Your Ultimate Guide to Sourcing Steel Companies Chicago Il

Introduction: Navigating the Global Market for steel companies chicago il

Navigating the global market for steel products can be a complex endeavor, especially for international B2B buyers targeting reliable suppliers in Chicago, Illinois. Renowned for its rich industrial heritage, Chicago is home to a robust network of steel companies that cater to a diverse range of industries—from construction to automotive manufacturing. Understanding this landscape is crucial for buyers from Africa, South America, the Middle East, and Europe, particularly those from countries like France and Italy, where quality steel is essential for infrastructure and manufacturing projects.

This guide offers a comprehensive overview of the steel companies in Chicago, detailing the types of steel products available, including specialty and standard grades, along with manufacturing and quality control processes. It will also explore key suppliers, pricing strategies, and market dynamics that influence sourcing decisions. By delving into frequently asked questions, buyers will gain insights into best practices for engaging with suppliers and negotiating contracts.

Empowered with this information, international buyers can make informed decisions that align with their project requirements and budget constraints. The goal is to facilitate a seamless sourcing experience, enabling businesses to tap into Chicago’s steel market efficiently and effectively. Whether you are looking for bulk steel supplies or specialized manufacturing services, this guide serves as your essential resource for navigating the vibrant steel industry in Chicago.

Understanding steel companies chicago il Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Contract Steel Manufacturers | Provide customized steel products; often focus on specific industries | Construction, automotive, aerospace | Pros: Tailored solutions; flexible production. Cons: Potentially higher costs for small orders. |

| Steel Service Centers | Large inventory of steel products; value-added processing capabilities | Wholesale distribution, manufacturing | Pros: Quick access to diverse products; processing services. Cons: May lack specialization in niche markets. |

| Fabrication Shops | Custom fabrication services; specialized in specific steel forms | Construction, machinery, custom projects | Pros: High customization; skilled labor. Cons: Longer lead times for complex projects. |

| Metal Recycling Companies | Focus on recycling and repurposing steel; sustainability emphasis | Manufacturing, construction, environmental | Pros: Cost-effective; eco-friendly solutions. Cons: Variability in material quality. |

| Specialty Steel Producers | Focus on high-performance or niche steel products; advanced alloys | Aerospace, defense, automotive | Pros: Superior material properties; tailored for specific applications. Cons: Higher price points; limited availability. |

Contract Steel Manufacturers

Contract steel manufacturers are pivotal in providing customized steel products tailored to specific industry needs. They often engage in long-term partnerships with clients, ensuring a steady supply of tailored solutions. Buyers should consider the manufacturer’s ability to accommodate specific requirements, lead times, and pricing structures, as these factors can significantly influence project timelines and budgets.

Steel Service Centers

Steel service centers act as intermediaries between steel mills and manufacturers, offering a wide range of steel products alongside value-added services like cutting, shaping, and inventory management. They are particularly beneficial for businesses needing quick access to various steel types without the need for large-scale production. When selecting a service center, buyers should evaluate the range of inventory, processing capabilities, and delivery options to ensure they meet their operational needs.

Fabrication Shops

Fabrication shops specialize in creating custom steel structures and components, often focusing on specific forms and applications. These shops employ skilled labor and advanced technology to deliver high-quality products tailored to client specifications. Buyers must consider the shop’s expertise in their required applications, potential lead times, and the complexity of the fabrication process to ensure a successful partnership.

Metal Recycling Companies

Metal recycling companies focus on the collection, processing, and resale of scrap steel, promoting sustainability within the industry. They provide an eco-friendly solution for manufacturers looking to reduce waste and lower material costs. Buyers should assess the quality and consistency of recycled materials, as well as the company’s processing capabilities, to ensure they meet their production standards.

Specialty Steel Producers

Specialty steel producers offer high-performance steel products designed for specific applications, such as aerospace and defense. These manufacturers typically focus on advanced alloys and unique material properties that cater to demanding industry requirements. While they provide exceptional quality, buyers should be prepared for higher price points and potential limitations in product availability, making it essential to assess their specific needs before engaging.

