Your Ultimate Guide to Sourcing Rotameter Flow Measurement

Introduction: Navigating the Global Market for rotameter flow measurement

Rotameter flow measurement is an essential component in various industries, providing accurate and reliable data on fluid flow rates. As global demand for precise measurement tools continues to rise, understanding the intricacies of rotameters becomes paramount for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. This guide aims to empower international buyers by delivering comprehensive insights into the types, applications, and materials used in rotameter construction, along with crucial manufacturing and quality control considerations.

By delving into the operational principles of rotameters, buyers will gain clarity on how these devices function and their significance in processes such as chemical dosing, water treatment, and petrochemical applications. The guide will also address supplier options, cost factors, and market dynamics, enabling informed sourcing decisions that align with specific operational needs.

Moreover, with a focus on common challenges and frequently asked questions, this resource serves as a vital tool for businesses looking to optimize their flow measurement solutions. Whether you’re based in Mexico, Italy, or beyond, understanding the nuances of rotameter technology will enhance your procurement strategies and ensure the selection of high-quality, cost-effective solutions tailored to your industry requirements. With this knowledge, international B2B buyers can navigate the global market confidently, driving efficiency and accuracy in their operations.

Understanding rotameter flow measurement Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Glass Rotameter | Transparent tube allows for visual flow monitoring. | Chemical processing, laboratories, water treatment. | Pros: Easy to read; Cons: Fragile, limited pressure range. |

| Metal Rotameter | Durable construction, suitable for harsh environments. | Oil and gas, petrochemical, food processing. | Pros: High durability; Cons: More expensive, heavier. |

| Plastic Rotameter | Lightweight and corrosion-resistant. | Water treatment, low-pressure applications. | Pros: Cost-effective; Cons: Limited temperature range. |

| Electronic Rotameter | Incorporates digital displays and advanced sensors. | HVAC systems, process automation, pharmaceuticals. | Pros: High accuracy, data logging; Cons: Higher initial cost. |

| Variable Area Rotameter | Adjusts flow area dynamically, often with a float. | Chemical dosing, gas flow measurement. | Pros: Versatile; Cons: Calibration can be complex. |

Glass Rotameter

Glass rotameters are widely used in applications where visual flow indication is crucial. Their transparent design allows operators to easily monitor flow rates, making them ideal for laboratories and chemical processing. However, their fragility poses a risk in industrial environments, and they typically operate under lower pressure conditions. When purchasing, buyers should consider the operational environment and the need for regular monitoring.

Metal Rotameter

Metal rotameters are constructed to withstand extreme conditions, making them suitable for the oil and gas industry, as well as food processing applications. Their robust design allows for accurate measurements in high-pressure environments. While they offer durability, buyers should be aware that metal rotameters tend to be heavier and more expensive compared to their glass counterparts. Selecting the right material is critical for compatibility with specific fluids.

Plastic Rotameter

Plastic rotameters are an economical choice for low-pressure applications, especially in water treatment processes. Their lightweight nature and resistance to corrosion make them suitable for various industries. However, they have limitations regarding temperature and pressure, which buyers must consider during selection. Cost-effectiveness is a significant advantage, but potential buyers should evaluate the specific requirements of their applications.

Electronic Rotameter

Electronic rotameters provide enhanced accuracy through digital displays and integrated sensors. They are increasingly utilized in HVAC systems and process automation, where precise flow measurement is essential. While they offer advanced features such as data logging, the initial investment is higher than traditional models. Businesses should weigh the benefits of accurate measurements against the upfront costs when considering this type of rotameter.

