Master 3 Prong Plug Types for Strategic B2B Sourcing Success

Introduction: Navigating the Global Market for 3 prong plug types

In today’s interconnected global marketplace, understanding the various types of three-prong plugs is crucial for B2B buyers navigating the complexities of international sourcing. These plugs, essential for safely powering a myriad of electrical devices, play a pivotal role in ensuring both user safety and device functionality. With diverse regional specifications and standards, buyers from Africa, South America, the Middle East, and Europe must be well-informed to make strategic procurement decisions.

This comprehensive guide delves into the different types of three-prong plugs, exploring their materials, manufacturing processes, and quality control measures. It covers essential aspects such as supplier selection, cost considerations, and market trends, enabling buyers to assess options effectively. Furthermore, we address common FAQs, demystifying the technicalities and regulatory requirements that can influence purchasing decisions.

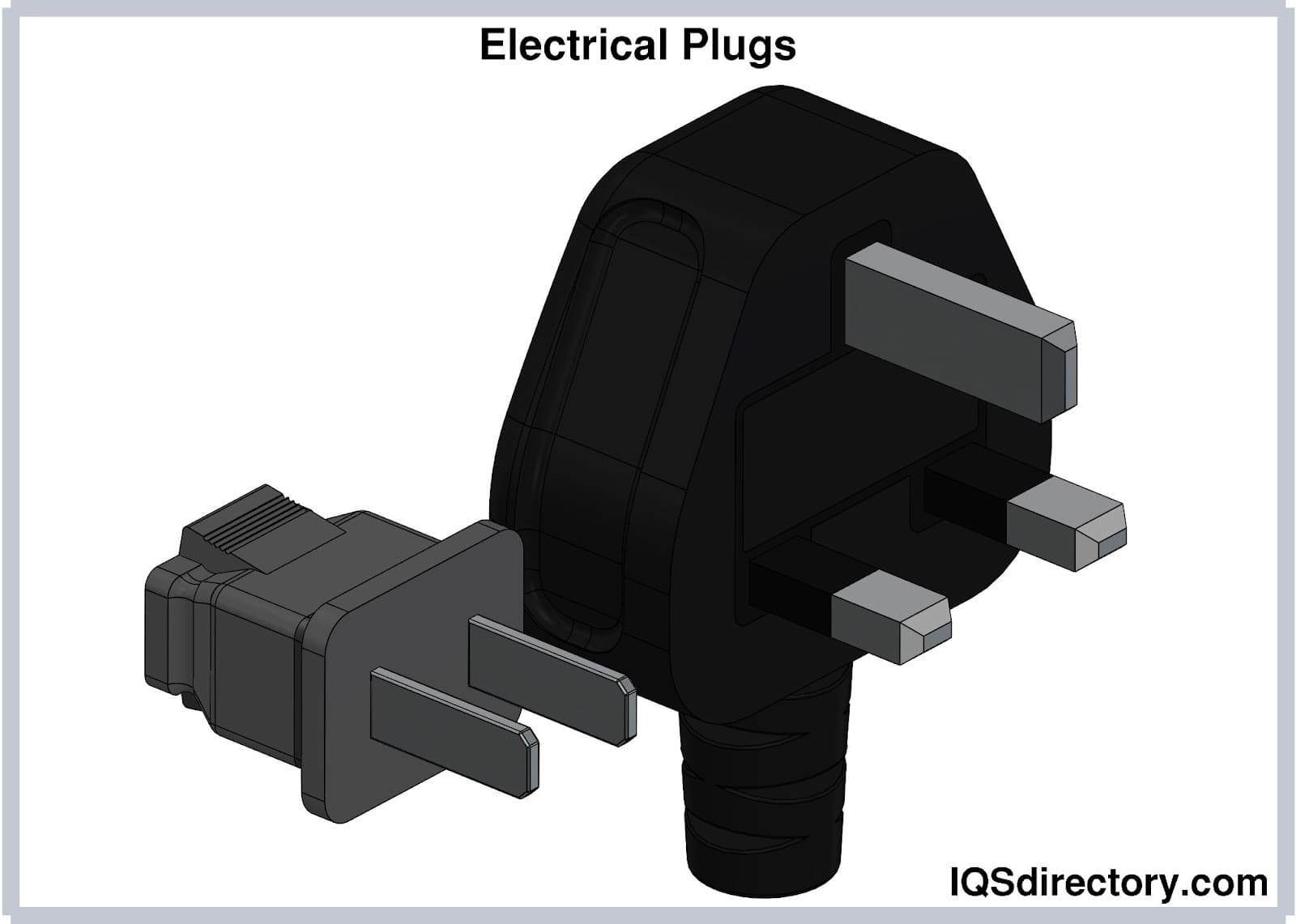

Illustrative Image (Source: Google Search)

By equipping international buyers with critical insights and actionable strategies, this guide empowers them to navigate the global market with confidence. Whether sourcing for large-scale projects or small enterprises, understanding three-prong plug types will facilitate informed decisions that enhance safety and reliability in electrical connections. Embrace the opportunity to optimize your sourcing strategy in this vital component of electrical infrastructure.

Understanding 3 prong plug types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| NEMA 5-15P | Standard North American plug with flat blades | Electronics, appliances, tools | Pros: Widely available, versatile; Cons: Not suitable for high voltage. |

| Type G | Rectangular prongs with a fuse, used in the UK and others | Home appliances, industrial equipment | Pros: High safety standards; Cons: Requires specific sockets. |

| Type I | Flat pins in a V-shape, used mainly in Australia and New Zealand | Power tools, consumer electronics | Pros: Good grounding; Cons: Limited compatibility outside its region. |

