Master the Types of Gate Latch: Essential Guide for B2B

Introduction: Navigating the Global Market for types of gate latch

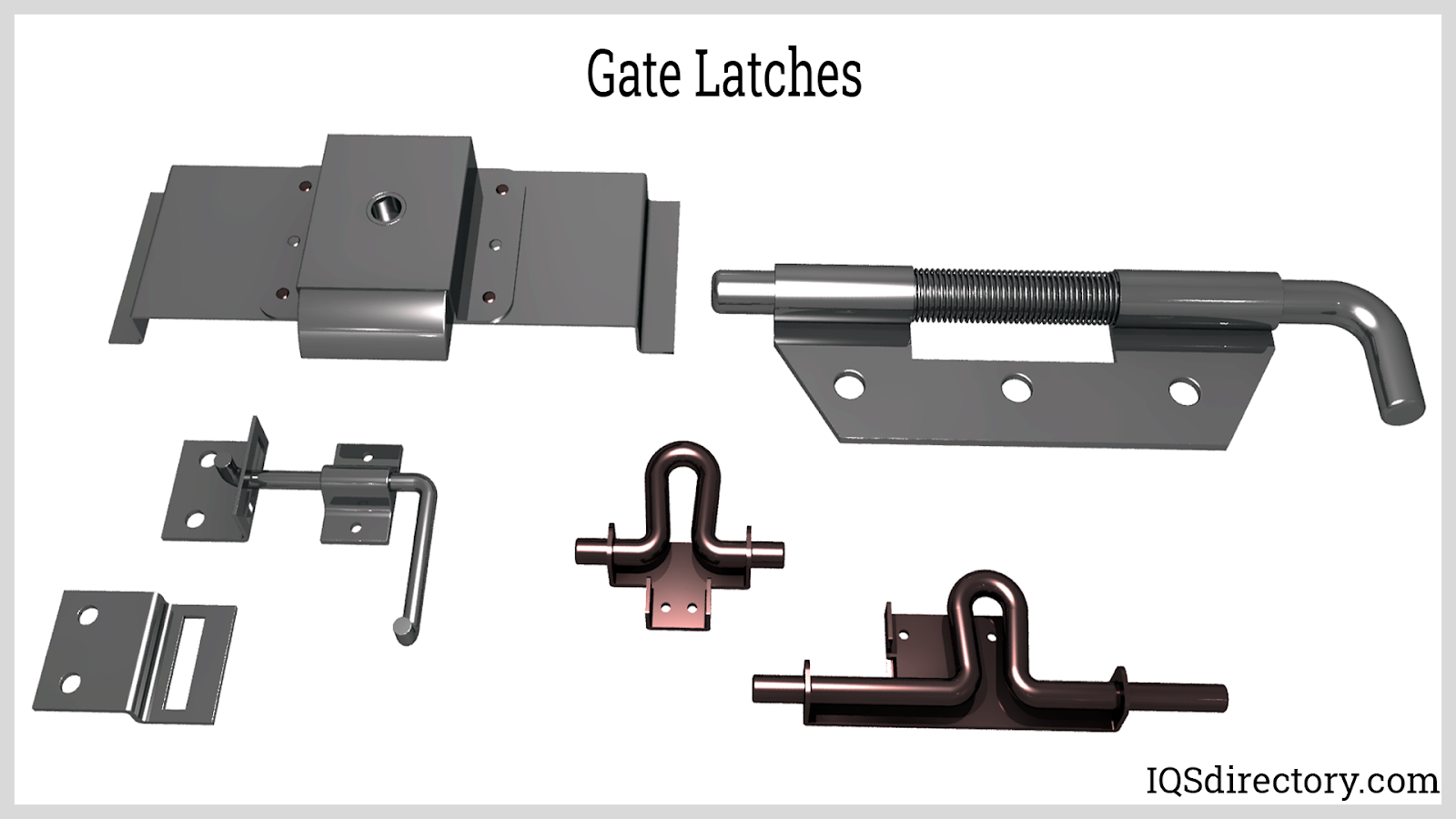

In the intricate landscape of global trade, the selection of gate latches stands as a pivotal element for international B2B buyers. These seemingly simple devices play a crucial role in securing properties, ensuring safety, and enhancing functionality in diverse environments, from residential settings to commercial applications. With advancements in design and technology, the market offers a wide array of options—from classic gravity latches to sophisticated magnetic systems—each tailored to meet specific security needs.

