Master Sourcing Anechoic Chambers Near Me: Essential Guide

Introduction: Navigating the Global Market for anechoic chambers near me

In today’s global marketplace, the significance of anechoic chambers cannot be overstated. These specialized environments are crucial for a variety of applications, from electromagnetic compatibility (EMC) testing to acoustic research, making them indispensable for businesses in sectors such as telecommunications, automotive, and electronics. For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and Kenya—understanding how to navigate the procurement of anechoic chambers is vital for ensuring compliance with industry standards and enhancing product development.

This comprehensive guide will equip you with the knowledge needed to make informed sourcing decisions. It covers an array of topics including:

- Types of Anechoic Chambers: Explore the differences between full and semi-anechoic chambers and their respective applications.

- Materials and Construction: Understand the various materials used in chamber design and their impact on performance.

- Manufacturing and Quality Control: Learn about the standards and certifications that ensure the reliability of these critical facilities.

- Suppliers and Market Trends: Gain insights into leading manufacturers and emerging suppliers globally.

- Cost Considerations: Analyze factors influencing pricing, from initial investment to maintenance.

- FAQs: Address common queries to demystify the purchasing process.

By empowering international B2B buyers with this knowledge, the guide aims to streamline the acquisition process, enhance operational efficiency, and ultimately support the growth of businesses navigating the complexities of the global market for anechoic chambers.

Understanding anechoic chambers near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Semi-Anechoic Chambers | Equipped with absorptive materials on walls and a reflective floor | EMC testing, product development | Pros: Versatile for various tests; Cons: Higher cost due to specialized design. |

| Full Anechoic Chambers | Completely isolated; all walls, ceiling, and floor are sound-absorbent | Research, audio equipment testing | Pros: Maximum sound isolation; Cons: Requires significant space and investment. |

| Industrial Anechoic Chambers | Designed for larger equipment and industrial applications | Machinery testing, automotive noise testing | Pros: Accommodates large equipment; Cons: Space and construction costs can be high. |

| Portable Anechoic Chambers | Mobile units that can be set up on-site | Field testing, temporary installations | Pros: Flexible and convenient; Cons: Limited space and acoustic performance. |

| Custom Anechoic Chambers | Tailored designs based on specific client needs | Specialized testing for unique products | Pros: Meets specific requirements; Cons: Longer lead times and potentially higher costs. |

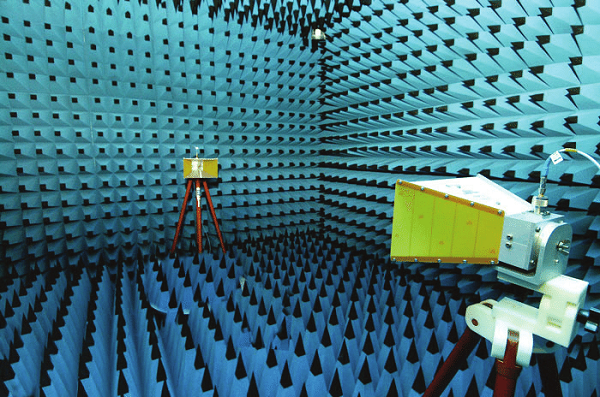

Semi-Anechoic Chambers

Semi-anechoic chambers feature walls lined with sound-absorbing materials while maintaining a reflective floor. These chambers are primarily used for electromagnetic compatibility (EMC) testing and product development, allowing companies to evaluate how products perform in terms of noise and interference. When considering a purchase, businesses should evaluate the chamber’s size and adaptability to various testing scenarios, as well as the reputation of the manufacturer in providing reliable testing environments.