| Type C | Two round pins, often used with an adapter for grounding | Small appliances, travel devices | Pros: Compact design; Cons: Lacks grounding without an adapter. |

| Schuko (Type F) | Two round pins with grounding clips | Heavy machinery, electrical appliances | Pros: Excellent grounding; Cons: Bulky design may not fit all outlets. |

NEMA 5-15P

The NEMA 5-15P is a standard three-prong plug commonly used in North America. It features two flat blades and a grounding pin, making it suitable for a wide range of devices including electronics, appliances, and tools. B2B buyers should consider the availability and compatibility of this plug type, as it is prevalent in the U.S. market. It is ideal for general use but may not be suitable for high-voltage applications.

Type G

The Type G plug is characterized by its rectangular prongs and a built-in fuse, commonly found in the UK and several other countries. It is primarily used in home appliances and industrial equipment. For B2B buyers, the key consideration is the safety and reliability it offers, thanks to its fuse. However, its requirement for specific sockets may limit its versatility in international settings.

Type I

This plug type features flat pins arranged in a V-shape and is predominantly used in Australia and New Zealand. It is suitable for power tools and consumer electronics, providing good grounding for safety. B2B buyers should evaluate their target markets when sourcing devices with Type I plugs, as compatibility may be an issue in regions where this plug is not standard.

Type C

Known for its two round pins, the Type C plug is often used in small appliances and travel devices. It is compact and versatile but lacks grounding unless paired with an adapter. B2B buyers should consider the need for grounding in their applications, as this may affect safety compliance. This plug is frequently used in Europe and can be easily adapted for various devices.

Schuko (Type F)

The Schuko plug features two round pins with grounding clips and is widely used across Europe for heavy machinery and electrical appliances. Its design ensures excellent grounding, making it a safe choice for high-power devices. B2B buyers should be aware of its bulkiness, which may not fit all outlet designs, and consider the specific requirements of their equipment when selecting this plug type.

