Your Ultimate Guide to Sourcing Kinds Of Weighing Scale

Introduction: Navigating the Global Market for kinds of weighing scale

In the rapidly evolving global market, the selection of the right weighing scale can significantly impact operational efficiency, compliance, and profitability for businesses across diverse industries. From agriculture to manufacturing, accurate weight measurements are essential for ensuring quality control, optimizing logistics, and meeting regulatory standards. As international B2B buyers from Africa, South America, the Middle East, and Europe seek reliable solutions, understanding the variety of weighing scales available becomes paramount.

This guide offers a comprehensive exploration of the different types of weighing scales, including industrial, commercial, and laboratory models. It delves into the materials and manufacturing processes that influence scale performance and durability, alongside quality control standards that ensure reliability. Additionally, we provide insights into selecting reputable suppliers, evaluating cost factors, and understanding market trends that affect pricing and availability.

Illustrative Image (Source: Google Search)

By addressing frequently asked questions and common concerns, this guide empowers decision-makers with actionable insights and best practices for sourcing weighing scales. With a focus on fostering informed purchasing decisions, it serves as a valuable resource for businesses navigating the complexities of the global market, ensuring they can choose equipment that meets their specific needs while enhancing operational effectiveness.

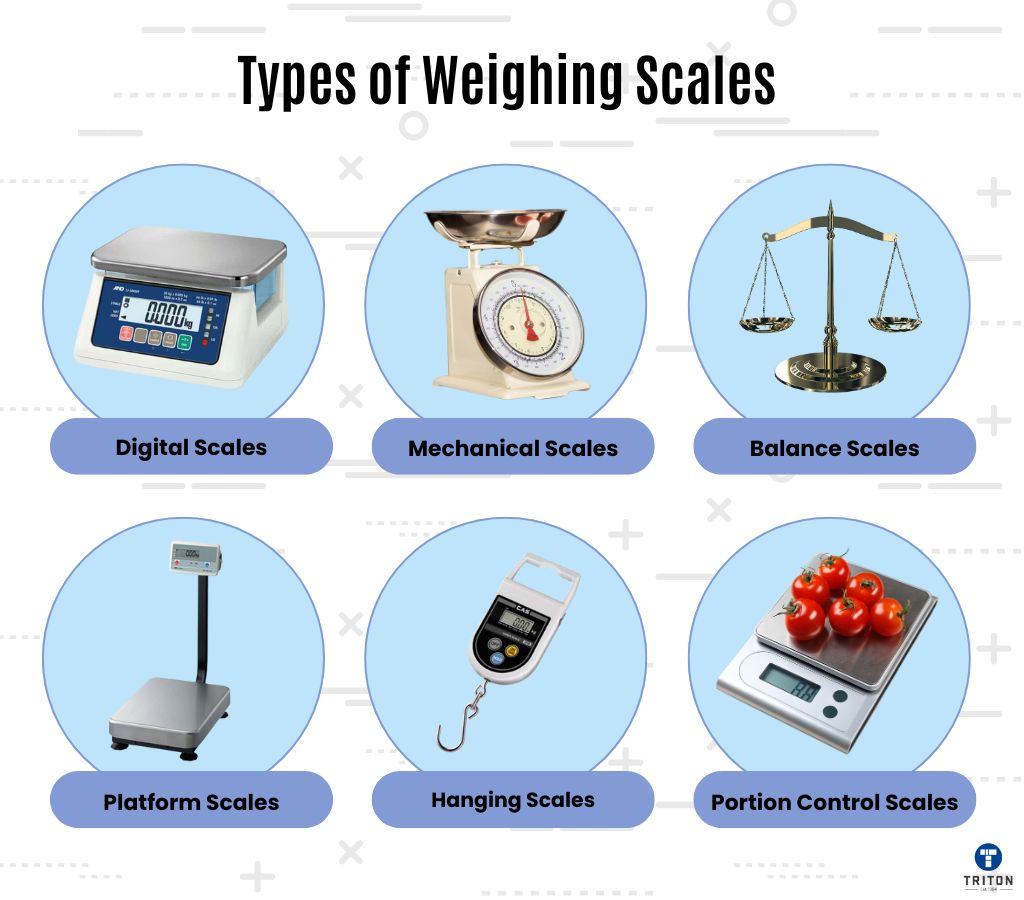

Understanding kinds of weighing scale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electronic Scales | Digital display, high accuracy, often with connectivity options | Warehousing, logistics, retail | Pros: Accurate, easy to use, data integration. Cons: Higher initial cost, requires power. |