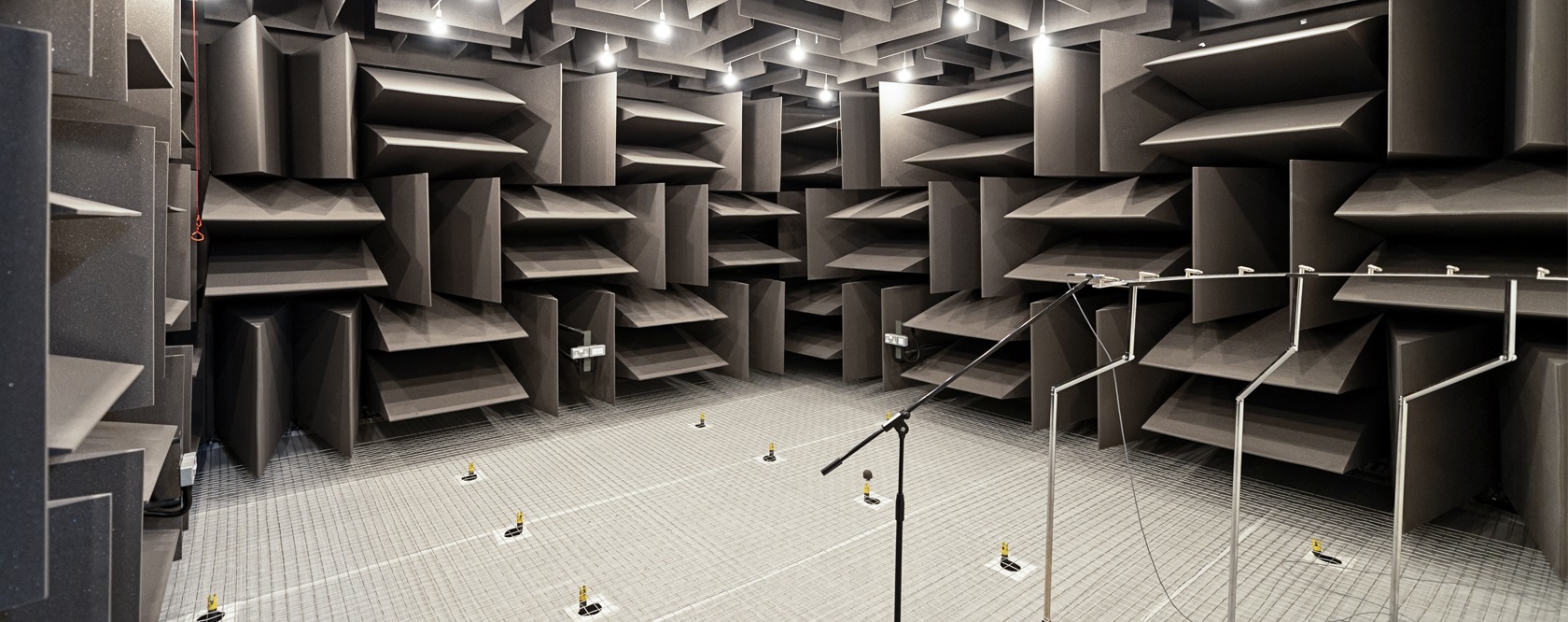

Full Anechoic Chambers

Full anechoic chambers offer complete sound isolation, with all surfaces designed to absorb sound waves. This type is ideal for advanced research and audio equipment testing, where precise acoustic measurements are critical. Buyers must consider the significant investment required for construction and maintenance, as well as the space needed for installation. The unparalleled isolation provided is a major advantage for companies focused on high-fidelity sound analysis.

Industrial Anechoic Chambers

Industrial anechoic chambers are built to accommodate larger machinery and equipment, making them suitable for industries such as automotive and manufacturing. These chambers facilitate noise testing and compliance evaluations, ensuring that industrial products meet regulatory standards. Buyers should assess the chamber’s dimensions and structural integrity, as well as the potential return on investment through enhanced product compliance and marketability.

Portable Anechoic Chambers

Portable anechoic chambers are mobile solutions designed for on-site testing and temporary installations. They are particularly useful for field testing and can be quickly set up in various locations. While they offer flexibility, buyers need to consider the limitations in size and acoustic performance compared to fixed chambers. The convenience of mobility can be a significant advantage for companies needing to conduct tests in diverse environments.

Custom Anechoic Chambers

Custom anechoic chambers are designed to meet specific client requirements, allowing for tailored solutions for unique testing needs. These chambers can accommodate a variety of applications, from specialized product testing to unique research projects. Buyers should weigh the benefits of customization against potential lead times and costs, as bespoke solutions can require more time and investment. Ensuring that the manufacturer has a proven track record in delivering quality custom solutions is essential for a successful purchase.