This comprehensive guide delves into the multifaceted world of gate latches, providing valuable insights into various types, materials, and manufacturing standards. By exploring the nuances of each latch type, buyers can make informed decisions that align with their operational requirements. The guide also covers essential factors such as quality control measures, reliable suppliers, cost considerations, and market trends, empowering buyers to navigate sourcing challenges effectively.

For B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding the intricacies of gate latch options is vital. This knowledge not only enhances purchasing strategies but also ensures compliance with local regulations and security standards. By leveraging the insights provided in this guide, businesses can optimize their procurement processes, ensuring that they select the most suitable gate latch solutions that bolster safety and operational efficiency.

Understanding types of gate latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gravity Latch | Simple design, relies on gravity for closure, often padlockable | Residential gates, garden gates | Pros: Easy installation, low cost. Cons: Limited security without additional locking mechanisms. |

| Spring-Activated Latch | Features a spring mechanism for automatic closure, typically one-way | Commercial properties, pool gates | Pros: Convenient operation, quick engagement. Cons: May lack robust security features. |

| Bolt Latch | Operates like a deadbolt, requires manual engagement, padlockable | Industrial gates, high-security areas | Pros: High security, durable. Cons: Requires more effort to operate compared to simpler latches. |

| Thumb Latch | Operable from both sides, often decorative, easy to use | Decorative gates, entryways | Pros: Aesthetic appeal, user-friendly. Cons: May not provide sufficient security for high-risk areas. |

| Magnetic Latch | Utilizes magnetism for closure, often includes alarms | High-security gates, pool areas | Pros: Enhanced security, often features alarms. Cons: Can be more expensive and complex to install. |

Gravity Latch

Gravity latches are among the simplest and most cost-effective gate latch solutions. They utilize a straightforward design where the latch arm drops into place when the gate closes, relying on gravity for secure closure. Ideal for residential and garden gates, these latches are easy to install and operate. However, buyers should consider that while they are economical, gravity latches may not provide robust security on their own; pairing them with a padlock or additional locking mechanisms is advisable for enhanced safety.

Spring-Activated Latch

Spring-activated latches are designed for convenience, featuring a spring mechanism that allows for quick and automatic closure. These latches are particularly suited for commercial properties and pool gates, where frequent access is required. They typically engage with a simple push or pull, making them user-friendly. However, businesses should note that while these latches are efficient, they may lack advanced security features, making them less suitable for high-risk environments without supplementary security measures.

Bolt Latch

Bolt latches function similarly to deadbolts, requiring manual engagement to secure the gate. This type of latch is commonly used in industrial settings and high-security areas due to its durability and reliability. Bolt latches can be locked with a padlock, providing an additional layer of security. Buyers should keep in mind that while they offer superior protection, they require more effort to operate compared to simpler latch types, which may not be ideal for all applications.

Thumb Latch

Thumb latches are designed for ease of use, allowing operation from both sides of the gate. They are often chosen for decorative gates and entryways, combining functionality with aesthetic appeal. While they are user-friendly and visually appealing, businesses should consider their security level; thumb latches may not be suitable for high-risk areas without additional locking features, as they primarily serve decorative and light-use purposes.

Magnetic Latch

Magnetic latches represent a modern approach to gate security, utilizing magnetism to keep gates closed. These latches often include alarms and are ideal for high-security environments, such as pool areas and commercial properties. Their enhanced security features make them a popular choice among B2B buyers looking for reliable gate solutions. However, the complexity of installation and higher price point may deter some buyers, making it essential to weigh the benefits against the costs when making purchasing decisions.