Variable Area Rotameter

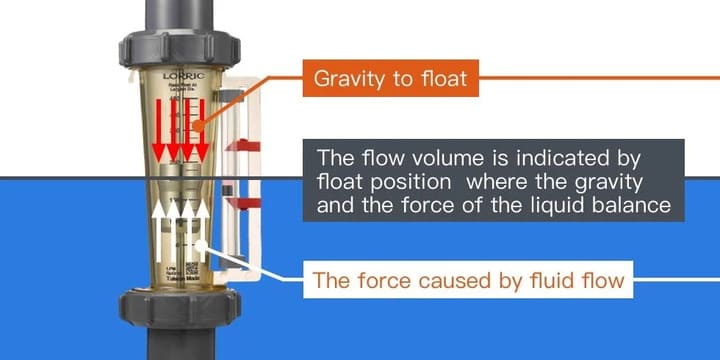

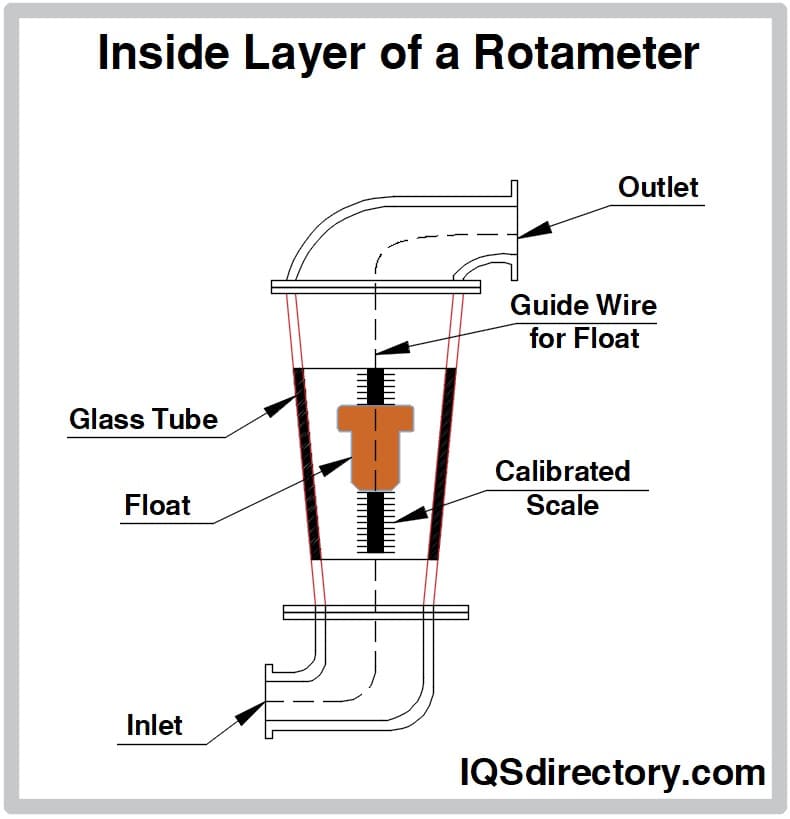

Variable area rotameters adjust the flow area dynamically through a float mechanism, making them versatile for various applications including chemical dosing and gas flow measurement. These rotameters are adaptable to different flow rates, but their calibration can be complex. Buyers should ensure they have the expertise to maintain calibration and consider the specific flow characteristics of their applications when selecting this type.

Related Video: Rotameter: Working Principle, Diagram, Advantages & Limitations, Application, Flow Rate Measurement

Key Industrial Applications of rotameter flow measurement

| Industry/Sector | Specific Application of rotameter flow measurement | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Chemical Manufacturing | Measuring chemical injection rates in reactors | Ensures precise dosing, improving product quality and consistency | Material compatibility, accuracy specifications, and calibration services |

| Water Treatment | Monitoring flow rates in filtration systems | Optimizes operational efficiency and reduces downtime | Durability against corrosive fluids, installation flexibility, and maintenance support |

| Oil & Gas | Flow measurement in pipeline transportation | Enhances safety and efficiency in fluid transfer | High-pressure rating, resistance to harsh environments, and certification compliance |

| Pharmaceutical | Controlling solvent flow in drug formulation | Guarantees accurate ingredient ratios for compliance | Calibration for specific fluids, accuracy requirements, and regulatory adherence |

| Food & Beverage | Monitoring liquid flow in bottling processes | Improves production accuracy and minimizes waste | Sanitary design, ease of cleaning, and compliance with food safety standards |

Chemical Manufacturing

In chemical manufacturing, rotameters are critical for measuring the injection rates of various chemicals into reactors. By ensuring precise dosing, these devices help maintain product quality and consistency, which is vital in industries where even minor variations can lead to significant issues. International buyers, particularly from Africa and South America, should consider the material compatibility of rotameters, ensuring they can withstand corrosive substances. Additionally, accuracy specifications and calibration services are essential for maintaining operational integrity.