Related Video: What Are The Different Atomic Models? Dalton, Rutherford, Bohr and Heisenberg Models Explained

Key Industrial Applications of anechoic chambers near me

| Industry/Sector | Specific Application of anechoic chambers near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics | Electromagnetic Compatibility (EMC) Testing | Ensures compliance with regulatory standards, reducing risk of product recalls. | Look for chambers with advanced shielding and testing capabilities. |

| Automotive | Noise and Vibration Testing | Enhances product quality by identifying noise-related issues early in the design phase. | Consider chambers equipped for both passive and active noise control. |

| Aerospace | Acoustic Testing for Components | Validates the performance of aircraft components under noise conditions, ensuring safety and comfort. | Seek suppliers with experience in aerospace standards and certifications. |

| Telecommunications | Signal Integrity Testing | Guarantees reliable performance of communication devices, minimizing interference. | Evaluate the chamber’s size and design to accommodate various device types. |

| Consumer Goods | Product Sound Quality Assessment | Improves market competitiveness by ensuring high-quality sound in consumer electronics. | Ensure the chamber can simulate real-world acoustic environments. |

Electronics: Electromagnetic Compatibility (EMC) Testing

In the electronics sector, anechoic chambers are pivotal for conducting Electromagnetic Compatibility (EMC) testing. These chambers allow for controlled environments where devices can be tested for electromagnetic interference (EMI) and susceptibility (EMS). For international buyers, especially in emerging markets, sourcing chambers that meet local and international compliance standards is crucial. This ensures products can be marketed globally without regulatory issues, thereby reducing potential recalls and associated costs.

Automotive: Noise and Vibration Testing

The automotive industry utilizes anechoic chambers for noise and vibration testing to enhance vehicle comfort and performance. By simulating various acoustic environments, manufacturers can identify noise-related issues in components early in the design process. Buyers should prioritize chambers with capabilities for both passive and active noise control. This not only improves product quality but also aids in meeting stringent safety and comfort standards demanded by consumers in Africa, South America, and Europe.

Illustrative Image (Source: Google Search)

Aerospace: Acoustic Testing for Components

In aerospace, anechoic chambers are essential for acoustic testing of components to ensure safety and comfort during flight. These chambers facilitate the assessment of how various parts respond to noise conditions, a critical aspect of aircraft design. Buyers in this sector should look for suppliers with expertise in aerospace standards and certifications, ensuring that the testing environment meets regulatory requirements for both commercial and military applications.

Telecommunications: Signal Integrity Testing

Telecommunications companies rely on anechoic chambers for signal integrity testing, ensuring that devices function reliably without interference. This is particularly important in regions experiencing rapid technological growth, where devices must meet both local and international standards. Buyers should evaluate the chamber’s design to accommodate a variety of device sizes and types, ensuring flexibility in testing processes that can keep pace with evolving technology.

Consumer Goods: Product Sound Quality Assessment

Consumer goods manufacturers use anechoic chambers to assess the sound quality of electronic products, such as speakers and headphones. By simulating real-world acoustic environments, businesses can optimize their products for better market competitiveness. International buyers should ensure that the chambers they source can mimic various sound conditions, allowing for thorough testing that can lead to improved product offerings and customer satisfaction.

Related Video: Hemi Anechoic Chamber Build Time Lapse

Strategic Material Selection Guide for anechoic chambers near me

When selecting materials for anechoic chambers, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in the construction of anechoic chambers, focusing on their key properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Acoustic Foam

Key Properties:

Acoustic foam is designed to absorb sound waves, reducing echo and reverberation within an anechoic chamber. It typically exhibits a high sound absorption coefficient, particularly at mid to high frequencies.

Pros & Cons:

The primary advantage of acoustic foam is its lightweight nature and ease of installation, making it cost-effective for large applications. However, it may not withstand extreme temperatures or humidity, leading to potential degradation over time.

Impact on Application:

Acoustic foam is ideal for environments that require sound isolation without significant temperature fluctuations. However, it may not be suitable for high-humidity applications, such as coastal regions.

