Your Ultimate Guide to Sourcing Septic Tank Manufacturers

Introduction: Navigating the Global Market for septic tank manufacturers

In today’s global marketplace, the role of septic tank manufacturers cannot be overstated. As urbanization accelerates and populations grow, the demand for effective wastewater management solutions has surged, particularly in regions such as Africa, South America, the Middle East, and Europe. Septic tanks serve as critical components in decentralized sanitation systems, providing safe and efficient treatment of sewage where centralized sewer systems are unavailable. For B2B buyers, selecting a reliable manufacturer is essential to ensure quality, compliance with local regulations, and long-term operational efficiency.

This comprehensive guide delves into the intricacies of the septic tank manufacturing industry, covering various aspects that are vital for informed decision-making. It outlines the different types of septic tanks, explores materials used in their construction, and examines manufacturing and quality control practices. Additionally, the guide provides insights into leading suppliers, cost considerations, and current market trends, along with a dedicated FAQ section addressing common buyer inquiries.

By equipping international B2B buyers with critical knowledge and actionable insights, this guide empowers them to navigate the complexities of sourcing septic tanks effectively. Whether you are a contractor seeking high-quality tanks for a project or a business looking to partner with top manufacturers, understanding these facets will enable you to make informed choices that align with your operational needs and sustainability goals.

Understanding septic tank manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Concrete Septic Tanks | Durable, heavy-duty construction; long lifespan | Residential, commercial applications | Pros: High strength, excellent longevity. Cons: Heavy, costly to transport and install. |

| Fiberglass Septic Tanks | Lightweight, corrosion-resistant, easy to install | Residential, remote locations | Pros: Resistant to corrosion, easier handling. Cons: Can be more expensive than concrete. |

| Plastic Septic Tanks | Blow-molded polyethylene; lightweight and flexible | Small homes, temporary installations | Pros: Cost-effective, easy to transport. Cons: Less durable than concrete or fiberglass. |

| Septic Tank Systems with Advanced Treatment | Integrated treatment features, eco-friendly options | Commercial, industrial applications | Pros: Enhanced treatment efficiency, lower environmental impact. Cons: Higher initial costs, complex installation. |

| Modular Septic Tank Systems | Customizable, scalable designs | Large residential, commercial projects | Pros: Flexible design, easy expansion. Cons: Potentially higher maintenance requirements. |

Concrete Septic Tanks

Concrete septic tanks are renowned for their durability and long lifespan, making them a popular choice for both residential and commercial applications. Their heavy-duty construction ensures they can withstand significant loads, which is particularly beneficial in areas with high water tables or heavy soil. When purchasing, buyers should consider the installation costs and logistics, as these tanks can be challenging to transport due to their weight. While they offer excellent longevity, the initial investment can be substantial.

Fiberglass Septic Tanks

Fiberglass septic tanks are characterized by their lightweight and corrosion-resistant properties, making them suitable for residential and remote installations. Their ease of installation is a significant advantage, especially in locations where access is limited. B2B buyers should weigh the benefits of reduced transportation costs against the higher price point compared to concrete tanks. Fiberglass tanks also tend to have a shorter lifespan than concrete options, which may influence long-term planning and budgeting.

