Master Sourcing High-Quality Jib Crane Parts for Optimal

Introduction: Navigating the Global Market for jib crane parts

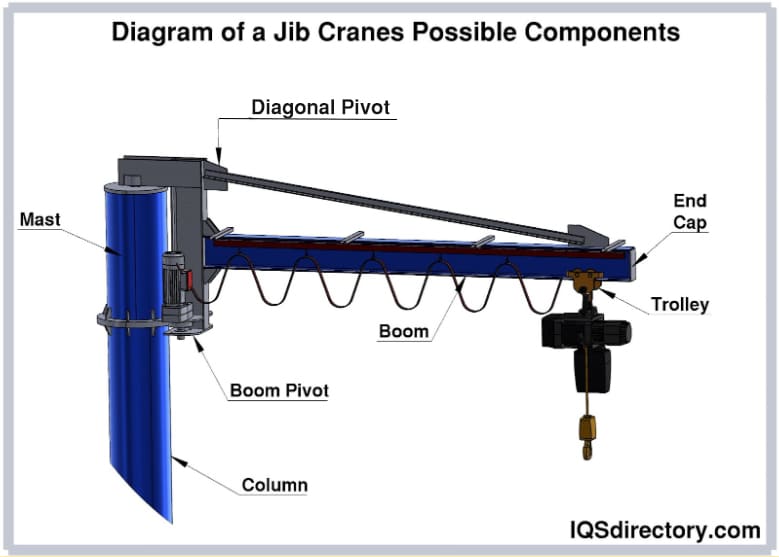

In the dynamic landscape of industrial operations, jib crane parts are pivotal for enhancing efficiency in material handling. These components, which include the mast, boom, hoist, trolley, and counterweights, are essential for safely lifting and moving heavy loads within confined spaces. As global markets expand, understanding the intricacies of jib crane parts becomes increasingly vital for international B2B buyers seeking reliable solutions.

This comprehensive guide equips you with valuable insights into the diverse types of jib crane parts, the materials used in their manufacturing, and the stringent quality control measures that ensure durability and safety. We delve into the sourcing landscape, offering strategies for identifying reputable suppliers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Turkey and Spain.

Moreover, we address critical considerations regarding cost factors and market trends that impact purchasing decisions. With a focus on empowering informed sourcing, this guide also answers frequently asked questions, helping you navigate the complexities of compatibility and installation.

By leveraging the knowledge shared in this guide, B2B buyers can confidently procure high-quality jib crane parts that meet their operational needs, ensuring both safety and efficiency in their material handling processes. Your journey towards effective sourcing starts here, paving the way for successful industrial operations across the globe.

Understanding jib crane parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Freestanding Jib Crane | Independent structure, 360-degree rotation, high load capacity | Manufacturing, warehouses, construction | Pros: High mobility, versatile; Cons: Requires floor space, higher initial investment. |

| Wall-Mounted Jib Crane | Fixed to walls, limited rotation (180-200 degrees), space-efficient | Assembly lines, workshops, small spaces | Pros: Space-saving, lower cost; Cons: Limited range of motion, dependent on wall strength. |

| Mast Jib Crane | Vertical mast support, can support heavier loads, often adjustable | Heavy-duty lifting in factories | Pros: High stability, excellent for heavy loads; Cons: More complex installation, higher maintenance. |

| Articulating Jib Crane | Flexible arm design, multiple pivot points, ideal for tight spaces | Loading docks, shipyards, automotive | Pros: Enhanced maneuverability, great for confined areas; Cons: More moving parts can lead to higher maintenance. |

| Portable Jib Crane | Lightweight, easily movable, often with wheels | Construction sites, outdoor applications | Pros: High portability, easy setup; Cons: Lower load capacity, less stability than fixed cranes. |

