums that tumble materials with hot air. | Mineral processing, aggregates, and bulk solids. | Pros: High capacity, uniform drying. Cons: Requires significant floor space, energy-intensive. |

| Fluid Bed Dryers | Employ heated air to suspend particles for even drying. | Pharmaceuticals, food, and chemical industries. | Pros: Gentle drying, energy-efficient. Cons: More complex design, higher initial investment. |

| Spray Dryers | Convert liquid into powder by spraying into a heated chamber. | Dairy products, chemicals, and pharmaceuticals. | Pros: Rapid drying, preserves product quality. Cons: Requires precise control, higher operational costs. |

| Freeze Dryers | Remove moisture by sublimation at low temperatures. | Pharmaceuticals, food preservation, and biotech. | Pros: Maintains product integrity, long shelf life. Cons: High capital and operational costs. |

Air Dryers

Air dryers are among the most common types of industrial dryers, leveraging heated air to evaporate moisture from products. They are particularly effective for applications involving textiles, plastics, and food processing. When selecting an air dryer, buyers should consider factors such as air flow rates, temperature control, and energy efficiency. While they are generally cost-effective and easy to maintain, air dryers may not be suitable for heat-sensitive materials, as excessive heat can degrade product quality.

Rotary Dryers

Rotary dryers consist of large, cylindrical drums that tumble materials while hot air is introduced. This design promotes uniform drying, making rotary dryers ideal for bulk solids like minerals and aggregates. When purchasing a rotary dryer, businesses should evaluate the required throughput, energy consumption, and floor space requirements. While rotary dryers offer high capacity and efficiency, they can be energy-intensive and may require significant space, which could be a limitation for smaller operations.