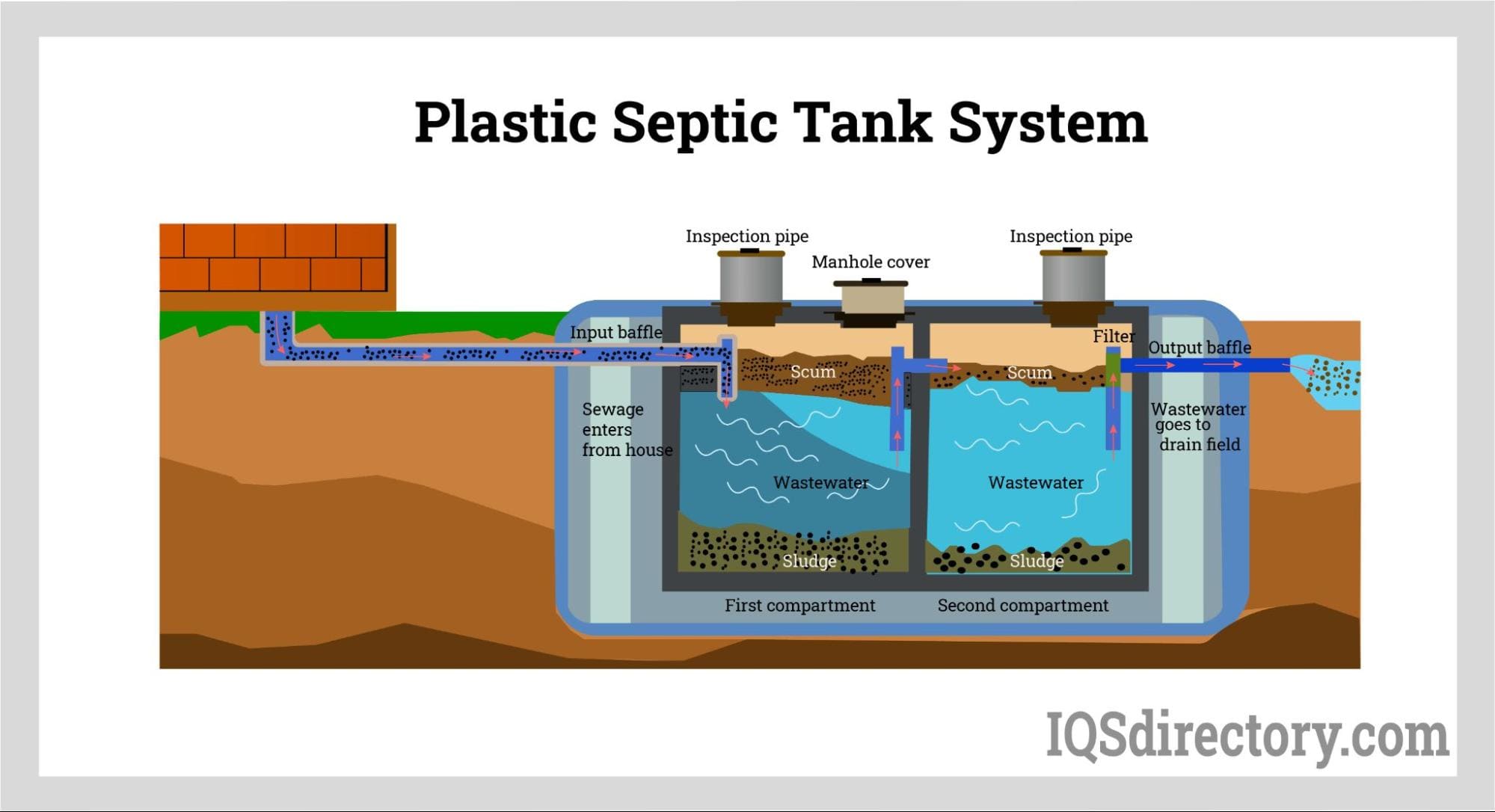

Plastic Septic Tanks

Plastic septic tanks, typically made from blow-molded polyethylene, offer a cost-effective solution for small homes or temporary installations. Their lightweight nature allows for easy transport and installation, which can significantly reduce labor costs. However, buyers should be cautious of their durability, as plastic tanks may not withstand harsh conditions as well as concrete or fiberglass alternatives. Understanding the specific environmental conditions of the installation site is crucial for making an informed purchase.

Septic Tank Systems with Advanced Treatment

These systems integrate advanced treatment features, making them ideal for commercial and industrial applications where enhanced wastewater treatment is critical. They often include eco-friendly options designed to minimize environmental impact, appealing to businesses focused on sustainability. However, buyers should be prepared for higher initial costs and potentially complex installation processes. Evaluating the long-term operational savings against upfront expenses can provide valuable insights for B2B buyers.

Modular Septic Tank Systems

Modular septic tank systems provide customizable and scalable designs, making them an excellent option for large residential and commercial projects. Their flexibility allows for easy expansion as the needs of the property change, which is particularly advantageous for growing businesses. However, B2B buyers should consider the potential for higher maintenance requirements due to the complexity of these systems. Thoroughly assessing the long-term operational needs and maintenance plans is essential for making an informed decision.

