Master the Types of DC Electric Motors for Optimal B2B

Introduction: Navigating the Global Market for types of dc electric motors

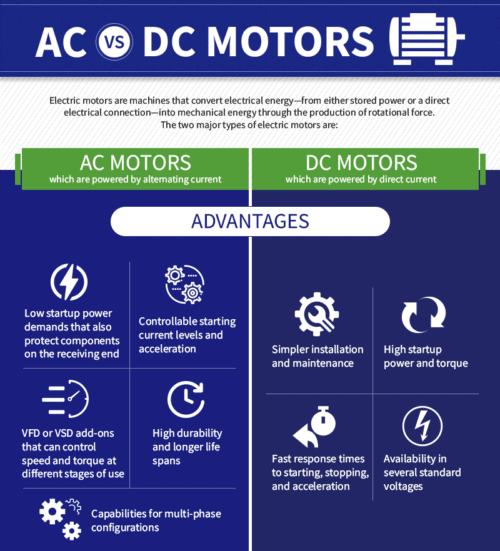

Electric motors, particularly DC motors, are pivotal in driving innovation and efficiency across various industries, from manufacturing to agriculture. For B2B buyers, understanding the different types of DC electric motors—such as separately excited, shunt-wound, and compound-wound motors—is crucial for optimizing operational performance and cost-effectiveness. Each motor type offers unique advantages and applications, making informed selection essential for maximizing productivity.

This comprehensive guide serves as a vital resource for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. It delves into the various types of DC electric motors, providing detailed insights into materials, manufacturing processes, and quality control standards. Buyers will gain a deeper understanding of how to evaluate suppliers, manage procurement costs, and navigate the complexities of international sourcing.

Moreover, the guide addresses common frequently asked questions that arise during the purchasing process, ensuring that buyers are equipped with practical knowledge to make sound decisions. By leveraging this guide, organizations can enhance their procurement strategies, align their motor selections with local regulations, and ultimately drive competitive advantages in their respective markets. In an era where operational efficiency is paramount, understanding the nuances of DC electric motors is not just beneficial—it’s essential.

Understanding types of dc electric motors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Separately Excited DC Motor | Independent power supply for field and armature windings | Elevators, cranes, and heavy machinery | Pros: Precise speed control; Cons: Requires complex control systems. |

| Permanent Magnet DC Motor | Uses permanent magnets for field excitation | Robotics, electric vehicles, and small appliances | Pros: Simple design, high efficiency; Cons: Limited torque at high speeds. |

| Series Wound DC Motor | Field winding in series with armature; high starting torque | Traction applications, electric trains | Pros: Excellent starting torque; Cons: Speed regulation challenges. |

| Shunt Wound DC Motor | Field winding in parallel with armature; stable speed control | Industrial equipment, fans, and pumps | Pros: Consistent speed; Cons: Lower starting torque. |

| Compound Wound DC Motor | Combination of series and shunt; versatile performance | Heavy-duty applications, conveyor systems | Pros: Good starting torque and speed regulation; Cons: More complex and costly. |

Separately Excited DC Motor

Separately excited DC motors feature independent power supplies for both the field and armature windings, allowing for precise control over speed and torque. This makes them ideal for applications such as elevators and cranes, where performance and reliability are critical. Buyers should consider the complexity of the control systems required, as well as the need for skilled technicians for installation and maintenance.

Permanent Magnet DC Motor

Permanent magnet DC motors utilize permanent magnets for field excitation, resulting in a compact and efficient design. They are commonly used in robotics, electric vehicles, and small appliances due to their simplicity and high efficiency. However, buyers should be aware that while these motors provide excellent performance at low speeds, they may struggle with torque at higher speeds, necessitating careful application evaluation.

Series Wound DC Motor

Series wound DC motors have their field winding connected in series with the armature, providing high starting torque, making them suitable for traction applications like electric trains. While they excel in initial torque, buyers must consider the challenges of speed regulation, as these motors can run at dangerously high speeds under no-load conditions. This makes them less ideal for applications requiring precise speed control.

Shunt Wound DC Motor

Shunt wound DC motors connect the field winding in parallel with the armature, allowing for stable speed control across various loads. They are widely used in industrial equipment, fans, and pumps, where consistent performance is essential. Buyers should note the lower starting torque compared to series motors, which may require additional considerations in applications with heavy starting loads.