Water Treatment

In water treatment facilities, rotameters are employed to monitor flow rates in filtration systems. Accurate flow measurement is crucial for optimizing operational efficiency and minimizing downtime. Buyers in the Middle East, facing challenges with water scarcity, should prioritize rotameters that offer durability against corrosive fluids. Installation flexibility is also a key consideration, as systems may need to be adapted to existing infrastructure, alongside ensuring robust maintenance support to prevent operational disruptions.

Oil & Gas

Within the oil and gas sector, rotameters play a vital role in measuring flow rates during the transportation of fluids through pipelines. Their accuracy enhances safety and efficiency, reducing the risk of leaks and ensuring compliance with environmental regulations. Buyers from Europe and the Middle East should seek rotameters that have a high-pressure rating and are resistant to harsh environmental conditions, as well as ensuring that they meet relevant certification compliance standards for safety and reliability.

Pharmaceutical

Rotameters are used in pharmaceutical applications to control solvent flow during drug formulation processes. Accurate flow measurement is necessary to guarantee that ingredient ratios are precise, which is crucial for compliance with stringent industry regulations. International buyers, particularly in Europe, should focus on rotameters that provide calibration for specific fluids and meet high accuracy requirements. Additionally, adherence to regulatory standards is paramount for maintaining product safety and efficacy.

Food & Beverage

In the food and beverage industry, rotameters are utilized to monitor liquid flow in bottling processes. This application is essential for improving production accuracy and minimizing waste, which directly impacts profitability. Buyers from South America and Africa should ensure that the rotameters they source have a sanitary design, allowing for easy cleaning and compliance with food safety standards. Furthermore, the ability to withstand varying temperatures and pressures is important for maintaining operational efficiency.

Illustrative Image (Source: Google Search)

Strategic Material Selection Guide for rotameter flow measurement

When selecting materials for rotameter flow measurement, it is essential to consider the specific requirements of the application, including the type of fluid being measured, operating conditions, and environmental factors. Below is an analysis of four common materials used in rotameter construction, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Glass

Key Properties:

Glass is often used for rotameter tubes due to its transparency and ability to withstand moderate pressure and temperature. Typical glass rotameters can handle temperatures up to 150°C and pressures around 1-2 bar.

Pros & Cons:

The primary advantage of glass is its excellent visibility, allowing for easy reading of the float position. However, glass is fragile and can break easily, which may lead to safety concerns in certain environments. Additionally, it may not be suitable for high-pressure applications.

Impact on Application:

Glass is compatible with many clear liquids and gases but is not suitable for corrosive fluids unless specifically treated.

Considerations for International Buyers:

Buyers should ensure compliance with safety standards, particularly in regions with stringent regulations. Glass rotameters must meet ASTM or DIN standards for material safety.

Stainless Steel

Key Properties:

Stainless steel is known for its strength and resistance to corrosion, making it suitable for harsh environments. It can typically withstand temperatures up to 300°C and pressures exceeding 10 bar.

Pros & Cons:

The durability of stainless steel makes it ideal for industrial applications, especially in the chemical and petrochemical sectors. However, it is more expensive than glass and may require additional machining, increasing manufacturing complexity.

Impact on Application:

Stainless steel rotameters can handle a wide range of fluids, including corrosive substances, which makes them versatile for various applications.

Considerations for International Buyers:

Buyers should verify the grade of stainless steel used, as different grades have varying corrosion resistance. Compliance with JIS or ASTM standards is also crucial for international shipments.