Freestanding Jib Crane

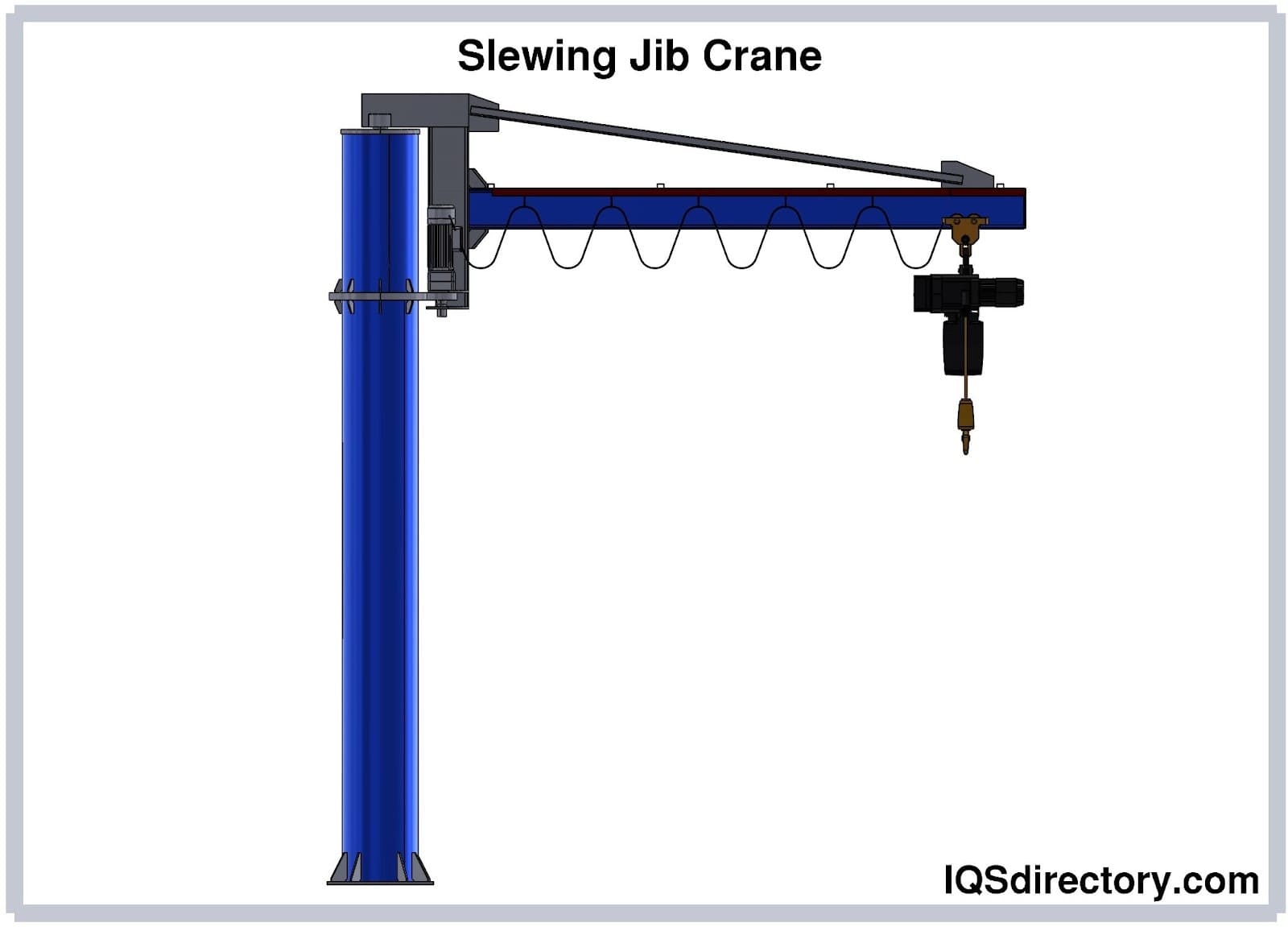

Freestanding jib cranes are versatile and can rotate 360 degrees, making them suitable for various applications, including manufacturing and construction. They are designed as independent structures that do not require support from walls or ceilings, allowing for high mobility and flexibility in load handling. When purchasing, consider the available floor space and the crane’s load capacity, as these factors can significantly affect its operational efficiency.

Wall-Mounted Jib Crane

Wall-mounted jib cranes are fixed to walls and typically offer a rotation range of 180 to 200 degrees. They are ideal for applications in assembly lines and workshops where space is limited. Buyers should assess the wall’s structural integrity and ensure that it can support the crane’s weight and load capacity. This type of crane is generally more cost-effective but may limit the range of motion compared to freestanding options.