Related Video: The Best Gate Latch For Your Fence And How To Install It | THE HANDYMAN |

Key Industrial Applications of types of gate latch

| Industry/Sector | Specific Application of types of gate latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Livestock pens and fencing | Enhances security and easy access for farmers | Durability against weather, ease of installation, and compatibility with existing fencing |

| Construction | Site security gates | Prevents unauthorized access, ensuring safety and compliance | Compliance with local regulations, robust materials for high-traffic areas |

| Residential | Garden and backyard gates | Provides safety for children and pets while maintaining aesthetics | Variety of designs, ease of use, and reliability under frequent use |

| Commercial | Access control for warehouses and facilities | Improves security and operational efficiency | Locking mechanisms, ease of integration with existing security systems |

| Recreational | Gates for parks and swimming pools | Ensures safety and compliance with regulations | Weather-resistant materials, safety features like automatic locking mechanisms |

Agriculture

In the agricultural sector, gate latches are crucial for securing livestock pens and fencing. A reliable latch ensures that animals cannot escape, which is vital for both safety and productivity. Buyers in this sector should prioritize durability against harsh weather conditions and ease of installation. Given the varied climates across Africa and South America, sourcing latches that can withstand these elements is essential. Additionally, compatibility with existing fencing systems can streamline installation and reduce costs.

Construction

For the construction industry, gate latches play a key role in securing site access. They prevent unauthorized entry, thereby enhancing safety and compliance with local regulations. Construction managers should consider latches that are robust and designed for high-traffic areas, as they need to withstand frequent use. Buyers must also ensure that the latches meet specific local compliance standards, which may vary by region, particularly in the Middle East and Europe.

Residential

In residential applications, gate latches are commonly used for garden and backyard gates. They provide safety for children and pets while allowing homeowners to maintain aesthetic appeal. Buyers should look for a variety of designs that match their home’s style, along with features that ensure reliability under frequent use. Given the diverse architectural styles in Europe and the Middle East, sourcing customizable options can enhance the overall appeal and functionality of residential gates.

Commercial

In commercial settings, gate latches are integral to access control for warehouses and facilities. They improve security by restricting unauthorized access, thereby protecting valuable assets. Key considerations for buyers in this sector include the locking mechanisms and the ease of integration with existing security systems. Sourcing latches that offer advanced features, such as electronic locking or remote access capabilities, can significantly enhance security measures, especially in urban areas of South America and Africa.

Recreational

Gate latches are also vital in recreational areas, such as parks and swimming pools, where safety regulations are stringent. They help ensure that children cannot easily access potentially dangerous areas, thus complying with safety regulations. Buyers should focus on weather-resistant materials and safety features, like automatic locking mechanisms, to provide peace of mind. In regions with heavy rainfall or extreme temperatures, durability and reliability in latch performance are crucial for maintaining safety standards.

Related Video: How to Install a Gate Latch

Strategic Material Selection Guide for types of gate latch

When selecting materials for gate latches, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. Below, we analyze four common materials used in the manufacturing of gate latches, highlighting their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high tensile strength, and ability to withstand extreme temperatures. It typically has a temperature rating of up to 800°F (427°C) and can handle moderate pressure without deforming.

Pros & Cons: The durability of stainless steel makes it ideal for outdoor applications, especially in coastal areas where salt exposure is a concern. However, it is more expensive than other materials like plastic or galvanized steel. The manufacturing process can be complex due to the need for specialized equipment.

Impact on Application: Stainless steel latches are suitable for environments where moisture and corrosion are prevalent, such as in marine or humid climates. They are also compatible with various media, including water and chemicals.

Considerations for International Buyers: Buyers should ensure compliance with ASTM standards for stainless steel grades, particularly ASTM A276 for bar and rod applications. In regions like Europe, adherence to EN standards may also be necessary.

Galvanized Steel

Key Properties: Galvanized steel is coated with a layer of zinc to provide corrosion resistance. It typically withstands temperatures up to 500°F (260°C) and is suitable for medium-pressure applications.