Compound Wound DC Motor

Compound wound DC motors combine both series and shunt winding configurations, offering a balance of good starting torque and speed regulation. This versatility makes them suitable for heavy-duty applications like conveyor systems. However, buyers should be aware of the increased complexity and cost associated with these motors, alongside the need for proper maintenance to ensure optimal performance.

Related Video: Types Of Electric Motors – DC | AC | Synchronous | Brushless | Brushed | Stepper | Servo

Key Industrial Applications of types of dc electric motors

| Industry/Sector | Specific Application of types of dc electric motors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Automated irrigation systems using shunt-wound DC motors | Enhances efficiency in water distribution, reducing labor costs and water waste | Ensure compatibility with local voltage standards and availability of service support |

| Manufacturing | Conveyor systems powered by permanent magnet DC motors | Increases production speed and reliability, minimizing downtime | Assess the motor’s torque requirements and sourcing of spare parts |

| Automotive | Electric vehicle drivetrains utilizing brushless DC motors | High efficiency and reduced maintenance, leading to lower operational costs | Evaluate the availability of electronic controllers and local technician expertise |

| Robotics | Precision motion control in robotic arms using servo motors | Enables high accuracy and repeatability in manufacturing processes | Consider the complexity of integration and the need for specialized programming support |

| Mining and Heavy Industry | Hoisting and winching systems employing series-wound DC motors | Provides robust power for heavy lifting, enhancing operational safety | Focus on durability, resistance to harsh environments, and compliance with local regulations |

Agriculture

In the agricultural sector, shunt-wound DC motors are commonly used in automated irrigation systems. These motors facilitate precise control of water flow, ensuring crops receive optimal hydration while minimizing waste. B2B buyers should prioritize sourcing motors that can withstand varying voltage levels typical in rural areas and ensure local availability of maintenance services. The integration of these motors can lead to significant labor savings and improved yield.

Manufacturing

Permanent magnet DC motors are integral to conveyor systems in manufacturing. Their design allows for high torque at low speeds, which is essential for transporting goods efficiently along production lines. For international buyers, sourcing considerations should include assessing the motor’s torque requirements to match specific applications and ensuring that spare parts are readily available to minimize downtime. This efficiency can lead to enhanced productivity and lower operational costs.

Automotive

In the automotive industry, brushless DC motors are pivotal for electric vehicle drivetrains. Their electronic commutation results in high efficiency and reduced maintenance needs, which are crucial for long-term operational savings. Buyers should evaluate the availability of compatible electronic controllers and ensure that local technicians possess the necessary skills for installation and maintenance. This focus on reliability and efficiency is vital in the competitive automotive market.

Robotics

Servo motors are essential in robotics, particularly for precision motion control in robotic arms. These motors provide closed-loop feedback, ensuring high accuracy and repeatability in manufacturing processes. Buyers in this sector must consider the complexity of integrating servo motors into existing systems and the potential need for specialized programming support. The ability to automate tasks with high precision can significantly enhance production capabilities.

Mining and Heavy Industry

In mining and heavy industry, series-wound DC motors are commonly employed in hoisting and winching systems. Their robust design offers the necessary power for heavy lifting, which is critical for operational safety. When sourcing these motors, buyers should focus on durability and resistance to harsh environmental conditions. Compliance with local regulations is also a key consideration, ensuring that operations remain safe and efficient in challenging environments.

Related Video: Types of DC Motors – Classification of DC Motors – Motor Types

Strategic Material Selection Guide for types of dc electric motors

When selecting materials for DC electric motors, it is crucial for B2B buyers to understand how different materials impact performance, durability, and cost. Below, we analyze four common materials used in the construction of various types of DC motors, focusing on their properties, advantages, limitations, and considerations for international buyers.

Copper

Key Properties:

Copper is renowned for its excellent electrical conductivity and thermal performance. It typically operates effectively within a temperature range of -40°C to 200°C, making it suitable for various environments. Its resistance to corrosion in many media also enhances its longevity.

Pros & Cons:

Copper’s high conductivity allows for efficient energy transfer, leading to improved motor performance. However, it is relatively expensive compared to alternatives like aluminum. Manufacturing complexity is moderate, as copper requires specific handling to avoid oxidation.