Related Video: How Large Language Models Work

Key Industrial Applications of steel companies chicago il

| Industry/Sector | Specific Application of steel companies chicago il | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural steel for building frameworks | Provides strength and durability for buildings | Compliance with local regulations and standards |

| Automotive | Steel components for vehicle manufacturing | Enhances vehicle safety and performance | Quality certifications and material specifications |

| Oil & Gas | Steel pipes and fittings for infrastructure | Ensures reliability in transporting fluids | Resistance to corrosion and pressure ratings |

| Manufacturing | Custom steel fabrications for machinery | Improves operational efficiency and productivity | Precision engineering capabilities and lead times |

| Aerospace | Lightweight steel alloys for aircraft components | Reduces weight while maintaining structural integrity | Certifications for aerospace-grade materials |

Construction

Steel companies in Chicago play a pivotal role in the construction industry by supplying structural steel that forms the backbone of buildings and infrastructure. These companies provide high-quality steel beams, columns, and reinforcements that ensure the structural integrity of constructions. For international buyers, particularly from regions like Africa and South America, it’s crucial to consider local building codes and standards to ensure compliance. Additionally, buyers should evaluate the supplier’s ability to provide timely delivery and adequate support during the construction phase.

Automotive

In the automotive sector, Chicago-based steel manufacturers supply essential components such as chassis and body panels that contribute to vehicle safety and performance. The use of high-strength steel enhances crashworthiness while reducing weight, which is vital for fuel efficiency. International buyers, especially from Europe and the Middle East, should prioritize suppliers with ISO certifications and a proven track record in automotive standards to ensure the reliability and safety of their components.

Oil & Gas

Steel companies in Chicago provide specialized pipes and fittings essential for the oil and gas industry, where the transportation of fluids under high pressure is critical. These products must meet stringent quality standards to withstand harsh environments. For buyers from Africa and the Middle East, sourcing from manufacturers that offer corrosion-resistant materials and comply with international safety standards is essential. It’s also important to assess the supplier’s capacity to provide customized solutions that meet specific project requirements.

Manufacturing

Custom steel fabrications from Chicago’s steel companies are integral to various manufacturing processes, enhancing machinery and equipment efficiency. These fabrications can include everything from brackets to complex assemblies tailored to specific operational needs. International B2B buyers should focus on suppliers that demonstrate advanced engineering capabilities and flexibility in production to meet unique specifications. Lead times and the ability to scale production quickly are also key considerations for maintaining operational continuity.

Aerospace

In the aerospace industry, lightweight steel alloys produced by Chicago steel companies are crucial for creating components that require a balance between strength and weight. These materials are used in aircraft frames, landing gear, and other critical parts. International buyers, particularly from Europe, must ensure that their suppliers have the necessary certifications for aerospace-grade materials and adhere to strict quality control processes. The ability to provide innovative solutions and rapid prototyping can also enhance competitiveness in this high-stakes industry.

Related Video: Uses of Metal – Gold, Copper, Aluminium & Steel | Properties of Matter| Chemistry | FuseSchool

Strategic Material Selection Guide for steel companies chicago il

When selecting materials for steel manufacturing, international B2B buyers must consider various factors that influence performance, cost, and compliance with industry standards. Below, we analyze four common materials used by steel companies in Chicago, IL, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Carbon Steel

Key Properties: Carbon steel is known for its high strength and toughness. It can withstand high temperatures and pressures, making it suitable for a wide range of applications.

Pros & Cons: The primary advantage of carbon steel is its durability and cost-effectiveness. However, it is prone to corrosion if not properly treated, which can limit its lifespan in certain environments. Manufacturing complexity is moderate, as it can be easily welded and formed.

Impact on Application: Carbon steel is compatible with various media, including water and oil, but its susceptibility to rust requires protective coatings in corrosive environments.

Considerations for International Buyers: Buyers should ensure compliance with ASTM standards for carbon steel grades. Additionally, understanding local corrosion risks is essential, especially in humid or saline environments typical in Africa and coastal areas of Europe.

Stainless Steel

Key Properties: Stainless steel is highly resistant to corrosion and oxidation. It can withstand extreme temperatures and is available in various grades, each tailored for specific applications.

Pros & Cons: The key advantage of stainless steel is its long-term durability and aesthetic appeal, making it ideal for applications requiring hygiene, such as food processing. However, it is more expensive than carbon steel and can be challenging to machine.