Pros & Cons: This material is cost-effective and offers decent durability for outdoor use. However, the zinc coating can wear off over time, especially in harsh environments, leading to rust formation. The manufacturing process is simpler compared to stainless steel, making it easier to produce.

Impact on Application: Galvanized steel latches are ideal for agricultural and industrial applications where cost is a significant factor. They perform well in dry to moderately humid conditions but may not be suitable for coastal areas.

Considerations for International Buyers: Buyers should verify that the galvanized steel meets relevant standards such as ASTM A123 for hot-dip galvanized coatings. In South America and Africa, local regulations may dictate specific corrosion resistance requirements.

Plastic (Nylon or Polypropylene)

Key Properties: Plastic latches, particularly those made from nylon or polypropylene, are lightweight, resistant to UV rays, and have good chemical resistance. They can typically withstand temperatures ranging from -40°F to 180°F (-40°C to 82°C).

Pros & Cons: The primary advantage of plastic latches is their low cost and ease of installation. They are also non-corrosive, making them suitable for environments with high humidity. However, they may not offer the same strength or durability as metal alternatives, especially under heavy loads.

Impact on Application: Plastic latches are often used in residential applications or in environments where weight is a concern, such as for garden gates. They are compatible with a variety of media, but extreme temperatures can affect their performance.

Considerations for International Buyers: Buyers should check for compliance with ISO standards for plastic materials, especially in Europe. In regions like the Middle East, where UV exposure is high, selecting UV-stabilized plastics is crucial.

Brass

Key Properties: Brass is an alloy of copper and zinc known for its excellent corrosion resistance and aesthetic appeal. It can withstand moderate temperatures and pressures, making it suitable for various applications.

Pros & Cons: The key advantage of brass latches is their durability and resistance to tarnishing, which makes them ideal for decorative applications. However, they are more expensive than steel and plastic options and can be prone to wear under heavy use.

Impact on Application: Brass latches are often used in residential and decorative applications where appearance matters. They perform well in dry environments but may require maintenance to prevent tarnishing.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards such as ASTM B16 for brass materials. In Europe, adherence to EN standards for brass fittings is also essential.

| Material | Typical Use Case for types of gate latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor gates in coastal areas | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Galvanized Steel | Agricultural and industrial applications | Cost-effective and durable | Zinc coating may wear off | Medium |

| Plastic | Residential and garden gates | Lightweight and non-corrosive | Lower strength compared to metals | Low |

| Brass | Decorative residential applications | Aesthetic appeal and durability | Higher cost and maintenance required | High |

In-depth Look: Manufacturing Processes and Quality Assurance for types of gate latch

The manufacturing and quality assurance processes for gate latches are critical for ensuring the durability and reliability of these essential security components. For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, understanding these processes can help in selecting reputable suppliers and ensuring product quality. This section delves into the typical manufacturing stages, quality control measures, and international standards that govern the production of gate latches.

Manufacturing Processes

The manufacturing of gate latches involves several key stages, each essential to producing a high-quality product. Here’s a breakdown of the typical processes:

1. Material Preparation

The first step in the manufacturing process is selecting the appropriate materials. Common materials for gate latches include:

– Steel: Known for its strength and durability, often used for heavy-duty latches.

– Stainless Steel: Offers corrosion resistance, making it suitable for outdoor applications.

– Plastic or Nylon: Lightweight and resistant to weather, often used in residential applications.

Once materials are selected, they are prepared through cutting, shaping, and sometimes surface treatment to enhance properties like corrosion resistance.

2. Forming

This stage involves shaping the prepared materials into their final forms. Key techniques include:

– Stamping: Metal sheets are stamped into desired shapes using high-pressure machines.

– Casting: Molten metal is poured into molds to create complex shapes.

– Machining: Precision tools are used to cut and shape materials for tight tolerances.

These forming techniques ensure that the latches meet design specifications and functional requirements.

3. Assembly

After forming, the individual components of the gate latch are assembled. This may include:

– Joining Components: Methods such as welding, riveting, or using adhesives to attach parts.