Mast Jib Crane

Mast jib cranes feature a vertical mast that provides robust support for heavy loads, making them suitable for heavy-duty lifting tasks in factories and industrial settings. Their design allows for greater stability, but they may require more complex installation and maintenance. B2B buyers should evaluate the specific lifting requirements and the crane’s compatibility with existing infrastructure to ensure optimal performance.

Articulating Jib Crane

Articulating jib cranes come with a flexible arm design that includes multiple pivot points, making them ideal for applications in loading docks, shipyards, and automotive industries where maneuverability is crucial. Their ability to navigate tight spaces enhances operational efficiency. Buyers should consider the potential for increased maintenance due to the complexity of moving parts and ensure that the crane meets their specific operational needs.

Portable Jib Crane

Portable jib cranes are lightweight and designed for easy mobility, often equipped with wheels for quick relocation. They are well-suited for construction sites and outdoor applications where flexibility is essential. While they offer high portability and easy setup, buyers should be aware of their lower load capacity and reduced stability compared to fixed installations. Assessing load requirements and site conditions is critical when considering this option.

Related Video: Gorbel Jib Crane Installation Part 2

Key Industrial Applications of jib crane parts

| Industry/Sector | Specific Application of jib crane parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Assembly line support | Enhances efficiency in material handling | Ensure compatibility with existing systems and load capacity. |

| Construction | Lifting and positioning heavy materials | Reduces labor costs and increases safety | Look for corrosion-resistant materials for outdoor use. |

| Warehousing | Loading/unloading goods in storage facilities | Optimizes space utilization and speeds up operations | Verify supplier certifications and warranty terms. |

| Automotive | Engine assembly and vehicle maintenance | Improves precision and reduces downtime | Consider the availability of spare parts for maintenance. |

| Logistics | Moving goods within distribution centers | Increases operational flexibility and speed | Assess supplier reliability and delivery timelines. |

Manufacturing

In the manufacturing sector, jib crane parts are crucial for supporting assembly lines, where they facilitate the lifting and positioning of components. By utilizing jib cranes, manufacturers can enhance efficiency in material handling, allowing for quicker assembly processes and reduced worker fatigue. Buyers in this sector should ensure that the jib crane parts are compatible with their existing systems and can handle the required load capacities, as well as evaluate the quality and durability of the materials used.

Construction

Jib cranes are widely used in construction for lifting and positioning heavy materials, such as steel beams and concrete blocks. Their ability to operate in confined spaces makes them ideal for various construction sites, helping to reduce labor costs and increase safety by minimizing manual lifting. International B2B buyers should prioritize sourcing jib crane parts made from corrosion-resistant materials, particularly for projects in humid or coastal environments, to ensure longevity and reliability.

Warehousing

In warehousing, jib crane parts play a vital role in the efficient loading and unloading of goods. They enable workers to move items swiftly and safely, optimizing space utilization within storage facilities. This leads to faster operations and improved inventory management. Buyers should verify the certifications of suppliers to ensure compliance with safety standards and check warranty terms to safeguard their investment against potential defects.

Automotive

The automotive industry relies on jib crane parts for engine assembly and vehicle maintenance tasks. These cranes improve precision in lifting heavy components, which can significantly reduce downtime and enhance productivity on the assembly line. For international buyers, it is essential to consider the availability of spare parts for ongoing maintenance, as well as the reputation of suppliers in providing high-quality components that meet industry standards.

Logistics

In logistics, jib crane parts are instrumental in moving goods within distribution centers. Their flexibility allows for quick adjustments to workflows, which can enhance operational speed and efficiency. Buyers should assess supplier reliability and delivery timelines to ensure that they can meet operational demands, particularly in fast-paced environments where downtime can lead to significant losses.

Related Video: VETTER Krantechnik – MOBILUS – The mobile slewing jib crane

Strategic Material Selection Guide for jib crane parts

When selecting materials for jib crane parts, it is essential to consider the specific properties, advantages, disadvantages, and application impacts of each material. This analysis will focus on four common materials used in jib crane components: Steel, Aluminum, Cast Iron, and Plastic Composites. Understanding these materials will help international B2B buyers make informed decisions based on their operational requirements and regional standards.