Plastic (Polycarbonate or Acrylic)

Key Properties:

Plastic rotameters, typically made from polycarbonate or acrylic, offer lightweight construction and good clarity. They can handle temperatures up to 70°C and pressures around 2-3 bar.

Pros & Cons:

The main advantage of plastic is its resistance to breakage, making it safer in environments where glass might shatter. However, plastics generally have lower temperature and pressure ratings compared to glass and stainless steel, limiting their application scope.

Impact on Application:

Plastic rotameters are suitable for non-corrosive liquids and gases but may not be appropriate for high-temperature or high-pressure applications.

Considerations for International Buyers:

Buyers should ensure that the selected plastic meets relevant chemical compatibility standards and consider local regulations regarding plastic materials.

Brass

Key Properties:

Brass is a copper-zinc alloy that provides good corrosion resistance and can withstand moderate temperatures (up to 200°C) and pressures (up to 10 bar).

Pros & Cons:

Brass is durable and has excellent machinability, allowing for complex designs. However, it can corrode in certain environments, especially when exposed to ammonia or chlorides, which may limit its use.

Impact on Application:

Brass rotameters are often used for water and gas applications but may not be suitable for corrosive fluids.

Considerations for International Buyers:

Buyers should check for compliance with local standards and ensure that the brass used is suitable for the intended application, particularly in regions with corrosive environments.

Summary Table

| Material | Typical Use Case for rotameter flow measurement | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Clear liquids and gases | Excellent visibility | Fragile and limited pressure tolerance | Low |

| Stainless Steel | Corrosive fluids and high-pressure applications | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic | Non-corrosive liquids and gases | Lightweight and shatter-resistant | Limited temperature and pressure ratings | Medium |

| Brass | Water and gas applications | Good machinability and durability | Corrosion potential in specific environments | Medium |

This material selection guide provides international B2B buyers with essential insights into the properties and implications of various materials used in rotameter flow measurement. Understanding these factors will aid in making informed purchasing decisions that align with specific application requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for rotameter flow measurement

Manufacturing Processes for Rotameter Flow Measurement

The manufacturing of rotameters involves several critical stages, each designed to ensure the final product meets the high standards required for accurate fluid measurement. Understanding these stages can help B2B buyers assess potential suppliers effectively.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Materials: Rotameters are typically made from materials such as glass, plastic, or metal, depending on the application. For example, glass is preferred for transparent fluids, while metals are used for corrosive substances. Buyers should confirm that the materials used are compatible with their specific applications.

– Material Testing: Before production, materials undergo tests to ensure they meet necessary specifications for durability and compatibility with various fluids. -

Forming

– Tube Fabrication: The tapered tube is formed using techniques such as blow molding for plastics or precision glass blowing. The taper is critical for the float’s operation and must be manufactured to exact specifications.

– Float Production: Floats are typically manufactured from stainless steel or other dense materials. The manufacturing process may include precision machining and surface finishing to enhance accuracy and reduce friction. -

Assembly

– Component Assembly: After forming, the various components—including the tube, float, and any electronic elements—are assembled. This step often involves the use of jigs to maintain alignment and ensure proper fit.

– Sealing and Calibration: Sealing the unit to prevent leaks is crucial. Calibration follows assembly to ensure that the flow readings are accurate. This process includes adjusting the float position according to the specific fluid properties. -

Finishing

– Surface Treatment: Final finishing processes may include polishing the glass or metal surfaces to reduce friction and improve readability. Coatings may also be applied to enhance corrosion resistance.

– Final Inspection: Each unit undergoes a thorough inspection to check for defects and ensure that it meets design specifications.

Quality Assurance in Rotameter Manufacturing

Quality assurance is a critical aspect of the manufacturing process for rotameters, ensuring that each device performs reliably in various applications. B2B buyers should be aware of the relevant standards and practices that govern quality assurance in this industry.