| Mechanical Scales | Analog display, no power required, simple design | Agriculture, shipping, manufacturing | Pros: Durable, low maintenance, no power needed. Cons: Less precise, limited features. |

| Floor Scales | Large platform, suitable for heavy items, often mobile | Factories, shipping docks, warehouses | Pros: High capacity, versatile, portable options. Cons: Can be bulky, may need calibration. |

| Counting Scales | Specialized for counting items, often with tare functions | Inventory management, manufacturing | Pros: Increases efficiency, reduces human error. Cons: Limited to counting tasks, may require training. |

| Crane Scales | Suspended design, often with remote displays, high capacity | Shipping, construction, heavy industry | Pros: Ideal for large loads, portable. Cons: Can be expensive, requires safety measures. |

Electronic Scales

Electronic scales are characterized by their digital displays and enhanced accuracy. They often come equipped with features such as data connectivity, allowing for seamless integration with inventory management systems. This type of scale is ideal for businesses in warehousing, logistics, and retail where precision and data tracking are crucial. When purchasing, consider the scale’s weight capacity, battery life, and compatibility with existing systems.

Mechanical Scales

Mechanical scales utilize an analog display and function without electricity, making them a reliable option in environments where power is unstable or unavailable. They are commonly used in agriculture and shipping due to their robust design and low maintenance requirements. However, buyers should be aware that while mechanical scales are durable, they may not provide the same level of precision as electronic options, which could impact operations that require exact measurements.

Floor Scales

Floor scales are designed with large platforms to accommodate heavy items, making them essential in factories and shipping docks. They often come with features like portability and high weight capacities, catering to diverse industrial needs. When selecting a floor scale, consider factors such as space availability, weight limits, and ease of calibration to ensure optimal functionality in your operations.

Counting Scales

Counting scales are specialized devices that streamline the process of counting items, particularly in inventory management and manufacturing. They often include tare functions to enhance accuracy and reduce human error. Businesses should evaluate the scale’s counting speed, accuracy, and ease of use, as these factors can significantly affect operational efficiency and productivity.

Crane Scales

Crane scales are designed for suspending heavy loads, often featuring remote displays for easy reading. They are commonly used in shipping and construction industries where lifting and weighing large items is routine. While crane scales are highly effective for heavy-duty applications, buyers should consider safety features and the total cost of ownership, including maintenance and calibration, to ensure they meet safety and operational standards.

Related Video: Lecture 1 Two compartment models

Key Industrial Applications of kinds of weighing scale

| Industry/Sector | Specific Application of kinds of weighing scale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Production Line Weighing | Ensures accurate ingredient measurement, improving product quality and consistency. | Look for scales with high precision and durability to withstand industrial environments. |

| Logistics and Transportation | Vehicle Weighing Scales | Prevents overloading, ensuring compliance with legal weight limits and enhancing road safety. | Consider portable options for flexibility and ease of use across various locations. |

| Agriculture | Livestock Weighing Scales | Provides accurate weight data for feed optimization and health monitoring of animals. | Ensure scales are robust and suitable for outdoor use, with easy calibration features. |

| Food Processing | Batch Weighing Scales | Facilitates accurate measurement of ingredients, reducing waste and costs. | Seek scales that meet food safety regulations and are easy to clean. |

| Chemical Industry | Hazardous Material Weighing Scales | Ensures safe handling and accurate measurement of hazardous substances, reducing risk. | Look for explosion-proof designs and compliance with safety standards. |

In the manufacturing sector, production line weighing scales are critical for maintaining quality control. These scales help ensure that raw materials are measured accurately, which is essential for product consistency. For international buyers, particularly in regions like Europe and Africa, sourcing scales that are durable and can operate under harsh conditions is vital. Precision and reliability are paramount to prevent costly production errors.

In logistics and transportation, vehicle weighing scales play a significant role in compliance and safety. These scales help businesses avoid penalties associated with overloading vehicles, which can lead to fines and increased maintenance costs. Buyers should consider portable vehicle scales for flexibility, especially in regions with varied transport regulations, such as the Middle East and South America.