Steel

Key Properties: Steel is known for its high tensile strength and durability, making it suitable for heavy-duty applications. It has excellent temperature and pressure ratings, allowing it to withstand extreme conditions without deforming. Additionally, corrosion-resistant alloys, such as stainless steel, can be used to enhance its longevity in harsh environments.

Pros & Cons: The primary advantage of steel is its strength and ability to handle heavy loads, which is critical for jib crane applications. However, it can be relatively heavy, increasing the overall weight of the crane. The manufacturing process can also be complex and costly, especially for high-grade or specialty steels.

Impact on Application: Steel is ideal for environments where heavy lifting is required, such as construction sites or manufacturing facilities. Its compatibility with various media, including corrosive substances, can be improved with appropriate coatings.

Considerations for Buyers: Buyers from regions like Africa and the Middle East should ensure that the steel used complies with local standards (e.g., ASTM, DIN). It’s essential to consider the availability of high-quality steel suppliers in their region to avoid delays and ensure compliance with safety regulations.

Aluminum

Key Properties: Aluminum is lightweight and has excellent corrosion resistance, making it suitable for various applications. It has a lower tensile strength compared to steel but offers good performance in environments where weight reduction is essential.

Pros & Cons: The main advantage of aluminum is its lightweight nature, which can lead to lower installation and operational costs. However, its lower strength limits its use in heavy-duty applications, and it may require additional supports or reinforcements.

Impact on Application: Aluminum is suitable for applications where mobility and ease of installation are critical, such as in temporary setups or smaller manufacturing facilities. Its resistance to corrosion makes it ideal for outdoor use.

Considerations for Buyers: Buyers in Europe, particularly in Spain, should look for aluminum parts that meet EU standards for safety and quality. Understanding the specific alloy types and their properties is crucial for ensuring compatibility with operational needs.

Cast Iron

Key Properties: Cast iron is known for its excellent wear resistance and ability to withstand compressive forces. It has good thermal properties, allowing it to dissipate heat effectively, which is beneficial in high-load applications.

Pros & Cons: The primary advantage of cast iron is its durability and ability to absorb vibrations, making it suitable for stable applications. However, it is brittle, which can lead to cracking under sudden impacts or overloads. Additionally, cast iron is heavier than both steel and aluminum.

Impact on Application: Cast iron is often used in the base or foundation components of jib cranes due to its stability. It is particularly effective in environments where heavy, static loads are present.

Considerations for Buyers: Buyers from South America should ensure that cast iron components comply with local standards and regulations. It is also important to consider the availability of suppliers who can provide high-quality cast iron parts.

Plastic Composites

Key Properties: Plastic composites are lightweight and offer good corrosion resistance. They can be engineered to provide specific mechanical properties, making them versatile for various applications.

Pros & Cons: The main advantage of plastic composites is their resistance to corrosion and chemical exposure, making them suitable for specialized environments. However, they generally have lower strength compared to metals, which limits their use in heavy-duty applications.

Impact on Application: Plastic composites are ideal for components that require lightweight solutions and resistance to harsh chemicals, such as in chemical processing plants. They can also be used in non-load-bearing applications.

Considerations for Buyers: Buyers in the Middle East should verify that plastic composite materials meet industry standards for safety and performance. Understanding the specific applications and limitations of these materials is crucial for effective use.

Summary Table

| Material | Typical Use Case for jib crane parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty lifting applications | High strength and durability | Heavy and costly manufacturing | High |

| Aluminum | Lightweight and portable setups | Lightweight and corrosion-resistant | Lower strength limits applications | Medium |

| Cast Iron | Stable base components | Excellent wear resistance | Brittle and heavy | Medium |

| Plastic Composites | Non-load-bearing or chemical exposure | Corrosion-resistant and lightweight | Lower strength compared to metals | Low |

This strategic material selection guide provides a comprehensive overview of the materials commonly used in jib crane parts, enabling international B2B buyers to make informed decisions tailored to their specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for jib crane parts

Manufacturing Processes for Jib Crane Parts

The manufacturing of jib crane parts involves a series of structured stages, each critical to ensuring the durability, reliability, and safety of the final product. Understanding these stages can help B2B buyers from Africa, South America, the Middle East, and Europe (including Turkey and Spain) make informed decisions when selecting suppliers.