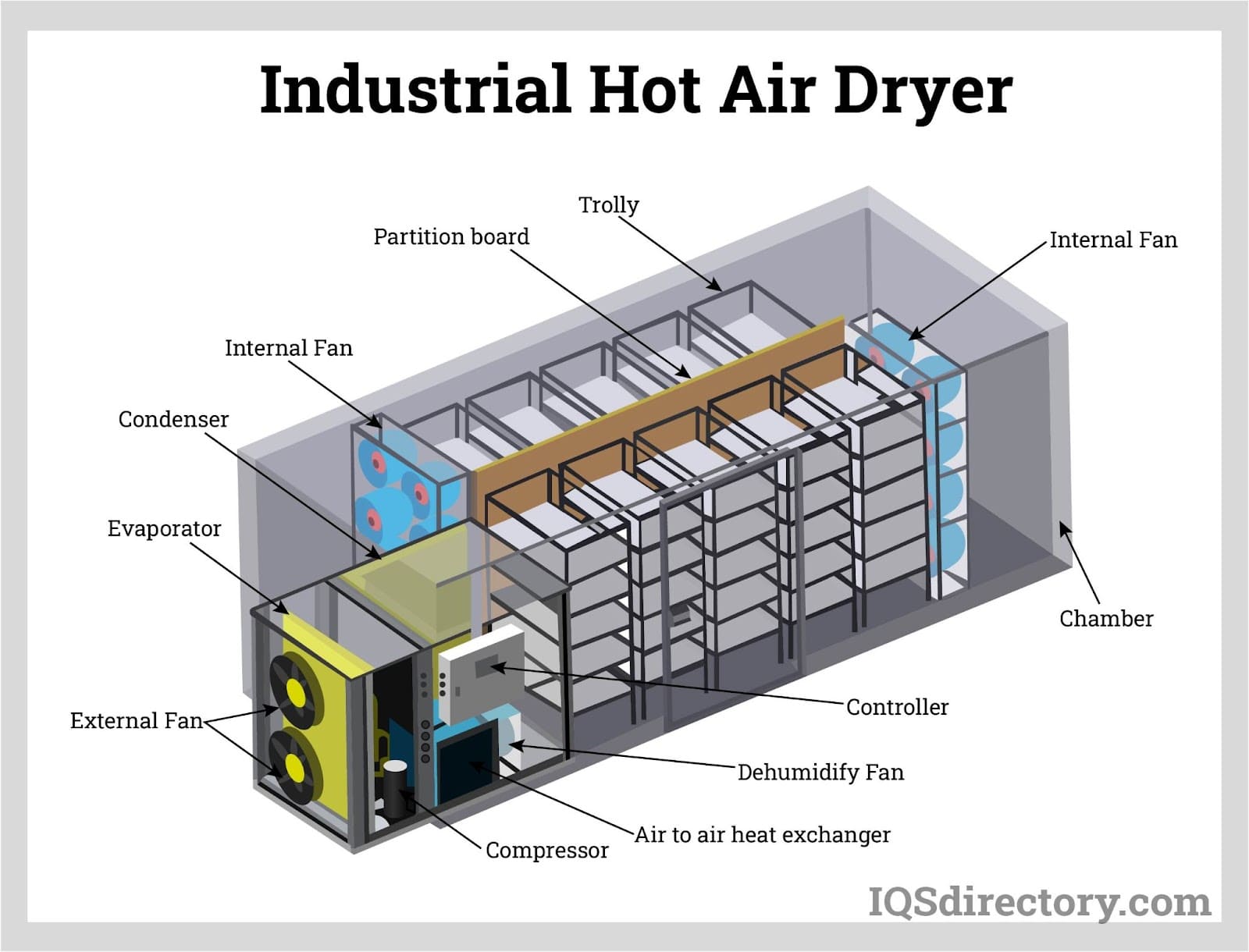

Illustrative Image (Source: Google Search)

Fluid Bed Dryers

Fluid bed dryers utilize a perforated plate to introduce heated air that suspends particles, allowing for even and gentle drying. This method is particularly suitable for sensitive materials found in pharmaceuticals and food industries. Buyers should focus on the design’s complexity, energy efficiency, and maintenance needs when considering fluid bed dryers. Although they provide a gentle drying process and conserve energy, the initial investment can be higher compared to simpler dryer types.

Spray Dryers

Spray dryers operate by atomizing liquid feeds into fine droplets and introducing them into a heated drying chamber. This method is prevalent in the dairy, chemical, and pharmaceutical sectors, where rapid moisture removal is crucial. Buyers should assess the control systems and operational costs associated with spray dryers. While they excel in preserving product quality and providing fast drying times, they require precise control and can incur higher operational costs due to the complexity of the system.

Freeze Dryers

Freeze dryers remove moisture from products by sublimation, typically at low temperatures, making them ideal for pharmaceuticals, food preservation, and biotech applications. When considering freeze dryers, buyers should look at capital costs, energy consumption, and the potential for maintaining product integrity. Although freeze dryers can significantly extend shelf life and preserve sensitive compounds, they are associated with high capital and operational costs, which may be a barrier for some businesses.

Key Industrial Applications of industrial dryers

| Industry/Sector | Specific Application of Industrial Dryers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Drying fruits, vegetables, and meat products | Extends shelf life, enhances flavor, and maintains nutritional value | Compliance with food safety standards and energy efficiency |

| Pharmaceuticals | Drying active pharmaceutical ingredients (APIs) | Ensures product stability and potency, meets regulatory requirements | Customizable drying temperatures and contamination prevention |

| Chemical Manufacturing | Drying powders and granules used in chemical formulations | Improves product quality and consistency, reduces waste | Material compatibility and heat sensitivity of products |

| Textile Industry | Drying fabrics and garments post-treatment | Enhances product quality and reduces production time | Adaptability to different fabric types and moisture removal rates |

| Mineral Processing | Drying ores and minerals post-extraction | Increases product purity and prepares materials for further processing | Durability against abrasive materials and temperature controls |

Food Processing

In the food processing sector, industrial dryers are crucial for drying fruits, vegetables, and meats. These dryers effectively remove moisture, which helps to extend the shelf life of products, enhance flavors, and maintain nutritional value. For international buyers, especially in Africa and South America, sourcing dryers that comply with stringent food safety standards is essential. Additionally, energy efficiency becomes a critical factor, as it directly impacts operational costs and sustainability efforts.

Pharmaceuticals

In the pharmaceutical industry, industrial dryers are utilized for drying active pharmaceutical ingredients (APIs). The drying process ensures that the final product is stable and potent, which is vital for meeting regulatory standards. Buyers in the Middle East and Europe should focus on suppliers that offer customizable drying temperatures to accommodate sensitive compounds. Moreover, the ability to prevent contamination during the drying process is paramount, necessitating advanced technologies in dryer design.

Chemical Manufacturing

Chemical manufacturers rely on industrial dryers to remove moisture from powders and granules used in various formulations. Efficient drying improves product quality and consistency, reducing waste and enhancing profitability. For B2B buyers, particularly in Europe, sourcing considerations should include the compatibility of drying equipment with various chemical compositions and the heat sensitivity of the materials. Additionally, understanding the regulatory landscape in different regions can influence purchasing decisions.

