Master 5-Axis CNC Machining: A Strategic Guide for B2B

Introduction: Navigating the Global Market for 5-axis cnc machining

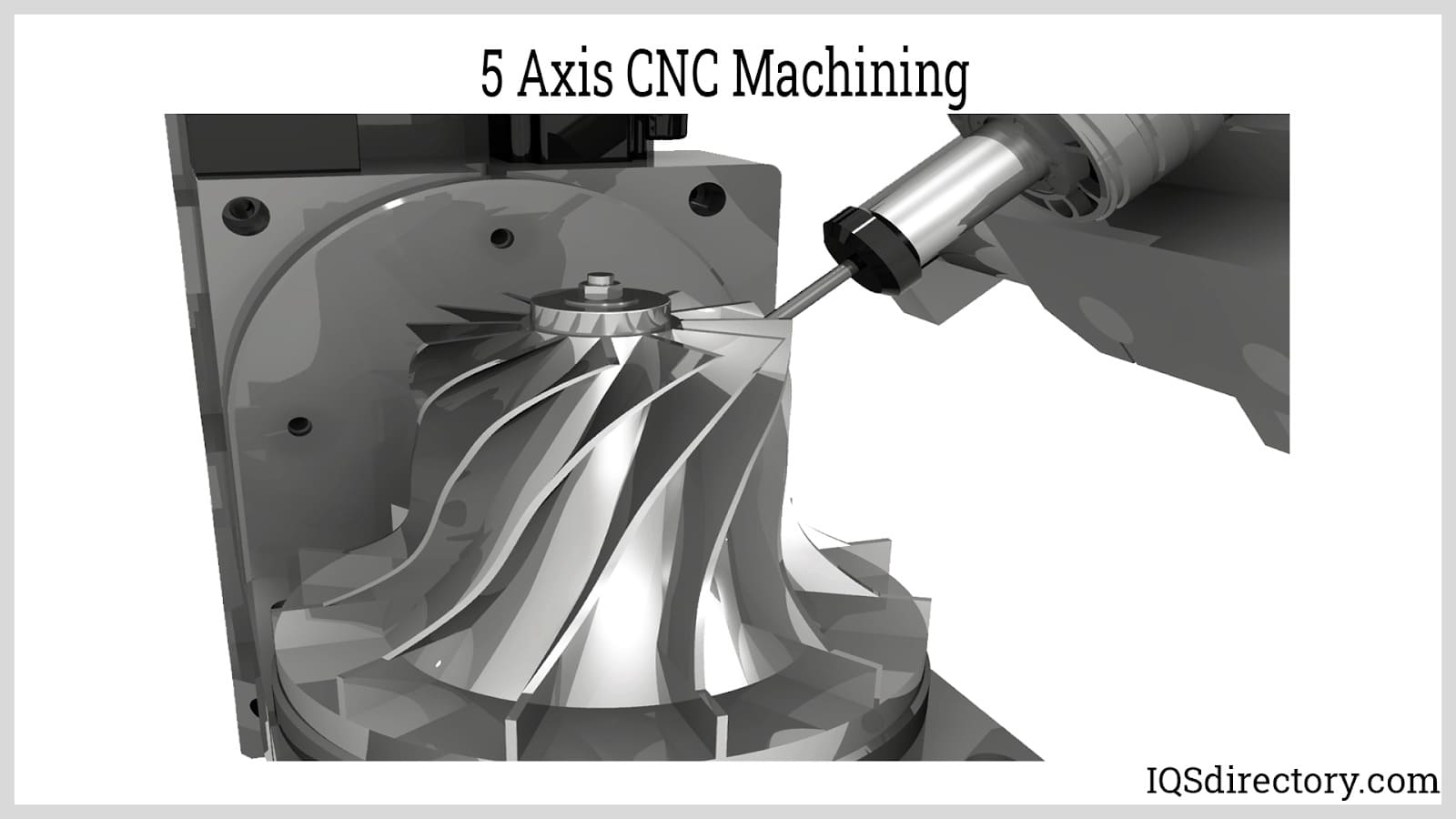

5-axis CNC machining stands at the forefront of modern manufacturing, offering unparalleled precision and versatility that is crucial for industries ranging from aerospace to medical devices. As global markets continue to evolve, the demand for intricate components with tight tolerances is rising, making 5-axis machining an essential consideration for international B2B buyers. This sophisticated technology not only enhances production efficiency but also reduces lead times and operational costs, providing a competitive edge in an increasingly interconnected world.