Impact on Application:

Copper is often used in armature windings and commutators, where efficient current flow is critical. Its compatibility with various media makes it versatile across applications, from automotive to industrial machinery.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM B170 for copper and verify the availability of copper components in their local markets. Regions like Africa and South America may face supply chain challenges, making it essential to establish reliable supplier relationships.

Steel

Key Properties:

Steel is a robust material known for its high tensile strength and durability. It can withstand significant mechanical stress and has a temperature rating typically up to 250°C, depending on the alloy used.

Pros & Cons:

The primary advantage of steel is its structural integrity, making it ideal for motor frames and shafts. However, its susceptibility to corrosion can be a drawback unless treated or alloyed. The manufacturing process can be complex, particularly for precision components.

Impact on Application:

Steel is commonly used in the housing and support structures of motors, providing stability and protection. Its strength is vital in applications requiring heavy loads, such as industrial machinery.

Considerations for International Buyers:

Buyers must consider local regulations regarding steel quality standards, such as DIN 17100 in Europe. Corrosion resistance treatments may be necessary in humid regions like parts of South America and Africa, where environmental conditions can lead to rapid degradation.

Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, with a temperature rating similar to copper. It offers decent electrical conductivity, though not as high as copper.

Pros & Cons:

Aluminum’s lightweight nature reduces overall motor weight, which is beneficial for mobile applications. However, its lower strength compared to steel may limit its use in high-stress environments. Manufacturing processes for aluminum are generally simpler and less costly.

Impact on Application:

Aluminum is often used in motor casings and heat sinks, where weight reduction is a priority. Its corrosion resistance makes it suitable for outdoor and marine applications.

Considerations for International Buyers:

Compliance with standards such as JIS H 4000 is essential for aluminum components. Buyers in the Middle East and Africa should evaluate local sourcing options, as aluminum prices can fluctuate based on global market conditions.

Insulation Materials (e.g., Polyester, Epoxy)

Key Properties:

Insulation materials like polyester and epoxy provide electrical insulation and thermal stability, with temperature ratings typically ranging from -40°C to 180°C.

Pros & Cons:

These materials are crucial for preventing short circuits and enhancing motor efficiency. They are relatively inexpensive and easy to apply. However, their performance can degrade under extreme temperatures or prolonged exposure to moisture.

Impact on Application:

Insulation materials are vital in windings and other electrical components, ensuring safe operation and longevity of the motor. They are particularly important in environments with high humidity or temperature fluctuations.

Considerations for International Buyers:

Buyers must ensure that insulation materials meet local and international standards, such as IEC 60085. In regions with high humidity, like parts of Southeast Asia, selecting materials with enhanced moisture resistance is critical.

Summary Table

| Material | Typical Use Case for types of dc electric motors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Armature windings, commutators | Excellent electrical conductivity | Higher cost compared to alternatives | High |

| Steel | Motor frames, shafts | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Casings, heat sinks | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Insulation Materials | Windings, electrical components | Prevents short circuits | Performance degradation in extreme conditions | Low |

This analysis provides a strategic overview of material selection for DC electric motors, empowering international B2B buyers to make informed decisions that align with their operational needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for types of dc electric motors

Manufacturing Processes for DC Electric Motors

The manufacturing of DC electric motors involves several critical stages that ensure the final product meets the required performance and quality standards. Understanding these processes is essential for B2B buyers to make informed decisions about sourcing and supplier selection.

Main Stages of Manufacturing

-

Material Preparation

– The first step involves sourcing high-quality raw materials, such as copper for windings, steel for the motor frame, and specialized magnets for permanent magnet motors.

– Material verification is crucial; suppliers should provide material certificates to confirm compliance with international standards. -

Forming

– This stage includes various techniques such as stamping, forging, and machining. For instance, the armature core is typically made by stamping steel sheets to reduce weight and improve efficiency.

– Precision machining is employed to create components like the shaft and commutator, ensuring tight tolerances that are critical for motor performance. -

Assembly

– During assembly, components such as the armature, field winding, and housing are brought together. Automated assembly lines are common, which enhance consistency and reduce human error.

– Key techniques include soldering for electrical connections and the use of specialized fixtures to hold parts in place during assembly. -

Finishing

– This final stage involves processes such as painting, coating, and insulation to protect against environmental factors and enhance durability.

– Surface finishing techniques, like anodizing or powder coating, are often employed to improve aesthetic appeal and corrosion resistance.