Relevant International Standards

- ISO 9001: This standard outlines a framework for quality management systems and is crucial for manufacturers seeking to ensure consistent quality in their products.

- CE Marking: For products sold in the European market, CE marking indicates compliance with safety and environmental standards.

- API Standards: The American Petroleum Institute (API) provides standards relevant to the oil and gas industry, ensuring that rotameters used in these sectors meet stringent safety and performance criteria.

Key Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Materials are inspected upon arrival at the manufacturing facility. This includes checking the quality and compliance of materials with specifications. -

In-Process Quality Control (IPQC)

– During manufacturing, several checkpoints are established to monitor production processes. This can include measuring the dimensions of tubes and floats at different stages to ensure they meet design specifications. -

Final Quality Control (FQC)

– After assembly, each rotameter undergoes final testing, including flow tests to verify accuracy and functionality. Calibration data is recorded, providing essential information for end-users.

Common Testing Methods

- Flow Calibration Tests: Rotameters are subjected to flow tests using known fluid rates to ensure that the readings are accurate. This is often done using a reference meter for comparison.

- Pressure Testing: To ensure that the device can withstand operational pressures, manufacturers conduct pressure tests, particularly for metal-bodied rotameters.

- Durability Tests: These tests simulate the operational conditions the rotameter will face, ensuring it can endure environmental stresses.

Verifying Supplier Quality Control

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. Here are several strategies:

-

Supplier Audits

– Conducting on-site audits allows buyers to assess the manufacturer’s quality control systems, production processes, and adherence to relevant standards. -

Requesting Quality Reports

– Buyers should request comprehensive quality reports that detail inspection results, testing methodologies, and any certifications held by the manufacturer. -

Third-Party Inspections

– Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and quality assurance measures in place. -

Certifications Verification

– Buyers should verify that manufacturers possess relevant certifications such as ISO 9001, CE, or API. This can often be done through official certification bodies or industry associations.

QC and Certification Nuances for International Buyers

When purchasing from international suppliers, B2B buyers should be aware of the following nuances:

- Regulatory Differences: Different regions may have varying regulations regarding the use and certification of rotameters. Understanding these differences is crucial for compliance and ensuring safe operation.

- Cultural Considerations: Business practices and communication styles can vary significantly across regions. Building strong relationships with suppliers can facilitate better quality assurance and smoother transactions.

- Import Regulations: Buyers should be familiar with the import regulations of their home country regarding measurement devices. This includes ensuring that the products meet local standards and certifications.

By understanding the manufacturing processes and quality assurance practices involved in rotameter production, B2B buyers can make informed decisions, ensuring they select reliable suppliers that will meet their operational needs.

Comprehensive Cost and Pricing Analysis for rotameter flow measurement Sourcing

Cost Structure of Rotameter Flow Measurement

Understanding the cost structure of rotameter flow measurement is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials (glass, plastic, or metal) significantly impacts cost. For example, stainless steel floats and high-quality glass tubes tend to be more expensive than their plastic counterparts, affecting the overall price.

-

Labor: Skilled labor is required for assembly and calibration. In regions with higher labor costs, such as parts of Europe, the labor component can constitute a larger share of the total cost.

-

Manufacturing Overhead: This includes costs related to factory operations, equipment maintenance, and utilities. Efficient production processes can help reduce overhead costs.

-

Tooling: Initial setup costs for specialized tools and molds can be substantial, especially for customized rotameters. These costs are usually amortized over production runs.

-

Quality Control (QC): Rigorous testing and certification processes add to the cost but are essential for ensuring accuracy and reliability. Certifications can also enhance marketability.

-

Logistics: Shipping costs can vary based on the destination, mode of transport, and packaging requirements. Incoterms play a crucial role in defining responsibilities and costs associated with logistics.

-

Margin: Suppliers typically mark up prices to cover their operational costs and achieve profitability. The margin can vary widely depending on market conditions and competition.

Price Influencers

Several factors influence the pricing of rotameters:

-

Volume/MOQ: Larger order volumes often lead to reduced prices per unit due to economies of scale. Establishing a minimum order quantity (MOQ) can help negotiate better pricing.