This comprehensive guide delves into the multifaceted landscape of 5-axis CNC machining, tailored specifically for buyers from Africa, South America, the Middle East, and Europe. It will explore various types of 5-axis machines, suitable materials for processing, and essential manufacturing and quality control practices. Furthermore, we will provide insights into identifying reliable suppliers, understanding cost structures, and analyzing market trends that impact procurement decisions.

By equipping B2B buyers with actionable insights and a thorough understanding of 5-axis CNC machining, this guide empowers informed sourcing decisions. Whether you’re a manufacturer looking to optimize production or a buyer seeking innovative solutions, navigating the global market for 5-axis CNC machining will unlock new opportunities and drive business growth.

Understanding 5-axis cnc machining Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Double Pivot Spindle Head | Utilizes two rotating coordinates to control tool direction. | Aerospace, automotive, and medical parts | Pros: High precision; versatile. Cons: Higher cost; complex setup. |

| Pitching Swing Head | Tool rotation axis is not perpendicular to linear axes. | Complex parts in aerospace and energy | Pros: Excellent for angular cuts; compact design. Cons: Limited tool options. |

| Table Tilt Type | Table tilts to achieve complex geometries. | Custom molds, automotive, and consumer goods | Pros: Efficient for intricate designs; single setup machining. Cons: Requires skilled operators. |

| Trunnion Type | Rotating table with two axes of rotation for enhanced access. | High-precision components in various industries | Pros: Highly flexible; great for larger parts. Cons: Space-consuming; maintenance-intensive. |

| Rotary Table Type | Features a rotary table that allows for continuous machining. | Prototyping and low-volume production | Pros: Continuous operation; good for repetitive tasks. Cons: Slower for complex geometries. |

Double Pivot Spindle Head

The Double Pivot Spindle Head type is characterized by its ability to control the tool’s direction through two rotating coordinates. This configuration is particularly suitable for industries like aerospace and automotive, where high precision is crucial. Buyers should consider the higher initial investment and the need for advanced setups, but the payoff is often seen in the form of intricate part production with exceptional accuracy.

Pitching Swing Head

The Pitching Swing Head variant features a tool rotation axis that is not perpendicular to the linear axes, making it ideal for creating complex angles and shapes. This type is commonly used in aerospace and energy sectors. While it offers excellent angular cutting capabilities, buyers should be aware of its limitations in tool options and the potential for higher operational costs.

Table Tilt Type

The Table Tilt Type allows the table to tilt, which is essential for achieving complex geometries in a single setup. This type is particularly advantageous in custom mold manufacturing and automotive applications. Although it can significantly enhance efficiency and reduce production times, it requires skilled operators familiar with the technology, which may lead to increased labor costs.

Trunnion Type

The Trunnion Type features a rotating table with two axes of rotation, providing enhanced access to the workpiece. This flexibility makes it suitable for high-precision components across various industries. While this type can handle larger parts, buyers must consider its space requirements and the potential for intensive maintenance.

Rotary Table Type

The Rotary Table Type is designed for continuous machining operations, making it ideal for prototyping and low-volume production runs. This type excels in repetitive tasks but may be slower when dealing with complex geometries. Buyers should weigh the benefits of continuous operation against the potential drawbacks of reduced speed for intricate designs.