– Installing Springs or Locks: For latches that require additional mechanisms, such as spring-loaded designs.

Effective assembly is crucial for ensuring that the latch operates smoothly and securely.

4. Finishing

Finishing processes enhance the latch’s appearance and performance. Common techniques include:

– Painting or Powder Coating: To provide a protective layer against corrosion.

– Plating: Applying a thin layer of another metal (like zinc) to improve durability and aesthetics.

– Quality Checks: Visual inspections for defects and proper assembly.

This stage not only improves the latch’s functionality but also its market appeal.

Quality Assurance

Quality assurance is paramount in manufacturing gate latches, particularly to comply with international standards and meet customer expectations. Here are the key aspects of QC in this sector:

1. Relevant International Standards

B2B buyers should be aware of the following standards that govern quality in the manufacturing of gate latches:

– ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent product quality.

– CE Marking: Indicates compliance with EU safety, health, and environmental protection standards.

– API Standards: For latches used in specific applications, such as those in the oil and gas industry.

Understanding these standards helps buyers assess supplier credibility and product safety.

2. Quality Control Checkpoints

The manufacturing process typically includes several QC checkpoints:

– Incoming Quality Control (IQC): Inspection of raw materials and components before production.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch defects early.

– Final Quality Control (FQC): Comprehensive testing of finished products to ensure they meet specifications.

These checkpoints are essential for maintaining high-quality output throughout the production cycle.

3. Common Testing Methods

To ensure that gate latches meet performance standards, manufacturers employ various testing methods, including:

– Load Testing: Assessing the latch’s strength under stress.

– Corrosion Testing: Evaluating how well the latch withstands environmental factors over time.

– Functional Testing: Ensuring that the latch operates as intended (e.g., ease of use, locking mechanism).

These tests help identify potential failures before the product reaches the market.

Verifying Supplier Quality Control

For B2B buyers, especially those sourcing from international suppliers, verifying quality control practices is crucial. Here are some actionable steps:

1. Supplier Audits

Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes, quality control measures, and overall operational practices. This firsthand insight can reveal a lot about the supplier’s commitment to quality.

2. Requesting Quality Reports

Buyers should request documentation of quality assurance processes, including results from IQC, IPQC, and FQC. These reports provide transparency and confidence in the supplier’s capabilities.

3. Third-Party Inspections

Engaging independent third-party inspection services can offer unbiased evaluations of products before shipment. This is particularly useful for buyers in regions with varying quality standards.

QC and Certification Nuances for International Buyers

International buyers must navigate various nuances when it comes to QC and certifications. Here are some considerations:

- Regional Standards: Familiarize yourself with local quality standards, as they may differ from international norms. For instance, certifications like ANAB in the USA or INMETRO in Brazil may be relevant.

- Customs Regulations: Ensure that the products comply with the customs regulations of the importing country, which may involve specific certifications or inspections.

- Cultural Considerations: Building relationships with suppliers in different regions can provide insights into their quality practices and help mitigate risks associated with international sourcing.

In conclusion, understanding the manufacturing processes and quality assurance measures for gate latches is vital for international B2B buyers. By considering these factors, buyers can make informed decisions, ensuring they select reliable suppliers that meet their quality standards.

Related Video: Awesome Scene! Best Mass Production Factory Manufacturing Process

Comprehensive Cost and Pricing Analysis for types of gate latch Sourcing

When sourcing gate latches for international markets, understanding the cost structure and pricing dynamics is essential for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. This analysis will cover the key cost components and price influencers, along with actionable tips for buyers.

Cost Components

- Materials: The choice of materials significantly impacts the overall cost of gate latches. Common materials include stainless steel, aluminum, and plastic composites. Stainless steel latches, while more expensive, offer higher durability and resistance to corrosion, making them suitable for harsh environments.

Illustrative Image (Source: Google Search)

-

Labor: Labor costs vary widely based on geographic location and manufacturing processes. Regions with lower labor costs may offer competitive pricing but could compromise on quality. It’s crucial to balance cost with the reliability of the workforce.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and maintenance. Efficient manufacturing processes can reduce overhead costs, which can be passed on to buyers.

