Master Sourcing Burn Barrels: Essential Guide for B2B

Introduction: Navigating the Global Market for burn barrel

The burn barrel, often perceived as a simple waste disposal tool, is a vital asset for businesses operating in various sectors, particularly in regions where traditional waste management systems may be lacking. In the face of increasing environmental regulations and the need for efficient waste management solutions, burn barrels offer an effective means to manage combustible waste while minimizing ecological impact. Whether you’re in the agricultural sector, construction, or manufacturing, understanding the nuances of burn barrels can lead to significant operational efficiencies.

This guide serves as a comprehensive resource for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, including countries like the UAE and Spain. It covers essential aspects such as types of burn barrels, materials used, manufacturing processes, and quality control standards. Additionally, you will find insights into leading suppliers, cost considerations, and market trends that are crucial for making informed purchasing decisions.

By equipping buyers with actionable knowledge about burn barrels, this guide empowers them to navigate the complexities of sourcing effectively. With a focus on best practices and compliance with local regulations, you will be better positioned to leverage burn barrels as a strategic tool for waste management in your operations. Embrace the potential of burn barrels to optimize your waste disposal processes while adhering to environmental standards.

Understanding burn barrel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Burn Barrel | 55-gallon steel drum, simple design, often repurposed | Wood processing, general waste | Pros: Cost-effective, easy to use. Cons: Limited airflow can lead to inefficiency. |

| Yard Waste Burn Barrel | Covered design, specifically for organic waste | Landscaping, agriculture | Pros: Reduces smoke and ash spread. Cons: Requires careful material selection. |

| Incinerator Barrel | Enclosed, with advanced airflow and emission control | Industrial waste management | Pros: High efficiency, reduced emissions. Cons: Higher initial investment. |

| Portable Burn Barrel | Smaller, lightweight, easy to transport | Small-scale operations, events | Pros: Versatile and convenient. Cons: Limited capacity requires frequent emptying. |

| Custom-Built Burn Barrel | Tailored designs for specific needs, can include features | Specialized industries | Pros: Optimized for unique waste types. Cons: Longer lead time and potentially higher cost. |

