Master Sourcing from Top Steel Stamping Companies to Boost

Introduction: Navigating the Global Market for steel stamping companies

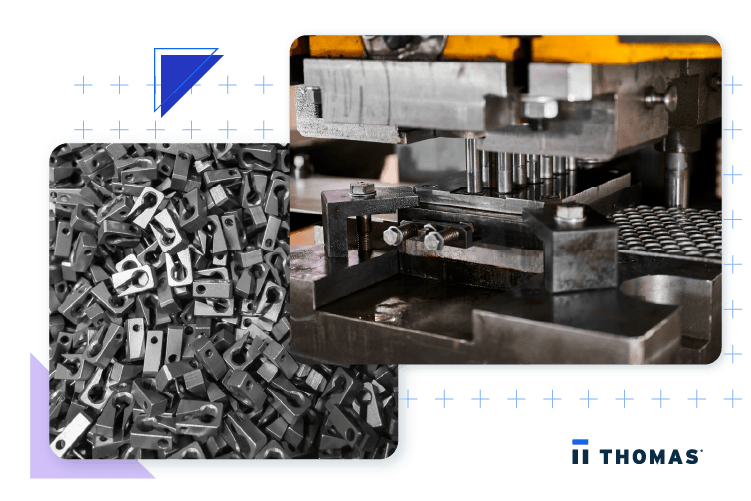

In an increasingly interconnected global economy, steel stamping companies play a pivotal role in the manufacturing supply chain. These firms specialize in the precision shaping and forming of metal parts essential for diverse industries, including automotive, aerospace, electronics, and consumer goods. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate the complexities of sourcing, understanding the dynamics of the steel stamping market becomes crucial.

This comprehensive guide offers a thorough exploration of the steel stamping landscape, covering critical aspects such as types of stamping processes, materials used, and manufacturing and quality control standards. Buyers will benefit from insights on leading suppliers, cost considerations, and market trends, empowering them to make informed decisions. Furthermore, the guide addresses common FAQs, helping to demystify the sourcing process and clarify expectations.

Illustrative Image (Source: Google Search)

As the steel stamping market is projected to grow significantly, with a valuation expected to reach $316.7 billion by 2030, now is the time for buyers to equip themselves with the knowledge necessary to capitalize on this growth. By leveraging the information provided in this guide, international buyers can enhance their sourcing strategies, ensuring they partner with reputable suppliers who meet their quality and production requirements. The pathway to successful procurement starts here, paving the way for sustainable business growth and competitive advantage in the global market.

Understanding steel stamping companies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Progressive Die Stamping | Utilizes a single die to perform multiple operations | Automotive parts, electronics housings | Pros: High efficiency, reduced labor costs; Cons: High initial tooling costs. |

| Deep Draw Stamping | Capable of creating deep, complex shapes | Beverage cans, medical equipment | Pros: Excellent for intricate designs; Cons: Limited to specific materials. |

| Custom Stamping | Tailored designs based on specific client requirements | Aerospace components, specialized tools | Pros: Fully customizable; Cons: Longer lead times for production. |

| Short Run Stamping | Designed for low-volume production | Prototyping, small batch manufacturing | Pros: Cost-effective for small orders; Cons: Higher per-unit cost. |

| Laser Cutting Stamping | Combines stamping with laser cutting for precision work | High-tech applications, intricate designs | Pros: High precision and flexibility; Cons: Slower production speeds. |

Progressive Die Stamping

Progressive die stamping is a highly efficient method where a single die performs multiple operations in a single pass. This technique is particularly suitable for high-volume production runs, making it ideal for industries like automotive and electronics. When considering suppliers, buyers should assess the supplier’s capability to handle complex designs and their experience with high-speed operations. The initial investment in tooling can be significant, but the long-term cost savings often justify this expense.

Deep Draw Stamping

Deep draw stamping is characterized by its ability to create deep and complex shapes from flat metal sheets. This technique is commonly used in producing beverage cans and medical equipment. Buyers should consider the material compatibility and the intricacy of the designs they require. While this method allows for creative designs, it is typically limited to certain metals, which can affect material sourcing and costs.