-

Tooling: Initial tooling costs can be significant, particularly for custom designs. Buyers should consider whether they require standard or bespoke latches. Custom tooling may lead to higher upfront costs but can lower per-unit costs for large orders.

-

Quality Control (QC): Investing in robust QC processes ensures that products meet safety and performance standards. This can involve additional costs, but it also reduces the risk of defects and returns, ultimately benefiting the buyer.

-

Logistics: Shipping costs are a major factor, especially for international transactions. Factors such as distance, shipping method, and the choice of Incoterms can influence logistics expenses significantly.

-

Margin: Suppliers typically include a margin in their pricing to cover their costs and ensure profitability. Understanding the typical margins in the gate latch industry can help buyers gauge fair pricing.

Price Influencers

-

Volume/MOQ: Minimum Order Quantities (MOQs) play a crucial role in pricing. Higher volumes often lead to discounts. Buyers should assess their needs carefully to optimize order size.

-

Specifications/Customization: Customized latches tailored to specific applications can drive up costs. Standard products are generally more economical, so buyers should evaluate if customization is truly necessary.

-

Materials and Quality Certifications: Higher quality materials and certifications (like ISO or ANSI standards) can increase costs but provide assurance of product reliability and safety.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge higher prices due to their brand value and service quality, but they often deliver better consistency and support.

-

Incoterms: The choice of Incoterms affects who is responsible for shipping costs and risks. For instance, terms like FOB (Free On Board) may lead to lower initial costs for buyers, while CIF (Cost, Insurance, and Freight) includes shipping and insurance, impacting overall expenses.

Buyer Tips

-

Negotiation: Engage suppliers in discussions to negotiate better pricing, especially when placing larger orders. Building long-term relationships can also lead to better deals over time.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the purchase price. Consider factors such as maintenance, durability, and replacement frequency when determining the best value.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and local tariffs that may impact pricing. It’s advisable to lock in prices when possible and factor in additional costs associated with importing goods.

Disclaimer

Prices can vary significantly based on market conditions, supplier negotiations, and regional factors. Buyers should conduct thorough research and obtain multiple quotes to ensure they receive competitive pricing tailored to their specific needs.

Spotlight on Potential types of gate latch Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘types of gate latch’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for types of gate latch

Understanding the essential technical properties and trade terminology related to gate latches is crucial for international B2B buyers, especially when sourcing from diverse markets such as Africa, South America, the Middle East, and Europe. Here’s an overview of the key specifications and commonly used terms in the industry.

Key Technical Properties of Gate Latches

-

Material Grade

The material used in gate latches can significantly impact durability and performance. Common materials include stainless steel, aluminum, and galvanized steel. Higher-grade materials resist rust, corrosion, and wear, making them suitable for various environmental conditions. Buyers should prioritize material grade to ensure longevity, especially in outdoor settings. -

Load Capacity

This specification refers to the maximum weight a latch can handle without failing. It’s particularly important for heavy gates or those exposed to high traffic. Selecting a latch with an appropriate load capacity is essential to prevent operational failures, which can lead to security vulnerabilities.

Illustrative Image (Source: Google Search)

-

Finish Type

The finish of a gate latch affects its resistance to environmental factors. Options include powder-coated, anodized, or painted finishes. Understanding the finish type helps buyers choose products that align with aesthetic preferences and functional requirements, such as resistance to fading or peeling in harsh climates. -

Locking Mechanism

Latches can feature various locking mechanisms, from simple padlocks to sophisticated key locks or electronic systems. The complexity of the locking mechanism influences security levels and ease of use. Buyers should evaluate their security needs and choose latches that offer the required level of protection. -

Installation Tolerance

This refers to the allowable variations in measurements during installation. Proper tolerances ensure that the latch fits securely and operates effectively. Buyers must consider installation tolerances to avoid compatibility issues with existing gates or fences, which can lead to additional costs. -