Related Video: 5 axis machining | 5 axis cnc machining | 5-axis cnc machining | multi-axis machining

Key Industrial Applications of 5-axis cnc machining

| Industry/Sector | Specific Application of 5-axis CNC Machining | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of turbine blades and aircraft components | High precision and reduced lead times for complex components | Certification standards, material specifications, and lead times |

| Automotive | Production of engine blocks and transmission housings | Enhanced accuracy and efficiency in mass production | Supplier reliability, tooling compatibility, and cost-effectiveness |

| Medical Devices | Custom prosthetics and surgical instruments | Tailored solutions with high precision for patient-specific needs | Regulatory compliance, material biocompatibility, and delivery timelines |

| Energy Sector | Machining of components for turbines and drilling equipment | Increased durability and performance in harsh environments | Material quality, machining tolerances, and after-sales support |

| Consumer Electronics | Production of intricate casings and components | Improved aesthetics and functionality in consumer products | Design flexibility, rapid prototyping capabilities, and cost management |

Aerospace Industry

In the aerospace sector, 5-axis CNC machining plays a pivotal role in the production of complex components such as turbine blades and structural parts of aircraft. The ability to machine intricate shapes with high precision ensures that parts meet the stringent safety and performance standards required in aviation. For international buyers, especially from regions like Africa and the Middle East, sourcing requires attention to certification standards such as AS9100, ensuring that suppliers can demonstrate compliance with aerospace manufacturing regulations.

Automotive Industry

The automotive industry leverages 5-axis CNC machining for the production of critical components like engine blocks and transmission housings. This technology enables manufacturers to achieve enhanced accuracy and efficiency, reducing lead times for mass production. B2B buyers from South America and Europe should focus on supplier reliability and tooling compatibility to ensure seamless integration into their production processes, as well as evaluating the cost-effectiveness of different machining solutions.

Medical Devices

5-axis CNC machining is essential in the medical device industry for creating custom prosthetics and surgical instruments. This capability allows manufacturers to produce patient-specific solutions with high precision, which is crucial for ensuring optimal fit and functionality. Buyers from Africa and South America must consider regulatory compliance and material biocompatibility when sourcing these components, as well as the importance of timely delivery to meet healthcare demands.

Energy Sector

In the energy sector, particularly in oil and gas, 5-axis CNC machining is utilized to manufacture components for turbines and drilling equipment. The enhanced durability and performance of machined parts are critical for operations in harsh environments. International buyers should prioritize material quality and machining tolerances when sourcing, as these factors directly impact the reliability and efficiency of energy production equipment.

Consumer Electronics

The consumer electronics industry benefits from 5-axis CNC machining in the production of intricate casings and components that require both aesthetic appeal and functionality. This technology allows for improved design flexibility and rapid prototyping, enabling manufacturers to respond quickly to market trends. Buyers from Europe and South America should focus on design capabilities and cost management when selecting suppliers, ensuring that they can deliver innovative products without compromising on quality.

Strategic Material Selection Guide for 5-axis cnc machining

When selecting materials for 5-axis CNC machining, it is crucial to consider both the specific properties of the materials and their suitability for the intended applications. Here, we analyze four common materials used in this advanced machining process, providing insights that are particularly relevant for international B2B buyers from Africa, South America, the Middle East, and Europe.

Aluminum Alloys

Key Properties: Aluminum alloys are lightweight yet strong, with excellent corrosion resistance and thermal conductivity. They typically have good machinability, allowing for complex shapes to be produced with high precision.

Pros & Cons: The primary advantage of aluminum alloys is their low density, which makes them ideal for applications in aerospace and automotive industries where weight savings are critical. However, they can be more expensive than other materials like steel, and their lower hardness may limit their use in high-wear applications.

Impact on Application: Aluminum alloys are compatible with a variety of media, including air and water, making them suitable for components like housings and brackets. However, they may not be ideal for high-temperature applications due to lower melting points.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and EN for aluminum alloys. Additionally, sourcing from local suppliers can mitigate import tariffs and reduce lead times.

Stainless Steel

Key Properties: Stainless steel is known for its high strength, excellent corrosion resistance, and ability to withstand high temperatures. It is often used in environments that require durability and resistance to oxidation.

Pros & Cons: The key advantage of stainless steel is its durability, making it suitable for demanding applications in industries such as medical and food processing. However, it is more challenging to machine than aluminum, which can lead to higher manufacturing costs and longer lead times.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances, making it ideal for components like valves and fittings. Its high strength-to-weight ratio also supports structural applications.

Considerations for International Buyers: Compliance with standards such as ASTM A240 and EN 10088 is essential. Buyers should also consider the availability of specific grades, as some may be more readily available in certain regions.