Textile Industry

The textile industry employs industrial dryers to dry fabrics and garments after treatment processes. This step is vital for enhancing the quality of the final products and reducing production time. Buyers from regions like Turkey and Spain should seek dryers that can adapt to various fabric types and moisture removal rates. The ability to fine-tune drying parameters is essential to prevent damage to delicate fabrics while ensuring efficiency.

Mineral Processing

In mineral processing, industrial dryers are essential for drying ores and minerals after extraction. Effective drying increases the purity of the final product and prepares materials for further processing. For international buyers, particularly in Africa, sourcing durable dryers that can withstand abrasive materials and extreme temperatures is critical. Additionally, understanding the specific drying requirements for different minerals can help in selecting the appropriate technology for optimal results.

Strategic Material Selection Guide for industrial dryers

When selecting materials for industrial dryers, it is essential to consider their properties, advantages, disadvantages, and compatibility with specific applications. The choice of material can significantly impact the performance, durability, and cost-effectiveness of the drying equipment. Below are analyses of four common materials used in the construction of industrial dryers.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high-temperature tolerance, and structural integrity. It typically withstands temperatures up to 900°C (1650°F) and is resistant to oxidation and scaling.

Pros & Cons: The durability and hygiene of stainless steel make it ideal for food and pharmaceutical applications. However, it can be more expensive than other materials, and its manufacturing process may involve complex welding techniques that increase production costs.

Impact on Application: Stainless steel is compatible with various media, including food products, chemicals, and pharmaceuticals. Its non-reactive nature ensures that the integrity of sensitive materials is maintained during the drying process.

Considerations for International Buyers: Compliance with international standards such as ASTM and FDA regulations is crucial for buyers in Europe and the Middle East. Buyers should also consider the availability of stainless steel grades that meet local regulations.

Carbon Steel

Key Properties: Carbon steel is robust and can handle high pressures and temperatures, typically up to 400°C (752°F). It is less resistant to corrosion compared to stainless steel but can be treated with coatings to enhance its durability.

Pros & Cons: The cost-effectiveness of carbon steel makes it a popular choice for larger industrial dryers. However, its susceptibility to rust and corrosion may require additional maintenance and protective measures, which can increase long-term costs.

Impact on Application: Carbon steel is suitable for applications involving non-corrosive materials such as minerals and plastics. Its strength makes it ideal for heavy-duty applications but may limit its use with sensitive or corrosive products.

Considerations for International Buyers: Buyers from Africa and South America should be aware of local environmental conditions that may accelerate corrosion. Compliance with local industrial standards is also essential to ensure safety and performance.

Aluminum

Key Properties: Aluminum is lightweight and has good thermal conductivity, making it suitable for certain drying applications. It can withstand temperatures up to 300°C (572°F) and offers some resistance to corrosion.

Pros & Cons: The lightweight nature of aluminum facilitates easier installation and maintenance. However, its lower temperature tolerance and potential for deformation under high heat can limit its applications compared to stainless steel and carbon steel.

Impact on Application: Aluminum is often used in smaller, less demanding drying applications, such as laboratory dryers or equipment for lightweight materials. It is not recommended for high-temperature or corrosive environments.

Considerations for International Buyers: Compliance with industry standards such as JIS in Japan or DIN in Germany is essential for ensuring product quality. Buyers should assess the specific requirements of their applications to determine if aluminum is a viable option.

Composite Materials

Key Properties: Composite materials combine various substances to achieve specific performance characteristics, such as enhanced thermal insulation and corrosion resistance. They can be engineered to withstand a range of temperatures and pressures.

Pros & Cons: The versatility of composite materials allows for customization to meet specific application needs. However, they can be more expensive to produce and may require specialized manufacturing techniques.

Impact on Application: Composites are ideal for applications where weight reduction and thermal efficiency are critical, such as in aerospace and automotive industries. They can also provide excellent chemical resistance for drying corrosive materials.