Related Video: ⚡⚡⚡ 3-Prong Electrical Plug Replacement! (Male End)

Key Industrial Applications of 3 prong plug types

| Industry/Sector | Specific Application of 3 Prong Plug Types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering heavy machinery and tools | Enhanced safety through grounding; reduced risk of electrical shocks | Compliance with local electrical standards; durability for heavy use |

| Healthcare | Medical devices and equipment | Ensures patient safety by preventing electrical hazards | Certification and compliance with medical regulations; reliability in critical environments |

| Construction | Use in power tools and temporary site installations | Reliable power supply for tools; improved efficiency on job sites | Weather resistance; compatibility with local power systems |

| Hospitality | Appliances in hotels and restaurants | Safe operation of kitchen and cleaning equipment; customer safety | Adherence to international safety standards; sourcing from reputable suppliers |

| Information Technology | Computers and networking equipment | Protects sensitive devices from electrical surges; enhances operational reliability | Compatibility with various voltage systems; availability of adapters for different regions |

Manufacturing

In the manufacturing sector, 3 prong plugs are essential for powering heavy machinery and tools. These plugs provide a secure and grounded connection, which is critical for preventing electrical shocks and ensuring worker safety. Buyers in this industry must ensure that the plugs comply with local electrical standards and are durable enough to withstand the rigors of heavy use. Additionally, sourcing from reputable suppliers can guarantee the quality and reliability needed for continuous operations.

Healthcare

In healthcare settings, 3 prong plugs are crucial for medical devices and equipment, such as imaging machines and life-support systems. The grounding feature of these plugs is vital for patient safety, as it minimizes the risk of electrical hazards that could lead to serious injuries. B2B buyers in this sector should prioritize sourcing plugs that meet stringent medical regulations and certifications, ensuring reliability in critical environments where equipment failure is not an option.

Construction

The construction industry frequently utilizes 3 prong plugs for powering tools and equipment at job sites. These plugs provide a reliable power supply, which is essential for maintaining productivity and efficiency. Buyers should consider sourcing plugs that are weather-resistant and compatible with local power systems, as construction environments can be unpredictable. Ensuring that the plugs can withstand outdoor conditions is crucial for maintaining a safe and effective worksite.

Hospitality

In the hospitality sector, 3 prong plugs are commonly used for various appliances in hotels and restaurants, including kitchen equipment and cleaning devices. These plugs enhance safety by preventing electrical malfunctions that could endanger customers and staff. B2B buyers should focus on sourcing plugs that adhere to international safety standards, ensuring that all electrical installations are safe and compliant. Partnering with reputable suppliers can also help mitigate risks associated with faulty equipment.

Information Technology

Within the information technology sector, 3 prong plugs are integral for connecting computers and networking equipment. These plugs protect sensitive devices from electrical surges, thereby enhancing operational reliability and reducing downtime. Buyers should ensure compatibility with various voltage systems, especially when sourcing equipment for international use. Additionally, the availability of adapters for different regions can be a key consideration for B2B buyers operating across multiple countries.

Related Video: #10 HOW TO Connect the three phases CEE plug

Strategic Material Selection Guide for 3 prong plug types

When selecting materials for three-prong plugs, understanding the properties, advantages, and limitations of each option is crucial for ensuring safety, performance, and compliance with international standards. Below is an analysis of four common materials used in the manufacturing of three-prong plugs, tailored for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

1. Polyvinyl Chloride (PVC)

Key Properties: PVC is a versatile thermoplastic known for its excellent electrical insulation properties. It has a temperature rating of up to 60°C and is resistant to moisture and chemicals, making it suitable for various environments.

Pros & Cons: PVC is cost-effective and easy to mold, which simplifies the manufacturing process. However, it is less durable than other materials and can become brittle over time, especially when exposed to UV light. This brittleness may limit its suitability for outdoor applications.

Impact on Application: PVC is compatible with a wide range of electrical devices, but its limitations in high-temperature environments may restrict its use in appliances that generate significant heat.

Considerations for International Buyers: Buyers should ensure that PVC plugs comply with relevant safety standards, such as IEC 60884-1. In regions with high UV exposure, alternatives may be preferred to enhance durability.

2. Thermoplastic Elastomer (TPE)

Key Properties: TPE combines the properties of rubber and plastic, offering flexibility and resilience. It can withstand temperatures ranging from -40°C to 100°C, making it suitable for various climates.