Impact on Application: Stainless steel is compatible with a wide range of media, including acids and alkalis, making it suitable for chemical processing industries.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers should also consider the specific grade of stainless steel required for their applications, as preferences may vary by region.

Alloy Steel

Key Properties: Alloy steel is made by adding elements like chromium, nickel, or molybdenum to carbon steel, enhancing its mechanical properties. It offers improved strength, toughness, and wear resistance.

Pros & Cons: The primary advantage of alloy steel is its versatility and enhanced performance in demanding applications. However, it tends to be more expensive than carbon steel and may require more complex manufacturing processes.

Impact on Application: Alloy steel is suitable for high-stress applications, such as automotive and aerospace components, where strength and durability are critical.

Considerations for International Buyers: Buyers should be aware of the specific alloying elements and their effects on performance. Compliance with relevant standards is essential, especially when exporting to regions with strict regulations.

Tool Steel

Key Properties: Tool steel is designed for manufacturing tools and dies. It exhibits high hardness, wear resistance, and the ability to retain its shape at elevated temperatures.

Pros & Cons: The key advantage of tool steel is its ability to withstand high levels of stress and wear, making it ideal for machining and cutting applications. However, it is more expensive and can be difficult to machine.

Impact on Application: Tool steel is primarily used in manufacturing tools that require precision and durability, such as dies, molds, and cutting instruments.

Considerations for International Buyers: Buyers must ensure that the tool steel meets the necessary specifications for their applications. Familiarity with standards such as JIS and ASTM is important for compliance and quality assurance.

Summary Table

| Material | Typical Use Case for steel companies chicago il | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Construction, automotive parts | Cost-effective and durable | Prone to corrosion | Medium |

| Stainless Steel | Food processing, chemical industries | Corrosion resistant | Higher cost, machining challenges | High |

| Alloy Steel | Aerospace, automotive components | Enhanced strength and versatility | More expensive, complex to manufacture | High |

| Tool Steel | Manufacturing tools and dies | High hardness and wear resistance | Difficult to machine | High |

This analysis provides a comprehensive overview of strategic material selection for international B2B buyers in the steel industry, ensuring informed decision-making that aligns with both performance requirements and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for steel companies chicago il

The manufacturing processes for steel companies in Chicago, IL, are designed to ensure high quality and efficiency, crucial for international B2B buyers. Understanding these processes and the associated quality assurance practices is vital for making informed purchasing decisions.

Manufacturing Processes

1. Material Preparation

The first stage in steel manufacturing involves sourcing and preparing raw materials, primarily iron ore, scrap metal, and alloying elements. Key steps include:

- Material Sourcing: Steel companies often source raw materials locally and internationally, ensuring they meet specific industry standards.

- Sorting and Cleaning: Incoming materials undergo sorting to eliminate contaminants. This is critical to maintaining the integrity of the final product.

- Melting: Materials are melted in electric arc furnaces (EAF) or basic oxygen furnaces (BOF), depending on the desired steel grade. EAFs are preferred for recycling scrap metal, while BOFs are used for producing steel from iron ore.

2. Forming

Once the material is prepared, the next step is forming, where molten steel is shaped into semi-finished products. Techniques include:

- Casting: Continuous casting is widely used, where molten steel is poured into molds to create slabs, blooms, or billets.

- Rolling: Hot rolling and cold rolling processes further shape the semi-finished products into desired dimensions. Hot rolling is typically used for larger sections, while cold rolling provides better surface finish and tighter tolerances.

3. Assembly

In this stage, various steel components are assembled to create final products. This may involve:

- Welding: Automated welding processes ensure strong and consistent joints between steel components. This is crucial for structural integrity.

- Machining: Additional machining processes, such as drilling and milling, may be employed to achieve precise dimensions and features.

4. Finishing

The finishing stage enhances the physical and aesthetic qualities of the steel products. Key processes include:

- Surface Treatment: Techniques like galvanizing, coating, or polishing are used to improve corrosion resistance and surface finish.

- Heat Treatment: Processes such as annealing or quenching are applied to alter the mechanical properties of steel, enhancing its strength and durability.

Quality Assurance

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that products meet international standards and customer specifications.