Considerations for International Buyers:

Buyers should ensure that the foam meets local fire safety standards, such as ASTM E84 or EN 13501. Additionally, sourcing from local manufacturers can mitigate shipping costs and lead times.

2. Mass Loaded Vinyl (MLV)

Key Properties:

Mass Loaded Vinyl is a dense material that provides excellent soundproofing capabilities. It is flexible and can be applied to various surfaces, enhancing its versatility.

Pros & Cons:

MLV is highly effective in blocking sound transmission and is resistant to moisture, making it suitable for diverse environments. However, its weight can complicate installation and increase shipping costs.

Impact on Application:

MLV is particularly useful in industrial settings where heavy machinery operates, as it can significantly reduce noise pollution. Its compatibility with various substrates makes it a preferred choice for retrofitting existing structures.

Considerations for International Buyers:

Compliance with local noise regulations is crucial. Buyers should also verify the material’s certifications, such as ASTM D751, to ensure it meets specific performance standards.

3. Concrete

Key Properties:

Concrete is a robust material known for its durability and sound insulation properties. It can be engineered to withstand high pressures and extreme environmental conditions.

Pros & Cons:

The primary advantage of concrete is its longevity and resistance to fire and pests. However, it requires significant investment in terms of labor and machinery for installation, making it less cost-effective for smaller projects.

Impact on Application:

Concrete is suitable for permanent installations, particularly in areas with high noise levels, such as near highways or industrial zones. Its thermal mass can also aid in temperature regulation within the chamber.

Considerations for International Buyers:

Buyers must consider local building codes and seismic regulations when using concrete. Additionally, sourcing locally can reduce transportation costs and ensure compliance with regional standards.

4. Acoustic Panels

Key Properties:

Acoustic panels are made from various materials, including fiberglass and wood, designed to absorb sound and reduce reflections. They come in various shapes and sizes, allowing for customizable designs.

Pros & Cons:

These panels offer aesthetic flexibility and can be tailored to specific acoustic needs. However, they may require regular maintenance and replacement, especially in high-traffic areas.

Impact on Application:

Acoustic panels are ideal for commercial environments, such as offices and conference rooms, where both sound control and aesthetics are important. They can also be used in educational settings to enhance learning environments.

Considerations for International Buyers:

Buyers should assess the environmental impact of the materials used in acoustic panels, opting for sustainable options when possible. Certification against standards like ISO 9001 can also be beneficial for quality assurance.

Summary Table

| Material | Typical Use Case for anechoic chambers near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acoustic Foam | Sound isolation in studios and offices | Lightweight and easy to install | Limited durability in extreme conditions | Low |

| Mass Loaded Vinyl | Industrial noise control | Excellent sound blocking | Heavy, complicates installation | Medium |

| Concrete | Permanent installations near noise sources | Extremely durable and fire-resistant | High installation costs | High |

| Acoustic Panels | Commercial spaces needing sound control | Aesthetic flexibility | Requires maintenance and replacement | Medium |

This strategic material selection guide aims to equip international B2B buyers with the necessary insights to make informed decisions when sourcing materials for anechoic chambers, ensuring compliance with local standards and optimizing performance for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for anechoic chambers near me

Anechoic chambers are specialized environments designed to attenuate sound and electromagnetic interference, making them essential for various industries, including telecommunications, automotive, and consumer electronics. Understanding the manufacturing processes and quality assurance protocols involved in creating these chambers is critical for international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe.

Manufacturing Processes

Material Preparation

The first step in manufacturing anechoic chambers involves selecting and preparing the right materials. Common materials used include:

- Acoustic Foam: This is used to absorb sound waves and reduce echoes. The foam must be treated to ensure durability and effectiveness.

- Mass Loaded Vinyl (MLV): This material is used for soundproofing, offering high-density barriers that block sound transmission.

- Steel or Aluminum Frames: These are often utilized for the structural framework of the chamber, providing stability and durability.

Once materials are selected, they undergo rigorous testing to ensure they meet specific acoustic and electromagnetic properties. Suppliers should provide certificates of compliance to verify material quality.