For the agriculture industry, livestock weighing scales are essential tools for farmers. They provide accurate weight measurements, which help optimize feed usage and monitor the health of animals. Sourcing scales that are rugged and suitable for outdoor conditions is crucial, especially in developing markets. Buyers should also prioritize ease of calibration to maintain accurate measurements over time.

In the food processing industry, batch weighing scales are utilized to ensure the precise measurement of ingredients, which directly impacts production costs and waste reduction. International B2B buyers should focus on scales that comply with food safety regulations and are easy to clean, particularly in regions with strict food quality standards, such as Europe.

Finally, in the chemical industry, weighing scales designed for hazardous materials are critical for safety and compliance. These scales help businesses manage and measure dangerous substances accurately, minimizing risks associated with handling chemicals. Buyers must prioritize sourcing scales that are explosion-proof and comply with local safety regulations, especially in regions like the Middle East where such measures are vital.

Related Video: DIY IoT Weighing Scale using Load Cell HX711 & ESP8266 for Remote Weight Monitoring | Blynk

Strategic Material Selection Guide for kinds of weighing scale

When selecting materials for weighing scales, international B2B buyers must consider various factors that impact performance, durability, and suitability for specific applications. Below is an analysis of four common materials used in the manufacture of weighing scales, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in diverse regions such as Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. It typically has a temperature rating up to 300°C and can handle pressures well, making it suitable for various industrial environments.

Pros & Cons:

The durability of stainless steel makes it ideal for heavy-duty applications. However, it can be more expensive than other materials and may require specialized manufacturing processes, which can increase lead times. Its aesthetic appeal is a plus for applications where appearance matters.

Impact on Application:

Stainless steel is compatible with a variety of media, including food and chemicals, making it a versatile choice for industries such as food processing and pharmaceuticals.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and DIN for quality assurance. In regions like the UAE, where humidity can be high, stainless steel’s corrosion resistance is particularly advantageous.

Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, with a temperature rating of around 200°C. It is also an excellent conductor of electricity, which can be beneficial for certain electronic scales.

Pros & Cons:

The primary advantage of aluminum is its low weight, making it easier to transport and install. However, it is less durable than stainless steel and can be prone to deformation under heavy loads, which may limit its use in high-capacity applications.

Impact on Application:

Aluminum scales are often used in portable applications or where weight is a critical factor, such as in shipping and logistics.

Considerations for International Buyers:

In markets like South America, where transportation logistics can be challenging, the lightweight nature of aluminum scales can lead to reduced shipping costs. Buyers should also verify that aluminum scales meet local safety and performance standards.

Cast Iron

Key Properties:

Cast iron is known for its exceptional durability and stability, with a high temperature rating that can exceed 500°C. It has good resistance to wear and can handle heavy loads effectively.

Pros & Cons:

The primary advantage of cast iron is its robustness, making it suitable for industrial applications where heavy items are weighed. However, it is heavy and can be prone to rust if not properly coated, which may require additional maintenance.

Impact on Application:

Cast iron scales are often used in manufacturing and heavy industry, where durability and load capacity are paramount.

Considerations for International Buyers:

Buyers in the Middle East should consider the potential for rust in humid environments and may need to look for coated options. Compliance with local standards for industrial equipment is also crucial.

Plastic Composites

Key Properties:

Plastic composites are lightweight and can be engineered to provide specific properties such as chemical resistance and flexibility. They typically have a lower temperature rating than metals, around 100-150°C.

Pros & Cons:

The lightweight nature of plastic composites makes them easy to handle and install, and they are often less expensive than metal options. However, they may not be suitable for high-capacity or high-temperature applications and can be less durable over time.

Impact on Application:

Plastic composites are ideal for applications in laboratories or environments where chemical exposure is a concern, such as in certain manufacturing processes.

Considerations for International Buyers:

In Europe, where regulations around chemical safety are stringent, buyers should ensure that plastic composites meet relevant standards. Additionally, understanding local preferences for materials can influence purchasing decisions.