Relevant International Standards

International standards play a significant role in quality assurance for steel manufacturing. Key standards include:

- ISO 9001: This standard outlines requirements for a quality management system (QMS), ensuring consistent product quality and customer satisfaction.

- CE Marking: For products sold in the European Economic Area, CE marking certifies compliance with health, safety, and environmental protection standards.

- API Standards: For steel products used in the oil and gas industry, API standards ensure products meet specific performance and safety criteria.

Quality Control Checkpoints

Quality control (QC) checkpoints are established throughout the manufacturing process to monitor and ensure quality at every stage:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to verify they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing helps identify and rectify defects early in the process.

- Final Quality Control (FQC): The final inspection ensures that finished products meet all quality requirements before shipment.

Common Testing Methods

Various testing methods are employed to ensure quality and compliance:

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, radiography, and magnetic particle testing are used to detect flaws without damaging the product.

- Mechanical Testing: Tensile, hardness, and impact tests assess the material properties and performance of steel products.

- Chemical Analysis: Testing the chemical composition of steel ensures it meets specified grades and standards.

Verifying Supplier Quality Control

For international B2B buyers, verifying the quality control processes of suppliers is crucial to ensure product reliability. Here are actionable steps:

- Conduct Audits: Periodic audits of suppliers can help assess their compliance with international standards and internal quality processes.

- Request Quality Reports: Suppliers should provide detailed quality reports, including results from testing and inspections conducted during manufacturing.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance processes and product quality.

- Review Certifications: Ensure suppliers hold relevant certifications (ISO, CE, API) that demonstrate their commitment to quality and compliance.

Quality Control Considerations for International Buyers

When sourcing steel products from Chicago for international markets, buyers from Africa, South America, the Middle East, and Europe should consider:

- Cultural and Regulatory Differences: Be aware of varying quality standards and regulations in your region. Ensure that the supplier can comply with local requirements.

- Logistics and Shipping: Quality assurance should extend to logistics. Ensure that the steel products are handled and transported in a manner that maintains their quality.

- Communication: Establish clear communication channels with suppliers to address any quality concerns promptly and effectively.

In summary, understanding the manufacturing processes and quality assurance practices of steel companies in Chicago is essential for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control measures, buyers can ensure they receive high-quality steel products that meet their specifications and standards.

Related Video: Steel Factory, Steel Production, Iron Making Process, How it’s Made

Comprehensive Cost and Pricing Analysis for steel companies chicago il Sourcing

In the competitive landscape of steel sourcing from Chicago, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will break down the cost components involved, identify key price influencers, and provide actionable tips for buyers, particularly those from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary cost driver in steel manufacturing. The prices of raw materials, such as iron ore and scrap steel, can fluctuate significantly based on global supply and demand. Buyers should keep abreast of these trends to negotiate better prices.

-

Labor: Labor costs in Chicago can be higher than in other regions due to the skilled workforce. Companies often account for wages, benefits, and potential overtime, all of which can affect the final pricing.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and administrative costs. Overhead is typically allocated per unit produced, so higher production volumes can lead to lower overhead costs per unit.

-

Tooling: Specialized tools and equipment required for manufacturing can be a substantial upfront investment. This cost is usually amortized over the production run, influencing pricing for customized orders.

-

Quality Control (QC): Ensuring compliance with industry standards and certifications adds to the cost. Companies often invest in rigorous QC processes to maintain product integrity, especially when exporting internationally.

-

Logistics: Transportation costs can vary based on destination, mode of transport, and shipping terms (Incoterms). For international shipments, logistics can significantly impact total costs, particularly in terms of customs duties and tariffs.

-

Margin: Manufacturers typically include a profit margin on top of their costs, which can vary based on market conditions and competitive pressures.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to discounted pricing. Buyers should assess their needs to take advantage of bulk pricing where feasible.

-

Specifications/Customization: Custom orders, while often necessary, can increase costs due to the need for specialized tooling and processes. Buyers should clarify their specifications upfront to avoid unexpected charges.

-

Materials Quality/Certifications: Higher-quality materials and necessary certifications (like ISO) can increase costs. However, they may be essential for compliance in certain markets, particularly in Europe.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products but often provide better service and quality assurance.