Titanium Alloys

Key Properties: Titanium alloys are characterized by their high strength-to-weight ratio and excellent corrosion resistance. They can withstand extreme temperatures and are non-magnetic, making them suitable for specialized applications.

Pros & Cons: The primary advantage of titanium alloys is their exceptional strength and lightweight nature, making them ideal for aerospace and medical implants. However, they are significantly more expensive and harder to machine than aluminum or stainless steel, which can increase production costs.

Impact on Application: Titanium is compatible with a variety of aggressive media, making it a preferred choice for chemical processing and aerospace applications. Its biocompatibility also makes it suitable for medical implants.

Considerations for International Buyers: Buyers should be aware of the stringent standards for titanium, such as ASTM F136 for medical applications. Due to the high cost, sourcing titanium locally or regionally can help reduce overall expenses.

Plastics (e.g., PEEK, Nylon)

Key Properties: Engineering plastics like PEEK and nylon offer excellent chemical resistance, low friction properties, and good thermal stability. They are lightweight and can be machined to tight tolerances.

Pros & Cons: The main advantage of plastics is their versatility and lower cost compared to metals. They are easier to machine, which can lead to shorter production times. However, they may not be suitable for high-load applications due to lower mechanical strength.

Impact on Application: Plastics are ideal for applications in electronics, automotive, and consumer goods where weight reduction and corrosion resistance are essential. They are compatible with various media, including water and oils.

Considerations for International Buyers: Ensure compliance with relevant standards such as ASTM D638 for plastics. Buyers should also consider the environmental impact of sourcing and disposing of plastic materials, especially in regions with strict regulations.

| Material | Typical Use Case for 5-axis CNC Machining | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Aerospace components, automotive parts | Lightweight and corrosion-resistant | Higher cost than some alternatives | Medium |

| Stainless Steel | Medical devices, food processing equipment | High durability and corrosion resistance | Challenging to machine, higher costs | High |

| Titanium Alloys | Aerospace, medical implants | Exceptional strength-to-weight ratio | Very high cost, difficult to machine | High |

| Plastics (PEEK, Nylon) | Electronics, consumer goods | Versatile and lower cost | Lower mechanical strength than metals | Low |

This strategic material selection guide provides B2B buyers with essential insights into the materials commonly used in 5-axis CNC machining, helping them make informed decisions that align with their specific industry needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 5-axis cnc machining

Manufacturing Processes for 5-Axis CNC Machining

5-axis CNC machining is a sophisticated manufacturing process that requires precise execution at each stage. Understanding the various stages of production is crucial for international B2B buyers to ensure they select the right supplier and achieve optimal results.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Raw Materials: The choice of material is critical, as it affects the machining process and the final product’s performance. Common materials include metals (aluminum, titanium), plastics, and composites.

– Cutting and Shaping: Raw materials are cut to size, often using saws or shears, to fit the specifications of the CNC program.

– Surface Treatment: Pre-machining surface treatments, such as degreasing or coating, may be applied to enhance the material’s machinability. -

Forming

– Setup of CNC Machine: The workpiece is securely mounted on the CNC machine, which may involve specific fixtures or clamps to hold the part in place during machining.

– Programming: Advanced CAM software is used to create detailed tool paths that dictate how the machine will operate. This programming is crucial for complex geometries typical in 5-axis machining.

– Machining Process: The CNC machine operates using simultaneous movement across five axes. This allows for intricate designs to be cut with high precision, reducing the need for multiple setups. -

Assembly

– Component Assembly: If the final product consists of multiple parts, assembly occurs post-machining. This stage may require additional processes like welding or fastening.

– Alignment and Calibration: Assembled parts must be aligned correctly to ensure functionality. This may involve precision measuring tools to verify tolerances. -

Finishing

– Surface Finishing Techniques: Techniques such as polishing, anodizing, or coating may be applied to enhance aesthetics and durability. The finishing process can significantly affect the product’s performance and appeal.

– Final Inspection: A thorough inspection is performed to ensure that the final product meets all specifications and quality standards.

Quality Assurance in 5-Axis CNC Machining

Quality assurance (QA) is vital in ensuring that the manufactured parts meet the required specifications and standards. For international B2B buyers, understanding the QA process can help in selecting reliable suppliers.

