Your Ultimate Guide to Sourcing Pallet Rack Manufacturers

Introduction: Navigating the Global Market for pallet rack manufacturers

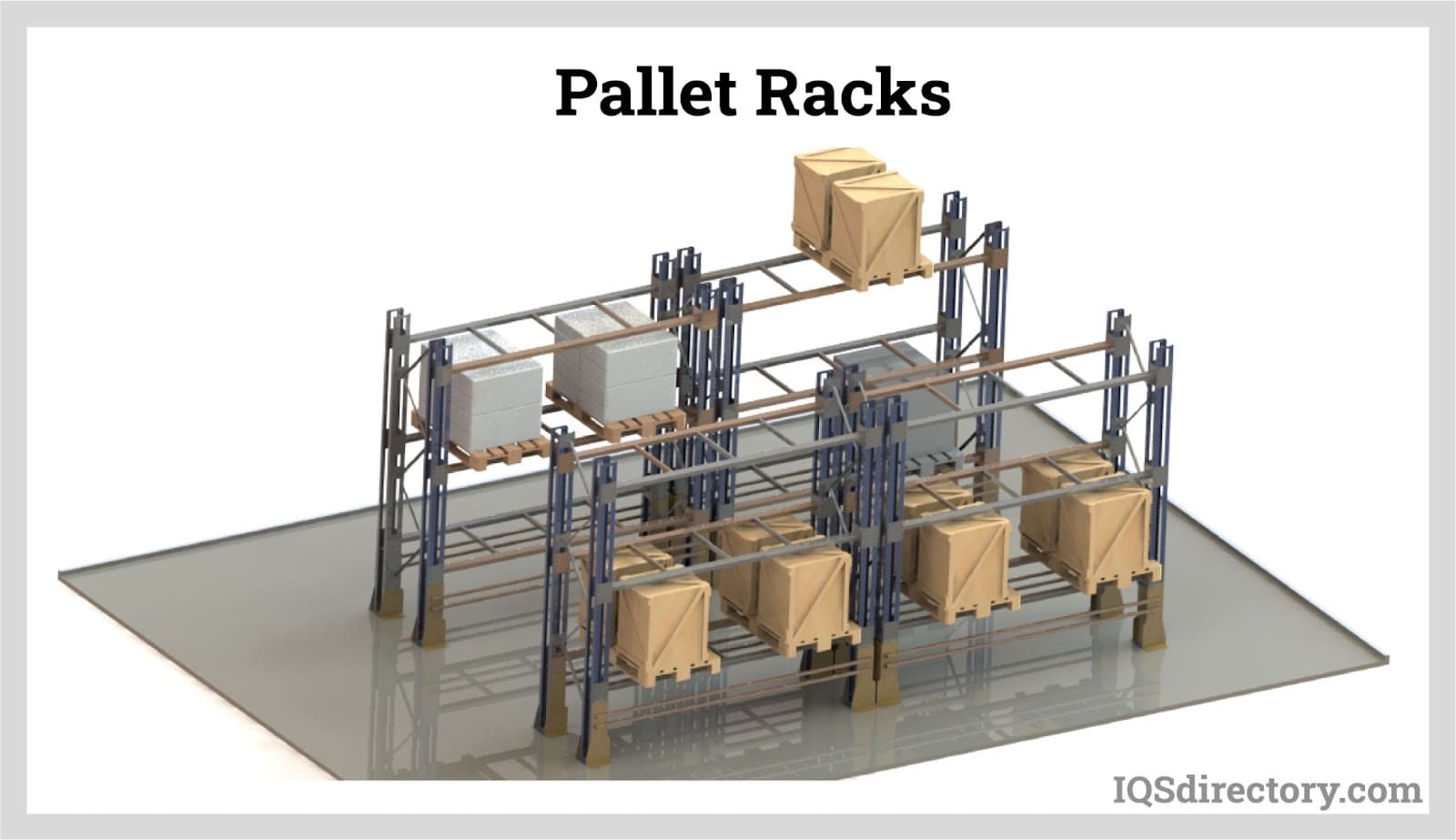

In the ever-evolving landscape of global trade and logistics, pallet rack manufacturers play a pivotal role in enhancing operational efficiency for businesses across various sectors. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the intricacies of pallet racking solutions is essential for optimizing warehouse space, ensuring safety, and facilitating seamless inventory management.