Pros & Cons: TPE is highly durable and resistant to wear and tear, which enhances the lifespan of plugs. However, the manufacturing process can be more complex and costly compared to PVC, impacting overall production costs.

Impact on Application: TPE is ideal for applications requiring flexibility, such as in portable devices. Its high resistance to environmental factors makes it suitable for both indoor and outdoor use.

Considerations for International Buyers: Buyers should verify compliance with international standards like ASTM D624 for rubber materials. The higher cost may be justified by the improved performance in demanding environments.

3. Nylon

Key Properties: Nylon is a strong, lightweight thermoplastic with excellent mechanical properties. It has a high-temperature rating (up to 120°C) and is resistant to abrasion and chemicals.

Pros & Cons: The durability of nylon makes it suitable for heavy-duty applications. However, its higher cost and manufacturing complexity can be a barrier for some manufacturers.

Impact on Application: Nylon is particularly effective in industrial settings where plugs may experience significant stress or exposure to harsh chemicals. Its strength and thermal resistance make it suitable for heavy machinery and appliances.

Considerations for International Buyers: Ensure that nylon plugs meet relevant standards such as ISO 9001 for quality management. The investment in nylon may be worthwhile for applications requiring long-term reliability.

4. Metal (Copper/Brass)

Key Properties: Metals like copper and brass are excellent conductors of electricity and have high corrosion resistance. They can withstand high temperatures and mechanical stress.

Pros & Cons: Metal plugs offer superior conductivity and durability. However, they are heavier and more expensive than plastic alternatives, which may limit their use in lightweight applications.

Impact on Application: Metal plugs are ideal for high-power applications, such as industrial machines and electrical equipment. Their robustness ensures reliable performance in demanding conditions.

Considerations for International Buyers: Buyers must ensure compliance with standards like ASTM B16 for brass and IEC 60309 for industrial connectors. The higher cost may be justified by the enhanced performance and safety in critical applications.

Summary Table

| Material | Typical Use Case for 3 prong plug types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Household appliances, indoor use | Cost-effective and easy to mold | Less durable, can become brittle | Low |

| Thermoplastic Elastomer (TPE) | Portable devices, outdoor use | Highly durable and flexible | Higher manufacturing complexity | Med |

| Nylon | Industrial machines, heavy-duty applications | Excellent strength and thermal resistance | Higher cost and complexity | High |

| Metal (Copper/Brass) | High-power industrial equipment | Superior conductivity and durability | Heavier and more expensive | High |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions regarding the materials used for three-prong plugs, ensuring safety, performance, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 3 prong plug types

Manufacturing Processes for 3 Prong Plug Types

The manufacturing of three-prong plugs involves several critical stages that ensure the safety, reliability, and functionality of the final product. Understanding these processes can aid international B2B buyers in making informed decisions when sourcing from suppliers.

Material Preparation

The first step in manufacturing three-prong plugs is the selection and preparation of materials. Typically, high-quality thermoplastics are used for the plug casing, while copper or brass is preferred for the prongs due to their excellent conductivity and resistance to corrosion.

- Material Sourcing: Ensure that suppliers use materials compliant with international standards, such as RoHS (Restriction of Hazardous Substances), which restricts the use of specific hazardous materials in electrical and electronic products.

- Pre-processing: Materials undergo a series of tests to verify their quality, including mechanical strength and thermal resistance. This step is crucial for ensuring long-term durability.

Forming

Once the materials are prepared, the forming stage begins. This involves shaping the plastic casing and prongs into their final forms.

- Injection Molding: This is the most common technique for creating the plastic casing. It involves injecting molten plastic into a mold and allowing it to cool and harden.

- Metal Stamping: The prongs are often produced through metal stamping, where metal sheets are cut and shaped under high pressure to form the desired prong configuration.

Assembly

After the individual components are formed, the next step is assembly. This stage combines the plastic casing and metal prongs into a single unit.