Relevant International Standards

- ISO 9001: This is a widely recognized standard for quality management systems. Suppliers adhering to ISO 9001 demonstrate their commitment to quality processes.

- Industry-Specific Standards: Depending on the industry, additional certifications may be required:

– CE Marking: For products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

– API Standards: Relevant for components used in the oil and gas industry, ensuring they meet specific performance and safety criteria.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Before production begins, raw materials are inspected for quality and compliance with specifications. This initial checkpoint is critical to prevent defects from entering the production process.

- In-Process Quality Control (IPQC): During machining, operators monitor processes to ensure they are adhering to the specified tolerances and procedures. This may involve real-time measurements and adjustments.

- Final Quality Control (FQC): After machining and finishing, a final inspection is conducted to verify that the part meets all specifications before shipping. This step often includes dimensional checks and visual inspections.

Common Testing Methods

- Dimensional Inspection: Utilizing calipers, micrometers, and CMM (Coordinate Measuring Machines) to verify that the parts meet specified dimensions.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or X-ray inspection may be employed to detect internal flaws without damaging the part.

- Functional Testing: For certain applications, functional testing ensures that the part performs as intended under operational conditions.

Verifying Supplier Quality Control

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential for risk management.

- Supplier Audits: Conducting on-site audits of suppliers can provide insights into their manufacturing processes, quality control systems, and adherence to international standards.

- Quality Reports: Requesting regular quality reports from suppliers helps track their performance and quality trends over time.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and product quality.

Quality Control and Certification Nuances for International B2B Buyers

Understanding the nuances of quality control and certifications is crucial for international B2B transactions. Different regions may have varying standards and expectations.

- Cultural Considerations: Buyers should be aware of cultural differences that may influence communication and expectations regarding quality. Building strong relationships with suppliers can help navigate these differences.

- Regulatory Compliance: Buyers must ensure that their suppliers comply with local regulations and international standards relevant to their industry. This is particularly important for industries like medical, aerospace, and automotive, where non-compliance can lead to severe repercussions.

- Traceability: Ensuring that suppliers maintain traceability of materials and processes can be vital, especially in industries where accountability is paramount.

By focusing on these critical aspects of manufacturing processes and quality assurance, international B2B buyers can make informed decisions, optimize their supply chains, and ensure the quality of their products in the competitive landscape of 5-axis CNC machining.

Related Video: How Terrific Mass Production of Mild Steel Tractor Nut Bolts / incredible Factory Manufacturing

Comprehensive Cost and Pricing Analysis for 5-axis cnc machining Sourcing

Understanding the Cost Structure of 5-Axis CNC Machining

When sourcing 5-axis CNC machining, international B2B buyers must navigate a complex cost structure comprising several components. Understanding these elements is crucial for optimizing costs and ensuring competitive pricing.

Key Cost Components

-

Materials

The choice of materials significantly affects pricing. Common materials include aluminum, titanium, and various plastics. Higher-grade materials typically incur additional costs due to their properties and processing requirements. Buyers should evaluate material needs based on project specifications to avoid overspending on unnecessary grades. -

Labor

Labor costs vary by region and the expertise required for 5-axis machining. Skilled operators are essential for maintaining precision and efficiency. In markets with high labor costs, such as parts of Europe, consider sourcing from regions with lower labor costs while ensuring quality standards are met.

-

Manufacturing Overhead

This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient operations and advanced technologies can reduce overhead, allowing suppliers to offer more competitive rates. -

Tooling

Tooling costs can be substantial, especially for custom projects. Buyers should consider the tool life and replacement frequency when evaluating quotes. Suppliers who offer comprehensive tooling solutions may provide better long-term value. -

Quality Control (QC)

Rigorous QC processes ensure that parts meet specified tolerances and quality standards. Implementing effective QC measures adds to manufacturing costs but is essential for reducing returns and ensuring customer satisfaction. -

Logistics

Shipping and handling fees can vary widely based on distance, shipping method, and packaging requirements. Buyers should evaluate logistics options, including Incoterms, to understand responsibilities for transportation costs and risks. -

Margin

Suppliers typically add a profit margin to their costs, which can vary based on market conditions and competition. Understanding the typical margins in different regions can help buyers negotiate better prices.