This comprehensive guide serves as an indispensable resource, delving into the diverse types of pallet racks available, such as selective, drive-in, and cantilever racks, alongside their respective materials, including steel and aluminum. It examines manufacturing processes and quality control standards that ensure durability and safety, while also highlighting reputable suppliers and their unique offerings. Additionally, we provide insights into cost considerations, market trends, and best practices for sourcing pallet racking systems tailored to your specific needs.

By navigating through this guide, you will be equipped with the knowledge to make informed sourcing decisions that align with your operational goals. Whether you are looking to expand existing facilities or invest in new storage solutions, understanding the global market for pallet rack manufacturers will empower you to enhance your supply chain efficiency and drive business growth.

Understanding pallet rack manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Selective Pallet Rack | Adjustable beams, versatile, easy access to pallets | General warehousing, retail, distribution | Pros: High accessibility; Cons: Less space-efficient for high-density storage. |

| Drive-In Rack | Compact design, allows for high-density storage | Cold storage, large inventory warehouses | Pros: Maximizes space; Cons: Limited access to individual pallets. |

| Push-Back Rack | Lateral storage, FIFO inventory management | E-commerce, food & beverage, automotive | Pros: Efficient space use; Cons: Higher initial investment. |

| Flow Rack | Gravity-driven, first-in-first-out (FIFO) system | Food and beverage, pharmaceuticals | Pros: Reduces product spoilage; Cons: Requires careful planning for setup. |

| Cantilever Rack | Open design for long or irregular items | Lumberyards, plumbing supplies, furniture | Pros: Flexible for various sizes; Cons: Less suitable for palletized goods. |

Selective Pallet Rack

Selective pallet racks are the most common type used in warehouses due to their adaptability and ease of access. They feature adjustable beams, allowing users to customize the height of storage levels according to their needs. This type is ideal for businesses with diverse inventory and frequent stock rotation. Buyers should consider the layout of their warehouse, as selective racks require ample aisle space for forklift maneuvering, making them less space-efficient compared to other designs.

Drive-In Rack

Drive-in racks are designed for high-density storage, enabling forklifts to drive directly into the rack system. This configuration maximizes vertical space and is particularly beneficial for cold storage facilities or warehouses with a large volume of similar products. While drive-in racks can significantly increase storage capacity, they limit access to individual pallets, making it crucial for buyers to assess their inventory turnover rates before investing.

Push-Back Rack

Push-back racks utilize a system of carts that allow pallets to be stored on inclined rails, enabling a first-in-first-out (FIFO) inventory management system. This design is especially useful for e-commerce and perishable goods, as it helps maintain product freshness. Buyers should weigh the initial costs against long-term benefits, considering the efficiency gains in inventory management and space utilization that push-back racks can provide.

Flow Rack

Flow racks employ a gravity-fed system where products are loaded from the back and flow to the front, ensuring a FIFO process. This type is particularly suited for industries like food and pharmaceuticals, where product shelf life is critical. While flow racks can reduce spoilage and improve picking efficiency, they require careful planning and investment in infrastructure, making them a more complex option for some businesses.

Cantilever Rack

Cantilever racks are characterized by their open design, making them ideal for storing long or irregularly shaped items such as lumber and piping. This type allows for easy loading and unloading while maximizing space vertically. Businesses in sectors like construction and manufacturing should consider cantilever racks for their flexibility, but they may not be suitable for palletized goods, requiring buyers to match their storage needs with the rack type carefully.