Forming

The forming stage includes cutting, shaping, and assembling the materials into the desired structure. Techniques employed may involve:

- CNC Machining: Precision cutting of metal components ensures accuracy in the chamber’s dimensions.

- Thermal Molding: This process shapes acoustic foam into specific designs that enhance sound absorption.

- Welding and Fastening: Metal components are welded or bolted together to create a robust frame.

During this stage, attention to detail is critical, as even minor deviations can impact the chamber’s performance.

Assembly

Once the components are formed, the next step is assembly. This involves:

- Installation of Acoustic Treatment: Acoustic panels and foam are installed inside the chamber to optimize sound absorption and minimize reflections.

- Electrical Wiring: If the chamber requires lighting, ventilation, or monitoring systems, wiring is installed at this stage.

- Sealing: Ensuring airtight seals is essential for maintaining the chamber’s effectiveness, particularly for electromagnetic compatibility.

Assembly requires skilled labor to ensure that all components fit together seamlessly and function as intended.

Finishing

The final stage involves finishing touches that enhance both performance and aesthetics. This may include:

- Surface Treatment: Painting or coating metal surfaces to prevent corrosion and improve appearance.

- Quality Checks: Before final delivery, chambers undergo extensive quality control checks to ensure they meet specified performance standards.

Quality Assurance

Quality assurance is paramount in the manufacturing of anechoic chambers, given their critical applications. International standards and industry-specific certifications guide this process.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent quality in manufacturing processes.

- CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: In specialized sectors like oil and gas, adherence to API standards is crucial for equipment used in harsh environments.

Quality Control Checkpoints

Quality control is typically segmented into various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting materials upon arrival to ensure they meet predefined specifications.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the production process and address any discrepancies immediately.

- Final Quality Control (FQC): Before shipment, the finished product is tested against performance criteria to ensure it meets all requirements.

Common Testing Methods

Testing methods for anechoic chambers include:

- Acoustic Testing: Measuring sound absorption and reflection characteristics to ensure compliance with required standards.

- Electromagnetic Compatibility Testing: Ensuring the chamber effectively shields against electromagnetic interference, often conducted in semi-anechoic chambers.

Verifying Supplier Quality Control

B2B buyers must take proactive steps to verify the quality assurance processes of suppliers:

- Audits: Conducting regular audits of manufacturing facilities can provide insights into their quality management systems and adherence to standards.

- Reports: Requesting detailed quality control reports can help assess a supplier’s commitment to maintaining high standards.

- Third-Party Inspections: Engaging independent inspectors to evaluate manufacturing processes and final products can offer an unbiased assessment of quality.

Quality Control and Certification Nuances for International Buyers

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances:

- Regional Compliance: Understand the regulatory requirements of the destination country for importation and usage, such as local EMC regulations.

- Cultural Considerations: Different regions may have varying expectations regarding quality and service. Establishing clear communication with suppliers can help bridge these gaps.

- Supply Chain Transparency: Ensure that suppliers maintain transparency throughout the supply chain, from raw material sourcing to final product delivery.

By carefully evaluating the manufacturing processes and quality assurance protocols of anechoic chamber suppliers, international B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

Related Video: The 10 steps of the Chocolate Manufacturing Process

Comprehensive Cost and Pricing Analysis for anechoic chambers near me Sourcing

When sourcing anechoic chambers, understanding the cost structure and pricing dynamics is crucial for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. The costs associated with these specialized soundproof environments can vary significantly based on several components and influencing factors.

Cost Components

-

Materials: The selection of materials for anechoic chambers directly impacts the overall cost. High-quality sound-absorbing materials, such as specialized foam and mass-loaded vinyl, are essential for optimal performance. The price will fluctuate based on the type and quality of these materials.

-

Labor: Skilled labor is required for the design, construction, and installation of anechoic chambers. Labor costs can vary based on geographic location and the complexity of the project. In regions with a shortage of skilled workers, labor costs may be higher.

-

Manufacturing Overhead: This includes the indirect costs associated with production, such as utilities, depreciation of machinery, and administrative expenses. Manufacturers with advanced facilities and technology may have higher overhead costs, which can influence pricing.