Quality Assurance in Manufacturing

Quality assurance (QA) is vital to ensuring that DC motors operate reliably and efficiently. B2B buyers must be aware of the various international and industry-specific standards that govern quality control in motor manufacturing.

Relevant International Standards

- ISO 9001: This standard provides a framework for quality management systems. Manufacturers certified under ISO 9001 demonstrate their commitment to consistently delivering products that meet customer and regulatory requirements.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: For motors used in oil and gas applications, adherence to American Petroleum Institute (API) standards ensures reliability and safety under harsh conditions.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– This step involves inspecting raw materials and components upon delivery. Buyers should ensure that suppliers have robust IQC processes, including material testing and certification. -

In-Process Quality Control (IPQC)

– Throughout the manufacturing process, regular inspections are conducted to catch defects early. This may include monitoring assembly accuracy and component fitting.

– Techniques like Statistical Process Control (SPC) can be employed to analyze production data and maintain quality. -

Final Quality Control (FQC)

– Before products are shipped, FQC involves comprehensive testing, including performance tests, insulation resistance tests, and vibration analysis.

– Buyers should request detailed FQC reports to understand the testing methodologies used.

Common Testing Methods

- Electrical Testing: Verifying voltage, current, and resistance to ensure electrical components function correctly.

- Mechanical Testing: Assessing the durability and strength of motor components under operational conditions.

- Thermal Testing: Evaluating the motor’s performance under different temperature conditions to ensure it can handle operational heat.

Verifying Supplier Quality Control

B2B buyers must conduct thorough due diligence when selecting suppliers. Here are actionable strategies to verify supplier quality control processes:

- Supplier Audits: Conduct on-site audits to assess the manufacturing environment, equipment, and processes. This provides insights into the supplier’s commitment to quality.

- Quality Reports: Request regular quality reports, including IQC, IPQC, and FQC data, to analyze trends and identify any recurring issues.

- Third-Party Inspection: Engage third-party inspection services to conduct independent quality assessments. This can be particularly valuable when sourcing from regions where local quality standards may vary.

Quality Control Nuances for International Buyers

B2B buyers from Africa, South America, the Middle East, and Europe must navigate specific challenges when sourcing DC electric motors internationally:

- Regulatory Compliance: Different regions have varying regulatory requirements. Buyers should ensure that suppliers can comply with local regulations, especially for electrical and safety standards.

- Cultural Considerations: Understanding the cultural context of suppliers can facilitate better communication and cooperation in quality assurance processes.

- Logistics and Supply Chain Reliability: Consider the reliability of logistics in the supplier’s region. Delays in shipping can affect the availability of spare parts and maintenance services, impacting overall operational efficiency.

Conclusion

In conclusion, the manufacturing processes and quality assurance practices for DC electric motors are integral to ensuring product reliability and performance. B2B buyers must prioritize thorough supplier evaluations, understand international quality standards, and leverage best practices in quality control to make informed procurement decisions. By doing so, they can enhance operational efficiency and mitigate risks associated with sourcing electric motors from various global markets.

Related Video: DC Motors explained – electric motor principle

Comprehensive Cost and Pricing Analysis for types of dc electric motors Sourcing

Understanding the cost structure and pricing dynamics of DC electric motors is crucial for international B2B buyers. This analysis will help streamline procurement strategies, especially for buyers from diverse markets in Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The bulk of the cost in manufacturing DC motors comes from raw materials such as copper, steel, and magnets. Prices for these materials can fluctuate based on market demand and geopolitical factors, impacting overall costs significantly.

-

Labor: Labor costs vary widely based on the region and the skill level required. Automated manufacturing processes can reduce labor costs, but skilled technicians may be necessary for assembly and quality checks, especially for more complex motor types.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment depreciation. Efficient production processes can help lower these costs, which can be a key differentiator among suppliers.

-

Tooling: The initial investment in tooling for specialized motors can be substantial. Custom designs or modifications will require additional tooling costs, which should be factored into the total procurement budget.

-

Quality Control (QC): Rigorous testing and quality assurance processes ensure the reliability and performance of the motors. These costs, while sometimes seen as overhead, are essential for maintaining product standards and reducing the risk of failures.

-

Logistics: Shipping costs, including freight, tariffs, and insurance, can vary dramatically based on the destination. Understanding local regulations and potential import duties is vital for accurate cost estimation.