Considerations for International Buyers: Buyers should evaluate the certifications and compliance of composite materials with international standards. Understanding local market preferences and regulations is crucial for successful implementation.

| Material | Typical Use Case for industrial dryers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing and pharmaceuticals | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Carbon Steel | Mineral and plastic drying | Cost-effective and robust | Susceptible to corrosion | Medium |

| Aluminum | Laboratory and lightweight applications | Lightweight and good thermal conductivity | Lower temperature tolerance | Medium |

| Composite Materials | Aerospace and automotive applications | Customizable performance characteristics | Higher production costs | High |

This strategic material selection guide provides essential insights for international B2B buyers, helping them make informed decisions based on the specific needs of their applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for industrial dryers

Industrial dryers are complex machines that require meticulous manufacturing processes and stringent quality assurance measures to meet the diverse needs of various industries. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these processes can aid in selecting the right supplier and ensuring product reliability and compliance with industry standards.

Manufacturing Processes for Industrial Dryers

The manufacturing of industrial dryers typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial in ensuring the final product meets the required specifications and performance standards.

Material Preparation

Before manufacturing begins, raw materials must be selected based on the specific requirements of the dryer type. Common materials include:

- Stainless Steel: Preferred for its durability and resistance to corrosion, especially in food and pharmaceutical applications.

- Carbon Steel: Often used for non-corrosive applications, typically coated or treated to enhance longevity.

- Insulation Materials: Essential for maintaining energy efficiency and minimizing heat loss.

The preparation phase includes cutting, treating, and sometimes pre-fabricating components, ensuring they meet precise dimensions and tolerances.

Forming

The forming process involves shaping the prepared materials into the required components of the dryer. Key techniques include:

- Welding: Essential for creating robust joints between components, particularly in the dryer chamber.

- Bending and Rolling: Used to create cylindrical shapes for rotary dryers or ducts.

- Machining: Precision machining ensures that components fit together seamlessly, which is critical for airflow and thermal efficiency.

Advanced technologies such as laser cutting and CNC machining are often employed to enhance precision and reduce waste.

Assembly

Once the components are formed, they move to the assembly stage. This typically involves:

- Component Integration: Each part, including heating elements, controls, and fans, is systematically assembled to form a complete unit.

- Electrical Installation: Wiring and controls are integrated into the dryer to ensure functionality and safety.

- Calibration: Initial testing and calibration are performed to ensure all systems work together effectively.

Finishing

The finishing stage enhances the durability and appearance of the dryer. Processes include:

- Coating: Application of protective coatings to prevent corrosion and enhance hygiene, particularly for food-grade equipment.

- Final Assembly: Any remaining parts, such as doors, sensors, and safety features, are added.

- Inspection: A thorough inspection is conducted to ensure that the dryer meets all specifications and quality standards before shipping.

Quality Assurance in Industrial Dryer Manufacturing

Quality assurance (QA) is critical in the manufacturing of industrial dryers, ensuring that each unit is safe, efficient, and reliable. This process often adheres to international standards and includes multiple checkpoints.

Relevant International Standards

For international buyers, understanding the standards that manufacturers comply with is crucial:

- ISO 9001: This quality management standard ensures that manufacturers have robust processes for continuous improvement and customer satisfaction.

- CE Marking: Indicates compliance with European safety, health, and environmental protection standards.

- API Standards: Relevant for manufacturers serving the oil and gas industries, ensuring equipment meets specific operational requirements.

Quality Control Checkpoints

Quality control (QC) is typically divided into several stages:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections are performed throughout the manufacturing process to catch defects early.

- Final Quality Control (FQC): Once assembly is complete, the dryer undergoes comprehensive testing to verify performance, safety, and compliance with specifications.

Common Testing Methods

Manufacturers employ various testing methods to ensure quality:

- Performance Testing: Evaluates the dryer’s ability to remove moisture effectively under specified conditions.

- Safety Testing: Ensures that all safety features are functional and meet regulatory requirements.

- Durability Testing: Simulates long-term use to assess the longevity and reliability of the dryer components.

Verifying Supplier Quality Control

For B2B buyers, especially those in regions with varying quality standards, verifying a supplier’s quality assurance processes is essential. Here are actionable steps:

- Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes and compliance with quality standards.

- Request Quality Reports: Ask suppliers for documentation on their quality control processes and results from recent tests.

- Third-Party Inspections: Engage independent inspectors to evaluate the manufacturing facilities and equipment before placing large orders.

- Certifications: Verify that suppliers hold relevant certifications (e.g., ISO 9001, CE) and understand any nuances in certification requirements specific to your region or industry.