-

Tooling: Custom tooling may be necessary for specific designs or configurations of anechoic chambers. The initial investment in tooling can affect the pricing structure, especially for low-volume orders.

-

Quality Control (QC): Ensuring that anechoic chambers meet stringent performance standards requires rigorous quality control processes. The costs associated with testing and certification can add to the overall price.

-

Logistics: Transportation of materials and the finished product can significantly affect costs, especially for international shipping. Factors such as distance, shipping method, and potential tariffs should be considered.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding the typical margins in your region can help in negotiations.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can influence pricing. Larger orders often result in lower per-unit costs due to economies of scale.

-

Specifications/Customization: Custom-built anechoic chambers tailored to specific requirements will incur higher costs compared to standard models. Clearly defining your needs will help in obtaining accurate quotes.

-

Quality/Certifications: Chambers that comply with international standards (e.g., ISO, ANSI) may be priced higher due to the additional testing and certification processes involved.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers may charge more but could offer better quality assurance and service.

-

Incoterms: The agreed Incoterms (International Commercial Terms) affect the total cost. For instance, costs may vary depending on whether the supplier or buyer is responsible for shipping and insurance.

Buyer Tips

-

Negotiation: Leverage your position as a buyer to negotiate terms. Understanding the supplier’s cost structure can provide insights into where there may be flexibility in pricing.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not only the initial purchase price but also installation, maintenance, and operational costs over the chamber’s lifespan.

-

Pricing Nuances: Be aware of regional pricing differences. Suppliers in developed regions may have higher prices due to labor and materials, while emerging markets may offer competitive rates but could have trade-offs in quality or service.

Disclaimer

Prices for anechoic chambers can vary widely based on the factors mentioned above. It is advisable to obtain multiple quotes and conduct thorough due diligence before making purchasing decisions. Always consult with suppliers for the most accurate and up-to-date pricing information tailored to your specific needs.

Spotlight on Potential anechoic chambers near me Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘anechoic chambers near me’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for anechoic chambers near me

Key Technical Properties of Anechoic Chambers

Understanding the essential technical specifications of anechoic chambers is crucial for B2B buyers, particularly when selecting the right chamber for specific applications. Here are some critical specifications to consider:

- Material Composition

Anechoic chambers are typically constructed from specialized materials designed to absorb sound and electromagnetic waves. Common materials include fiberglass, polyurethane foam, and mass-loaded vinyl. The choice of material affects the chamber’s sound absorption coefficient and electromagnetic interference (EMI) shielding capabilities. Buyers should ensure that the materials meet industry standards for durability and effectiveness.

Illustrative Image (Source: Google Search)

-

Sound Absorption Coefficient (SAC)

The sound absorption coefficient is a measure of how effectively a chamber can absorb sound across various frequencies. Values range from 0 (no absorption) to 1 (total absorption). A higher SAC is essential for applications requiring precise acoustic measurements, such as product testing and research. Buyers must evaluate the SAC ratings to ensure the chamber meets their specific testing requirements. -

Size and Tolerance

The internal dimensions of an anechoic chamber must be suitable for the intended use, whether for testing small electronic devices or large machinery. Tolerance refers to the permissible deviation from specified dimensions, which can impact measurement accuracy. Buyers should specify their size requirements and tolerances in their requests to ensure compatibility with their equipment. -

Frequency Range

Different applications require different frequency ranges for testing. Anechoic chambers are designed to perform effectively within specific frequency bands, such as low frequencies (20 Hz) to high frequencies (20 kHz) for audio testing, or up to several gigahertz for electromagnetic testing. Understanding the frequency range is vital for buyers to ensure that the chamber can accommodate their testing needs. -

Isolation Level

The level of isolation defines how effectively the chamber prevents external noise and electromagnetic interference from affecting the tests conducted inside. Isolation levels can be quantified in terms of decibels (dB). For precise testing, a chamber with high isolation (e.g., 80 dB or more) is often necessary. Buyers should evaluate isolation requirements based on the intended use of the chamber.