Related Video: India’s No.1 Bio Septic Tank | DRDO Certified Technology | Bio Septic Tank Process | Septic Tank

Key Industrial Applications of septic tank manufacturers

| Industry/Sector | Specific Application of Septic Tank Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Residential Construction | On-site wastewater management systems | Provides a reliable solution for homes without sewer access, ensuring proper sanitation and compliance with health regulations. | Look for manufacturers with durable materials and local support for installation. |

| Agriculture | Wastewater treatment for farms | Helps in managing livestock waste, preventing contamination of soil and water sources, and promoting sustainable farming practices. | Consider tank capacity and regulatory compliance based on local farming regulations. |

| Commercial Developments | Wastewater systems for hotels and resorts | Ensures effective sewage treatment for high occupancy facilities, enhancing guest experience and meeting environmental standards. | Evaluate manufacturers with experience in high-volume applications and robust customer service. |

| Industrial Facilities | Wastewater management for manufacturing plants | Minimizes environmental impact and ensures compliance with industrial waste regulations, protecting company reputation and avoiding fines. | Assess the technology and materials used for durability and maintenance requirements. |

| Remote Communities | Decentralized sewage systems | Provides essential sanitation solutions in areas lacking infrastructure, improving public health and quality of life. | Focus on suppliers who can offer cost-effective solutions and local installation support. |

Residential Construction

In residential construction, septic tanks serve as essential systems for on-site wastewater management, particularly in areas without access to centralized sewer systems. These tanks collect and treat sewage, ensuring compliance with local health regulations and promoting sanitation. Buyers in this sector must prioritize manufacturers that offer durable materials, ease of installation, and reliable customer support, particularly in regions like Africa and South America, where building codes may vary significantly.

Agriculture

In the agricultural sector, septic tank manufacturers provide critical wastewater treatment solutions for farms, especially those with livestock. Proper management of animal waste is vital to prevent soil and water contamination, thus safeguarding environmental health. Buyers should seek manufacturers that offer tanks designed to handle high volumes and comply with local agricultural regulations, which can differ greatly between regions, including the Middle East and Europe.

Commercial Developments

For hotels and resorts, septic tanks are integral to maintaining effective sewage treatment systems, particularly in high-occupancy scenarios. These systems help manage wastewater efficiently, enhancing the guest experience and ensuring compliance with environmental standards. B2B buyers should consider manufacturers with proven expertise in high-volume applications and those who can provide robust customer service, especially in regions where tourism is a significant economic driver.

Industrial Facilities

In manufacturing plants, effective wastewater management is crucial to minimize environmental impact and adhere to strict industrial waste regulations. Septic tanks designed for industrial use help ensure compliance and protect the company’s reputation by preventing potential fines and environmental damage. Buyers should evaluate the technology and materials utilized in these tanks, focusing on durability and maintenance needs, particularly in regions with stringent environmental laws.

Remote Communities

Septic tanks play a vital role in providing decentralized sewage systems for remote communities lacking infrastructure. These systems enhance public health by ensuring safe sanitation solutions. Buyers in this sector should look for cost-effective options and suppliers capable of offering local installation support, particularly in developing regions of Africa and South America, where infrastructure challenges are prevalent.

Related Video: Pressure Distribution Septic System

Strategic Material Selection Guide for septic tank manufacturers

When selecting materials for septic tanks, manufacturers must consider a variety of factors that directly impact product performance, durability, and compliance with local regulations. Below is an analysis of four common materials used in septic tank manufacturing, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

Concrete

Key Properties: Concrete septic tanks are known for their high compressive strength and ability to withstand heavy loads. They typically have a temperature rating of up to 100°F (38°C) and can handle significant pressure, making them suitable for various soil conditions.

Pros & Cons: Concrete tanks are highly durable and resistant to corrosion. However, they can be heavy and difficult to transport, leading to higher shipping costs. The installation process may also require specialized equipment. Additionally, they are prone to cracking if not properly maintained.

Impact on Application: Concrete tanks are compatible with a wide range of media, including effluent from residential and commercial properties. They can be used in both rural and urban settings, provided they meet local regulations.

Considerations for International Buyers: Buyers should ensure that concrete tanks comply with local standards such as ASTM or DIN, particularly in regions with stringent building codes. In areas prone to seismic activity, additional reinforcement may be required.

Fiberglass

Key Properties: Fiberglass septic tanks are lightweight and resistant to corrosion and chemicals. They can withstand temperatures up to 120°F (49°C) and are designed to handle moderate pressure, making them suitable for various applications.