Influencers on Pricing

Several factors can influence the pricing of 5-axis CNC machining:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to reduced per-unit costs. Buyers should negotiate MOQs that align with their production needs to maximize savings.

-

Specifications/Customization: Highly customized parts can increase costs due to the need for specialized tooling and programming. Buyers should provide clear specifications to minimize revisions and associated costs.

-

Material Selection: The type and grade of material can significantly impact pricing. Discussing alternatives with suppliers can lead to cost-effective solutions without compromising quality.

-

Quality Certifications: Suppliers with certifications (e.g., ISO) may charge a premium, but this often ensures higher quality and reliability. Buyers should weigh the benefits of certified suppliers against their budget constraints.

-

Supplier Factors: The reputation and capabilities of the supplier can affect pricing. Established suppliers may offer more reliable services, justifying higher prices.

-

Incoterms: Understanding Incoterms (International Commercial Terms) can clarify costs related to shipping, insurance, and liability. This knowledge helps buyers budget accurately.

Buyer Tips for Cost-Efficiency

-

Negotiate Effectively: Leverage volume orders and long-term partnerships to negotiate better terms. Building strong relationships with suppliers can lead to favorable pricing arrangements.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also ongoing costs, including maintenance, logistics, and potential downtime. A lower initial cost may not always yield the best long-term value.

-

Understand Pricing Nuances: Pricing can vary significantly based on geographic location. Buyers from Africa, South America, the Middle East, and Europe should account for local economic conditions and currency fluctuations when evaluating costs.

-

Request Detailed Quotes: Ensure that quotes break down costs into components. This transparency allows for better comparisons and helps identify areas for potential savings.

Disclaimer

Pricing for 5-axis CNC machining is highly variable and influenced by numerous factors. The insights provided are indicative and should be used as a guide rather than definitive pricing. Always consult multiple suppliers to obtain the most accurate and competitive quotes tailored to specific project needs.

Spotlight on Potential 5-axis cnc machining Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘5-axis cnc machining’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for 5-axis cnc machining

5-axis CNC machining is a sophisticated manufacturing process that demands a clear understanding of its technical properties and the terminology used in the industry. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, grasping these elements is crucial for making informed purchasing decisions and optimizing manufacturing operations.

Key Technical Properties

-

Material Grade

– Definition: Refers to the specific type and quality of material used in machining, such as aluminum, titanium, or various alloys.

– Importance: The choice of material affects the strength, weight, and machinability of the final product. Understanding material grades helps buyers select appropriate components that meet their performance and durability requirements. -

Tolerance

– Definition: Tolerance is the permissible limit of variation in a physical dimension or measured value.

– Importance: High precision is critical in industries like aerospace and medical. Knowing the required tolerances ensures parts fit and function correctly, reducing the risk of costly reworks or failures.

-

Surface Finish

– Definition: This refers to the texture and smoothness of the machined surface, often measured in micrometers (µm).

– Importance: The surface finish can impact the aesthetic appeal and functionality of parts. A smoother finish may reduce friction and wear, which is particularly important in high-performance applications. -

Cutting Speed and Feed Rate

– Definition: Cutting speed is the speed at which the cutting tool moves through the material, while the feed rate is the distance the tool advances during one rotation.

– Importance: Optimizing these parameters is essential for maximizing production efficiency and tool life. Buyers need to understand these metrics to ensure that the machining process aligns with their production goals. -

Axis Configuration

– Definition: This refers to the arrangement and movement capabilities of the axes in a 5-axis CNC machine, which can include configurations like A, B, and C axes.

– Importance: Different configurations provide varying levels of flexibility and precision. Understanding these can aid buyers in selecting machines that best fit their specific manufacturing needs.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Significance: Understanding OEM relationships is crucial for buyers looking to source high-quality components that are compatible with their existing systems. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Significance: Knowing the MOQ helps buyers budget their purchases and determine whether a supplier can meet their production scale. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to invite them to submit a proposal for the supply of specific goods or services.