-

Incoterms: The terms of shipment can drastically affect overall costs. Understanding the implications of different Incoterms (like FOB, CIF, etc.) can help buyers negotiate better shipping arrangements.

Buyer Tips

-

Negotiation: Engage suppliers in open discussions about pricing structures. Understanding their cost components can provide leverage in negotiations.

-

Cost-Efficiency: Evaluate total cost of ownership (TCO) rather than just the purchase price. Consider logistics, maintenance, and potential downtime when assessing value.

-

Pricing Nuances: Be aware of pricing fluctuations due to market changes or geopolitical events, especially relevant for buyers in Africa and the Middle East.

-

Supplier Relationships: Cultivating strong relationships with suppliers can lead to better pricing and service. Consider long-term partnerships for consistent supply and better rates.

-

Research and Benchmarking: Compare quotes and services from multiple suppliers in Chicago. Benchmarking against industry standards can reveal competitive pricing opportunities.

Disclaimer

Prices and cost structures mentioned herein are indicative and subject to change based on market conditions, supplier negotiations, and other external factors. Buyers are encouraged to conduct thorough due diligence and obtain updated quotes tailored to their specific requirements.

Spotlight on Potential steel companies chicago il Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘steel companies chicago il’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for steel companies chicago il

Key Technical Properties for Steel Companies in Chicago, IL

Understanding the essential technical properties of steel is crucial for international B2B buyers, particularly when sourcing from companies in Chicago, IL. The following specifications are vital for assessing steel products:

-

Material Grade

Material grade refers to the classification of steel based on its chemical composition and mechanical properties. Common grades include ASTM A36 (structural steel), ASTM A992 (used for wide-flange beams), and A572 (high-strength low-alloy steel). Knowing the material grade helps buyers ensure that the steel meets specific performance and safety standards required for their applications. -

Tensile Strength

This property measures the maximum amount of tensile (pulling) stress that a material can withstand before failure. Tensile strength is crucial for applications where steel is subjected to stretching or pulling forces. High tensile strength is often required in construction, automotive, and aerospace industries, making it a significant consideration for buyers. -

Yield Strength

Yield strength is the amount of stress at which a material begins to deform plastically. It is essential for determining how much load a steel component can bear before it permanently deforms. Buyers should prioritize yield strength to ensure that the materials will perform reliably under expected loads. -

Ductility

Ductility refers to the ability of steel to deform under tensile stress, which is crucial for applications requiring bending or shaping without breaking. Ductile materials can absorb energy and are less likely to fracture under stress. Buyers should consider ductility when selecting steel for construction and manufacturing processes. -

Tolerance

Tolerance defines the allowable variation in dimensions and properties of steel products. Precision in manufacturing is critical for applications requiring exact fits and performance. Understanding the tolerance levels can help buyers minimize waste and avoid costly rework. -

Corrosion Resistance

This property indicates how well steel can withstand degradation from environmental factors like moisture and chemicals. For buyers sourcing steel for outdoor or industrial applications, corrosion resistance is essential to ensure longevity and reduce maintenance costs.

Common Trade Terminology in Steel Procurement

Familiarity with industry jargon is equally important for effective communication and negotiation in B2B transactions. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers navigate their supply chains and ensure compatibility with existing products. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Buyers must be aware of MOQs to manage inventory costs effectively and align their purchasing strategies with production needs. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. Issuing an RFQ allows buyers to compare prices, terms, and capabilities among different suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping, insurance, and duty obligations, ensuring smoother logistics. -

Lead Time

Lead time is the amount of time required from placing an order to receiving the product. Understanding lead times is crucial for project planning and scheduling, especially in industries where timing can significantly impact operations.

Illustrative Image (Source: Google Search)

- Value-Added Services

This term refers to additional services provided by suppliers, such as cutting, welding, or coating. Buyers should consider value-added services to enhance the functionality of their steel products and potentially reduce overall project costs.

By understanding these essential properties and terms, international B2B buyers can make informed decisions when sourcing steel from Chicago, IL, ensuring that they meet their project requirements efficiently and effectively.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the steel companies chicago il Sector

Market Overview & Key Trends

The steel industry in Chicago, a crucial hub for manufacturing and distribution in the United States, is influenced by several global drivers that shape market dynamics for international B2B buyers. Key trends include advancements in automation and Industry 4.0 technologies, which are enhancing production efficiency and reducing operational costs. The integration of artificial intelligence and IoT in manufacturing processes is enabling better supply chain visibility and predictive maintenance, thus offering significant advantages to buyers looking to streamline operations.