Pros & Cons: The primary advantage of fiberglass tanks is their ease of installation due to their lightweight nature. They are also less prone to cracking compared to concrete. However, they can be more expensive to manufacture and may not be as durable as concrete in high-pressure environments.

Impact on Application: Fiberglass tanks are ideal for residential applications and are often used in areas where soil conditions are less stable. They are also compatible with various effluent types, including those from industrial sources.

Considerations for International Buyers: Buyers should verify that fiberglass tanks meet local standards and regulations. In regions with extreme weather conditions, additional insulation may be necessary to prevent damage.

Polyethylene

Key Properties: Polyethylene septic tanks are known for their lightweight and corrosion-resistant properties. They can handle temperatures up to 100°F (38°C) and are designed for low-pressure applications, making them suitable for residential use.

Pros & Cons: The main advantage of polyethylene tanks is their ease of handling and installation, which can significantly reduce labor costs. However, they may not be suitable for high-load applications and can be more susceptible to damage from UV exposure if not properly treated.

Impact on Application: Polyethylene tanks are commonly used in residential settings and are effective for treating domestic wastewater. They are compatible with various effluent types, but care must be taken to ensure proper installation to avoid floatation in saturated soils.

Considerations for International Buyers: Buyers should ensure that polyethylene tanks comply with local environmental regulations and standards. In regions with high UV exposure, selecting UV-resistant materials is crucial.

Steel

Key Properties: Steel septic tanks are robust and can withstand high pressures and temperatures. They are often coated to enhance corrosion resistance and can handle temperatures up to 150°F (65°C).

Pros & Cons: Steel tanks are highly durable and can be manufactured to meet specific project requirements. However, they are heavier than other materials, which can increase transportation costs. Additionally, they require regular maintenance to prevent rust and corrosion.

Impact on Application: Steel tanks are suitable for both residential and commercial applications, particularly in environments where high durability is required. They can handle a variety of wastewater types effectively.

Considerations for International Buyers: Buyers should ensure that steel tanks meet local standards and regulations, particularly regarding corrosion resistance. In areas with high humidity or saline conditions, additional protective coatings may be necessary.

Summary Table

| Material | Typical Use Case for septic tank manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Concrete | Residential and commercial applications | High durability and load-bearing capacity | Heavy and difficult to transport | Medium |

| Fiberglass | Residential applications | Lightweight and easy to install | More expensive and less durable under pressure | High |

| Polyethylene | Residential settings | Easy handling and installation | Susceptible to UV damage | Medium |

| Steel | Residential and commercial applications | High durability and customizable | Heavier and requires maintenance | Medium |

This strategic material selection guide provides essential insights for international B2B buyers, helping them make informed decisions based on performance, application suitability, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for septic tank manufacturers

Understanding the Manufacturing Processes for Septic Tank Manufacturers

The manufacturing of septic tanks is a meticulous process that involves several critical stages to ensure the production of high-quality, durable products. Each stage is designed to meet the specific requirements of various markets, particularly in regions such as Africa, South America, the Middle East, and Europe.

Main Stages of Manufacturing

-

Material Preparation

– The first step involves selecting the right materials based on the tank type (concrete, fiberglass, or polyethylene). For instance, polyethylene is favored for its corrosion resistance and lightweight properties.

– Raw materials undergo quality checks to ensure they meet industry standards. This may involve testing for strength, durability, and compliance with environmental regulations. -

Forming

– Molding Techniques: Depending on the material, various forming techniques are employed. For polyethylene tanks, blow molding is commonly used, which provides a seamless finish and reduces the risk of leaks.

– Casting: For concrete tanks, a casting process is used, where molds are created, and concrete is poured and allowed to set, ensuring the desired shape and thickness. -

Assembly

– After forming, components are assembled. This may include attaching lids, baffles, and other internal structures necessary for the effective treatment of wastewater.

– For modular designs, sections are pre-fabricated and then assembled at the manufacturing facility or on-site, allowing for flexibility in installation. -

Finishing

– This stage includes surface treatments to enhance durability and resistance to environmental factors. For example, fiberglass tanks might receive a protective gel coat.

– Final inspections are conducted to ensure that all components fit correctly and meet the specified dimensions.

Quality Assurance in Septic Tank Manufacturing

Quality assurance (QA) is essential in the septic tank manufacturing process. It not only ensures that products meet legal and safety standards but also enhances customer satisfaction and reduces warranty claims.