Main Stages of Manufacturing

- Material Preparation

– Selection of Raw Materials: The process begins with the selection of high-quality raw materials, primarily high-strength steel, which is essential for providing strength and durability. Suppliers should be able to demonstrate the origin and specifications of their materials.

– Cutting and Shaping: Raw materials are then cut to specified dimensions using techniques such as laser cutting or plasma cutting, which ensure precision and reduce waste.

Illustrative Image (Source: Google Search)

-

Forming

– Welding and Assembly: The cut parts are welded together to form the structural components of the jib crane, including the mast, boom, and supports. Advanced welding techniques such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) are commonly used to ensure strong joints.

– Machining: After welding, parts may undergo machining processes to achieve the required tolerances and surface finishes. This includes turning, milling, and grinding operations. -

Finishing

– Surface Treatment: To enhance corrosion resistance and aesthetic appeal, parts are often treated through processes such as galvanizing, powder coating, or painting. These treatments are vital, especially for cranes used in harsh environments.

– Quality Control Checks: Before moving to assembly, parts should undergo initial quality control checks to ensure they meet predefined specifications. -

Final Assembly

– Component Integration: The final assembly stage involves integrating all components, including the hoist, trolley, and control systems. This stage requires precision to ensure smooth operation.

– Testing: Post-assembly testing is critical. Each crane is typically subjected to load testing to verify its lifting capacity and operational safety.

Quality Assurance in Manufacturing

Quality assurance (QA) is crucial in the manufacturing of jib crane parts, ensuring that products meet international safety and performance standards. For international B2B buyers, understanding QA processes is key to ensuring product reliability.

Relevant International Standards

-

ISO 9001: This international standard focuses on quality management systems, ensuring that suppliers consistently meet customer and regulatory requirements. A supplier with ISO 9001 certification demonstrates a commitment to quality.

-

CE Marking: For suppliers in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards. Buyers should ensure that the parts they procure are CE certified, particularly for use in European markets.

-

API Standards: The American Petroleum Institute (API) sets standards for equipment used in the oil and gas industry. If your operations intersect with this sector, confirm that suppliers adhere to relevant API specifications.

Quality Control Checkpoints

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival at the manufacturing facility. Buyers should inquire about the supplier’s IQC processes to ensure that materials meet quality specifications before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections ensure that production processes adhere to quality standards. This includes monitoring welding quality, dimensional accuracy, and surface finishes.

-

Final Quality Control (FQC): Before shipping, a final inspection assesses the entire jib crane assembly for compliance with specifications and safety standards. This stage often includes load testing to verify lifting capabilities.

Common Testing Methods

- Load Testing: Simulates operational conditions to ensure the crane can safely lift its rated load without failure.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or magnetic particle testing are employed to detect internal flaws without damaging the components.

- Performance Testing: Evaluates the operational efficiency and functionality of the crane, including hoisting speed and control responsiveness.

Verifying Supplier Quality Control

For B2B buyers, particularly in diverse markets like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential.

-

Supplier Audits: Conducting on-site audits of potential suppliers helps assess their manufacturing processes, quality control measures, and overall operational integrity. This firsthand evaluation can uncover potential issues that may not be evident from documentation alone.

-

Requesting Quality Reports: Suppliers should be willing to provide detailed quality reports, including results from IQC, IPQC, and FQC. These documents offer insights into the consistency and reliability of their production processes.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control processes. This is particularly beneficial for buyers unfamiliar with local suppliers in regions like Africa or South America.

QC and Certification Nuances for International Buyers

International buyers need to be aware of specific nuances in quality control and certification when sourcing jib crane parts:

- Cultural and Regulatory Differences: Be mindful that manufacturing practices and quality standards can vary significantly across regions. Understanding these differences can prevent misunderstandings and ensure compliance with local regulations.

- Documentation and Traceability: Ensure that suppliers maintain comprehensive documentation for each part, including material certifications and inspection reports. This traceability is vital for accountability and future reference.

- Language Barriers: When dealing with suppliers from non-English speaking countries, ensure that all quality documentation is clear and comprehensible to avoid miscommunication.