-

Margin: Suppliers will typically include a profit margin that reflects their operational costs and market positioning. Buyers should expect variations in margin percentages based on the supplier’s reputation, product quality, and service levels.

Price Influencers

-

Volume/MOQ: Larger orders often attract significant discounts. Establishing a minimum order quantity (MOQ) can lead to better pricing structures.

-

Specifications/Customization: Custom motors designed for specific applications can incur higher costs. Buyers should weigh the benefits of customization against the associated price increases.

-

Materials: The choice of materials directly influences the motor’s performance and durability. Higher-quality materials may lead to higher upfront costs but can reduce maintenance and replacement expenses over time.

-

Quality/Certifications: Motors that meet international standards (like ISO or CE certifications) may command higher prices. These certifications can also enhance trust and reliability in the product.

-

Supplier Factors: Established suppliers with a proven track record may charge premium prices, but they often provide better support and reliability. Conversely, newer suppliers may offer lower prices but might lack the necessary experience.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects the total cost of procurement. Buyers should carefully consider terms like CIF (Cost, Insurance, and Freight) versus FOB (Free on Board) to understand responsibilities and costs associated with shipping.

Buyer Tips

-

Negotiation: Engaging in open dialogue with suppliers can lead to better pricing and terms. Consider leveraging multiple quotes to strengthen your negotiating position.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO) rather than just the initial purchase price. Lower-quality motors might save money upfront but could lead to higher maintenance costs and downtime.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and regional economic conditions that can impact pricing. Building relationships with suppliers can also lead to more favorable pricing and terms over time.

In summary, understanding the comprehensive cost and pricing analysis for DC electric motors is essential for informed procurement decisions. Buyers should approach sourcing with a strategic mindset, considering all cost components and pricing influencers to optimize their investments. Always remember that indicative prices can vary based on numerous factors, so continuous market research and supplier engagement are key.

Spotlight on Potential types of dc electric motors Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘types of dc electric motors’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for types of dc electric motors

When sourcing DC electric motors, understanding the essential technical properties and trade terminology is crucial for making informed procurement decisions. Here are the key specifications and terms that B2B buyers should be familiar with.

Critical Specifications

-

Material Grade

– Definition: This refers to the composition and quality of materials used in the motor’s construction, including the rotor, stator, and windings.

– B2B Importance: Higher material grades enhance durability and performance, reducing the likelihood of failure and maintenance costs. Buyers should ensure that materials meet local and international standards, especially in industries with stringent regulations. -

Torque Rating

– Definition: Torque rating measures the rotational force a motor can produce, typically expressed in Newton-meters (Nm).

– B2B Importance: Understanding torque requirements is essential for selecting motors that can handle specific applications. Underestimating torque needs may lead to motor failure or reduced operational efficiency. -

Voltage and Current Ratings

– Definition: These specifications indicate the voltage and current levels required for optimal motor operation.

– B2B Importance: Proper voltage and current ratings ensure compatibility with existing systems, preventing electrical issues that could lead to downtime. Buyers should verify these ratings against local power supply conditions. -

Speed Rating (RPM)

– Definition: Speed rating, measured in revolutions per minute (RPM), indicates the operational speed of the motor under load.

– B2B Importance: Knowing the required RPM for an application allows buyers to choose motors that will deliver the necessary performance. Variability in speed ratings can also affect the motor’s efficiency and lifespan. -

Efficiency Class

– Definition: This is a measure of how effectively a motor converts electrical energy into mechanical energy, often categorized by efficiency classes (e.g., IE1, IE2, IE3).

– B2B Importance: Higher efficiency classes mean lower energy consumption, leading to significant cost savings over time. Buyers should consider the long-term operational costs associated with lower efficiency motors. -

Insulation Class

– Definition: Insulation class indicates the temperature rating of the motor’s insulation materials, which affects the motor’s heat tolerance.

– B2B Importance: Selecting a motor with the appropriate insulation class is vital for ensuring reliability in varying operational environments, particularly in regions with extreme temperatures.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Significance for Buyers: Engaging with OEMs can ensure that the motor components are compatible with existing systems and of high quality, which is crucial for maintenance and support. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Significance for Buyers: Understanding MOQ helps in budgeting and inventory management. Buyers should negotiate MOQs to align with their operational needs without overcommitting resources. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products.

– Significance for Buyers: Issuing RFQs allows buyers to compare prices and terms from multiple suppliers, facilitating better decision-making and cost management. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping and delivery.