Relevant International Standards

-

ISO 9001

– This standard is a cornerstone for quality management systems. It emphasizes a process approach to enhance customer satisfaction by meeting customer and regulatory requirements. -

CE Marking

– Particularly relevant for products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards. It is crucial for B2B buyers in Europe to ensure that their suppliers are CE certified. -

API Standards

– For manufacturers targeting the oil and gas sector, adherence to American Petroleum Institute (API) standards may be necessary, especially for tanks designed for industrial applications.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Raw materials are inspected upon arrival to ensure they meet specifications. This includes checking for certifications and conducting physical tests. -

In-Process Quality Control (IPQC)

– During manufacturing, ongoing inspections are performed to monitor processes and ensure that any defects are caught early. This could involve checking the temperature and pressure during molding or inspecting welds in metal tanks. -

Final Quality Control (FQC)

– The final inspection stage involves comprehensive testing of the finished product, including pressure tests for leaks and structural integrity tests. Documentation of these tests should be available for B2B buyers.

Illustrative Image (Source: Google Search)

Common Testing Methods

- Hydrostatic Testing: This is used to check for leaks by filling the tank with water and observing if there is any drop in levels.

- Load Testing: Ensures that tanks can withstand the weight of soil and water without deforming.

- Chemical Resistance Testing: Particularly important for tanks that will be used in industrial applications, ensuring that the materials can withstand various chemicals.

How B2B Buyers Can Verify Supplier Quality Control

When sourcing septic tanks, particularly in international markets, B2B buyers should take several steps to ensure the reliability of their suppliers’ quality control processes:

-

Supplier Audits

– Conducting on-site audits allows buyers to assess the manufacturing capabilities, quality control processes, and compliance with international standards. -

Requesting Quality Reports

– Buyers should request detailed quality assurance reports, including IQC, IPQC, and FQC results, along with any certifications relevant to the products being purchased. -

Third-Party Inspections

– Engaging third-party inspection agencies can provide an unbiased assessment of the manufacturing processes and product quality. This is particularly useful for buyers in regions with less stringent regulations.

QC and Certification Nuances for International Buyers

International buyers, especially from Africa, South America, the Middle East, and Europe, should be aware of certain nuances in quality control and certification:

-

Regulatory Compliance: Different regions may have varying regulations regarding wastewater treatment products. It is vital to ensure that the supplier’s products comply with local regulations in the buyer’s country.

-

Cultural and Economic Factors: In some regions, the cost of compliance may affect the price of septic tanks. Buyers should consider the total cost of ownership, which includes installation and maintenance costs, not just the upfront purchase price.

-

Sustainability Practices: There is an increasing demand for environmentally friendly products. Suppliers that implement sustainable manufacturing practices may have a competitive edge in international markets.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions, ensuring they procure high-quality septic tanks that meet their specific needs and regulatory requirements.

Related Video: Awesome Scene! Best Mass Production Factory Manufacturing Process

Comprehensive Cost and Pricing Analysis for septic tank manufacturers Sourcing

When sourcing septic tanks from manufacturers, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This analysis focuses on the critical cost components, price influencers, and actionable tips for negotiation and procurement.

Cost Components

-

Materials: The primary materials used in septic tank manufacturing include concrete, fiberglass, and polyethylene. Each material has different cost implications, with fiberglass often being more expensive due to its durability and resistance to corrosion. Buyers should assess the lifecycle benefits of each material to justify the initial costs.

-

Labor: Labor costs can vary significantly depending on the region and the complexity of the manufacturing process. In regions like Africa and South America, labor may be less expensive, but this could also impact quality if not managed properly. Understanding local labor dynamics is crucial when evaluating total costs.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Manufacturers with higher overhead may pass these costs onto buyers, affecting pricing. Buyers should consider manufacturers that optimize overhead through efficient operations.

-

Tooling: Custom tooling for unique septic tank designs or specifications can add to initial costs. While this may be necessary for specific projects, buyers should weigh the benefits of customization against the increased tooling expenses.

-

Quality Control (QC): Rigorous QC processes can increase production costs but are vital for ensuring product reliability. Tanks that meet international certifications (like ISO) may command higher prices but can reduce long-term maintenance costs and risks.