Temperature Resistance

Gate latches may be exposed to extreme temperatures, affecting their performance and longevity. Specifications indicating temperature resistance help buyers select latches suitable for their specific climate, ensuring functionality across various conditions.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of gate latches, understanding OEM relationships can help buyers ensure they are sourcing high-quality components that meet industry standards. -

MOQ (Minimum Order Quantity)

This term indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for buyers to plan their procurement strategies and manage inventory effectively, especially when dealing with multiple suppliers. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to bid on specific products or services. It’s a crucial step in the sourcing process, allowing buyers to compare pricing, terms, and delivery options before making purchasing decisions. -

Incoterms (International Commercial Terms)

These are international rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, insurance, and risk management, which are essential for seamless cross-border transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving it. Understanding lead times is crucial for buyers to effectively manage project timelines and ensure that materials arrive when needed. -

Certification Standards

These are benchmarks set by regulatory bodies to ensure product safety and performance. Buyers should seek products that comply with relevant certification standards to guarantee quality and reliability, particularly in safety-sensitive applications like gates.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when sourcing gate latches that meet their specific needs while navigating the complexities of international trade.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the types of gate latch Sector

Market Overview & Key Trends

The gate latch sector is witnessing robust growth driven by increasing demand for enhanced security solutions across various applications, including residential, commercial, and industrial settings. Global drivers include rising crime rates and heightened awareness of safety, particularly in regions like Africa and South America, where security concerns are paramount. Additionally, the expansion of urban areas and infrastructure development in the Middle East and Europe is propelling the need for reliable and durable gate latching systems.

Emerging B2B technology trends are reshaping sourcing strategies, with innovations such as smart gate latches equipped with IoT capabilities gaining traction. These advanced systems allow for remote access control, real-time monitoring, and integration with home automation systems, appealing to tech-savvy buyers in Europe and affluent markets in South America. Furthermore, the shift towards e-commerce platforms for procurement is streamlining the sourcing process, providing international buyers with broader access to diverse product offerings and competitive pricing.

The market dynamics are also influenced by regional preferences and regulations. For instance, buyers from Africa may prioritize cost-effective solutions that do not compromise on quality, while European buyers might lean towards products that comply with stringent safety standards. Understanding these regional differences is crucial for manufacturers and suppliers aiming to penetrate these markets effectively.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a significant consideration in the gate latch sector, driven by increasing regulatory pressures and consumer demand for environmentally friendly products. The environmental impact of manufacturing processes, particularly concerning the use of metals and plastics, is under scrutiny. As a result, many companies are adopting practices to minimize waste, reduce carbon footprints, and utilize recyclable materials in their products.

Ethical sourcing has emerged as a critical factor for B2B buyers. Suppliers are encouraged to ensure that their raw materials are sourced responsibly, adhering to fair labor practices and environmental standards. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) for wood products are becoming increasingly important in the procurement process. Buyers from regions such as Europe and North America are particularly focused on these certifications, seeking suppliers that demonstrate a commitment to sustainability.

Incorporating ‘green’ materials in gate latch production, such as recycled metals or sustainably sourced wood, not only enhances a company’s reputation but also meets the growing demand from eco-conscious consumers. For international buyers, aligning with suppliers that prioritize sustainability can create a competitive advantage and foster brand loyalty in markets increasingly influenced by environmental considerations.

Brief Evolution/History

The evolution of gate latches reflects advancements in technology and changing security needs over the years. Traditionally, gate latches were simple mechanical devices, often made from wood or basic metals. However, as security threats evolved, so did the designs and materials used in gate latches. The introduction of more sophisticated mechanisms, such as spring-loaded and magnetic latches, has improved functionality and security.

In recent years, the integration of smart technology into gate latches represents a significant leap forward. These modern latches not only offer enhanced security features but also cater to the growing demand for smart home solutions. This evolution highlights the importance of innovation in meeting the diverse needs of international B2B buyers, who are increasingly looking for products that combine functionality with advanced technology.