Custom Stamping

Custom stamping services offer tailored designs based on specific client requirements, catering to unique applications in aerospace and specialized tools. This flexibility is beneficial for buyers who need specific dimensions or features. However, the lead times for custom projects can be longer, and buyers should evaluate the supplier’s design capabilities and past projects to ensure they meet their needs.

Short Run Stamping

Short run stamping is designed for low-volume production, making it an excellent choice for prototyping or small batch manufacturing. This method is particularly cost-effective for initial designs or limited market releases. However, buyers should be aware that the per-unit cost can be higher compared to mass production methods. It’s essential to communicate clearly with suppliers about volume expectations and timelines.

Laser Cutting Stamping

Laser cutting stamping combines traditional stamping with laser cutting technology, providing high precision and flexibility for intricate designs. This method is often used in high-tech applications where accuracy is critical. Buyers should assess the supplier’s technology capabilities and turnaround times, as laser cutting can be slower than conventional methods. The benefits of precision must be weighed against potential production delays.

Related Video: What is Progressive Stamping Die?

Key Industrial Applications of steel stamping companies

| Industry/Sector | Specific Application of steel stamping companies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of body panels, brackets, and chassis components | Enhances vehicle safety, reduces weight, and improves fuel efficiency | Look for suppliers with experience in automotive standards and certifications (ISO/TS 16949) |

| Electronics | Fabrication of housings, connectors, and circuit board components | Improves product durability and enhances electromagnetic compatibility | Ensure precision capabilities and compliance with RoHS standards for environmentally friendly materials |

| Construction | Manufacturing of metal framing, brackets, and structural components | Increases structural integrity and reduces construction costs | Consider suppliers with expertise in local building codes and regulations, especially for international projects |

| Aerospace | Creation of precision components for aircraft and spacecraft | Ensures safety and compliance with stringent aerospace regulations | Prioritize suppliers with AS9100 certification and a proven track record in aerospace applications |

| Appliance Manufacturing | Production of parts for refrigerators, ovens, and washing machines | Improves product reliability and extends lifespan of appliances | Seek suppliers who can handle high-volume orders and offer custom solutions tailored to specific appliance designs |

Automotive Applications

Steel stamping companies play a crucial role in the automotive industry by producing essential components such as body panels, brackets, and chassis parts. These stamped parts are vital for vehicle safety and performance, as they contribute to structural integrity while minimizing weight. International buyers should prioritize suppliers with certifications like ISO/TS 16949 to ensure compliance with automotive industry standards, particularly when sourcing from regions like Africa or South America, where local regulations may differ.

Electronics Applications

In the electronics sector, steel stamping is used to fabricate housings, connectors, and circuit board components. The precision of stamped parts enhances the durability of electronic devices and ensures they meet electromagnetic compatibility standards. Buyers from the Middle East and Europe should focus on suppliers with advanced precision capabilities and adherence to RoHS regulations to guarantee that materials used are environmentally friendly and safe for electronic applications.

Construction Applications

Steel stamping is integral to the construction industry, where it is used to manufacture metal framing, brackets, and various structural components. These parts increase the overall structural integrity of buildings while also reducing costs associated with construction. For international projects, especially in developing markets, it is vital to engage suppliers familiar with local building codes and regulations to ensure compliance and safety in construction practices.

Aerospace Applications

In the aerospace industry, precision is paramount. Steel stamping companies provide critical components for aircraft and spacecraft, ensuring they meet stringent safety and regulatory standards. Buyers should look for suppliers with AS9100 certification and experience in aerospace applications, as this guarantees the quality and reliability of the stamped parts, which are essential for safe flight operations.

Appliance Manufacturing Applications

Steel stamping is widely used in the manufacturing of parts for household appliances, including refrigerators, ovens, and washing machines. By utilizing stamped components, manufacturers can improve the reliability and longevity of their products. Buyers should seek suppliers capable of high-volume production while offering custom solutions tailored to specific appliance designs, ensuring that the final products meet consumer demands and industry standards.

Related Video: Sheet Metal Stamping Process Step by Step

Strategic Material Selection Guide for steel stamping companies

When selecting materials for steel stamping processes, it is crucial to consider the properties, advantages, disadvantages, and specific requirements of each material. Below is an analysis of four common materials used in steel stamping, with insights tailored for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

1. Carbon Steel

Key Properties:

Carbon steel is known for its high strength and hardness, making it suitable for various applications. It typically has a temperature rating of up to 300°C and offers moderate corrosion resistance, which can be improved with coatings.