-

Logistics: Transportation costs vary based on the distance between the manufacturer and the buyer, as well as the shipping method. For international buyers, understanding Incoterms (International Commercial Terms) is essential to clarify who bears the costs at various points in the shipping process.

-

Margin: Manufacturers typically include a profit margin in their pricing. This margin can fluctuate based on competition, market demand, and the manufacturer’s brand reputation. Understanding the market landscape can provide leverage during negotiations.

Price Influencers

-

Volume/MOQ: Buying in bulk often leads to lower unit prices. Minimum Order Quantities (MOQs) can also affect pricing; manufacturers may offer discounts for larger orders, making it advantageous for companies planning extensive installations.

-

Specifications/Customization: Customized tanks tailored to specific project requirements can significantly impact pricing. Buyers should ensure that the benefits of customization justify the additional costs.

-

Quality/Certifications: Tanks that comply with stringent quality standards and certifications may have a higher upfront cost but can save money in the long run due to fewer repairs and replacements.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established manufacturers with a track record of quality may charge a premium, but they also reduce risks associated with product failures.

-

Incoterms: Understanding Incoterms is critical for international buyers. They dictate the responsibilities of buyers and sellers in shipping, which can affect overall costs. For instance, “CIF” (Cost, Insurance, and Freight) includes shipping costs, while “EXW” (Ex Works) places the shipping responsibility on the buyer.

Buyer Tips

-

Negotiation: Leverage volume purchases to negotiate better pricing. Establishing long-term relationships with manufacturers can also yield discounts and favorable terms.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO) rather than just the purchase price. Consider installation, maintenance, and potential replacement costs when evaluating options.

-

Pricing Nuances: Be aware of currency fluctuations, tariffs, and import duties that can affect final costs, particularly in international transactions. Engaging local experts can help navigate these complexities.

-

Research and Compare: Thoroughly research multiple suppliers and compare their offerings. Don’t hesitate to request quotes and specifications to ensure you’re making informed decisions.

Disclaimer

The prices and cost components discussed are indicative and can vary based on market conditions, supplier negotiations, and specific project requirements. Always conduct thorough due diligence and consult with financial advisors to ensure sound investment decisions.

Spotlight on Potential septic tank manufacturers Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘septic tank manufacturers’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for septic tank manufacturers

Key Technical Properties for Septic Tanks

Understanding the essential technical properties of septic tanks is crucial for B2B buyers, particularly when evaluating manufacturers and ensuring compliance with local regulations. Here are some of the most critical specifications to consider:

-

Material Grade

– Definition: The type of material used to construct the septic tank, typically concrete, fiberglass, or polyethylene.

– Importance: Different materials offer varying levels of durability, resistance to corrosion, and weight. For instance, fiberglass tanks are lighter and resistant to rust, making them easier to install in challenging environments, whereas concrete tanks provide excellent strength and longevity. -

Tank Capacity

– Definition: The volume of wastewater a septic tank can hold, usually measured in gallons or liters.

– Importance: Correct capacity is vital to ensure efficient treatment of wastewater. Oversized tanks may lead to unnecessary costs, while undersized tanks can result in system failure and environmental hazards. -

Tolerance Levels

– Definition: The allowable variations in dimensions and construction standards during manufacturing.

– Importance: Tighter tolerances ensure that tanks fit properly into designated spaces and function effectively. This reduces the risk of leaks or structural failure, which can lead to costly repairs and environmental damage. -

Weight and Handling Specifications

– Definition: The weight of the tank and its design features that facilitate transport and installation.

– Importance: Understanding the weight is crucial for logistics planning, especially in regions with limited access. Lighter tanks may be easier to transport and install, which can reduce labor costs. -

Sealing and Joint Integrity

– Definition: The effectiveness of the seals and joints used in the tank’s construction to prevent leaks.

– Importance: Proper sealing is essential to prevent groundwater contamination and ensure the longevity of the tank. Manufacturers should provide details on testing methods for joint integrity. -

Regulatory Compliance

– Definition: Adherence to local, national, and international standards governing wastewater treatment systems.

– Importance: Compliance ensures that the septic systems meet health and safety regulations, which is particularly important for buyers in different regions with varying standards.