Related Video: Selective Pallet Racking – Emrack International

Key Industrial Applications of pallet rack manufacturers

| Industry/Sector | Specific Application of pallet rack manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| E-commerce | Automated pallet racking systems for order fulfillment | Maximizes storage density and speeds up retrieval | Consider automation compatibility and scalability options |

| Food & Beverage | Temperature-controlled pallet racks | Ensures product safety and compliance with regulations | Verify materials suitable for cold storage and hygiene standards |

| Automotive | Heavy-duty pallet racks for parts storage | Increases efficiency in inventory management | Assess load capacity and modularity for future expansion |

| Pharmaceuticals | Specialized racking for sensitive products | Maintains integrity of products and regulatory compliance | Evaluate customization options for specific product needs |

| Retail | Multi-tier pallet racking for bulk storage | Enhances accessibility and organization of stock | Focus on flexibility in design to accommodate various products |

E-commerce

In the fast-paced e-commerce sector, pallet rack manufacturers provide automated pallet racking systems that significantly enhance order fulfillment processes. These systems enable businesses to optimize storage density while facilitating quick retrieval of goods, which is crucial for maintaining customer satisfaction. International buyers should focus on sourcing solutions that offer scalability and compatibility with existing automated systems, ensuring that their investments can grow alongside their operations.

Food & Beverage

The food and beverage industry often requires temperature-controlled pallet racks to ensure product safety and adherence to health regulations. These racks help maintain the integrity of perishable goods, reducing spoilage and waste. Buyers in this sector, particularly from regions like Africa and the Middle East, should prioritize materials that meet hygiene standards and are designed for cold storage environments, ensuring compliance with local and international food safety regulations.

Illustrative Image (Source: Google Search)

Automotive

Pallet rack manufacturers serve the automotive industry by providing heavy-duty pallet racks designed for parts storage. These racks facilitate efficient inventory management, allowing businesses to organize and access parts quickly, which is vital for production timelines. When sourcing, companies should assess the load capacity of the racks and consider modular designs that allow for future expansion, accommodating the evolving needs of their operations.

Pharmaceuticals

In the pharmaceutical sector, specialized racking systems are essential for storing sensitive products that require stringent handling procedures. Pallet rack manufacturers offer customized solutions that help maintain product integrity while ensuring compliance with regulatory standards. International buyers must evaluate the options available for customization, ensuring that the racks meet specific storage requirements and can adapt to various product lines.

Retail

Retail businesses utilize multi-tier pallet racking systems to optimize bulk storage of products, enhancing accessibility and organization. These systems allow for easy stock management, which is crucial for maintaining inventory levels and meeting customer demand. Buyers should focus on flexibility in design, ensuring that the racking systems can accommodate a wide range of products and adapt to seasonal changes in inventory.

Related Video: Push-Back Pallet Rack Storage Systems | Apex Companies

Strategic Material Selection Guide for pallet rack manufacturers

When selecting materials for pallet racks, manufacturers must consider various factors that can significantly impact performance, durability, and overall cost-effectiveness. Below is an analysis of four common materials used in pallet rack manufacturing, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Steel

Key Properties:

Steel is renowned for its high tensile strength and durability. It can withstand significant loads and is resistant to deformation under pressure. Steel racks typically have excellent corrosion resistance when treated with appropriate coatings, making them suitable for various environments.

Pros & Cons:

The primary advantage of steel is its strength and longevity, which makes it ideal for heavy-duty applications. However, the manufacturing process can be complex, and the cost of high-quality steel can be substantial, leading to higher initial investment costs. Additionally, steel racks may require regular maintenance to prevent rust in humid environments.

Impact on Application:

Steel is compatible with a wide range of media, including heavy pallets and industrial goods. Its strength allows for the stacking of heavy items, making it a preferred choice in warehouses with high storage demands.

Considerations for International Buyers:

Buyers from regions like Africa and the Middle East should ensure compliance with local safety standards and regulations. Familiarity with international standards such as ASTM and DIN can help in selecting the right steel grades for specific applications.

Aluminum

Key Properties:

Aluminum is lightweight yet strong, offering excellent corrosion resistance. Its lower density allows for easier handling and installation compared to heavier materials like steel.

Pros & Cons:

Aluminum racks are easier to transport and install, which can reduce labor costs. However, they are generally more expensive than steel and may not support as much weight, limiting their application in heavy-duty environments.

Impact on Application:

Aluminum is particularly well-suited for environments where corrosion is a concern, such as food processing facilities or coastal areas. Its lightweight nature allows for flexibility in design and configuration.

Considerations for International Buyers:

In regions with stringent environmental regulations, such as Europe, aluminum’s recyclability can be a significant advantage. Buyers should also consider the material’s compliance with local standards and certifications.