Conclusion

In summary, the manufacturing processes and quality assurance for jib crane parts are crucial for ensuring safety and efficiency in operations. B2B buyers should prioritize suppliers with robust manufacturing practices, adherence to international standards, and thorough quality control measures. By conducting diligent research and verification, buyers can secure high-quality jib crane parts that meet their operational needs.

Comprehensive Cost and Pricing Analysis for jib crane parts Sourcing

When sourcing jib crane parts, understanding the comprehensive cost structure is crucial for making informed purchasing decisions. The costs associated with these parts can be broken down into several key components:

Cost Components

-

Materials: The primary cost driver in jib crane parts is the raw materials used, typically high-strength steel or aluminum. The choice of materials directly impacts durability and performance. Corrosion-resistant coatings may also add to material costs.

-

Labor: Labor costs encompass the wages of skilled workers involved in manufacturing, assembly, and quality control. Regions with lower labor costs may offer competitive pricing, but it’s essential to consider the skill level and experience of the workforce.

-

Manufacturing Overhead: This includes indirect costs such as utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help minimize these costs, which can vary significantly between suppliers.

-

Tooling: The investment in specialized tools and equipment for production can affect pricing. Suppliers with established tooling may offer lower prices due to amortization of these costs over higher production volumes.

-

Quality Control (QC): Rigorous quality control processes ensure that parts meet safety and performance standards. This may involve additional testing and inspection costs, which can influence the overall price.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, are significant for international transactions. The location of the supplier relative to the buyer can greatly affect logistics costs.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on competition, brand reputation, and the perceived value of the product.

Price Influencers

Several factors can influence the final pricing of jib crane parts:

-

Volume/MOQ: The minimum order quantity (MOQ) can significantly impact pricing. Larger orders often lead to volume discounts, making it beneficial for buyers to consolidate purchases.

-

Specifications/Customization: Custom parts or specific configurations may incur higher costs due to the additional design and manufacturing efforts required. Standard parts are generally more cost-effective.

-

Materials and Quality/Certifications: Higher quality materials and certifications (e.g., ISO compliance) can increase initial costs but may lead to lower maintenance and replacement expenses over time.

-

Supplier Factors: The reputation and reliability of the supplier play a critical role in pricing. Established suppliers with a track record of quality may charge a premium but offer better long-term value.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects the distribution of costs and responsibilities between buyer and seller. Understanding these terms can help buyers manage total costs effectively.

Buyer Tips

To optimize costs when sourcing jib crane parts, consider the following strategies:

-

Negotiation: Engage suppliers in discussions to negotiate pricing, especially for larger orders. Leverage competition among suppliers to secure better terms.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO) rather than just initial purchase price. Consider factors such as maintenance, downtime, and replacement costs when assessing value.

-

Research and Compare: Conduct thorough market research to compare prices across multiple suppliers. Pay attention to reviews and certifications that indicate reliability and quality.

-

Understand Pricing Nuances: Be aware of regional pricing differences and additional costs associated with international shipping. Factors such as tariffs, taxes, and currency fluctuations can significantly impact total expenses.

-

Build Long-term Relationships: Establishing long-term relationships with suppliers can lead to better pricing, priority service, and favorable terms in future transactions.

Disclaimer

The prices and cost components outlined are indicative and can vary based on specific requirements, market conditions, and supplier negotiations. Always seek detailed quotes and conduct due diligence before finalizing any agreements.

Spotlight on Potential jib crane parts Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘jib crane parts’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for jib crane parts

Understanding the essential technical properties and trade terminology for jib crane parts is crucial for international B2B buyers looking to make informed purchasing decisions. This section outlines key specifications and common industry jargon that can aid in selecting the right components for your needs.

Key Technical Properties

-

Material Grade

– The material used in jib crane parts, typically high-strength steel, is critical for durability and load-bearing capacity. Different grades signify varying tensile strengths and resistance to wear and corrosion. Selecting the right material grade ensures the crane can handle the intended loads without failure. -

Tolerance

– Tolerance refers to the allowable deviation in dimensions of crane parts. Precise tolerances are crucial for ensuring compatibility between components and the overall assembly of the crane. Inaccurate tolerances can lead to operational inefficiencies and increased wear and tear. -

Load Capacity

– Load capacity indicates the maximum weight a jib crane can safely lift. This specification is vital for ensuring that the crane is suited to the specific operational requirements of your business. It is essential to verify that the load capacity aligns with your material handling needs to prevent accidents and equipment failure. -