Pros & Cons:

The primary advantage of carbon steel is its durability and cost-effectiveness. However, it is susceptible to rusting if not properly treated, which can limit its use in humid environments. Manufacturing complexity is moderate, as it can be easily stamped and formed.

Impact on Application:

Carbon steel is widely used in automotive and construction components due to its strength. However, in regions with high humidity, buyers should consider additional protective coatings to enhance corrosion resistance.

Considerations for International Buyers:

Buyers should ensure compliance with ASTM standards and consider local regulations regarding material quality and environmental impact. Understanding the local availability of carbon steel grades is also essential.

2. Stainless Steel

Key Properties:

Stainless steel is characterized by its excellent corrosion resistance and ability to withstand high temperatures (up to 800°C). It is also non-reactive, making it ideal for food and medical applications.

Pros & Cons:

The key advantage of stainless steel is its longevity and resistance to corrosion, which reduces maintenance costs. However, it is more expensive than carbon steel and requires more complex manufacturing processes, which can increase lead times.

Impact on Application:

Stainless steel is suitable for applications in harsh environments, such as marine or chemical industries. It maintains integrity even when exposed to aggressive media.

Considerations for International Buyers:

Buyers should verify compliance with international standards such as ASTM and DIN. The higher cost of stainless steel may impact budget considerations, particularly in developing regions.

3. Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, with a temperature rating of approximately 200°C. It is also a good conductor of electricity and heat.

Pros & Cons:

The main advantage of aluminum is its lightweight nature, which is beneficial for applications requiring reduced weight, such as in the aerospace industry. However, it is less durable than steel and can be more expensive depending on the alloy used.

Impact on Application:

Aluminum is often used in automotive and aerospace applications where weight savings are critical. Its compatibility with various media makes it versatile but may not be suitable for high-stress applications.

Considerations for International Buyers:

Buyers should be aware of the specific aluminum alloys available in their region and ensure they meet relevant standards. Understanding the cost implications of aluminum compared to steel is also vital.

4. High-Strength Low-Alloy (HSLA) Steel

Key Properties:

HSLA steel is designed to provide better mechanical properties and greater resistance to corrosion than conventional carbon steel. It typically has a temperature rating similar to carbon steel but offers improved strength-to-weight ratios.

Pros & Cons:

The key advantage of HSLA steel is its ability to reduce weight while maintaining strength, making it suitable for automotive applications. However, it can be more expensive than standard carbon steel and may require specialized manufacturing techniques.

Impact on Application:

HSLA steel is ideal for applications where weight reduction is essential without compromising strength, such as in vehicle frames. Its enhanced properties make it suitable for various industrial applications.

Considerations for International Buyers:

Buyers should check for compliance with local and international standards, including ASTM and JIS. The availability of HSLA steel grades may vary by region, influencing sourcing decisions.

Summary Table

| Material | Typical Use Case for steel stamping companies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Automotive parts, construction components | Cost-effective and durable | Susceptible to corrosion | Low |

| Stainless Steel | Food processing, medical equipment | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Aerospace parts, lightweight automotive parts | Lightweight and good corrosion resistance | Less durable than steel | Med |

| High-Strength Low-Alloy Steel | Vehicle frames, industrial applications | Improved strength-to-weight ratio | More expensive and specialized processing | Med |

This guide provides a comprehensive overview of material selection for steel stamping companies, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for steel stamping companies

Manufacturing Processes for Steel Stamping Companies

Steel stamping is a critical manufacturing process that involves shaping and forming metal parts through various techniques. For international B2B buyers, understanding the typical manufacturing stages and key techniques used in steel stamping is essential for making informed purchasing decisions.

Main Stages of Manufacturing

-

Material Preparation

– The process begins with selecting the appropriate steel or alloy based on the desired properties of the final product. Common materials include carbon steel, stainless steel, and aluminum.

– Sheets of metal are cut to size, often using shearing machines or laser cutting for precision. The material must be inspected for defects before proceeding. -

Forming

– The forming stage involves the use of dies to shape the metal. Techniques include:- Progressive Die Stamping: Multiple operations are performed in a single machine cycle, allowing for high-volume production of complex parts.