- Automated Assembly Lines: Many manufacturers utilize automated systems for efficiency and precision. Automated processes reduce human error and improve production speed.

- Manual Assembly: In some cases, especially for high-end or custom plugs, manual assembly may be employed. This allows for more flexibility in configurations and quality checks.

Finishing

The finishing stage is critical for ensuring that the plugs meet aesthetic and functional standards.

- Surface Treatment: Components may undergo surface treatments, such as plating, to enhance corrosion resistance and improve conductivity.

- Quality Marking: Plugs are often marked with certification logos (e.g., CE, UL) to indicate compliance with safety and performance standards.

Quality Assurance in Manufacturing

Quality assurance (QA) is vital in the manufacturing of three-prong plugs to ensure safety and reliability. This involves several international standards and industry-specific certifications.

International Standards

- ISO 9001: This quality management standard ensures that manufacturers follow consistent processes to meet customer and regulatory requirements.

- IEC 60884: This standard specifically addresses the safety requirements for plugs and socket-outlets for household and similar purposes.

Industry-Specific Certifications

- CE Marking: Required for products sold within the European Economic Area, the CE mark indicates compliance with health, safety, and environmental protection standards.

- UL Certification: Particularly relevant for the North American market, UL certification ensures that the product meets specific safety standards.

Quality Control Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections are performed at various stages of production to catch defects early.

- Final Quality Control (FQC): The finished products undergo rigorous testing to verify they meet all applicable standards before packaging and shipment.

Illustrative Image (Source: Google Search)

Common Testing Methods

Testing methods for three-prong plugs include:

- Electrical Testing: Ensures that the plug functions correctly under various loads and conditions.

- Mechanical Testing: Assesses durability through stress tests, including pulling and twisting.

- Thermal Testing: Evaluates the product’s performance under high-temperature conditions to prevent overheating.

Verifying Supplier Quality Control

For international B2B buyers, verifying the quality control processes of suppliers is essential. Here are actionable strategies:

- Supplier Audits: Conduct on-site audits to evaluate the manufacturing processes, QA systems, and compliance with international standards.

- Request Quality Reports: Suppliers should provide documentation of their quality control processes, including testing results and certifications.

- Third-Party Inspections: Engage independent inspection agencies to verify that products meet the required standards before shipment. This is particularly useful for buyers in regions like Africa and South America, where local regulations may vary.

Quality Control Considerations for International Buyers

When sourcing three-prong plugs, buyers from Africa, South America, the Middle East, and Europe should consider the following:

- Regulatory Compliance: Ensure that the plugs meet the specific electrical standards of the target market. For instance, European buyers should focus on CE certification, while Middle Eastern buyers might prioritize compliance with GSO standards.

- Cultural and Regional Variations: Be aware of regional differences in electrical systems and standards, as this may affect product compatibility.

- Logistics and Supply Chain: Assess the supplier’s ability to manage logistics effectively, ensuring timely delivery while maintaining quality throughout the shipping process.

By understanding the manufacturing processes and quality assurance measures for three-prong plugs, international B2B buyers can make informed decisions, ensuring they source reliable and safe electrical components for their needs.

Related Video: Manufacturing System, Mass Production, Batch Production, Job shop, Project, Operations Management

Comprehensive Cost and Pricing Analysis for 3 prong plug types Sourcing

When sourcing three-prong plugs, understanding the comprehensive cost structure and pricing is crucial for B2B buyers. The cost of these plugs can be broken down into several key components:

Cost Components

-

Materials: The primary materials used in three-prong plugs include high-quality plastics for insulation and metals like copper for the prongs. The choice of materials significantly impacts the overall cost; for instance, using high-grade copper can enhance conductivity but may increase expenses.

-

Labor: Labor costs vary by region and supplier. In countries with lower labor costs, such as some in South America and Africa, manufacturers can offer competitive pricing. However, skilled labor is necessary for quality assurance and production efficiency, which can drive up costs in regions with higher labor standards.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Overhead can fluctuate based on the location of the manufacturing facility and the efficiency of production processes.