Conclusion

Understanding the manufacturing processes and quality assurance measures for industrial dryers is vital for international B2B buyers. By focusing on detailed inspections, compliance with global standards, and effective supplier verification, buyers can ensure they select reliable equipment that meets their operational needs. This knowledge not only aids in making informed purchasing decisions but also helps in fostering long-term partnerships with reputable manufacturers.

Related Video: Production process

Comprehensive Cost and Pricing Analysis for industrial dryers Sourcing

Industrial dryers are critical investments for businesses across various sectors, and understanding their cost structure is essential for international B2B buyers. The cost of sourcing industrial dryers involves multiple components, each influencing the final price.

Cost Components

-

Materials: The raw materials used in constructing industrial dryers significantly impact costs. High-quality materials such as stainless steel or specialized alloys are preferred for their durability and compliance with industry standards, particularly in food and pharmaceutical applications. The choice of materials affects not only the initial price but also the longevity and maintenance costs of the equipment.

-

Labor: Labor costs encompass the wages of skilled workers involved in the design, manufacturing, and assembly of the dryers. Regions with higher labor costs, such as parts of Europe, may see increased pricing. Conversely, manufacturers in countries with lower labor costs may offer more competitive pricing, but this can sometimes compromise quality.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help reduce overhead, thereby lowering the overall price of the dryers.

-

Tooling: Specialized tooling required for the production of custom dryers can add to costs. Buyers should consider whether they need standard models or customized solutions, as the latter often entails higher tooling expenses.

-

Quality Control (QC): Rigorous QC processes ensure that the dryers meet specific performance and safety standards. Enhanced QC measures can lead to higher manufacturing costs, which will be reflected in the price.

-

Logistics: The transportation of heavy industrial equipment involves significant logistics costs, especially for international shipments. Factors like distance, shipping methods, and tariffs can affect overall pricing.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can vary significantly between manufacturers based on their market positioning and value proposition.

Price Influencers

Several factors can influence the pricing of industrial dryers:

- Volume/MOQ (Minimum Order Quantity): Larger orders may qualify for bulk pricing discounts. Buyers should assess their production needs to maximize cost-efficiency.

- Specifications/Customization: Custom specifications, such as size, capacity, and features, can lead to increased costs. Buyers should carefully evaluate whether customization is necessary for their application.

- Materials: The choice of materials not only affects durability but also the price. For instance, eco-friendly or specialized materials may carry a premium.

- Quality/Certifications: Equipment that meets international certifications (like ISO or FDA) may command higher prices due to compliance with stringent regulations.

- Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established manufacturers with proven track records may charge more but offer better service and support.

- Incoterms: Understanding shipping terms (such as FOB, CIF, DDP) is essential, as they dictate who is responsible for shipping costs and risks, impacting the total landed cost of the dryer.

Buyer Tips

To navigate the complexities of pricing in the industrial dryer market, buyers should consider the following strategies:

- Negotiation: Engage in discussions with suppliers about price structures and seek discounts based on order volumes or long-term contracts. Clear communication about your needs can also foster better deals.

- Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not just the purchase price but also operational costs, maintenance, and energy consumption over the dryer’s lifespan.

- Pricing Nuances: International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of currency fluctuations, import duties, and regional market conditions that can affect pricing.

Disclaimer

Prices for industrial dryers can vary widely based on the aforementioned factors, and this analysis serves as a guideline. Buyers should conduct thorough market research and solicit multiple quotes to ensure they are making informed purchasing decisions.

Spotlight on Potential industrial dryers Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘industrial dryers’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for industrial dryers

Essential Technical Properties

Understanding the critical specifications of industrial dryers is vital for international B2B buyers. These specifications not only influence the performance and efficiency of the drying process but also impact operational costs and product quality. Here are some key technical properties:

-

Material Grade

Industrial dryers are typically constructed from materials like stainless steel, carbon steel, or specialized alloys. The choice of material affects durability, corrosion resistance, and compliance with industry standards (especially in food and pharmaceutical sectors). Buyers should ensure that the material grade aligns with their specific application requirements to avoid premature wear and tear. -

Drying Capacity

Measured in pounds per hour (PPH) or cubic feet, drying capacity determines how much material can be processed within a given timeframe. For manufacturers, selecting a dryer with the appropriate capacity is crucial to meet production demands without bottlenecking operations. Overestimating capacity can lead to higher energy costs and inefficiencies. -