Summary Table

| Material | Typical Use Case for kinds of weighing scale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Portable applications, shipping | Lightweight and easy to transport | Less durable under heavy loads | Medium |

| Cast Iron | Heavy industrial applications | Exceptional durability | Heavy and prone to rust | Medium |

| Plastic Composites | Laboratories, chemical exposure environments | Lightweight and cost-effective | Limited capacity and durability | Low |

This guide provides valuable insights into material selection for weighing scales, helping international B2B buyers make informed decisions that align with their operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for kinds of weighing scale

The manufacturing and quality assurance processes for weighing scales are crucial for ensuring accuracy, reliability, and compliance with international standards. International B2B buyers, especially those from Africa, South America, the Middle East, and Europe, should be well-informed about these processes to make educated purchasing decisions. This section will cover the key stages of manufacturing, techniques employed, and the quality control measures that are standard in the industry.

Manufacturing Processes

The manufacturing of weighing scales typically involves several key stages:

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Common materials used include stainless steel for its durability and corrosion resistance, aluminum for lighter scales, and high-grade plastics for electronic components. During this stage:

– Material Inspection: Incoming materials are inspected for quality and conformity to specifications.

– Certification: Suppliers often provide material certificates that detail the chemical composition and mechanical properties.

2. Forming

The next stage involves shaping the materials into components. This can include:

– Metal Fabrication: Techniques such as laser cutting, stamping, and CNC machining are used to create precise components.

– Molding: For plastic parts, injection molding is commonly employed to achieve the desired shapes and dimensions.

3. Assembly

Once the components are formed, they are assembled into the final product. This stage includes:

– Electronics Integration: Load cells, displays, and other electronic components are integrated. Precision in this stage is critical as it affects the overall accuracy of the scale.

– Mechanical Assembly: Components are fastened together, ensuring proper alignment and functionality. Automated assembly lines may be utilized to enhance efficiency.

4. Finishing

The final stage involves polishing, painting, or coating the scales to enhance their appearance and protect against environmental factors. This can include:

– Surface Treatments: Processes such as powder coating or anodizing can improve corrosion resistance.

– Final Inspection: Before packaging, a thorough inspection is conducted to ensure that all components function correctly and meet quality standards.

Quality Assurance

Quality assurance in the weighing scale industry is essential to ensure that products meet both customer expectations and regulatory requirements. Here are the key components of quality assurance:

International Standards

Manufacturers often adhere to international standards such as:

– ISO 9001: This standard outlines requirements for a quality management system and is crucial for ensuring consistent quality in manufacturing.

– CE Marking: This indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

Industry-Specific Standards

Certain industries require compliance with additional standards, including:

– API (American Petroleum Institute): For scales used in the petroleum industry, adherence to API standards is essential.

– OIML (International Organization of Legal Metrology): This is crucial for scales used in trade to ensure legal compliance.

Quality Control Checkpoints

Quality control involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials before they enter production.

– In-Process Quality Control (IPQC): Regular checks during manufacturing help identify any issues early in the process.

– Final Quality Control (FQC): The finished product undergoes rigorous testing to ensure it meets all specifications.

Common Testing Methods

Testing methods for weighing scales vary, but commonly include:

– Calibration Testing: Ensuring accuracy by comparing the scale’s readings with standard weights.

– Load Testing: Applying known weights to verify the scale’s performance under various load conditions.

– Environmental Testing: Assessing the scale’s performance in different environmental conditions, such as temperature and humidity variations.

Verifying Supplier Quality Control

International B2B buyers should employ several strategies to verify the quality control measures of potential suppliers:

Supplier Audits

Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and overall operations of suppliers. This includes reviewing documentation and observing practices firsthand.

Quality Control Reports

Requesting detailed reports from suppliers can provide insights into their quality assurance processes. Reports should include data on product testing, compliance with international standards, and any corrective actions taken in case of non-conformance.

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. These firms can conduct inspections at various stages of the manufacturing process, ensuring compliance with standards.

Considerations for International Buyers

When dealing with suppliers from different regions, B2B buyers should be aware of specific nuances in quality control and certification:

– Regional Regulations: Understand the local regulations that may affect the quality standards of the products.

– Language Barriers: Ensure that communication regarding quality standards and specifications is clear, possibly requiring translation or the use of bilingual personnel.

– Cultural Differences: Awareness of cultural differences in business practices can help in negotiations and establishing trust with suppliers.