-

Specifications/Customization: Customized rotameters tailored to specific applications (e.g., for corrosive fluids or extreme temperatures) can significantly increase costs. Buyers should weigh the necessity of customization against standard options.

-

Materials: Premium materials enhance durability and accuracy but come at a higher price. Understanding the application requirements helps in making cost-effective material choices.

-

Quality/Certifications: Higher quality standards and certifications (ISO, CE, etc.) usually result in higher prices. Buyers should evaluate whether such certifications are necessary for their operations.

-

Supplier Factors: The reputation, location, and reliability of suppliers can affect pricing. Suppliers with a strong track record may charge a premium for their products.

-

Incoterms: Different Incoterms can significantly impact total costs, as they define shipping responsibilities, insurance, and tariffs. Understanding these terms is crucial for effective cost management.

Buyer Tips for Cost Efficiency

International B2B buyers, particularly in Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Negotiation: Leverage volume discounts and long-term contracts to negotiate better prices. Building strong relationships with suppliers can also facilitate more favorable terms.

-

Total Cost of Ownership (TCO): Evaluate not just the upfront costs but also the long-term operational costs, including maintenance and potential downtime. A cheaper rotameter may lead to higher costs in the long run if it requires frequent replacements or repairs.

-

Pricing Nuances: Be aware of currency fluctuations and regional pricing strategies. Prices may vary significantly between regions, influenced by local market conditions and demand.

-

Supplier Diversity: Consider multiple suppliers to foster competition and ensure you are getting the best possible price and service.

-

Research and Compare: Regularly review market prices and trends. Utilizing online platforms and industry reports can provide insights into current pricing and help identify cost-saving opportunities.

Disclaimer on Indicative Prices

Prices for rotameter flow measurement devices can vary widely based on the aforementioned factors. It is advisable for buyers to obtain multiple quotes and conduct thorough market research before making purchasing decisions.

Spotlight on Potential rotameter flow measurement Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘rotameter flow measurement’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for rotameter flow measurement

Key Technical Properties of Rotameter Flow Measurement

When selecting a rotameter for fluid flow measurement, understanding its technical properties is crucial for ensuring optimal performance and compatibility with specific applications. Here are several critical specifications to consider:

-

Material Grade: Rotameters are typically constructed from materials such as glass, plastic, or metal. The choice of material affects durability and compatibility with various fluids. For example, glass rotameters are ideal for measuring clear liquids and gases, while metal rotameters are better suited for corrosive fluids. Selecting the right material ensures the longevity of the device and accuracy in measurements.

-

Accuracy: This specification indicates how closely the measured value aligns with the true flow rate. Rotameters generally offer an accuracy of ±2% of the full scale. For B2B buyers, understanding accuracy is essential to ensure that the flow measurements meet the required standards for their specific industrial applications, particularly in sectors such as petrochemicals and pharmaceuticals.

-

Flow Range: Defined by the minimum and maximum flow rates the rotameter can accurately measure, the flow range is critical for ensuring that the device can handle the expected flow conditions. Buyers must assess whether the flow range of a rotameter aligns with their operational requirements to avoid underperformance or damage.

-

Calibration: Calibration involves adjusting the rotameter to ensure accurate flow measurement under specific conditions. Regular calibration is necessary, especially in applications requiring precise dosing or monitoring. B2B buyers should inquire about the calibration procedures offered by manufacturers to maintain the device’s accuracy over time.

-

Pressure Rating: This property specifies the maximum pressure the rotameter can withstand during operation. A higher pressure rating is essential for applications involving high-pressure systems. Buyers should consider the pressure rating to ensure safety and reliability in their fluid measurement processes.