Temperature Tolerance

This specification indicates the maximum and minimum temperatures that the dryer can handle. Different materials require specific temperature ranges to ensure effective moisture removal without compromising quality. For instance, heat-sensitive products may require lower temperatures to prevent degradation. Buyers must assess the temperature tolerance to ensure compatibility with their materials. -

Energy Efficiency

Energy consumption is a significant operational cost. Many modern dryers come equipped with advanced energy-saving technologies, which can drastically reduce electricity usage. Understanding the energy efficiency rating helps buyers select dryers that not only lower costs but also align with sustainability goals. -

Control Systems

Advanced control systems allow for precise monitoring and adjustment of drying parameters such as temperature, humidity, and time. Features like programmable logic controllers (PLCs) and user-friendly interfaces enhance operational efficiency and product consistency. Buyers should consider the complexity of the control systems and the training required for their workforce.

Industry/Trade Terms

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and maintain equipment compatibility for parts and services. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to manage inventory and cash flow effectively, especially when purchasing specialized equipment like industrial dryers. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products or services. It is a critical step in the procurement process, enabling buyers to compare offers and negotiate better terms. Providing clear specifications in the RFQ can lead to more accurate and favorable responses.

Illustrative Image (Source: Google Search)

-

Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers regarding the delivery of goods, including shipping, insurance, and tariffs. Understanding Incoterms is essential for international transactions, as they clarify who bears the risk and costs during transportation. -

Batch vs. Continuous Drying

These terms describe the two primary methods of industrial drying. Batch drying processes materials in discrete quantities, while continuous drying involves a steady flow of materials through the dryer. Buyers must determine which method aligns with their production processes to optimize efficiency and product quality. -

Heat Transfer Method

This refers to the method by which heat is applied to the material being dried, such as conduction, convection, or radiation. Understanding different heat transfer methods helps buyers select the appropriate dryer technology for their specific material properties and drying requirements.

By grasping these technical properties and industry terms, international B2B buyers can make informed decisions when selecting industrial dryers, ensuring they meet their operational needs and enhance production efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the industrial dryers Sector

Market Overview & Key Trends

The industrial dryers market is experiencing robust growth, driven by several global factors including rising demand for efficient moisture removal processes across various sectors such as food processing, pharmaceuticals, and chemicals. Key trends influencing this market include the integration of Industry 4.0 technologies, where automation and data analytics enhance operational efficiency and product quality. B2B buyers from regions like Africa, South America, the Middle East, and Europe (notably Turkey and Spain) are increasingly focusing on sourcing advanced dryer technologies that offer scalability, energy efficiency, and versatility.

Emerging technologies such as microwave and infrared drying are gaining traction, providing faster drying times and preserving the integrity of sensitive materials. Additionally, the shift towards sustainable manufacturing practices is prompting buyers to seek out dryers that minimize energy consumption and waste. The rise of e-commerce platforms is also changing how buyers source industrial dryers, facilitating easier comparison of suppliers and technologies across borders. Moreover, regulatory compliance related to product safety and environmental impact is becoming a critical consideration for international buyers, emphasizing the need for reliable and certified equipment.

Sustainability & Ethical Sourcing in B2B

Sustainability is now a pivotal factor in the decision-making process for B2B buyers in the industrial dryers sector. The environmental impact of drying processes can be significant, particularly in terms of energy usage and emissions. Therefore, buyers are increasingly prioritizing energy-efficient dryers that utilize renewable energy sources or advanced heat recovery systems.

Furthermore, the importance of ethical supply chains cannot be overstated. Buyers are encouraged to partner with manufacturers who adhere to ethical labor practices and demonstrate transparency in their sourcing methods. Certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) are becoming essential benchmarks for assessing the sustainability of suppliers. Using green materials in the construction of dryers, such as recyclable metals or low-impact coatings, further enhances a supplier’s sustainability profile. By aligning with environmentally responsible manufacturers, B2B buyers not only reduce their carbon footprint but also enhance their brand reputation in an increasingly eco-conscious market.

Brief Evolution/History

The evolution of industrial dryers can be traced back to the late 19th century, when early forms of drying equipment were used primarily in agriculture and food preservation. As industrial processes advanced, so did drying technologies, leading to the development of specialized dryers for various applications. The introduction of electric and gas-powered dryers in the mid-20th century revolutionized the industry, allowing for greater control over drying conditions and efficiency.