In summary, understanding the manufacturing processes and quality assurance practices for weighing scales is essential for B2B buyers. By focusing on these aspects, international buyers can ensure they are sourcing reliable, high-quality products that meet their operational needs.

Related Video: Exploring 5 Intriguing Factory Mass Production Processes in China.

Comprehensive Cost and Pricing Analysis for kinds of weighing scale Sourcing

In the B2B marketplace for weighing scales, understanding the cost structure and pricing dynamics is crucial for international buyers, especially those from Africa, South America, the Middle East, and Europe. This analysis breaks down the essential components of cost, identifies factors influencing pricing, and offers actionable tips for buyers to optimize their purchasing decisions.

Cost Components

-

Materials: The choice of materials significantly impacts the cost of weighing scales. High-quality stainless steel or specialized alloys can increase initial costs but may lead to lower maintenance expenses and longer lifespans. Understanding the material’s suitability for specific applications is essential.

-

Labor: Labor costs vary by region and can affect the final pricing of weighing scales. In regions with higher labor costs, such as Western Europe, manufacturers may charge more compared to those in regions like Asia or Eastern Europe.

-

Manufacturing Overhead: This includes expenses related to utilities, rent, and other operational costs incurred during production. Buyers should consider suppliers with efficient manufacturing processes to minimize overhead costs, which can be passed down in pricing.

-

Tooling: Custom scales often require specialized tooling, which can add to upfront costs. It’s vital to factor in these costs when ordering customized solutions.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with international standards. While stringent QC may increase costs, it enhances product quality and reduces the likelihood of returns or failures.

-

Logistics: Shipping and handling costs, including customs duties and tariffs, can vary widely based on the origin and destination of the scales. Buyers should account for these costs in their total budget.

-

Margin: Supplier margins can vary based on market competition and brand reputation. Understanding the average margins in the industry can help buyers assess whether they are receiving a fair price.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to lower per-unit costs. Negotiating for bulk purchase discounts can significantly reduce overall expenditure.

-

Specifications/Customization: Custom features or specifications will often lead to increased costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials and Quality Certifications: Scales that meet specific industry certifications or use premium materials may carry a higher price tag. Ensure that the certifications align with your operational needs to justify the cost.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium but often provide better support and warranty services.

-

Incoterms: Understanding the terms of shipping (like FOB, CIF, etc.) is critical as they determine who is responsible for shipping costs and risks. This knowledge helps in making informed decisions about total costs.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing. Leverage your purchasing power, especially for bulk orders, to negotiate better terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs over the scale’s lifespan. A lower initial price may not always equate to long-term savings.

-

Pricing Nuances: For international buyers, be aware of currency fluctuations and their potential impact on pricing. It’s advisable to secure prices in stable currencies or understand the terms for currency adjustments.

-

Research and Benchmarking: Conduct thorough market research to compare prices and features across different suppliers. This enables you to make informed decisions and identify the best value for your needs.

Disclaimer

Prices can vary significantly based on market conditions, supplier negotiations, and specific buyer requirements. It’s advisable to obtain multiple quotes and conduct due diligence before finalizing any purchase.

Spotlight on Potential kinds of weighing scale Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘kinds of weighing scale’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for kinds of weighing scale

Essential Technical Properties

When selecting weighing scales for industrial applications, understanding the technical specifications is crucial for ensuring the equipment meets operational needs. Below are some key properties to consider:

-

Material Grade

The material grade of a weighing scale significantly affects its durability and performance. Common materials include stainless steel, aluminum, and carbon steel. Stainless steel is preferred in environments exposed to moisture or corrosive substances due to its resistance to rust and wear. For B2B buyers, selecting the right material can impact the scale’s longevity and maintenance costs. -

Capacity

The capacity of a scale refers to the maximum weight it can accurately measure. It’s important to choose a scale with a capacity that exceeds the heaviest item you plan to weigh. Underestimating this can lead to inaccurate measurements and damage to the scale. Buyers should assess their typical loads to ensure proper selection. -

Tolerance

Tolerance defines the permissible deviation from the actual weight measurement. A scale with a low tolerance (high accuracy) is critical in industries where precision is vital, such as pharmaceuticals or food processing. B2B buyers should prioritize scales with tight tolerances to maintain quality control and compliance with industry regulations. -