Related Video: The Shadow World: Inside the Global Arms Trade

Frequently Asked Questions (FAQs) for B2B Buyers of types of gate latch

-

What should I consider when vetting suppliers for gate latches?

When vetting suppliers for gate latches, prioritize their industry experience, product quality, and customer reviews. Assess their manufacturing capabilities and whether they can meet international standards. Request certifications like ISO 9001 to ensure quality management practices. It’s also beneficial to ask for samples before committing to larger orders, as this allows you to evaluate the latch’s quality and functionality firsthand. -

Can I customize gate latches to fit my specific needs?

Yes, many suppliers offer customization options for gate latches. This may include variations in size, color, material, and locking mechanisms. When discussing customization, provide detailed specifications and consider the intended application of the latches. Be clear about your design requirements and confirm that the supplier has the capability to deliver customized products within your timeline. -

What are the typical minimum order quantities (MOQ) and lead times for gate latches?

MOQs can vary significantly among suppliers, ranging from small quantities of 50-100 units to larger orders of several thousand, depending on the manufacturer. Lead times also differ based on the supplier’s location, production capacity, and whether the order is custom or standard. Generally, expect lead times of 4-12 weeks. Always clarify these details upfront to avoid delays in your supply chain. -

How can I ensure the quality of gate latches before finalizing my order?

To ensure quality, request samples or prototypes from suppliers before placing bulk orders. Verify that the latches meet relevant safety and durability standards for your region, especially if they will be used in commercial applications. Additionally, inquire about the supplier’s quality assurance processes, including inspections and testing methods, to confirm their commitment to delivering high-quality products. -

What payment options are typically available for international orders?

Payment options for international orders usually include wire transfers, letters of credit, and PayPal. The choice often depends on the order size and the relationship with the supplier. It’s crucial to establish a secure payment method that protects both parties, especially in large transactions. Discuss payment terms in advance, including deposit requirements and payment schedules, to ensure clarity and mutual agreement. -

How do logistics work for shipping gate latches internationally?

Logistics for international shipping involve coordinating with freight forwarders and understanding customs regulations in both the exporting and importing countries. Suppliers typically assist with shipping arrangements, but it’s essential to clarify whether shipping costs are included in the quote. Be aware of potential delays due to customs processing and ensure that all necessary documentation, such as invoices and certificates of origin, is prepared in advance. -

What should I do if there’s a dispute with my supplier regarding gate latches?

In the event of a dispute, maintain clear communication with your supplier and document all interactions. Attempt to resolve the issue amicably by discussing the problem and seeking a mutually beneficial solution. If the dispute escalates, refer to the terms outlined in your contract, including any clauses regarding dispute resolution. In some cases, mediation or arbitration may be necessary to reach a satisfactory conclusion. -

What certifications should I look for in gate latches?

When sourcing gate latches, look for certifications that demonstrate compliance with international standards. Common certifications include ISO 9001 for quality management systems and ASTM or EN standards for product safety and performance. For specific applications, such as pool safety, check for certifications that meet local regulations. Certifications not only enhance product credibility but also provide assurance regarding quality and safety.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of gate latch

Strategic sourcing of gate latches is essential for international B2B buyers, particularly in diverse markets across Africa, South America, the Middle East, and Europe. Understanding the various types of gate latches—ranging from gravity latches and spring-loaded options to modern magnetic designs—enables buyers to select solutions that best fit their security needs, installation preferences, and environmental conditions.

By prioritizing quality, durability, and ease of installation, businesses can enhance the safety and functionality of their properties while ensuring compliance with regional standards. Furthermore, engaging with reliable suppliers can lead to cost-effective purchasing agreements, streamlined logistics, and access to innovative products tailored to specific market demands.

As global trends evolve towards smarter and more secure solutions, international B2B buyers should stay informed about emerging technologies in gate latch designs. Investing in high-quality latch systems today not only secures assets but also positions businesses for future growth. Explore partnerships with reputable manufacturers and distributors to leverage the latest advancements and ensure your operations remain secure and efficient in an increasingly competitive landscape.