In recent decades, the push for sustainability and energy efficiency has spurred innovation in dryer technology, including the adoption of smart sensors and automated controls. These advancements are pivotal for modern manufacturers seeking to optimize production while minimizing environmental impact. Today, industrial dryers are integral to a wide range of industries, embodying both technological sophistication and a commitment to sustainable practices.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of industrial dryers

-

What criteria should I consider when vetting suppliers for industrial dryers?

When vetting suppliers, prioritize their industry experience and reputation. Look for companies with a proven track record in manufacturing industrial dryers relevant to your sector. Evaluate their certifications, such as ISO standards, which indicate compliance with international quality management systems. Additionally, request client references and case studies to assess their reliability and product performance. It’s also beneficial to check for after-sales support and service capabilities to ensure you have assistance post-purchase. -

Can industrial dryers be customized to meet specific processing needs?

Yes, many manufacturers offer customization options for industrial dryers. This can include modifications to heating methods, chamber sizes, and material compatibility based on your specific application requirements. Communicate your needs clearly during discussions with potential suppliers, including any industry regulations or standards that must be met. A tailored solution can enhance efficiency and ensure that the dryer integrates seamlessly into your existing production processes. -

What are the typical minimum order quantities (MOQs) and lead times for industrial dryers?

Minimum order quantities can vary significantly based on the manufacturer and the complexity of the dryer. Some suppliers may have MOQs as low as one unit for standard models, while custom-built dryers may require larger orders. Lead times also depend on the type of dryer and customization level, ranging from a few weeks for standard units to several months for tailored solutions. Always confirm these details during negotiations to align with your production schedules. -

What payment terms should I expect when purchasing industrial dryers?

Payment terms can vary among suppliers, but common practices include a deposit upon order placement (usually 30-50%) and the balance upon delivery or prior to installation. Some manufacturers may offer financing options or extended payment plans, especially for larger orders. Ensure you discuss payment terms upfront and get them in writing to avoid any misunderstandings later in the transaction process. -

How can I ensure quality assurance and necessary certifications for my industrial dryer?

To ensure quality assurance, request documentation of the dryer’s compliance with industry-specific standards and certifications, such as CE marking for European markets or FDA approval for food-related applications. Manufacturers should provide test reports and quality control procedures that demonstrate their commitment to product integrity. Regular audits and third-party inspections can also be arranged to verify ongoing compliance and quality standards. -

What logistical considerations should I be aware of when importing industrial dryers?

Importing industrial dryers involves several logistical considerations, including shipping methods, customs clearance, and local regulations. Determine whether you need specialized transport due to the size or weight of the dryer. Engage with a logistics provider experienced in handling industrial equipment to streamline the process. Be aware of any import tariffs or duties that may apply, and ensure you have all necessary documentation for customs to avoid delays. -

What steps should I take in case of a dispute with a supplier?

In the event of a dispute, start by reviewing the contract terms to understand your rights and obligations. Attempt to resolve the issue amicably through direct communication with the supplier. If informal discussions do not yield results, consider mediation or arbitration, as these methods can be less costly and time-consuming than litigation. Document all communications and agreements, as this information can be crucial if further action is needed. -

How can I assess the long-term reliability and maintenance needs of industrial dryers?

Assessing long-term reliability involves understanding the dryer’s design, materials used, and maintenance requirements. Inquire about the expected lifespan of the equipment and the manufacturer’s recommendations for routine maintenance. Look for features that facilitate easy access for servicing and consider suppliers that offer comprehensive maintenance contracts. Additionally, review feedback from other users regarding reliability and support to gauge the dryer’s performance over time.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for industrial dryers

In conclusion, the strategic sourcing of industrial dryers is crucial for companies aiming to enhance efficiency and maintain product quality across various sectors. By understanding the diverse types of industrial dryers and their specific applications—from air and rotary dryers to fluid bed systems—buyers can make informed decisions that align with their operational needs.

Key takeaways include the importance of selecting dryers that not only meet regulatory standards but also preserve material integrity and optimize energy consumption. Engaging with reputable manufacturers and suppliers ensures access to innovative technologies and reliable support, which are vital in today’s competitive market.

Looking ahead, international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should remain proactive in evaluating advancements in drying technology. The growing emphasis on sustainability and energy efficiency will likely shape future developments, presenting new opportunities for cost savings and improved performance.

Call to action: Take the next step in your sourcing journey by connecting with leading industrial dryer manufacturers and exploring tailored solutions that meet your unique operational requirements. The right partnership can significantly impact your production capabilities and market competitiveness.