-

Tooling: Initial tooling costs for molds and specialized machinery can be substantial, especially for custom designs. Buyers should consider these costs when evaluating suppliers, as they often impact the pricing structure.

-

Quality Control (QC): Implementing robust QC processes ensures the safety and reliability of the plugs, which is vital for compliance with international standards. The cost of QC can be a significant factor, especially for buyers in Europe and the Middle East, where regulatory requirements are stringent.

-

Logistics: Shipping and handling costs are influenced by the mode of transport, distance, and import/export tariffs. International buyers must factor in these costs, as they can substantially impact the total price.

-

Margin: Supplier margins vary widely based on their operational efficiency and market positioning. Understanding the expected profit margins can help buyers negotiate better pricing.

Price Influencers

Several factors influence the pricing of three-prong plugs, including:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders typically yield lower per-unit costs, making bulk purchasing advantageous for buyers.

-

Specifications/Customization: Custom designs or specific technical requirements can increase costs. Buyers should weigh the benefits of customization against potential price hikes.

-

Quality/Certifications: Products with international safety certifications (like CE or UL) may carry higher price tags due to the rigorous testing involved. Buyers should prioritize quality to avoid future liabilities.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a track record of quality may charge more but can provide peace of mind regarding product safety and consistency.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) agreed upon in contracts is essential. They define responsibilities regarding shipping, insurance, and tariffs, which can affect total costs.

Buyer Tips

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, the following strategies can enhance cost efficiency:

-

Negotiate: Always negotiate pricing, especially on larger orders. Suppliers may have flexibility in pricing based on order size or payment terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also installation, maintenance, and potential failure costs. A slightly higher initial investment in quality plugs can save money long-term.

-

Understand Pricing Nuances: Be aware of regional pricing differences and currency fluctuations. Buyers from Europe may encounter different pricing structures compared to those in Africa or South America, so it’s essential to conduct market research.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and terms. Regular communication can also facilitate smoother negotiations and understanding of market trends.

Disclaimer

Prices for three-prong plugs can vary widely based on the factors mentioned above. The information provided here is indicative and should be verified with specific suppliers to obtain accurate quotes and terms.

Spotlight on Potential 3 prong plug types Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘3 prong plug types’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for 3 prong plug types

Key Technical Properties of 3 Prong Plug Types

When selecting three-prong plugs for electrical devices, several technical properties are crucial for ensuring safety, compliance, and performance. Here are some critical specifications:

-

Material Grade

The materials used for the prongs and casing significantly impact durability and conductivity. Common materials include brass for prongs due to its excellent conductivity and thermoplastic for insulation, which provides heat resistance. Buyers should prioritize plugs made from high-grade materials to ensure longevity and safety in high-demand environments. -

Current Rating

This specification indicates the maximum current that the plug can safely handle, typically measured in amperes (A). Common ratings include 10A, 15A, and 20A. Understanding the current rating is essential for B2B buyers to match plugs with the power requirements of their devices, preventing overheating and electrical failures. -

Voltage Rating

Voltage rating indicates the maximum voltage the plug can handle, often expressed in volts (V). Standard ratings are 110-250V, depending on the region. Selecting plugs with appropriate voltage ratings is critical to ensure compatibility with local electrical systems and to comply with safety regulations. -

Tolerance

Tolerance refers to the acceptable deviation from specified measurements. For plugs, tolerances can affect how well the plug fits into sockets and how securely it connects. Manufacturers often list tolerances in millimeters (mm), and tighter tolerances can lead to improved safety and performance by reducing the risk of electrical arcing. -

Environmental Ratings

Some plugs are designed for specific environments, such as wet or outdoor conditions. Look for plugs with IP ratings (Ingress Protection) that indicate their resistance to dust and moisture. Understanding environmental ratings helps buyers choose suitable plugs for specific applications, enhancing safety and performance.