International buyers from regions like Africa, South America, the Middle East, and Europe are increasingly focused on sourcing high-quality steel products that meet stringent regulatory standards. This demand is bolstered by infrastructure developments and urbanization trends in emerging markets. Furthermore, the shift towards digital procurement platforms is transforming how buyers engage with suppliers, allowing for more competitive pricing, faster lead times, and enhanced collaboration.

Sourcing trends are also leaning towards just-in-time inventory systems, which help reduce holding costs and improve cash flow for buyers. However, fluctuating raw material prices and geopolitical factors can affect supply stability, making it essential for buyers to establish strong relationships with reputable suppliers. Chicago’s steel companies are well-positioned to meet these demands, given their extensive inventory and value-added services.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a pivotal concern for B2B buyers in the steel sector, driven by increasing environmental regulations and consumer demand for responsible sourcing. Steel production is energy-intensive and contributes significantly to carbon emissions; therefore, companies in Chicago are adopting sustainable practices to mitigate environmental impact. This includes using recycled materials, optimizing energy consumption, and investing in cleaner technologies.

Illustrative Image (Source: Google Search)

For international buyers, the importance of ethical supply chains cannot be overstated. Establishing partnerships with suppliers who prioritize sustainability can enhance brand reputation and meet compliance requirements in their home markets. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming vital credentials that buyers should look for when selecting steel suppliers.

Moreover, many Chicago-based steel companies are exploring ‘green’ steel initiatives, utilizing renewable energy sources and innovative recycling processes. By sourcing from these environmentally conscious suppliers, international buyers not only contribute to global sustainability efforts but can also capitalize on potential cost savings associated with energy-efficient practices.

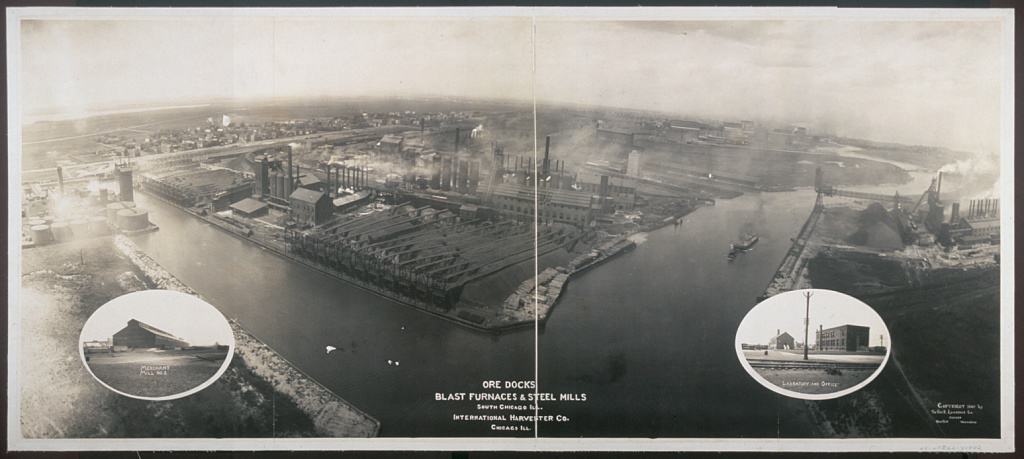

Brief Evolution/History

The steel industry in Chicago has a rich history that dates back to the late 19th century, when it became a cornerstone of American manufacturing. Over the years, the sector has evolved from traditional steel production methods to more advanced and automated processes. The rise of mini-mills and the shift towards electric arc furnace technology have significantly transformed production capabilities, allowing for higher quality and more sustainable steel products.

As global markets have become more interconnected, Chicago’s steel companies have adapted to meet the changing demands of international buyers. This evolution has been marked by a focus on innovation, quality assurance, and sustainability, positioning the region as a leading player in the global steel market. Today, Chicago’s steel sector continues to thrive, driven by a commitment to excellence and a strategic vision for future growth.