– Significance: An RFQ allows buyers to compare pricing and terms from different suppliers, enabling informed decision-making. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that are widely used in international commercial transactions.

– Significance: Familiarity with Incoterms is essential for understanding shipping responsibilities and cost allocations between buyers and sellers. -

Lead Time

– Definition: The amount of time that passes from the initiation of a process until its completion.

– Significance: Knowing lead times is vital for production planning and ensuring that components are available when needed to avoid delays in manufacturing.

By understanding these technical properties and trade terminologies, international B2B buyers can navigate the complexities of 5-axis CNC machining more effectively, ensuring they make informed decisions that align with their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 5-axis cnc machining Sector

Market Overview & Key Trends

The global market for 5-axis CNC machining is experiencing robust growth, driven by the increasing demand for precision engineering across various sectors, including aerospace, automotive, and medical. As industries continue to evolve, the need for complex geometries and high-quality finishes is propelling the adoption of 5-axis machining technologies. Notably, emerging economies in Africa, South America, the Middle East, and Europe are witnessing a surge in manufacturing activities, creating significant opportunities for international B2B buyers.

One of the most notable trends is the integration of advanced technologies such as Artificial Intelligence (AI) and the Internet of Things (IoT) into CNC machining processes. These innovations enhance operational efficiency by enabling predictive maintenance, reducing downtime, and optimizing production schedules. Additionally, the growing popularity of additive manufacturing is complementing traditional CNC machining, allowing for hybrid manufacturing solutions that combine the strengths of both processes.

Moreover, there is a notable shift toward customized solutions. B2B buyers are increasingly seeking suppliers that can offer tailored services and flexible production capabilities. This trend is particularly evident in regions like South America and Africa, where local manufacturers are striving to meet specific market demands. Understanding these dynamics will be crucial for international buyers looking to establish competitive advantages in their sourcing strategies.

Sustainability & Ethical Sourcing in B2B

As environmental concerns gain prominence globally, the 5-axis CNC machining sector is increasingly focusing on sustainability and ethical sourcing. The manufacturing process often generates significant waste and energy consumption, making it essential for companies to adopt environmentally friendly practices. B2B buyers are now prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint through efficient energy use and waste management strategies.

Illustrative Image (Source: Google Search)

Ethical supply chains are also becoming a critical consideration. Buyers are looking for partners who not only comply with regulations but also uphold high standards of labor practices and environmental stewardship. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming prerequisites for suppliers aiming to penetrate international markets.

In terms of materials, the demand for “green” alternatives is on the rise. B2B buyers should consider suppliers that utilize sustainable materials or those that have undergone lifecycle assessments to minimize environmental impact. By prioritizing sustainability and ethical sourcing, companies can enhance their brand reputation and appeal to a growing segment of eco-conscious consumers.

Brief Evolution/History

The evolution of 5-axis CNC machining dates back to the 1980s when the technology was first introduced to improve the efficiency and precision of machining operations. Initially, these machines were primarily used in aerospace and defense applications, where high precision was critical. Over the years, advancements in computer technology and software have allowed for more complex machining capabilities, making 5-axis CNC machining accessible to a wider range of industries, including automotive, medical, and consumer goods.

Today, 5-axis CNC machining is recognized as a standard in high-precision manufacturing, enabling the production of intricate components with minimal human intervention. The ongoing development of advanced materials and cutting tools continues to push the boundaries of what is possible, further solidifying its role in modern manufacturing processes. As this technology continues to evolve, B2B buyers must stay informed about these advancements to make strategic sourcing decisions that align with their operational goals.

Frequently Asked Questions (FAQs) for B2B Buyers of 5-axis cnc machining

-

What should I consider when vetting suppliers for 5-axis CNC machining?

When vetting suppliers, focus on their experience in 5-axis CNC machining, production capabilities, and technology used. Request references or case studies to assess their past projects. It’s crucial to evaluate their quality assurance processes, certifications (such as ISO 9001), and compliance with industry standards. Additionally, consider their geographical location for logistics efficiency and potential tariffs. A supplier’s ability to provide customization options and scale production based on your needs is also essential. -

Can I customize parts when ordering 5-axis CNC machining services?