- Deep Draw Stamping: Used for creating deep, cup-like shapes. This technique requires careful control of material flow to prevent wrinkling.

- Blanking: A process where the desired shape is cut out from the sheet metal before further processing.

-

Assembly

– After forming, parts may be assembled into larger components. This can involve welding, riveting, or using fasteners. Precision in this stage is crucial to ensure the integrity of the final product. -

Finishing

– The finishing stage enhances the aesthetics and functionality of the parts. Techniques include:- Deburring: Removing sharp edges and burrs from stamped parts.

- Coating: Applying protective coatings (e.g., powder coating, plating) to prevent corrosion and improve appearance.

- Quality Inspection: Ensuring all parts meet specifications through various testing methods.

Quality Assurance in Steel Stamping

Quality assurance (QA) is vital in ensuring that products meet international standards and customer expectations. The following outlines key QA processes and certifications relevant to the steel stamping industry.

Relevant International Standards

- ISO 9001: This standard outlines the requirements for a quality management system (QMS). It emphasizes continuous improvement and customer satisfaction, making it crucial for suppliers looking to engage international buyers.

- CE Marking: Relevant for products sold within the European Economic Area (EEA), indicating compliance with health, safety, and environmental protection standards.

- API Certification: Important for manufacturers supplying to the oil and gas industry, ensuring that products meet stringent industry-specific requirements.

QC Checkpoints

-

Incoming Quality Control (IQC)

– Raw materials are inspected upon arrival to ensure they meet specified quality standards. This involves checking for material properties, dimensions, and any visible defects. -

In-Process Quality Control (IPQC)

– Continuous monitoring during the manufacturing process is essential. This includes checking dimensions, tolerances, and process parameters to detect any deviations early. -

Final Quality Control (FQC)

– After the manufacturing process, finished products undergo comprehensive inspections. This typically involves functional testing, dimensional checks, and visual inspections to ensure compliance with specifications.

Common Testing Methods

- Dimensional Inspection: Using tools like calipers and micrometers to verify part dimensions.

- Tensile Testing: Assessing the strength and ductility of materials.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic or magnetic particle testing to detect internal defects without damaging the parts.

Verifying Supplier Quality Control

For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s QC processes is crucial to mitigate risks.

-

Supplier Audits

– Conducting regular audits of potential suppliers can provide insights into their manufacturing practices, adherence to standards, and overall quality culture. -

Quality Reports

– Requesting quality assurance reports can help buyers assess the supplier’s compliance with international standards and their internal QC processes. -

Third-Party Inspections

– Engaging third-party inspection services can provide an unbiased evaluation of product quality before shipment. This is particularly important for buyers who may not have the capacity to perform on-site inspections.

QC and Certification Nuances for International Buyers

Understanding the nuances of QC and certification is vital for international B2B transactions.

- Local Regulations: Different regions may have specific regulations affecting quality and safety. Buyers must be aware of these to ensure compliance.

- Cultural Differences: Communication and expectations regarding quality may vary across cultures. Establishing clear criteria and open channels for feedback can help bridge these gaps.

- Documentation: Ensure that suppliers provide comprehensive documentation, including certificates of compliance, test reports, and material certifications, to facilitate smoother transactions and compliance checks.

Conclusion

In summary, a thorough understanding of the manufacturing processes and quality assurance measures in steel stamping is essential for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, alongside robust quality control processes, buyers can make informed decisions that align with their standards and expectations. Engaging with suppliers who prioritize quality through relevant certifications and transparent practices will contribute to successful and sustainable partnerships in the global marketplace.

Related Video: Complete Steel Making Process in easy steps ll. TATA VOCATIONAL TRAINING

Comprehensive Cost and Pricing Analysis for steel stamping companies Sourcing

The cost structure for steel stamping companies involves several key components that directly impact pricing. Understanding these elements is crucial for international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The cost of raw materials, primarily steel, is a significant portion of the total cost. Prices can fluctuate based on market conditions, availability, and quality specifications. Buyers should consider sourcing from suppliers that provide material certifications to ensure quality.