– Significance for Buyers: Familiarity with Incoterms is essential for understanding shipping responsibilities, costs, and risks, particularly in cross-border transactions. -

Lead Time

– Definition: The time taken from placing an order to the delivery of the product.

– Significance for Buyers: Knowing lead times helps in planning and minimizing disruptions in operations. Buyers should account for potential delays, especially when sourcing from international suppliers.

Illustrative Image (Source: Google Search)

- Warranty Period

– Definition: The timeframe during which the manufacturer guarantees the performance of the motor.

– Significance for Buyers: A robust warranty period can indicate the manufacturer’s confidence in their product quality. Buyers should assess warranty terms to mitigate risks associated with motor failures.

Illustrative Image (Source: Google Search)

By mastering these specifications and terms, B2B buyers can navigate the complexities of sourcing DC electric motors more effectively, ensuring that their procurement decisions align with operational needs and strategic goals.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the types of dc electric motors Sector

Market Overview & Key Trends

The global market for DC electric motors is experiencing significant transformation driven by a combination of technological advancements, rising energy efficiency standards, and growing demand across various sectors. Key drivers include the proliferation of electric vehicles (EVs) and automation in manufacturing processes, particularly in regions like Africa, South America, the Middle East, and Europe. These areas are witnessing rapid industrialization, leading to an increased adoption of DC motors, which are preferred for their efficiency and control capabilities.

Current sourcing trends indicate a shift towards more integrated supply chains, with buyers increasingly favoring suppliers that can provide not just motors but also comprehensive solutions that include control systems and support. In addition, the demand for customizable and modular motor solutions is on the rise, allowing businesses to tailor their equipment to specific operational requirements. Furthermore, international buyers are increasingly prioritizing suppliers with strong after-sales support and spare parts availability, essential for minimizing downtime in high-demand environments.

Emerging technologies such as IoT (Internet of Things) are also reshaping the landscape, with connected motors enabling predictive maintenance and real-time performance monitoring. This trend is particularly relevant for sectors like agriculture in Africa and logistics in South America, where operational efficiency can significantly impact profitability. As B2B buyers navigate these market dynamics, aligning procurement strategies with these trends will be crucial for maintaining competitiveness.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a central pillar in the sourcing strategies of DC electric motors, driven by both regulatory pressures and consumer demand for environmentally friendly products. The production of electric motors, particularly those using rare earth materials, poses environmental challenges, prompting buyers to seek suppliers who prioritize sustainable practices. This includes minimizing waste, reducing energy consumption during manufacturing, and employing responsible sourcing of raw materials.

Ethical supply chains are critical for international buyers, especially in regions like Africa and South America, where labor practices may vary significantly. Buyers should ensure that their suppliers adhere to fair labor practices and environmental standards, which can be validated through certifications such as ISO 14001 for environmental management and ISO 9001 for quality management systems. Additionally, the use of ‘green’ materials—such as recycled metals or biodegradable components—can enhance the sustainability profile of DC motors.

Investing in sustainable technologies not only helps mitigate environmental impact but can also provide a competitive edge in the marketplace. Companies that communicate their commitment to sustainability often resonate better with customers, leading to increased brand loyalty and market share.

Brief Evolution/History

The development of DC electric motors has a rich history that has significantly influenced modern manufacturing and transportation. Initially introduced in the 19th century, these motors were pivotal in the Industrial Revolution, providing a reliable source of mechanical power. Over the years, advancements in materials and design have led to the creation of various types of DC motors, including brushed and brushless variants, each tailored to specific applications.

As industries evolved, so did the technology behind DC motors. The introduction of electronic control systems in the late 20th century marked a significant leap, enhancing performance and efficiency. This evolution continues today, with innovations focused on integrating smart technologies and improving energy efficiency, ensuring that DC motors remain essential components in a wide range of applications from automotive to industrial automation. Understanding this historical context can aid B2B buyers in making informed decisions regarding the sourcing and application of DC motors, aligning their procurement strategies with ongoing technological trends.

Related Video: Types of DC Motors

Frequently Asked Questions (FAQs) for B2B Buyers of types of dc electric motors

-

How do I vet suppliers when sourcing DC electric motors internationally?