Composite Materials

Key Properties:

Composite materials, often made from a mix of plastics and fiberglass, offer unique properties like lightweight construction and resistance to chemicals and moisture.

Pros & Cons:

The main advantage of composites is their resistance to corrosion and chemicals, making them suitable for specialized applications. However, they may not provide the same load-bearing capacity as steel or aluminum, which can limit their use in heavy-duty storage.

Impact on Application:

Composite racks are ideal for environments that require high resistance to chemicals, such as laboratories or food production facilities. Their lightweight nature also allows for easy reconfiguration.

Considerations for International Buyers:

Buyers should be aware of the specific chemical compatibility of composite materials with the products they intend to store. Understanding local standards for composite materials is crucial, especially in regions with strict safety regulations.

Wood

Key Properties:

Wood is a traditional material that provides good load-bearing capacity and is relatively easy to work with. Its natural properties offer a degree of insulation against temperature fluctuations.

Pros & Cons:

Wood is often more cost-effective than metal alternatives and can be sourced sustainably. However, it is susceptible to pests and moisture damage, which can affect longevity and safety.

Impact on Application:

Wooden racks are typically used in less demanding environments, such as retail or light storage applications. They are suitable for lighter loads and can be aesthetically pleasing in customer-facing areas.

Considerations for International Buyers:

Buyers should ensure that wood materials comply with local regulations regarding pest treatment and sustainability. In Europe, for example, adherence to standards such as EN 13556 can be essential.

Summary Table

| Material | Typical Use Case for pallet rack manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty storage in industrial warehouses | High strength and durability | Higher initial cost and maintenance | High |

| Aluminum | Lightweight applications in corrosive environments | Lightweight and corrosion-resistant | More expensive and lower load capacity | Medium |

| Composite | Chemical storage in laboratories | Chemical and moisture resistance | Limited load-bearing capacity | Medium |

| Wood | Retail and light storage applications | Cost-effective and sustainable | Susceptible to pests and moisture | Low |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions when sourcing pallet racks, ensuring they choose the right material for their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for pallet rack manufacturers

When evaluating pallet rack manufacturers, it is essential to understand their manufacturing processes and quality assurance protocols. This insight not only helps in selecting a reliable supplier but also ensures that the products meet the specific needs of your warehouse operations. Below is a comprehensive overview of typical manufacturing stages, quality control measures, and actionable strategies for international B2B buyers.

Manufacturing Processes

The manufacturing of pallet racks involves several critical stages, each requiring specific techniques and quality controls to ensure the final product’s durability and functionality.

1. Material Preparation

The first step in the manufacturing process is material preparation. This typically involves sourcing high-quality raw materials, predominantly steel or aluminum, known for their strength and longevity.

- Key Techniques:

- Material Selection: Manufacturers often choose cold-rolled steel for its strength and weldability, while galvanized steel is selected for corrosion resistance.

- Cutting and Shaping: Materials are cut to size using laser cutting or plasma cutting technologies, ensuring precision and minimizing waste.

2. Forming

Once the materials are prepared, they undergo forming, where they are shaped into the required components of the pallet rack.

- Key Techniques:

- Bending and Stamping: Processes such as press braking and stamping are used to create structural elements like beams and uprights.

- Welding: Automated welding techniques, such as MIG (Metal Inert Gas) welding, ensure strong joints that can withstand heavy loads.

3. Assembly

Following forming, the individual components are assembled into complete pallet rack systems. This stage is critical for ensuring that the racks are structurally sound and ready for use.

- Key Techniques:

- Modular Assembly: Many manufacturers employ modular designs, allowing for easy customization based on client specifications.

- Quality Checks: Assembly includes in-process inspections to ensure that all components fit correctly and meet design specifications.

4. Finishing

The final stage of the manufacturing process involves finishing touches that enhance both aesthetics and durability.

- Key Techniques:

- Coating: Powder coating is a common technique used to protect against corrosion and improve the visual appeal of pallet racks.

- Quality Assurance: Final inspections are conducted to assess the finish and integrity of the product before it is shipped.

Quality Assurance

Quality assurance is paramount in the manufacturing of pallet racks. Adhering to international standards and conducting thorough inspections at various checkpoints ensures that the products are safe and reliable.