Resolution

Resolution indicates the smallest weight increment that can be measured by the scale. Higher resolution is essential for applications requiring fine measurements, such as laboratory settings. For buyers, this specification can influence operational efficiency and product quality, particularly in industries where precision is non-negotiable. -

Calibration

Calibration refers to the process of adjusting the scale to ensure accurate measurements. Many scales come with self-calibrating features, while others may require manual calibration. Understanding calibration requirements is essential for maintaining accuracy and compliance with standards, making it a key consideration for B2B buyers. -

Power Source

Weighing scales can be powered by batteries, AC power, or rechargeable sources. The choice of power source can affect portability and operational flexibility. For example, battery-powered scales are ideal for mobile applications, while AC-powered scales are suited for fixed installations. Buyers should evaluate their operational environment to select the most suitable option.

Common Trade Terminology

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the weighing scale industry, OEMs provide components that can be integrated into various scales. Understanding OEM relationships can help buyers ensure they are sourcing high-quality components. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers, as it can affect inventory management and cash flow. Knowing the MOQ helps in planning purchases and negotiating better terms with suppliers. -

RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to suppliers to request pricing and other details for specific products or services. This is an important step in the procurement process, as it allows buyers to compare options and make informed decisions based on pricing and specifications. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized terms that define the responsibilities of buyers and sellers in international transactions. They cover aspects like shipping, insurance, and tariffs. Understanding Incoterms is vital for B2B buyers to clarify costs and responsibilities in cross-border trade. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. This is a critical factor in supply chain management, as it affects inventory levels and production schedules. Buyers should consider lead time when planning their operations to avoid delays. -

Certification

Certification indicates that a product meets specific standards and regulations, often required in industries like food and pharmaceuticals. Understanding certification requirements helps buyers ensure compliance and maintain product integrity.

By grasping these essential properties and terms, B2B buyers can navigate the complexities of purchasing weighing scales more effectively, ensuring that they choose the right equipment for their specific needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the kinds of weighing scale Sector

Global demand for weighing scales is experiencing a robust growth driven by advancements in technology, increased automation in industries, and a greater emphasis on precision and compliance in various sectors. In particular, B2B buyers from Africa, South America, the Middle East, and Europe must be aware of several key trends shaping the market. First, the integration of IoT (Internet of Things) technologies is enabling real-time data collection and analytics, enhancing operational efficiencies. Scales that connect seamlessly with existing systems through APIs are becoming increasingly popular, allowing for better inventory management and supply chain visibility.

Another significant trend is the shift towards digital and automated weighing solutions, which reduces human error and improves accuracy. This is particularly beneficial for industries such as logistics, agriculture, and manufacturing, where precise measurements are crucial. Moreover, the rising demand for portable and versatile scales, capable of handling various environments and conditions, is noteworthy. Buyers should also consider the regional market dynamics, as preferences and regulations vary significantly across continents. For instance, compliance with specific measurement standards in the EU or the Middle East can affect sourcing decisions.

Sustainability & Ethical Sourcing in B2B

As sustainability becomes a priority in global supply chains, the weighing scale sector is not exempt from this trend. The environmental impact of manufacturing processes and materials used in scales is under scrutiny. B2B buyers are increasingly seeking suppliers who demonstrate a commitment to sustainability through the use of eco-friendly materials and production methods. This includes sourcing scales made from recycled materials or those that are energy-efficient in their operation.

Illustrative Image (Source: Google Search)

Ethical sourcing is also crucial. Buyers should prioritize suppliers who maintain transparent supply chains and adhere to fair labor practices. Certifications such as ISO 14001 for environmental management and SA8000 for social accountability can serve as indicators of a supplier’s commitment to sustainability and ethical standards. By choosing suppliers with these certifications, businesses not only support sustainable practices but also enhance their brand reputation and comply with increasingly stringent regulations in various markets.

Brief Evolution/History

The history of weighing scales dates back thousands of years, evolving from simple balance scales used in ancient trade to today’s sophisticated digital and automated systems. Initially, scales were crafted from materials like wood and metal, relying on physical weights for measurement. Over time, technological advancements led to the development of electronic scales, which offered greater precision and ease of use. The introduction of digital displays and connectivity features has further transformed the sector, catering to the needs of modern industries that demand accuracy, efficiency, and integration with digital systems. Today, the evolution continues with innovations in smart technology and sustainability, shaping the future of weighing scales in the B2B marketplace.