Yes, most suppliers offer customization for parts manufactured through 5-axis CNC machining. When discussing your project, provide detailed specifications, including dimensions, materials, and tolerances. Some suppliers might have limitations based on their machinery capabilities, so confirm this upfront. It’s also beneficial to discuss design iterations and prototyping options to ensure the final product meets your requirements. Engaging in early communication about customization can help streamline the production process. -

What are the typical minimum order quantities (MOQ) and lead times for 5-axis CNC machining?

Minimum order quantities for 5-axis CNC machining can vary significantly depending on the supplier and project complexity. Many suppliers have MOQs ranging from 10 to 100 units, while others may accommodate smaller runs for prototypes. Lead times typically range from 2 to 6 weeks, influenced by the supplier’s workload and the complexity of the parts. Always clarify these details in your initial discussions to set realistic expectations and ensure timely delivery. -

What payment terms are commonly used in international B2B transactions for 5-axis CNC machining?

Payment terms in international B2B transactions often vary by supplier and geographical region. Common practices include a deposit (20-50%) before production, with the balance due upon completion or prior to shipping. Some suppliers may offer letters of credit or escrow services for larger orders to ensure security for both parties. It’s essential to discuss and agree upon payment methods, currencies, and any potential fees upfront to avoid misunderstandings later in the process. -

How can I ensure quality assurance and certifications are met during the machining process?

To ensure quality assurance, request documentation of the supplier’s certifications and quality control processes. Look for ISO certifications or specific industry-related certifications that indicate adherence to quality standards. It’s advisable to discuss the inspection methods employed during production, such as in-process inspections and final quality checks. Additionally, consider requesting samples or conducting an on-site visit to assess the supplier’s quality management practices firsthand. -

What logistics considerations should I keep in mind when sourcing 5-axis CNC machining internationally?

When sourcing internationally, consider shipping methods, costs, and customs regulations. Discuss with your supplier the best shipping options based on your delivery timeline and budget. Ensure that the supplier can provide necessary documentation for customs clearance, including invoices, packing lists, and certificates of origin. Additionally, be aware of potential tariffs or duties that may apply to your shipments, and factor these into your overall cost calculations. -

What should I do if a dispute arises with my CNC machining supplier?

If a dispute arises, first attempt to resolve the issue through direct communication with the supplier. Clearly outline your concerns and seek a mutual resolution. If informal discussions do not yield results, refer to the contractual terms agreed upon, which should specify dispute resolution procedures, such as mediation or arbitration. Engage a legal professional with expertise in international trade if necessary. Maintaining a record of all communications can be beneficial for resolving disputes effectively. -

What are the common risks involved in international sourcing of 5-axis CNC machining, and how can I mitigate them?

Common risks include quality discrepancies, shipping delays, and supplier reliability issues. To mitigate these risks, conduct thorough due diligence during the supplier vetting process, and consider using third-party inspection services to verify quality before shipment. Establish clear contractual terms that outline expectations, responsibilities, and penalties for non-compliance. Additionally, maintain open lines of communication throughout the production process to address any issues promptly, and consider diversifying your supplier base to reduce dependency on a single source.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 5-axis cnc machining

5-axis CNC machining stands at the forefront of modern manufacturing, offering unparalleled precision and efficiency for creating complex components across various industries. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the strategic advantages of sourcing 5-axis machining services is crucial. Key benefits include enhanced surface finishes, reduced production times, and the ability to work with a wide array of materials, all of which can significantly improve product quality and reduce operational costs.

Strategic sourcing in this context involves not only selecting the right suppliers but also leveraging technological advancements, such as advanced CAM software and skilled operators, to optimize manufacturing processes. Buyers should prioritize partnerships with suppliers who demonstrate expertise in 5-axis machining and can provide tailored solutions to meet specific project requirements.

Looking ahead, the demand for precision-engineered components will continue to grow, driven by advancements in industries like aerospace, automotive, and medical devices. Now is the time to engage with leading 5-axis CNC machining providers to secure a competitive edge in your market. By investing in high-quality machining capabilities, businesses can enhance their product offerings and ensure sustainable growth in an increasingly complex global landscape.

Illustrative Image (Source: Google Search)