Common Trade Terminology

Familiarity with industry jargon is vital for effective communication and negotiation in the B2B space. Here are several key terms relevant to rotameter flow measurement:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of rotameters, understanding OEM relationships can help buyers identify reputable manufacturers and ensure quality.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. For rotameters, knowing the MOQ can assist buyers in planning their purchasing strategy and inventory management, particularly when sourcing from international suppliers.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For B2B buyers, issuing an RFQ for rotameters can help compare pricing, specifications, and lead times, ensuring they make informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to manage logistics, shipping costs, and risk transfer effectively.

-

Lead Time: This term refers to the amount of time it takes for an order to be fulfilled. In the context of rotameters, lead time can affect project timelines and operational efficiency. Buyers should consider lead times when planning their procurement schedules to avoid delays in production.

By comprehensively understanding these technical properties and trade terms, B2B buyers can enhance their decision-making process, ensuring they select the right rotameter for their specific needs while navigating the complexities of international procurement.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the rotameter flow measurement Sector

Market Overview & Key Trends

The rotameter flow measurement sector is witnessing transformative dynamics driven by globalization, technological advancement, and the increasing need for precision in fluid measurement. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding these market drivers is crucial for informed sourcing decisions.

Global Drivers: The growing industrialization in emerging markets, coupled with the expansion of the chemical, petrochemical, and water treatment industries, is fueling the demand for rotameters. Increased regulatory requirements surrounding fluid measurement accuracy are prompting companies to invest in high-quality measurement solutions.

Current and Emerging Trends: Digitalization and the integration of Industry 4.0 technologies are reshaping the rotameter landscape. Advanced rotameters equipped with IoT capabilities enable real-time monitoring and data analytics, enhancing operational efficiency and maintenance scheduling. Buyers should consider sourcing these smart flow measurement devices to remain competitive.

Market Dynamics: The market is characterized by a shift towards customized solutions that cater to specific industry needs, such as high-pressure or corrosive environments. Suppliers are increasingly offering modular designs that can be adapted based on customer requirements. Additionally, the rise of e-commerce platforms is changing the traditional procurement processes, allowing buyers to access a wider range of suppliers and products with ease.

Sustainability & Ethical Sourcing in B2B

As environmental concerns gain prominence globally, sustainability is becoming a key criterion for B2B buyers in the rotameter flow measurement sector. The production and disposal of rotameters can have significant environmental impacts, particularly concerning the materials used and energy consumed during manufacturing.

Importance of Ethical Supply Chains: Buyers are encouraged to prioritize suppliers who demonstrate commitment to sustainability through responsible sourcing practices. This includes using recycled materials, minimizing waste, and ensuring fair labor practices throughout the supply chain. By aligning with ethical suppliers, companies can enhance their brand reputation and comply with increasing regulatory scrutiny regarding sustainability.

Green Certifications and Materials: Many manufacturers are now offering rotameters made from eco-friendly materials that minimize environmental impact. Certifications such as ISO 14001 for environmental management can help buyers identify suppliers that adhere to sustainable practices. Investing in rotameters that are designed for longevity and recyclability not only supports sustainability goals but can also lead to cost savings over time through reduced replacement and disposal costs.

Brief Evolution/History

The concept of the rotameter dates back to the early 20th century, with its design evolving significantly since its inception. Initially, rotameters were simple glass tubes with floats, primarily used in laboratory settings. Over the decades, advancements in materials and technology have led to the development of robust, versatile rotameters capable of measuring a wide range of fluids under varying conditions.

The introduction of digital displays and smart technology in the late 20th and early 21st centuries has further transformed rotameter functionality, allowing for enhanced accuracy and real-time data transmission. This evolution underscores the importance of staying abreast of technological advancements for international buyers aiming to optimize their fluid measurement solutions.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of rotameter flow measurement

-

What should I consider when vetting suppliers for rotameters?

When vetting suppliers for rotameters, assess their industry experience and reputation. Look for certifications such as ISO 9001, which indicates quality management systems. Investigate their production capabilities and whether they can meet your specific requirements, including customization options. Request references or case studies from previous clients to gauge their reliability. Additionally, verify their after-sales support and warranty policies to ensure you receive comprehensive service post-purchase. -

Can rotameters be customized to meet specific application needs?