Common Trade Terms in 3 Prong Plug Transactions

Familiarity with trade terminology is vital for B2B buyers to navigate procurement processes effectively. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in another company’s end products. Understanding OEM relationships can help buyers identify reliable suppliers of three-prong plugs that meet their specific requirements. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers, especially when sourcing plugs in bulk, as it affects pricing and inventory management. Buyers should negotiate MOQs to align with their demand while minimizing excess stock. -

RFQ (Request for Quotation)

An RFQ is a standard business process to invite suppliers to bid on specific products or services. For buyers of three-prong plugs, issuing an RFQ allows them to gather pricing, specifications, and delivery terms from multiple suppliers, enabling informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers to understand shipping responsibilities, risk transfer, and cost allocation when procuring plugs from overseas suppliers. -

Certification Standards

Certification standards, such as UL (Underwriters Laboratories) or CE (Conformité Européenne), indicate that a product meets specific safety and performance criteria. Buyers should seek plugs that comply with relevant certification standards to ensure safety and legal compliance in their markets.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when procuring three-prong plugs, ensuring compatibility, safety, and compliance across various applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 3 prong plug types Sector

Market Overview & Key Trends

The global market for three-prong plugs is witnessing significant growth, driven by increasing demand for electrical safety and standardization across regions. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are navigating a landscape shaped by technological advancements and regulatory changes. Key trends include the integration of smart technology into electrical devices, which requires robust and reliable connections, thus increasing the need for three-prong plugs.

Emerging markets are particularly influential, as urbanization and economic development lead to greater infrastructure investments. Countries in Africa and South America are enhancing their electrical grids, which opens opportunities for sourcing high-quality electrical components, including three-prong plugs. Additionally, the rise of e-commerce and digital supply chains is transforming traditional procurement processes, allowing international buyers easier access to a diverse range of suppliers.

Sourcing strategies are also evolving, with buyers increasingly favoring suppliers that can offer customization options to meet specific regional standards. For instance, plugs used in Europe may need to comply with stricter safety regulations compared to those in other regions. Therefore, understanding local compliance requirements is essential for B2B buyers looking to mitigate risks associated with non-compliance.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of procurement strategies in the three-prong plug sector. The environmental impact of electrical components, from production to disposal, is under scrutiny. B2B buyers are increasingly prioritizing suppliers who demonstrate commitment to sustainable practices, including the use of eco-friendly materials and energy-efficient manufacturing processes.

The importance of ethical supply chains cannot be overstated. Buyers are encouraged to engage with suppliers who uphold fair labor practices and demonstrate transparency in their sourcing methods. Certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) are critical for verifying the sustainability claims of suppliers.

Furthermore, the adoption of recyclable materials in the production of three-prong plugs is gaining traction. Buyers can look for products made from recycled plastics or bio-based materials that contribute to reducing environmental footprints. By prioritizing sustainability and ethical sourcing, B2B buyers not only align with global trends but also enhance their brand reputation and customer loyalty.

Brief Evolution/History

The three-prong plug has evolved significantly since its inception in the early 20th century. Originally designed to improve safety in electrical connections, the three-prong configuration provided a grounding mechanism that was absent in two-prong designs. As electrical appliances became more complex, the necessity for grounding became paramount, leading to widespread adoption across various regions.

In recent decades, innovations in materials and design have further enhanced the functionality and safety of three-prong plugs. The emergence of smart technology has also prompted the development of smart plugs that integrate seamlessly with home automation systems. Understanding this evolution is crucial for B2B buyers as it highlights the importance of sourcing updated and compliant electrical components that meet modern safety and technological standards.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of 3 prong plug types

-

What factors should I consider when vetting suppliers of 3 prong plugs?

When vetting suppliers for 3 prong plugs, prioritize their certifications and compliance with international safety standards, such as IEC, UL, or CE. Evaluate their production capabilities, including machinery and technology used. Request samples to assess quality and inspect their facilities if possible. Additionally, consider their reputation by checking references and customer reviews. A supplier with a solid track record in your region can also facilitate smoother communication and logistics. -

Can I customize 3 prong plugs to meet specific requirements?