International Standards

Pallet rack manufacturers often comply with several international quality standards, including:

- ISO 9001: This standard outlines the criteria for a quality management system, focusing on continuous improvement and customer satisfaction.

- CE Marking: Required for products sold within the European Economic Area, CE marking indicates that the product meets EU safety, health, and environmental protection standards.

- API Certification: For manufacturers involved in sectors like oil and gas, API standards ensure that the equipment can handle specific operational demands.

Quality Control Checkpoints

Quality control is integrated throughout the manufacturing process, with several key checkpoints:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify issues early.

- Final Quality Control (FQC): A thorough examination of finished products before shipping ensures that they meet all quality standards and specifications.

Common Testing Methods

To verify the quality of pallet racks, manufacturers employ various testing methods, including:

- Load Testing: Simulating real-world conditions by applying weight to ensure the racks can support specified loads.

- Durability Testing: Assessing the resistance of coatings and materials to corrosion and wear.

- Structural Integrity Testing: Using non-destructive testing methods, like ultrasonic testing, to evaluate welds and joints.

How B2B Buyers Can Verify Supplier Quality Control

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a manufacturer’s quality control measures is crucial. Here are actionable strategies:

- Audits: Conducting regular audits of suppliers can provide firsthand insight into their manufacturing processes and quality assurance practices. This includes reviewing documentation, inspecting production facilities, and assessing quality control measures.

- Requesting Reports: Buyers should request quality assurance reports, including test results and compliance certificates, to verify that the manufacturer adheres to international standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturer’s processes and products. This is particularly useful for buyers unfamiliar with local suppliers or those seeking additional assurance.

Quality Control and Certification Nuances for International Buyers

When sourcing pallet racks from international manufacturers, buyers must be aware of specific nuances:

- Cultural Considerations: Different regions may have varying standards and practices regarding quality assurance. Understanding local regulations and customs can aid in better supplier selection.

- Import Regulations: Ensure that the products meet the import regulations of your country, which may include specific certifications or testing requirements.

- After-Sales Support: Evaluate the manufacturer’s commitment to after-sales support, including warranty terms and availability of spare parts, as this reflects their confidence in product quality.

By understanding the manufacturing processes and quality assurance practices of pallet rack manufacturers, international B2B buyers can make informed decisions that align with their operational needs and standards. This comprehensive approach ensures that the chosen suppliers not only meet quality expectations but also contribute to the overall efficiency and safety of warehouse operations.

Related Video: Amazing factories and processes| Manufacturing method and top 5 processes| Mass production process

Comprehensive Cost and Pricing Analysis for pallet rack manufacturers Sourcing

Understanding the cost structure and pricing of pallet rack manufacturing is crucial for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. This analysis focuses on the key components of cost, the factors that influence pricing, and actionable tips for buyers to optimize their sourcing strategies.

Cost Components

-

Materials: The primary materials used in pallet rack manufacturing include steel and aluminum. The cost of these raw materials can fluctuate based on market demand, tariffs, and global supply chain issues. Buyers should stay informed about material price trends to anticipate changes in overall costs.

-

Labor: Labor costs vary significantly across regions. In countries with higher wages, such as those in Western Europe, labor can be a substantial part of the manufacturing cost. Conversely, regions like Africa or South America may have lower labor costs, impacting the total price.

-

Manufacturing Overhead: This includes costs related to factory operations, maintenance, utilities, and administrative expenses. Efficient manufacturing processes and automation can help reduce overhead costs, which can be reflected in competitive pricing.

-

Tooling: The initial investment in tooling and machinery is significant for pallet rack manufacturers. Custom designs require specialized tools, which can increase costs. However, high-quality tooling often leads to better product quality and efficiency.

-

Quality Control (QC): Maintaining high standards through rigorous quality control processes adds to the cost structure. Certifications and compliance with international standards (such as ISO) may also incur additional expenses but are essential for ensuring product reliability and safety.

Illustrative Image (Source: Google Search)

-

Logistics: Shipping costs can vary widely based on distance, mode of transport, and current logistics challenges. For international buyers, understanding the implications of Incoterms is crucial, as they determine who bears the shipping costs and risks.