Vetting suppliers is crucial in ensuring quality and reliability. Start by checking their business credentials, such as certifications (ISO, CE), and financial stability. Request references from previous clients, especially those in your region or industry. Use platforms like Alibaba or ThomasNet for additional reviews. It’s also beneficial to conduct site visits or virtual tours to assess their manufacturing capabilities and quality control processes. Engaging third-party inspection services can further enhance your supplier evaluation. -

Can I customize DC electric motors to fit specific applications?

Yes, many suppliers offer customization options for DC electric motors to meet specific operational requirements. This may include modifications in voltage, speed, torque, and even physical dimensions. When considering customization, ensure that your supplier has a proven track record in engineering and design. Clearly communicate your needs and verify the supplier’s ability to deliver prototypes or samples before committing to larger orders. This ensures the final product aligns with your operational requirements. -

What are the typical minimum order quantities (MOQ) and lead times for DC motors?

Minimum order quantities (MOQ) can vary widely depending on the supplier and the complexity of the motor. For standard models, MOQs may range from 50 to 200 units, while custom motors might require higher quantities. Lead times typically range from 4 to 12 weeks, depending on production schedules and shipping logistics. Always discuss these factors upfront and consider negotiating MOQs if you require smaller quantities. Planning ahead can help mitigate delays in your supply chain. -

What payment terms are common when sourcing DC motors internationally?

Common payment terms for international transactions include letters of credit, wire transfers, and payment upon delivery. For larger orders, consider negotiating partial payments (e.g., 30% upfront and 70% upon delivery) to reduce risk. Be aware of currency fluctuations and choose a stable currency for transactions. Additionally, ensure that payment methods are secure and that you have recourse options in case of disputes. Discussing terms clearly before placing an order can help avoid misunderstandings. -

How can I ensure quality assurance and certification compliance for DC motors?

To ensure quality assurance, request documentation of the motor’s compliance with international standards such as IEC or NEMA. Suppliers should provide test reports and certificates for materials and performance. Consider conducting third-party audits or inspections during manufacturing to verify compliance. Establishing clear quality metrics in your procurement contract can also help maintain standards. Regularly review supplier performance and quality reports to ensure ongoing compliance. -

What logistics considerations should I keep in mind when sourcing DC motors?

Logistics can significantly impact the timely delivery of DC motors. Consider the shipping methods (air, sea, or land) based on urgency and cost. Ensure your supplier can handle customs clearance and understand import regulations in your country. It’s wise to work with logistics partners familiar with your region to streamline the process. Additionally, factor in storage and handling requirements upon arrival, as well as potential tariffs or import duties that could affect overall costs. -

How should I handle disputes with suppliers over DC motor quality or delivery?

Handling disputes requires a structured approach. First, document all communications and agreements made with the supplier. If a quality issue arises, communicate your concerns promptly, referencing the agreed specifications. If the supplier is unresponsive, escalate the issue through formal channels, such as a dispute resolution clause in your contract. Consider mediation or arbitration to resolve conflicts amicably. Establishing a clear process for dispute resolution in your contracts can help mitigate risks and foster better supplier relationships. -

What are the best practices for maintaining a long-term relationship with DC motor suppliers?

Building a long-term relationship with suppliers hinges on effective communication and trust. Regularly engage with your suppliers through updates on your needs and feedback on their performance. Consider collaborative efforts on product development or improvements. Establishing clear expectations and maintaining transparency in operations can lead to better service and support. Additionally, timely payments and honoring agreements will strengthen your partnership, making suppliers more inclined to prioritize your orders and assist with future needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of dc electric motors

In conclusion, the strategic sourcing of DC electric motors is a critical decision that can significantly influence operational efficiency and productivity across various industries. Buyers must prioritize understanding the specific types of DC motors—such as separately excited, permanent magnet, and compound wound—each offering unique benefits and applications. Evaluating suppliers based on their ability to provide reliable products, after-sales support, and compliance with regional standards is essential to mitigate risks associated with procurement.

International B2B buyers from Africa, South America, the Middle East, and Europe should adopt a proactive approach, leveraging market insights and local expertise to make informed choices. Investing in quality motors not only enhances performance but also leads to long-term cost savings through improved energy efficiency and reduced maintenance needs.

As the global landscape continues to evolve, staying abreast of technological advancements and market trends will be crucial. Engage with trusted suppliers, participate in industry forums, and continuously refine your sourcing strategies to ensure your organization remains competitive and resilient in an increasingly interconnected marketplace.