Reach

– Reach is the horizontal distance the jib arm can extend from the mast. This property affects how effectively the crane can maneuver loads within its operational area. Understanding the required reach helps in selecting the appropriate crane configuration for your workspace. -

Height of Lift

– This specification indicates the maximum vertical distance the hoist can travel. It is important to ensure that the height of lift meets the demands of your operations, particularly in environments with overhead obstacles. -

Rotation Range

– The rotation range defines how far the jib can pivot around its mast. A wider rotation range enhances the crane’s versatility in moving loads without repositioning the entire unit. This is particularly beneficial in confined spaces or when precise load placement is required.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce parts that are sold under another company’s brand. Understanding OEM products is important for buyers looking for quality assurance and compatibility with existing equipment. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchases and manage inventory levels efficiently. It can also impact overall costs, especially for smaller operations. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and terms for specific products. This process helps buyers compare costs and services from multiple suppliers, enabling more informed decision-making.

Illustrative Image (Source: Google Search)

-

Incoterms (International Commercial Terms)

– Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They dictate the shipping, insurance, and delivery terms, which are essential for understanding overall costs and liabilities. -

Lead Time

– Lead time refers to the period between placing an order and receiving the goods. Understanding lead times is critical for project planning and ensuring that operations are not delayed due to equipment shortages. -

Certification Standards

– Certification standards, such as ISO 9001, indicate that products meet specific quality management principles. Buyers should seek certified parts to ensure compliance with safety and quality regulations, which is particularly important in high-stakes environments.

By familiarizing yourself with these technical properties and trade terms, you can streamline the procurement process and ensure that your investments in jib crane parts meet both operational and safety standards. This knowledge ultimately contributes to more effective material handling and improved operational efficiency in your business.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the jib crane parts Sector

Market Overview & Key Trends

The jib crane parts market is witnessing significant growth driven by industrial expansion, particularly in sectors like construction, manufacturing, and logistics. Key global drivers include the increasing demand for efficient material handling solutions and automation in factories. In regions such as Africa and South America, rapid urbanization and infrastructural development are fueling the need for cranes and their components. Moreover, in Europe and the Middle East, stringent safety regulations and a push for advanced lifting technologies are shaping market dynamics.

Emerging B2B tech trends are reshaping how buyers source jib crane parts. The integration of digital platforms for procurement is on the rise, enabling buyers to access a broader range of suppliers and products. Technologies such as IoT and AI are enhancing operational efficiencies, providing real-time data on equipment performance, and reducing downtime through predictive maintenance. Additionally, sustainability considerations are influencing procurement decisions, with buyers increasingly prioritizing suppliers who demonstrate environmental responsibility.

International B2B buyers must stay attuned to these trends to make informed purchasing decisions. This includes evaluating suppliers not just on cost and quality but also on their ability to meet evolving regulatory and sustainability standards. As the market matures, leveraging digital tools and data analytics will be crucial for optimizing sourcing strategies and ensuring competitive advantage.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the sourcing of jib crane parts. The environmental impact of manufacturing processes, including emissions and waste generation, is under scrutiny. Buyers are encouraged to assess suppliers based on their environmental practices, such as the use of renewable energy sources and waste management strategies.

Moreover, ethical sourcing is gaining importance as companies seek to ensure that their supply chains are free from exploitation and contribute positively to local communities. This includes verifying that suppliers adhere to fair labor practices and comply with international labor standards.

Buyers should also look for green certifications such as ISO 14001, which indicates effective environmental management systems. Sourcing materials that are recyclable or produced through sustainable practices, like using steel from recycled sources, can further enhance a company’s green credentials. By prioritizing sustainability and ethical sourcing, international buyers not only meet regulatory requirements but also appeal to increasingly eco-conscious consumers.

Brief Evolution/History

The jib crane has evolved significantly since its inception, originally designed for straightforward lifting tasks in shipyards and construction sites. Over time, advancements in materials and engineering have led to the development of more sophisticated designs that offer enhanced capabilities, such as increased reach, load capacity, and mobility.