-

Margin: Manufacturers typically add a profit margin to cover their expenses and generate profit. This margin can vary based on market competition and the manufacturer’s positioning.

Price Influencers

-

Volume/MOQ: Bulk purchases can lead to significant discounts. Buyers should negotiate minimum order quantities (MOQs) to maximize savings.

-

Specifications/Customization: Customized pallet racks typically cost more due to the additional design and manufacturing efforts involved. Clearly define your requirements to get accurate quotes.

-

Materials: The choice of materials directly affects pricing. High-strength steel may cost more upfront but can offer long-term savings through durability.

-

Quality/Certifications: Products that meet certain quality standards or certifications may command higher prices but provide assurance of safety and reliability.

-

Supplier Factors: Established suppliers may have higher prices due to their reputation and reliability. However, they often provide better customer service and support.

-

Incoterms: Understanding Incoterms helps buyers manage logistics costs and risks effectively. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can impact overall pricing.

Buyer Tips

-

Negotiate: Always negotiate terms and pricing. Leverage your purchasing power, especially if you are ordering in bulk.

-

Cost-Efficiency: Look beyond the initial price. Consider the Total Cost of Ownership (TCO), which includes installation, maintenance, and potential repair costs over the product’s lifespan.

-

Pricing Nuances: Be aware of regional pricing variations. For example, manufacturers in Europe may have higher base prices due to labor costs, but may offer better quality and certifications that justify the investment.

-

Research and Compare: Utilize platforms that aggregate supplier information, allowing for comparison of offerings, prices, and customer reviews. This can provide insights into which suppliers offer the best value.

Disclaimer

Prices for pallet racks can vary widely based on the aforementioned factors, and this analysis serves as a guideline rather than a definitive pricing structure. Always request detailed quotes from multiple manufacturers to ensure you are making the most informed purchasing decision.

Spotlight on Potential pallet rack manufacturers Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘pallet rack manufacturers’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for pallet rack manufacturers

Key Technical Properties of Pallet Racks

Understanding the technical specifications of pallet racks is essential for B2B buyers to ensure that the chosen storage solutions meet their operational requirements and safety standards. Here are some critical specifications:

-

Material Grade

– Definition: This refers to the type and quality of materials used in the construction of pallet racks, commonly steel or aluminum.

– B2B Importance: High-grade materials enhance the durability and load-bearing capacity of racks, which is crucial for long-term investment and safety. For buyers, selecting racks made from high-grade materials can minimize maintenance costs and extend the lifespan of the equipment. -

Load Capacity

– Definition: The maximum weight that a pallet rack can safely support without risk of failure.

– B2B Importance: Knowing the load capacity is vital for ensuring that the racks can handle the specific weights of the products stored. Overloading can lead to structural failure, injuries, and significant financial loss. Buyers must assess their storage needs accurately to select racks with appropriate load capacities. -

Dimensions and Tolerance

– Definition: This includes the height, width, and depth of the pallet racks, along with permissible variations (tolerances) in these measurements.

– B2B Importance: Precise dimensions ensure that racks fit into the designated warehouse space and can accommodate the pallets being used. Tolerance levels are crucial for ensuring compatibility with forklifts and other handling equipment, which aids in operational efficiency. -

Finish and Coating

– Definition: The protective layer applied to the racks, such as powder coating or galvanization, which prevents rust and wear.

– B2B Importance: A robust finish enhances the longevity of pallet racks, particularly in environments with high humidity or corrosive materials. Buyers in regions with challenging climates should prioritize racks with protective coatings to avoid premature deterioration.

- Safety Features

– Definition: These include elements like safety clips, bolted connections, and guardrails that contribute to the structural integrity and safety of pallet racks.

– B2B Importance: Understanding safety features is critical for compliance with local regulations and industry standards. Buyers should prioritize racks with comprehensive safety features to protect their workforce and inventory.

Common Trade Terminology in Pallet Rack Manufacturing

Navigating the procurement process involves familiarizing oneself with industry jargon. Here are several essential terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify the quality and reliability of the products they are purchasing. OEM parts often ensure better compatibility and performance. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units that a supplier is willing to sell.

– Importance: Buyers need to be aware of MOQs to avoid overcommitting to a purchase that exceeds their immediate needs. This term is crucial for budgeting and inventory management. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and other details for specific products.