Yes, many manufacturers offer customization options for 3 prong plugs, including variations in prong size, material, and color. Customization can also extend to branding, such as adding your logo or specific packaging requirements. When discussing customization, clearly outline your needs and confirm that the supplier can meet safety and compliance standards. Be aware that custom orders may have higher minimum order quantities (MOQs) and longer lead times. -

What are typical MOQs and lead times for ordering 3 prong plugs?

Minimum Order Quantities (MOQs) for 3 prong plugs can vary significantly based on the supplier and the complexity of your order. Generally, MOQs can range from 1,000 to 10,000 units. Lead times also depend on the supplier’s production capacity and your order specifications, typically ranging from 4 to 12 weeks. When placing an order, confirm the exact MOQ and lead times to ensure they align with your project timelines. -

What payment options are commonly accepted by suppliers of 3 prong plugs?

Most suppliers accept a range of payment methods, including bank transfers, letters of credit, and online payment platforms like PayPal. For larger orders, a deposit (often 30%) is common, with the balance due before shipment. Always ensure that payment terms are clearly defined in your contract. Additionally, consider using secure payment methods to protect against potential fraud, especially when dealing with new suppliers. -

How can I ensure quality assurance and compliance with international standards?

To ensure quality assurance, request documentation of the supplier’s certifications, such as ISO 9001 or other relevant industry standards. Discuss their quality control processes, including testing procedures for electrical safety and durability. It may also be beneficial to conduct third-party inspections before shipment. Ensure that the products comply with the specific regulations applicable in your target market, which can differ by country. -

What logistics considerations should I keep in mind when sourcing 3 prong plugs?

Logistics is crucial when sourcing 3 prong plugs. Assess the supplier’s ability to handle shipping, including freight options, delivery times, and costs. Understand the customs regulations in your country to avoid delays and unexpected charges. Additionally, consider whether the supplier offers assistance with logistics, such as arranging shipping or providing documentation for customs clearance. -

How can I resolve disputes with suppliers regarding 3 prong plugs?

To resolve disputes effectively, first, try to address the issue directly with the supplier through open communication. Clearly document all correspondence and agreements. If informal discussions do not lead to a resolution, refer to the terms outlined in your contract, which should specify dispute resolution procedures, including arbitration or mediation. Engaging legal counsel familiar with international trade can also be beneficial if disputes escalate. -

What are the common safety certifications I should look for in 3 prong plugs?

When sourcing 3 prong plugs, look for safety certifications such as UL (Underwriters Laboratories), CE (Conformité Européenne), and IEC (International Electrotechnical Commission) standards. These certifications indicate that the plugs have been tested for safety and performance. Depending on your region, additional certifications may be required, such as SABS in South Africa or INMETRO in Brazil. Ensuring compliance with local regulations is vital to avoid legal issues and ensure user safety.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 3 prong plug types

The growing global demand for three-prong plugs underscores the importance of strategic sourcing for international B2B buyers. Understanding the nuances of different plug types, their safety features, and regional compatibility is essential for making informed purchasing decisions. As buyers from Africa, South America, the Middle East, and Europe navigate the complexities of sourcing, prioritizing suppliers that emphasize quality, compliance with international standards, and reliable customer service can significantly enhance operational efficiency.

Key Takeaways:

- Safety and Compliance: Always ensure that products meet local safety regulations to prevent liabilities and ensure user safety.

- Versatility in Sourcing: Leverage the use of adapters for compatibility with various socket types, enhancing product utility in diverse markets.

- Supplier Relationships: Build strong partnerships with reliable suppliers who can provide consistent quality and support for troubleshooting.

As we look ahead, the evolution of electrical standards and the increasing integration of smart technologies present exciting opportunities for innovation in the plug market. B2B buyers are encouraged to stay informed and adaptable, ensuring they source products that meet both current and future market needs. Engage with trusted suppliers and invest in quality products to secure a competitive edge in your operations.