-

Labor: Labor costs vary significantly by region. In countries with higher wage standards, such as those in Europe, labor costs can be a major factor. Conversely, labor costs may be lower in regions like Africa or South America, potentially allowing for cost savings. Buyers should evaluate the skill level of the workforce and associated costs.

-

Manufacturing Overhead: This includes utilities, maintenance, and facility costs. Efficient manufacturing processes can reduce overhead, but these savings may not always be passed on to the buyer. Understanding a supplier’s operational efficiency can provide insights into potential cost savings.

-

Tooling: Initial tooling costs for custom parts can be substantial. This includes dies and molds necessary for the stamping process. Buyers should assess the tooling costs and amortization over production runs, as high initial costs can be offset by lower per-unit costs in larger volumes.

-

Quality Control (QC): Ensuring quality through inspections and testing adds to the overall cost. Certifications such as ISO 9001 can increase costs but may provide assurance of quality, which is particularly important for critical applications.

-

Logistics: Shipping costs are influenced by the distance from the supplier, the mode of transport, and any tariffs or duties applicable to international trade. Incoterms also play a role in determining who is responsible for various shipping costs and risks.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure sustainability. This margin can vary widely based on competition, market demand, and the supplier’s business model.

Price Influencers

When negotiating prices, several factors come into play:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should assess their needs and negotiate terms that align with their purchasing capacity.

-

Specifications/Customization: Custom parts require more complex processes, which can increase costs. Buyers should clearly define specifications to avoid unexpected expenses.

-

Quality/Certifications: Higher quality standards and certifications often come at a premium. Buyers should weigh the importance of these certifications against their budget and application requirements.

-

Supplier Factors: The supplier’s reputation, experience, and operational capabilities can significantly influence pricing. Researching suppliers can help buyers find the best balance of cost and quality.

-

Incoterms: These terms define responsibilities in shipping and can affect overall costs. Buyers should choose terms that minimize their risk and align with their logistics capabilities.

Buyer Tips

-

Negotiate: Use insights about cost components to negotiate better prices. Understanding the breakdown can provide leverage when discussing pricing with suppliers.

-

Cost-Efficiency: Focus on total cost of ownership rather than just initial pricing. Consider logistics, quality, and potential rework costs when evaluating suppliers.

-

Pricing Nuances: International buyers should be aware of currency fluctuations, trade tariffs, and local market conditions that may affect pricing. Establishing long-term relationships with suppliers can also lead to more favorable terms over time.

-

Disclaimer on Prices: It’s important to note that prices can vary widely based on specific requirements and market conditions. Always request detailed quotes and confirm pricing structures with suppliers before finalizing agreements.

By understanding these components and influencers, B2B buyers can make informed decisions that balance cost and quality, ensuring they select the best steel stamping partners for their needs.

Spotlight on Potential steel stamping companies Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘steel stamping companies’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for steel stamping companies

Understanding the essential technical properties and trade terminology in the steel stamping industry is crucial for international B2B buyers. This knowledge not only facilitates better communication with suppliers but also ensures that purchasing decisions are aligned with business needs.

Key Technical Properties

-

Material Grade

– Definition: This refers to the classification of steel based on its chemical composition and mechanical properties. Common grades include ASTM A36 for structural steel and ASTM A992 for steel used in buildings.

– Importance: Selecting the appropriate material grade is vital for ensuring the strength, durability, and performance of stamped components, particularly in demanding applications like automotive and aerospace. -

Tolerance

– Definition: Tolerance defines the permissible limit or limits of variation in a physical dimension. For instance, a tolerance of ±0.005 inches means the actual measurement can vary by that amount.

– Importance: Tight tolerances are essential for ensuring that parts fit correctly in assemblies. Inaccurate tolerances can lead to increased costs due to rework or parts that do not meet specifications. -

Finish

– Definition: This refers to the surface texture and treatment of the stamped part, such as galvanization or powder coating.

– Importance: The finish can affect both the aesthetic appeal and the corrosion resistance of parts. For buyers, understanding finish requirements can help in selecting suppliers who can meet specific quality standards. -

Thickness

– Definition: Thickness is the measurement of the material’s depth, typically expressed in inches or millimeters.

– Importance: The thickness of the steel impacts the strength and weight of the final product. Buyers must specify thickness to ensure compatibility with design requirements and structural integrity. -

Yield Strength

– Definition: Yield strength is the amount of stress at which a material begins to deform plastically. Beyond this point, the material will not return to its original shape.