– Importance: Issuing an RFQ allows buyers to compare offers from multiple suppliers, ensuring they receive competitive pricing and terms. It’s a fundamental step in the procurement process. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of buyers and sellers regarding the delivery of goods.

– Importance: Understanding Incoterms is essential for international transactions, as they clarify who is responsible for shipping costs, insurance, and risk during transport. This knowledge helps buyers negotiate better terms and reduce potential disputes. -

Lead Time

– Definition: The time it takes from placing an order to the delivery of goods.

– Importance: Knowing lead times helps buyers plan their inventory and operations effectively. Shorter lead times can improve responsiveness to market demands.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing pallet racks, ultimately enhancing their operational efficiency and safety.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the pallet rack manufacturers Sector

Market Overview & Key Trends

The pallet rack manufacturing sector is experiencing robust growth driven by several global factors. Increasing e-commerce activities, the need for efficient warehousing solutions, and the expansion of supply chain networks are key drivers shaping the market landscape. As businesses strive to optimize their storage capabilities, pallet rack systems have become essential for maximizing space utilization and enhancing operational efficiency.

Emerging Trends in B2B Technology and Sourcing:

1. Automation and Smart Solutions: The adoption of automated storage and retrieval systems (AS/RS) is on the rise. Companies are investing in smart pallet racks equipped with sensors and IoT technology to streamline inventory management and enhance real-time tracking.

2. Customization and Flexibility: Manufacturers are increasingly offering tailored solutions to meet specific needs of businesses. Buyers are looking for racks that can easily adapt to changing inventory levels and warehouse layouts.

3. Sourcing from Local Manufacturers: International buyers from Africa, South America, the Middle East, and Europe are increasingly seeking local suppliers to reduce lead times and shipping costs. This trend emphasizes the importance of establishing strong relationships with regional manufacturers.

In addition, sustainability practices are becoming a significant consideration in procurement decisions. Buyers are prioritizing suppliers that demonstrate a commitment to environmentally friendly materials and processes, reflecting a broader shift towards sustainable business practices.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer just a buzzword; it is a fundamental aspect of business strategy in the pallet rack manufacturing sector. The environmental impact of manufacturing processes, from raw material extraction to production and disposal, is under scrutiny. Buyers must consider the ecological footprint of their suppliers and the materials used in their products.

Importance of Ethical Supply Chains:

– Transparency: Buyers should seek manufacturers that provide clear insights into their supply chains, ensuring that materials are sourced ethically and responsibly.

– Green Certifications: Look for manufacturers with certifications such as ISO 14001 (Environmental Management) or FSC (Forest Stewardship Council) to ensure adherence to sustainable practices. These certifications indicate a commitment to reducing environmental impact and promoting responsible resource management.

– Sustainable Materials: The use of recyclable and sustainable materials in pallet rack production is gaining traction. Buyers should prioritize suppliers who utilize steel and other materials that can be recycled at the end of their lifecycle.

By focusing on sustainability and ethical sourcing, international B2B buyers can enhance their brand reputation while contributing positively to environmental conservation.

Brief Evolution/History

The pallet rack industry has evolved significantly since its inception in the mid-20th century. Initially designed for basic storage needs, pallet racks have transformed into sophisticated systems that cater to diverse operational requirements. Over the decades, technological advancements have led to innovations such as adjustable pallet racks, drive-in racks, and automated systems. The shift towards e-commerce has further accelerated this evolution, prompting manufacturers to develop solutions that optimize space and enhance efficiency. Today, pallet racks are not only pivotal in warehouse operations but also play a crucial role in the overall logistics and supply chain management strategies of businesses worldwide.

In summary, the pallet rack manufacturing sector is positioned at the intersection of technological innovation, sustainability, and evolving market demands. International B2B buyers must navigate these dynamics to make informed sourcing decisions that align with their operational goals and ethical standards.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of pallet rack manufacturers

-

How should I vet potential pallet rack manufacturers?