In the past two decades, the integration of technology has transformed jib cranes from simple mechanical devices into smart, automated systems equipped with sensors and IoT connectivity. This evolution reflects broader trends in industrial automation, where efficiency and safety are paramount. As the market continues to evolve, understanding this historical context can provide B2B buyers with insights into the reliability and suitability of various jib crane parts for their specific applications.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of jib crane parts

-

What criteria should I use to vet suppliers of jib crane parts?

When vetting suppliers, prioritize their reputation, years in business, and customer reviews. Look for suppliers who have industry certifications such as ISO 9001, which indicates adherence to quality management standards. Additionally, assess their experience with international shipping, particularly to your region, and inquire about their sourcing practices to ensure they use high-quality materials. Establishing a direct line of communication can also help clarify any concerns regarding reliability and service. -

Can I customize jib crane parts to fit my specific needs?

Yes, many suppliers offer customization options for jib crane parts. It’s essential to communicate your specific requirements clearly, including dimensions, load capacities, and any additional features you may need. Ensure that the supplier has experience in custom fabrication and can provide documentation or examples of previous projects. This will help you gauge their capability to meet your specifications effectively. -

What are the typical minimum order quantities (MOQ) and lead times for jib crane parts?

MOQs can vary significantly among suppliers; some may require a minimum of five units, while others may accommodate smaller orders. Lead times typically range from 4 to 12 weeks depending on the complexity of the parts, customization, and the supplier’s location. To avoid delays, confirm these details upfront and plan your procurement timeline accordingly. Additionally, consider whether the supplier can expedite orders for urgent needs. -

What payment options are available when sourcing jib crane parts internationally?

Payment options can include bank transfers, letters of credit, and payment platforms like PayPal. Many suppliers also accept partial upfront payments with the balance due upon delivery or after quality inspection. Always verify the payment terms and ensure they are secure and favorable for both parties. Understanding the currency exchange rates and potential transaction fees is also crucial for budgeting. -

How can I ensure the quality and safety certifications of jib crane parts?

Request copies of quality assurance certifications and compliance documents from your supplier. Certifications like CE marking for Europe or ANSI for North America can indicate adherence to safety and performance standards. Conducting third-party inspections or audits before shipment can also provide additional assurance. It’s wise to establish a quality control process that aligns with your operational standards. -

What logistics considerations should I be aware of when importing jib crane parts?

Understand the logistics involved in shipping, including freight costs, customs duties, and import regulations in your country. Collaborate with a logistics provider experienced in international shipping to handle the complexities of customs clearance. Ensure that the supplier is knowledgeable about export documentation and can provide necessary paperwork to facilitate smooth transit. -

How can I resolve disputes with suppliers regarding jib crane parts?

Establish clear contracts that outline terms of service, delivery timelines, and quality expectations to mitigate potential disputes. If issues arise, start with direct communication to seek resolution amicably. If necessary, refer to the dispute resolution clause in your contract, which may include mediation or arbitration. Maintaining documentation of all communications and agreements will be beneficial in case formal resolution is required. -

What after-sales support should I expect from suppliers of jib crane parts?

Reliable suppliers should offer comprehensive after-sales support, including installation guidance, maintenance recommendations, and warranty services. Confirm the length and terms of any warranties provided, as well as the process for handling defective parts. Additionally, inquire about the availability of spare parts and technical support for future needs, which can enhance your operational efficiency and minimize downtime.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for jib crane parts

In conclusion, effective strategic sourcing of jib crane parts is essential for international B2B buyers aiming to enhance operational efficiency and safety. Key takeaways include the importance of sourcing high-quality components from reputable suppliers, understanding the critical roles of each part, and ensuring compliance with necessary certifications. Buyers should prioritize cost-effectiveness while also considering long-term durability and performance.

As the global demand for jib cranes rises, particularly in rapidly developing regions such as Africa, South America, the Middle East, and Europe, it is imperative to stay informed about market trends and supplier capabilities. Establishing strong relationships with trusted suppliers can lead to better pricing, reliable delivery, and access to innovative solutions tailored to specific needs.

Looking ahead, B2B buyers should actively engage in market research and networking opportunities to identify emerging suppliers and technologies in jib crane parts. By leveraging these insights, businesses can position themselves competitively, ensuring they meet their material handling challenges head-on. Take action now to secure the best parts for your operations and drive your business forward.