Related Video: The Shadow World: Inside the Global Arms Trade

Frequently Asked Questions (FAQs) for B2B Buyers of kinds of weighing scale

-

How can I effectively vet suppliers for weighing scales?

To vet suppliers, start by checking their certifications and compliance with international standards, such as ISO and OIML. Look for reviews and testimonials from other businesses in your region. Engage in direct communication to assess their responsiveness and willingness to provide detailed product information. Additionally, consider visiting their facilities or requesting a video tour to evaluate their manufacturing processes and quality control measures. -

What customization options are typically available for weighing scales?

Many suppliers offer customization options tailored to specific industry needs. This can include modifications in scale size, capacity, and features such as connectivity options (e.g., Wi-Fi, Bluetooth). Discuss your requirements with potential suppliers to understand their capabilities. Ensure that any customization does not compromise the scale’s accuracy or compliance with local regulations. -

What are the typical minimum order quantities (MOQs) and lead times?

MOQs can vary significantly based on the supplier and the type of scale. Generally, industrial scales may require a MOQ of 5 to 20 units, while specialized scales might have higher MOQs. Lead times can range from a few weeks to several months, depending on the complexity of the order and the supplier’s production capacity. Always clarify these details upfront to avoid delays in your procurement process. -

What payment terms should I expect when sourcing weighing scales internationally?

Payment terms can vary, but common practices include a deposit (typically 30-50%) upfront, with the balance paid before shipment. Some suppliers may offer letters of credit or payment through escrow services to secure transactions. Discuss and negotiate terms that work for both parties, and ensure you understand the implications of currency exchange rates, especially when dealing with international transactions. -

What quality assurance measures should I look for in weighing scales?

Ensure the supplier has a robust quality assurance (QA) process, including regular testing of their scales for accuracy and reliability. Request documentation of compliance with international standards and certifications, such as CE marking in Europe or NTEP certification in the US. Additionally, inquire about warranty terms and the supplier’s policy on handling defects or malfunctions post-purchase. -

How can I manage logistics effectively when importing weighing scales?

Work with logistics providers experienced in handling industrial equipment to ensure safe and compliant transportation. Understand the import regulations and tariffs applicable in your country, as these can affect costs and lead times. Properly document all shipments and consider insurance options to protect your investment during transit. -

What steps should I take in case of disputes with suppliers?

In case of a dispute, start by addressing the issue directly with the supplier through clear communication. Document all correspondence and agreements. If the issue remains unresolved, refer to the terms outlined in your contract regarding dispute resolution processes, which may include mediation or arbitration. Consider involving legal counsel familiar with international trade laws if necessary. -

How do I ensure compliance with local regulations when sourcing weighing scales?

Research the specific regulations and standards governing weighing scales in your region, which may include accuracy, calibration, and safety requirements. Engage with local authorities or industry associations to gain insights. Ensure that your supplier can provide documentation proving compliance with these regulations, such as calibration certificates and test reports, to avoid potential legal issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for kinds of weighing scale

In the rapidly evolving landscape of industrial operations, the strategic sourcing of weighing scales emerges as a critical factor for businesses aiming to enhance efficiency and accuracy. By understanding the diverse types of scales available—ranging from industrial floor scales to portable vehicle scales—buyers can make informed decisions that align with their operational needs. The emphasis on cost-effectiveness, precision, and compliance with regional standards cannot be overstated, particularly for businesses in Africa, South America, the Middle East, and Europe.

As international B2B buyers navigate their sourcing strategies, it is essential to consider not only the immediate requirements but also the long-term implications of scale investments. Leveraging advanced technologies, such as IoT connectivity and data integration capabilities, can significantly improve workflow efficiency and data accuracy.

Looking ahead, the demand for innovative and reliable weighing solutions is expected to grow. Buyers are encouraged to proactively engage with suppliers who offer comprehensive support, customization options, and cutting-edge technology. By prioritizing strategic sourcing, businesses can position themselves competitively in their respective markets and ensure sustainable growth. Embrace this opportunity to elevate your operations through informed purchasing decisions in the weighing scale sector.