When vetting pallet rack manufacturers, consider their industry experience, reputation, and customer reviews. Look for certifications such as ISO 9001 or compliance with local safety standards. Request case studies or references from similar businesses in your region to gauge their reliability. Additionally, evaluate their production capabilities and whether they can scale with your needs. Conducting virtual meetings can also help assess their communication skills and commitment to customer service. -

Can pallet racks be customized to fit my specific requirements?

Yes, many pallet rack manufacturers offer customization options. When discussing your needs, be specific about dimensions, load capacity, and any specialized features (e.g., adjustable heights, specific materials). Customization can also extend to color and branding, which can enhance your warehouse’s aesthetics. Ensure to request detailed drawings or prototypes before finalizing the order to avoid miscommunication. This approach not only guarantees a better fit but also enhances operational efficiency. -

What is the typical Minimum Order Quantity (MOQ) and lead time for pallet racks?

Minimum Order Quantities (MOQs) vary by manufacturer and can range from a few units to several hundred. Lead times can also differ significantly based on the complexity of the order, customization requirements, and the manufacturer’s location. Generally, expect lead times between 4 to 12 weeks. For international buyers, consider discussing bulk orders to negotiate lower MOQs and expedite processing times. Always confirm these details in writing before placing an order. -

What payment options are typically available for international purchases?

Payment options for international purchases often include wire transfers, letters of credit, and secure online payment platforms. Some manufacturers may offer financing options for larger orders. When negotiating terms, consider the currency exchange rates and any additional fees associated with international transactions. Always request a pro forma invoice that outlines payment terms clearly to avoid misunderstandings. Make sure that the payment method you choose provides adequate security for both parties. -

What quality assurance measures should I expect from manufacturers?

Reputable pallet rack manufacturers implement rigorous quality assurance (QA) processes to ensure product safety and durability. This includes material testing, structural integrity assessments, and compliance with international standards. Request documentation of their QA practices, including inspection reports and certifications. Additionally, inquire about warranty terms and conditions, as a solid warranty can serve as an indicator of the manufacturer’s confidence in their products. -

How can I manage logistics and shipping for international orders?

Managing logistics for international orders involves understanding shipping options, costs, and timelines. Discuss with your supplier whether they handle shipping or if you need to arrange it separately. Consider using freight forwarders who specialize in international shipping to streamline the process. Ensure that you understand customs regulations in your country to avoid delays. Always factor in potential tariffs and taxes when budgeting for your order. -

What should I do if there are disputes regarding my order?

In the event of a dispute, start by reviewing the contract and communication history with the manufacturer. Most reputable companies will have a clear dispute resolution process, often including mediation or arbitration clauses. Document all interactions and maintain a professional tone in communications. If the issue remains unresolved, consider escalating it to higher management within the company. As a last resort, legal action may be necessary, but this should be avoided if possible due to the costs involved. -

What certifications should I look for in pallet rack manufacturers?

Look for manufacturers with certifications that demonstrate compliance with safety and quality standards, such as ISO 9001 for quality management and ISO 14001 for environmental management. Additionally, check for compliance with local safety regulations (e.g., ANSI, OSHA in the U.S.) that pertain to warehouse equipment. Certifications can provide assurance that the manufacturer adheres to best practices in production and product safety, which is crucial for operational reliability in your warehouse.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for pallet rack manufacturers

The strategic sourcing of pallet racks is pivotal for enhancing operational efficiency and maximizing storage space in warehouses. As international buyers from regions such as Africa, South America, the Middle East, and Europe seek to optimize their supply chains, understanding the diverse offerings from leading manufacturers is essential. Companies like Mecalux, Material Handling Exchange, and TSSC Co. LLC are at the forefront of innovation, providing customized solutions that meet the evolving demands of e-commerce and automated warehousing.

B2B buyers should prioritize partnerships with manufacturers who demonstrate flexibility in design and a commitment to sustainability. This not only ensures compliance with international standards but also aligns with the growing trend of eco-conscious logistics. Additionally, leveraging technology in sourcing can facilitate better price negotiations and streamline procurement processes.

Looking ahead, the pallet rack industry is poised for significant growth driven by advancements in automation and smart storage solutions. International buyers are encouraged to stay informed about emerging trends and actively engage with suppliers to harness these innovations. By doing so, they can position themselves for success in an increasingly competitive market. Act now to explore your options and secure the best solutions for your warehouse needs.