Common Trade Terminology

Familiarity with industry jargon can facilitate smoother communication and negotiation processes. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Usage: When sourcing septic tanks, buyers might work with OEMs to create customized solutions tailored to specific project needs. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Usage: Understanding MOQ is crucial for budget planning and inventory management. Buyers should negotiate MOQs to align with their purchasing capabilities. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and terms for specific products or services.

– Usage: Issuing an RFQ helps buyers gather competitive offers and make informed decisions based on pricing, delivery, and payment terms. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules defining the responsibilities of sellers and buyers for the delivery of goods.

– Usage: Knowledge of Incoterms is vital for international transactions, as they clarify who is responsible for shipping costs, insurance, and risk during transit. -

Lead Time

– Definition: The time it takes from placing an order to delivery.

– Usage: Understanding lead times helps buyers plan their projects effectively and manage expectations regarding delivery schedules. -

Warranty and Service Agreements

– Definition: Contracts outlining the manufacturer’s commitment to repair or replace defective products within a specified period.

– Usage: Buyers should assess warranty terms to ensure they receive adequate support post-purchase, which is vital for long-term operational reliability.

Illustrative Image (Source: Google Search)

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make more informed decisions when selecting septic tank manufacturers that meet their specific needs and standards.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the septic tank manufacturers Sector

Market Overview & Key Trends

The septic tank manufacturing sector is experiencing significant growth driven by several global factors. Increasing urbanization, particularly in developing regions such as Africa and South America, is leading to a surge in demand for effective wastewater management solutions. As cities expand, the need for decentralized sanitation systems, like septic tanks, becomes critical, particularly in areas lacking access to centralized sewer systems.

Current B2B trends highlight the integration of advanced technologies in septic tank production. Manufacturers are increasingly adopting smart technologies that allow for real-time monitoring of tank performance and maintenance needs. This tech-driven approach enhances operational efficiency and reduces long-term costs for buyers. Furthermore, there is a marked shift towards modular septic systems, which offer flexibility and ease of installation, catering to the diverse landscape of international markets.

Another noteworthy trend is the emphasis on sustainable materials and practices. Manufacturers are exploring alternatives to traditional materials, focusing on lightweight, corrosion-resistant plastics and fiberglass that are easier to handle and install. These innovations not only meet regulatory demands but also align with the increasing consumer awareness surrounding environmental sustainability.

International B2B buyers should also consider regional regulations and standards when sourcing septic tanks. Compliance with local environmental laws is essential, as non-compliance can lead to costly fines and project delays. Thus, staying updated on the evolving regulatory landscape in target markets is crucial for making informed purchasing decisions.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of the septic tank manufacturing industry. The environmental impact of wastewater systems cannot be overlooked, as improper disposal can lead to soil and water contamination. Consequently, there is a growing demand for septic systems that minimize ecological footprints. This demand is particularly evident in regions like the Middle East and Africa, where water scarcity is a pressing concern.

Ethical sourcing practices are also gaining traction. Buyers are increasingly interested in understanding the supply chains of their manufacturers. Ensuring that raw materials are sourced responsibly and that labor practices are ethical is essential for maintaining corporate social responsibility (CSR) standards. Manufacturers that can demonstrate adherence to ethical sourcing are likely to gain a competitive edge in the marketplace.

Moreover, many septic tank manufacturers are pursuing green certifications and using sustainable materials in their products. Certifications such as ISO 14001 for environmental management systems can serve as valuable indicators for international buyers looking for reputable suppliers. By prioritizing sustainability and ethical practices, manufacturers not only contribute to environmental preservation but also enhance their brand reputation and appeal to a conscientious customer base.

Brief Evolution/History

The septic tank industry has evolved significantly over the past century. Originally constructed from concrete, these systems were often heavy, cumbersome, and prone to damage. With the advent of new materials such as fiberglass and high-density polyethylene in the late 20th century, the design and functionality of septic tanks improved dramatically. These modern materials not only enhanced durability but also allowed for lighter and more efficient tank designs.

As awareness of environmental issues grew in the 21st century, the industry began to shift towards sustainable practices. Manufacturers started adopting technologies that reduce the ecological impact of wastewater treatment and promote water conservation. Today, the focus on innovation, sustainability, and ethical sourcing is shaping the future of septic tank manufacturing, making it a dynamic sector ripe for investment and growth.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of septic tank manufacturers

-

How can I effectively vet septic tank manufacturers before making a purchase?