Yes, many suppliers offer customization options for rotameters to cater to specific applications. Customization can include adjustments to size, materials, and scale markings to suit different fluids or gases. When discussing your requirements with suppliers, clearly outline the operational conditions, such as temperature and pressure, and the type of fluid being measured. This will help suppliers recommend the best configurations to enhance performance and accuracy in your applications. -

What are the typical minimum order quantities (MOQs) and lead times for rotameters?

Minimum order quantities for rotameters can vary significantly among suppliers, often ranging from 10 to 50 units for standard models. Custom designs may require higher MOQs due to the complexity of production. Lead times also depend on customization; standard products may ship within 2-4 weeks, while bespoke models could take 6-12 weeks. Always confirm these details during negotiations to ensure they align with your project timelines and inventory needs. -

What payment methods are commonly accepted for international purchases of rotameters?

Most suppliers accept various payment methods for international transactions, including bank transfers, letters of credit, and online payment systems like PayPal. It’s essential to discuss payment terms upfront, including any deposit requirements and payment schedules. Ensure you understand any currency conversion fees that may apply and consider negotiating favorable terms, especially if placing large orders, to optimize cash flow.

Illustrative Image (Source: Google Search)

-

What quality assurance measures should I look for in rotameter suppliers?

Quality assurance measures are crucial when sourcing rotameters. Look for suppliers that implement rigorous testing protocols, including calibration against industry standards. Inquire about their quality control processes and whether they provide certification of compliance with relevant standards, such as those from the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO). Suppliers should also be willing to provide documentation and test results upon request. -

How can I ensure the logistics of shipping rotameters are handled efficiently?

To ensure efficient logistics for shipping rotameters, discuss shipping methods and options with your supplier. Consider factors such as shipping time, costs, and insurance coverage. It’s advisable to work with suppliers who have experience in international shipping and can handle customs clearance. Establish clear communication regarding tracking shipments, and consider using third-party logistics providers if you anticipate needing additional support in managing imports. -

What should I do in case of a dispute with a supplier over rotameter quality or delivery?

In the event of a dispute with a supplier regarding rotameter quality or delivery, first attempt to resolve the issue through direct communication. Document all correspondence and agreements related to your order. If resolution is not achieved, refer to the terms outlined in your purchase agreement regarding dispute resolution processes. This may include mediation or arbitration clauses. Engage legal counsel if necessary, especially when dealing with significant financial implications. -

What certifications should I look for to ensure the rotameters are suitable for my industry?

When sourcing rotameters, look for certifications relevant to your industry. Common certifications include those for safety (like CE marking in Europe), environmental compliance (such as RoHS), and specific standards for fluid measurement (like ISO 4064). These certifications indicate that the product meets rigorous performance and safety standards. Verify that the certifications are current and applicable to the specific model you are considering for purchase, ensuring it meets the necessary regulatory requirements for your applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for rotameter flow measurement

In the evolving landscape of industrial processes, rotameters play a crucial role in accurately measuring fluid flow, thereby enhancing operational efficiency and safety. As you consider strategic sourcing for rotameter flow measurement devices, it’s vital to evaluate suppliers based on their product quality, customization options, and after-sales support. The choice of materials, particularly for specific applications involving corrosive fluids, can significantly impact both performance and longevity.

Key takeaways include the importance of understanding the operating principles of rotameters, the benefits of various construction materials, and the implications of calibration for specific applications. By investing in high-quality rotameters, businesses can achieve improved accuracy, reduce downtime, and ensure compliance with industry standards.

Looking ahead, the demand for reliable flow measurement solutions is expected to grow, particularly in emerging markets across Africa, South America, and the Middle East. International B2B buyers should leverage strategic sourcing to establish partnerships with reputable manufacturers. This proactive approach will not only secure competitive pricing but also foster innovation and sustainability in fluid management. Act now to explore your options and ensure your operations are equipped with the best flow measurement technology available.