Related Video: How Global Trade Runs on U.S. Dollars | WSJ

Frequently Asked Questions (FAQs) for B2B Buyers of steel companies chicago il

-

What criteria should I use to vet steel suppliers in Chicago?

When vetting steel suppliers, consider their industry experience, client reviews, and certifications. Look for suppliers with ISO certifications, which indicate adherence to international quality standards. Additionally, assess their financial stability through credit reports and seek references from past clients, particularly those from your region. It’s also beneficial to visit their facilities if possible, as this allows you to evaluate their operations firsthand and ensure they meet your quality expectations. -

Can I customize my steel orders, and what is the process?

Yes, many Chicago steel companies offer customization options for steel products. This often includes specifications related to dimensions, grades, and finishes. To initiate the process, provide detailed requirements to the supplier, including drawings or models if available. Discuss potential costs and lead times for customized orders, as these can vary significantly based on complexity and the supplier’s production capacity.

-

What are the typical minimum order quantities (MOQs) and lead times for steel products?

Minimum order quantities (MOQs) can vary widely among suppliers. Some may require a minimum order of several tons, while others might allow smaller quantities for specific products. Lead times typically range from a few days to several weeks, depending on the product type and customization level. It’s crucial to communicate your timeline needs upfront to ensure that the supplier can accommodate your schedule. -

What payment terms should I expect when dealing with Chicago steel companies?

Payment terms can differ significantly between suppliers, but common practices include upfront deposits (typically 30% to 50%) with the balance due upon delivery or within a specified period post-delivery. For international transactions, consider using letters of credit or escrow services to mitigate risk. Always clarify payment terms before finalizing contracts to avoid misunderstandings. -

What quality assurance measures do steel suppliers implement?

Reputable steel suppliers employ various quality assurance (QA) measures, including material testing, certification processes, and compliance with international standards. They may conduct tensile tests, hardness tests, and chemical composition analyses to ensure product integrity. Ask potential suppliers for documentation of their QA processes and any third-party inspections they undergo, as this can give you confidence in their product quality. -

How do logistics and shipping work for international orders from Chicago?

Logistics for international orders typically involve freight forwarders who handle the transportation of goods from the supplier to your location. Discuss shipping options with your supplier, including costs, timelines, and any necessary customs documentation. Ensure that the supplier is experienced in international shipping and can provide Incoterms (International Commercial Terms) that clarify responsibilities for shipping, insurance, and tariffs. -

What should I do if there is a dispute with my steel supplier?

In the event of a dispute, first attempt to resolve the issue directly with the supplier through open communication. If that fails, refer to the contract terms regarding dispute resolution, which may include mediation or arbitration clauses. It’s advisable to keep thorough documentation of all communications and transactions. If necessary, consult legal counsel experienced in international trade to explore your options. -

What certifications should I look for in steel products?

Look for certifications such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) that indicate compliance with recognized quality standards. Additionally, specific industry certifications may be relevant depending on your intended application, such as API (American Petroleum Institute) for oil and gas applications. Request documentation from suppliers to verify these certifications, as they are critical for ensuring product reliability and safety in your projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for steel companies chicago il

The strategic sourcing landscape for steel companies in Chicago offers a wealth of opportunities for international buyers, particularly those from Africa, South America, the Middle East, and Europe. The region is home to a diverse array of steel manufacturers and service centers, each providing unique capabilities that cater to a variety of industries. With companies like Chicago Tube & Iron and Dedert Corporation at the forefront, buyers can access high-quality materials and advanced processing services.

Key Takeaways:

– Diverse Offerings: Chicago’s steel companies provide a wide range of products, including specialty steel, value-added processing, and custom fabrication, ensuring that international buyers can find tailored solutions to meet their needs.

– Reliability and Service: Established manufacturers emphasize consistent quality and customer service, which are crucial for maintaining supply chain efficiency.

– Geographic Advantage: Chicago’s strategic location enhances logistics, facilitating easier access to North American markets and beyond.

As global demand for steel continues to rise, now is the time for international B2B buyers to engage with Chicago’s steel manufacturers. By fostering partnerships with these companies, buyers can enhance their sourcing strategies, ensuring they remain competitive in their respective markets. Explore the potential of strategic sourcing in Chicago and leverage these relationships to drive your business forward.