– Importance: Knowing the yield strength is critical for applications where parts will be subjected to significant loads. It ensures that the selected material can withstand operational stresses without failure.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships helps buyers identify reliable suppliers who produce high-quality components that meet industry standards. -

MOQ (Minimum Order Quantity)

– Definition: This is the smallest quantity of goods that a supplier is willing to sell.

– Relevance: Knowing the MOQ can help buyers plan their inventory and budget effectively. It can also influence negotiation strategies with suppliers. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers to invite them to provide price quotes for specific products or services.

– Relevance: Issuing an RFQ is a standard practice for buyers to gauge market pricing and supplier capabilities, ensuring competitive sourcing. -

Incoterms (International Commercial Terms)

– Definition: These are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms is essential for understanding shipping responsibilities, risks, and costs, which can significantly impact the total landed cost of goods. -

Lead Time

– Definition: The lead time is the amount of time from the placement of an order until the product is delivered.

– Relevance: Understanding lead times is crucial for inventory management and production planning, allowing buyers to align their supply chain with operational needs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, negotiate effectively, and foster successful partnerships in the steel stamping industry.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the steel stamping companies Sector

Market Overview & Key Trends

The global steel stamping market is on an upward trajectory, projected to grow from $236.8 billion in 2023 to $316.7 billion by 2030, driven by a compound annual growth rate (CAGR) of 4.2%. This growth is largely attributed to increasing demand from key industries such as automotive, aerospace, and electronics. International B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of several market dynamics that are shaping sourcing strategies today.

Firstly, technology integration is becoming a game-changer. Automation, IoT, and AI are enhancing production efficiency and precision in steel stamping processes. Buyers should seek suppliers who leverage these technologies to ensure high-quality outputs and reduced lead times. Additionally, the trend towards just-in-time (JIT) manufacturing is compelling suppliers to optimize their inventory management, allowing for more flexible and responsive sourcing options.

Moreover, the emphasis on local sourcing is gaining traction. International buyers are increasingly inclined to partner with regional suppliers to mitigate risks associated with global supply chain disruptions. This approach not only ensures faster delivery times but also reduces transportation costs and carbon emissions. Lastly, the rise of digital platforms for supplier discovery is streamlining the procurement process. Platforms like Thomasnet and D&B Hoovers provide valuable insights and connections, enabling buyers to identify and vet potential suppliers effectively.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer just a buzzword; it is a critical component of supply chain strategy. The steel stamping industry has a significant environmental impact, particularly in terms of energy consumption and waste generation. B2B buyers must prioritize suppliers who are committed to sustainable practices, such as reducing energy use, minimizing waste, and adhering to environmental regulations.

One effective way to assess a supplier’s commitment to sustainability is through certifications. Look for suppliers with recognized ‘green’ certifications, such as ISO 14001 for environmental management or LEED certification for sustainable manufacturing processes. Additionally, sourcing materials from suppliers who utilize recycled steel can further enhance your supply chain’s sustainability profile.

Ethical sourcing is equally important. Buyers should ensure that their suppliers maintain ethical labor practices and transparency in their supply chains. This not only helps mitigate risks but also enhances brand reputation. Engaging with suppliers who prioritize ethical standards fosters trust and long-term partnerships, ultimately benefiting all parties involved.

Brief Evolution/History

The steel stamping industry has evolved significantly since its inception in the early 20th century. Initially, the process was manual and labor-intensive, with limited precision. The introduction of mechanization in the 1950s marked a turning point, increasing production capacity and efficiency. As technology advanced, the industry saw the integration of computer numerical control (CNC) machines in the late 20th century, allowing for greater accuracy and reduced lead times.

Today, the industry is experiencing a digital transformation, with automation and data analytics playing pivotal roles in production and supply chain management. For international B2B buyers, understanding this evolution is crucial for navigating the current landscape and making informed sourcing decisions.

Related Video: The Shadow World: Inside the Global Arms Trade

Frequently Asked Questions (FAQs) for B2B Buyers of steel stamping companies

-

What factors should I consider when vetting steel stamping suppliers?