When vetting septic tank manufacturers, consider several key factors: reputation, experience, and certifications. Look for manufacturers with a long history of operation and positive customer reviews. Verify their compliance with international standards (like ISO certifications) and local regulations relevant to your region. Engaging with past clients can provide insights into their reliability and product quality. Additionally, request product samples to assess the material quality and construction standards before committing to a larger order. -

Can septic tanks be customized to meet specific project requirements?

Many septic tank manufacturers offer customization options to suit unique project needs. This may include variations in size, material, or design features, such as additional compartments or specific access points. When discussing customization, clearly communicate your project specifications, including local regulations and installation conditions. Ensure that the manufacturer has the capability and experience to deliver custom solutions, and request samples or prototypes to validate their offerings. -

What are the typical minimum order quantities (MOQ) and lead times for septic tanks?

Minimum order quantities (MOQ) for septic tanks can vary significantly among manufacturers. Generally, larger manufacturers might have higher MOQs due to production efficiency, while smaller firms may accommodate lower quantities. Lead times can also differ based on the complexity of the order and current demand. It is crucial to discuss these factors upfront during negotiations, as well as any potential rush order options if you have urgent project timelines. -

What payment terms should I expect when sourcing septic tanks internationally?

Payment terms can vary widely based on the manufacturer and the buyer’s relationship. Common terms include 50% upfront payment and 50% upon delivery, or full payment in advance, especially for new clients. Be sure to discuss payment methods, such as bank transfers or letters of credit, which can provide security for both parties. Additionally, clarify any extra costs that may arise, including shipping fees and customs duties, to avoid surprises later in the transaction. -

How can I ensure quality assurance and certifications for septic tanks?

To ensure quality assurance, request documentation of the manufacturer’s certifications and testing procedures. Look for compliance with relevant international standards, such as ASTM or EN standards for septic tanks. Manufacturers should provide quality control processes, including material testing and final inspections. If possible, arrange for third-party inspections to validate the quality of the tanks before shipment, especially for larger orders. -

What logistics considerations should I keep in mind when importing septic tanks?

Logistics is a critical aspect when importing septic tanks. Consider factors such as shipping methods, customs clearance, and delivery timelines. Coordinate with the manufacturer to determine the best shipping options based on cost and urgency. Engage a reliable freight forwarder who understands international trade regulations and can handle the complexities of customs documentation. It’s also essential to plan for potential delays, especially in regions with stringent import regulations. -

How should disputes over septic tank quality or delivery be handled?

To manage disputes effectively, establish clear communication channels with the manufacturer from the outset. Document all agreements, including specifications, delivery timelines, and payment terms, to provide a reference in case of issues. If a dispute arises, approach the manufacturer with documented evidence of the problem and attempt to resolve it amicably. If necessary, refer to the contract’s dispute resolution clause, which may include mediation or arbitration, to settle the matter without escalating to legal action. -

What environmental considerations should I be aware of when sourcing septic tanks?

Environmental regulations can significantly impact the design and installation of septic tanks. Familiarize yourself with local laws regarding wastewater management and disposal, as well as any eco-friendly standards manufacturers may adhere to. Look for tanks made from sustainable materials and those designed to minimize environmental impact. Discuss with the manufacturer their commitment to sustainability and any certifications they possess, such as LEED or other environmental quality standards, to ensure compliance with regulations in your region.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for septic tank manufacturers

In today’s rapidly evolving landscape of wastewater management, strategic sourcing of septic tank manufacturers is paramount for international B2B buyers. Key takeaways highlight the importance of selecting reputable manufacturers that prioritize innovation, sustainability, and compliance with regulatory standards. Companies such as Infiltrator Water Technologies, Roth Global Plastics, and Xerxes by Shawcor exemplify the high-quality options available, each offering unique solutions tailored to diverse applications.

Strategic sourcing not only enhances the reliability and efficiency of wastewater systems but also aligns with growing demands for environmental sustainability. As urbanization continues to increase, particularly in developing regions of Africa and South America, the need for effective sanitation solutions becomes critical.

Looking ahead, B2B buyers are encouraged to engage with manufacturers that demonstrate a commitment to technological advancements and customer support. By prioritizing these partnerships, businesses can ensure the longevity and effectiveness of their septic systems. Embrace this opportunity to explore the market, leverage innovative products, and contribute to a sustainable future in wastewater management.