Common Trade Terminology

Familiarizing oneself with industry-specific terminology is essential for effective communication and negotiation. Here are some key terms relevant to the procurement of anechoic chambers:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of anechoic chambers, OEMs may supply specific components like sound-absorbing materials or electronics used for testing. Understanding OEM relationships helps buyers ensure they are sourcing quality components from reputable manufacturers. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For anechoic chambers, MOQs can affect procurement strategies, especially for smaller companies or startups. Buyers should negotiate MOQs to align with their budget and project needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. In the case of anechoic chambers, an RFQ should detail technical specifications, desired materials, and delivery timelines. A well-structured RFQ can streamline the procurement process and ensure accurate pricing. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms like EXW (Ex Works) or CIF (Cost, Insurance, and Freight) is essential for buyers to manage logistics and cost responsibilities effectively. -

Lead Time

Lead time refers to the amount of time from the placement of an order until the product is delivered. For anechoic chambers, lead times can vary significantly based on customization, manufacturing processes, and supplier capabilities. Buyers should factor in lead times when planning project timelines to avoid delays. -

Certification Standards

Certification standards, such as ISO or ANSI, indicate compliance with industry-specific regulations and quality benchmarks. Buyers should ensure that the anechoic chambers they procure meet relevant certification standards to guarantee performance and reliability in testing environments.

By understanding these essential technical properties and trade terminology, B2B buyers can make informed decisions when sourcing anechoic chambers tailored to their specific needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the anechoic chambers near me Sector

In recent years, the demand for anechoic chambers has surged globally, driven by the increasing need for precise acoustic measurements and testing in various industries, including electronics, automotive, and telecommunications. Key market drivers include advancements in technology, stringent regulatory standards for electromagnetic compatibility (EMC), and the rising importance of sound quality in consumer products. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to enhance product quality, anechoic chambers are becoming essential for product development and compliance testing.

Current and emerging trends in sourcing include the integration of advanced materials and technologies, such as mass-loaded vinyl and acoustic wall panels, which are increasingly favored for their effectiveness in soundproofing. Furthermore, the shift towards customized solutions tailored to specific industry needs is notable, allowing buyers to optimize their testing environments. Buyers should also be aware of digital transformation trends, such as the use of IoT for real-time monitoring and data collection, which can enhance the efficiency of testing processes.

Market dynamics are influenced by regional factors, including varying regulatory requirements and levels of technological adoption. For instance, buyers in Europe may face stricter EMC regulations compared to those in Africa or South America. As a result, understanding local market conditions and compliance standards is crucial for successful sourcing strategies.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration for B2B buyers in the anechoic chamber sector. The environmental impact of manufacturing materials and the operation of these chambers can be significant. Therefore, sourcing eco-friendly materials is essential. Materials such as recycled acoustic panels and sustainable soundproofing products not only reduce the carbon footprint but also align with corporate social responsibility (CSR) goals.

The importance of ethical supply chains cannot be overstated. Buyers should prioritize suppliers who demonstrate transparency in their sourcing practices and adhere to international labor standards. Certifications like LEED (Leadership in Energy and Environmental Design) or ISO 14001 can serve as indicators of a supplier’s commitment to sustainability. By opting for suppliers with green certifications, buyers not only contribute to environmental preservation but also enhance their brand reputation among increasingly eco-conscious consumers.

Brief Evolution/History

The concept of anechoic chambers dates back to the mid-20th century, initially developed for military and scientific research purposes. Over time, their application expanded into various industries, including telecommunications and consumer electronics, due to the growing need for accurate acoustic and electromagnetic testing. As technological advancements continue, the design and functionality of anechoic chambers have evolved, incorporating modern materials and digital technologies, making them indispensable tools for B2B buyers focused on innovation and compliance.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of anechoic chambers near me

-

What should I consider when vetting suppliers of anechoic chambers?

When vetting suppliers, prioritize their experience in manufacturing anechoic chambers and verify their track record with previous clients. Look for certifications such as ISO 9001, which indicates quality management systems, and any relevant compliance with international standards like IEC or ASTM. Request case studies or testimonials to assess their credibility. Additionally, consider their ability to provide after-sales support and maintenance services, as this can be crucial for long-term satisfaction. -

Can anechoic chambers be customized for specific testing requirements?