When vetting steel stamping suppliers, consider their experience in your specific industry, production capabilities, and quality certifications (such as ISO 9001). Request references from previous clients to assess their reliability and service quality. Additionally, evaluate their facility through virtual tours or on-site visits if feasible. Understanding their supply chain management and capacity to meet your volume needs is crucial, especially for international trade. -

Can steel stamping companies customize products to meet specific requirements?

Yes, many steel stamping companies offer customization options. This can include alterations to dimensions, material types, and finishes to meet your project specifications. When discussing your needs, provide detailed drawings and specifications to ensure accurate quotes and prototypes. It’s advisable to confirm the supplier’s design capabilities and past experience with similar customizations, as this can significantly affect the quality and performance of the final product. -

What are the typical minimum order quantities (MOQs) and lead times for steel stamping?

Minimum order quantities (MOQs) can vary widely among suppliers, often ranging from hundreds to thousands of units, depending on the complexity of the part and production methods. Lead times typically range from 4 to 12 weeks, influenced by the supplier’s current workload and the complexity of the project. Communicate your timeline needs upfront, as many suppliers offer expedited services for an additional fee, which can be crucial for urgent projects.

Illustrative Image (Source: Google Search)

-

What payment terms should I expect when sourcing internationally?

Payment terms can vary by supplier and region, but common practices include advance payments, net 30/60/90 days, or letters of credit for larger orders. It’s essential to clarify payment methods, including wire transfers, PayPal, or credit terms. For international transactions, consider potential currency fluctuations and additional banking fees. Establishing clear payment terms in a contract can help mitigate disputes and ensure smooth transactions. -

How can I ensure quality assurance (QA) and certifications from my supplier?

To ensure quality assurance, request copies of certifications such as ISO 9001, ISO/TS 16949 (for automotive), or specific industry-related certifications. Establish a quality control plan that includes inspections at various production stages. It may also be beneficial to arrange for third-party audits or inspections before shipment to verify compliance with your specifications. Regular communication with the supplier about quality standards is vital to prevent discrepancies. -

What logistics considerations should I be aware of when importing stamped steel parts?

When importing stamped steel parts, consider shipping methods (air vs. sea), customs regulations, and import duties that may apply. Ensure that the supplier can provide the necessary documentation, such as bills of lading and certificates of origin, to facilitate smooth customs clearance. Collaborate with a reliable freight forwarder to manage logistics efficiently, and factor in potential delays due to customs or other regulatory requirements. -

How should I handle disputes with a steel stamping supplier?

Handling disputes requires a clear understanding of the terms outlined in your contract, including dispute resolution processes. Start by addressing the issue directly with the supplier to seek a resolution. If informal discussions do not yield results, refer to the contract for mediation or arbitration clauses. Maintaining documentation of all communications and agreements can be crucial in supporting your case, especially in international trade where laws may vary. -

What are the trends impacting the steel stamping industry that I should be aware of?

The steel stamping industry is influenced by trends such as increased automation and the adoption of advanced technologies like 3D printing and Industry 4.0 practices. Sustainability is also becoming a focal point, with more companies seeking eco-friendly materials and processes. Understanding these trends can help you choose suppliers that align with your values and business goals, as well as stay competitive in a rapidly evolving market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for steel stamping companies

In summary, strategic sourcing in the steel stamping sector is pivotal for international B2B buyers aiming to enhance operational efficiency and cost-effectiveness. By leveraging a diverse supplier base across regions, buyers can access high-quality stamped components tailored to various applications, from automotive to electronics. The growing global metal stamping market, projected to reach $316.7 billion by 2030, underscores the increasing demand for precision and innovation in manufacturing processes.

For buyers in Africa, South America, the Middle East, and Europe, establishing robust relationships with reliable suppliers can lead to significant competitive advantages. Key considerations include evaluating suppliers based on their certifications, production capabilities, and historical performance, as well as understanding regional market dynamics that may affect sourcing decisions.

Looking ahead, the emphasis on sustainability and technological advancements, such as automation and smart manufacturing, will shape the future of the steel stamping industry. B2B buyers are encouraged to engage with suppliers who prioritize innovation and sustainability, ensuring they remain at the forefront of industry trends. Now is the time to explore partnerships that will drive growth and efficiency in your operations, positioning your business for success in an evolving market landscape.