Yes, many suppliers offer customization options for anechoic chambers to meet specific testing needs. This may include adjustments in size, acoustic insulation materials, or additional features such as temperature control or vibration isolation. When discussing customization, provide detailed specifications regarding your testing parameters and requirements. Ensure that the supplier has experience in delivering customized solutions, as this will significantly impact the chamber’s effectiveness for your applications. -

What are the typical minimum order quantities (MOQ) and lead times for anechoic chambers?

Minimum order quantities for anechoic chambers can vary widely depending on the supplier and the complexity of the design. Generally, custom-built chambers may require a higher MOQ due to the specific materials and labor involved. Lead times can range from a few weeks to several months, influenced by factors such as customization, production capacity, and shipping logistics. Always confirm these details upfront to align your project timelines and avoid delays. -

What payment terms are commonly offered by suppliers?

Payment terms can differ significantly among suppliers, but common practices include a deposit upon order confirmation (typically 30-50%) with the balance due upon completion or before shipment. Some suppliers may offer financing options or payment plans, particularly for larger orders. It’s advisable to negotiate terms that suit your cash flow needs while ensuring a secure transaction. Make sure to review any warranties or guarantees in relation to payment terms to protect your investment. -

How can I ensure quality assurance and certification for the anechoic chambers I purchase?

To ensure quality assurance, request documentation of the supplier’s quality management processes and any relevant certifications, such as ISO 17025 for testing laboratories. Inquire about their testing protocols and whether they conduct performance evaluations on their chambers before delivery. Additionally, consider suppliers who are willing to provide third-party validation or certification from recognized bodies, which can enhance the credibility of the products. -

What logistics considerations should I keep in mind when sourcing anechoic chambers?

Logistics play a critical role in the procurement of anechoic chambers, particularly regarding transportation and installation. Verify the supplier’s experience in handling international shipping, including customs clearance processes for your region. Discuss delivery timelines, shipping costs, and the supplier’s policy on damages during transport. Additionally, consider the installation requirements, as some chambers may need specialized setup that could necessitate on-site assistance from the supplier. -

How should I handle disputes with suppliers?

To effectively manage disputes, establish clear terms and conditions in your purchase agreement, including clauses on dispute resolution. Open communication is vital; address issues promptly and professionally to seek a mutual resolution. If necessary, engage in mediation or arbitration as outlined in your contract. It’s also beneficial to maintain a record of all communications and agreements to support your case should formal dispute resolution become necessary. -

What are the common applications for anechoic chambers in different industries?

Anechoic chambers are utilized across various industries for applications such as electromagnetic compatibility (EMC) testing, audio equipment testing, and research in acoustics. In the automotive sector, they are essential for assessing noise, vibration, and harshness (NVH) levels. In telecommunications, they help in evaluating antenna performance. Understanding your industry’s specific needs can help you select the right type of chamber and testing protocols to ensure compliance and performance standards are met.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for anechoic chambers near me

In conclusion, strategic sourcing of anechoic chambers presents a significant opportunity for international B2B buyers, especially those operating in sectors requiring precision testing and compliance, such as electronics and automotive. By prioritizing partnerships with reputable suppliers, buyers can ensure access to high-quality chambers that meet stringent electromagnetic compatibility (EMC) regulations and other industry standards.

Key Takeaways:

– Quality Assurance: Investing in certified anechoic chambers can enhance product reliability and compliance, mitigating risks associated with electromagnetic interference.

– Local Sourcing Benefits: Engaging with local suppliers in regions like Africa, South America, the Middle East, and Europe can reduce lead times and shipping costs, facilitating more agile project management.

– Innovation and Collaboration: Collaborating with manufacturers that offer customized solutions and ongoing support can lead to better outcomes in product development and testing.

As the demand for advanced testing facilities continues to rise, now is the time for B2B buyers to evaluate their sourcing strategies. Embrace the potential of anechoic chambers to drive innovation and ensure compliance in your projects. Take action today by exploring local suppliers and leveraging their expertise to gain a competitive edge in your industry.