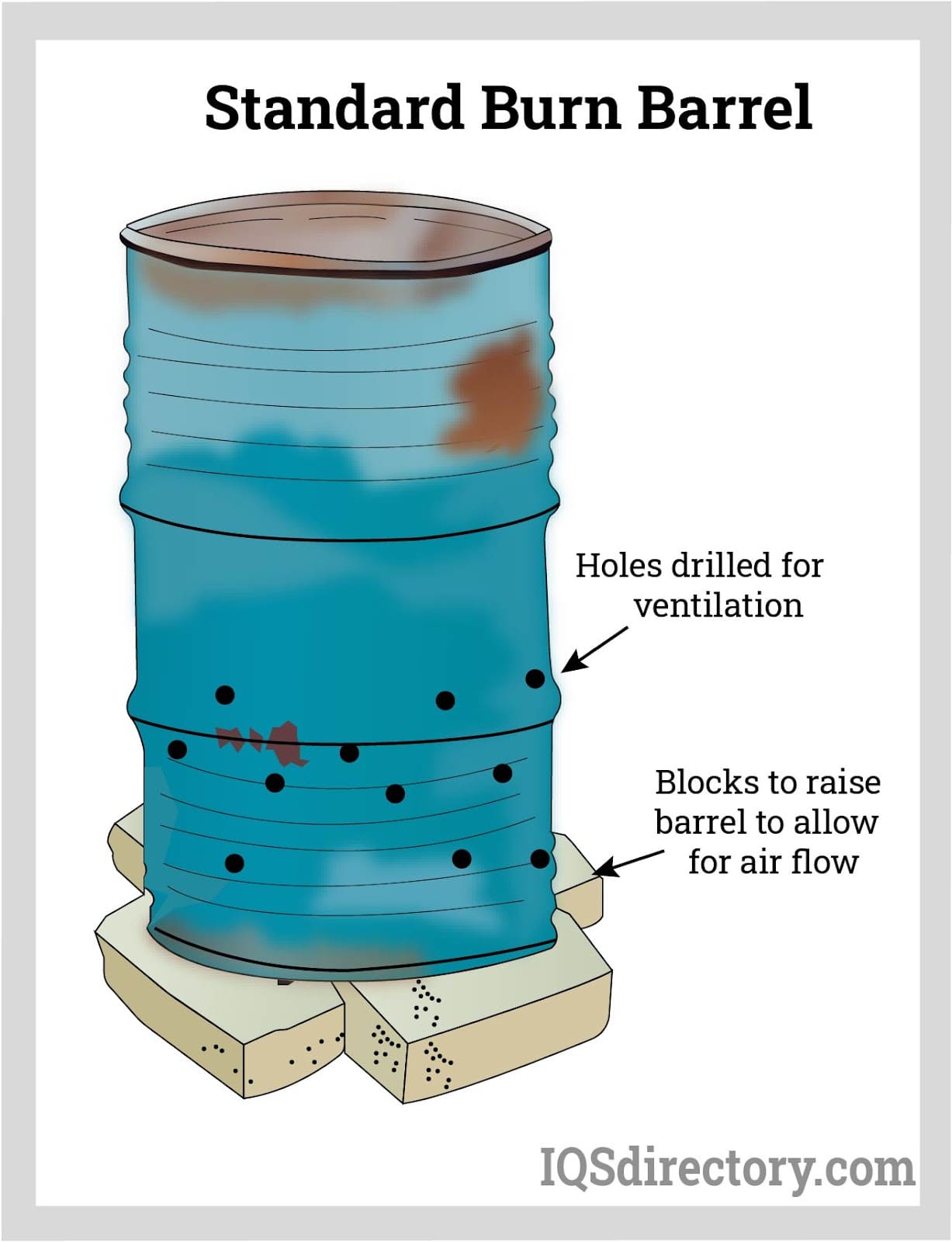

Standard Burn Barrel

The standard burn barrel, typically a 55-gallon steel drum, is a widely used option for incinerating combustible waste. Its simplicity makes it a popular choice among businesses managing wood processing or general waste. When purchasing, consider the barrel’s previous contents to avoid hazardous residues. Proper airflow modifications, such as creating openings at the base, can enhance burning efficiency, making this option both cost-effective and functional.

Yard Waste Burn Barrel

Designed specifically for organic materials, the yard waste burn barrel features a covered design to minimize smoke and ash dispersal. This type is particularly valuable for landscaping and agricultural businesses that need to dispose of tree trimmings and grass clippings efficiently. Buyers should ensure compliance with local regulations regarding yard waste burning and avoid burning treated wood or invasive species, which can release harmful chemicals or seeds.

Incinerator Barrel

Incinerator barrels are advanced burn barrels equipped with features that enhance combustion efficiency and reduce emissions. These barrels are suitable for industrial waste management, where compliance with environmental regulations is critical. While they require a higher initial investment, their effectiveness in managing waste and mitigating air pollution can lead to long-term cost savings. Businesses should evaluate their specific waste types to determine if this option aligns with their operational needs.

Portable Burn Barrel

The portable burn barrel offers versatility and ease of transport, making it ideal for small-scale operations or events where waste disposal is needed temporarily. While its lightweight design facilitates mobility, buyers must consider the limited capacity, which necessitates frequent emptying. This type is especially beneficial for businesses that require a flexible waste management solution without committing to a permanent installation.

Custom-Built Burn Barrel

Custom-built burn barrels are tailored to meet specific waste disposal needs, incorporating features such as enhanced airflow or specialized materials. They are particularly advantageous for specialized industries that manage unique waste types. While these barrels may come with a higher upfront cost and longer lead times, the ability to optimize waste management processes can provide significant operational advantages. Buyers should collaborate closely with manufacturers to ensure their custom designs meet all safety and regulatory requirements.

Related Video: HOW TO MAKE A BURN BARREL— THE SECRET TO BURNING CLEANER!

Key Industrial Applications of burn barrel

| Industry/Sector | Specific Application of burn barrel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Wood Processing | Efficient disposal of wood waste and offcuts | Reduces waste management costs and minimizes environmental impact | Sourcing food-grade drums, ensuring compliance with local regulations |

| Agriculture | Incineration of agricultural waste (e.g., crop residues) | Enhances soil health through ash return and reduces pest populations | Understanding local agricultural regulations and obtaining necessary permits |

| Construction | Disposal of construction debris (untreated wood, paper) | Streamlines waste management processes and reduces landfill fees | Selecting barrels with adequate capacity and safety features |

| Landscaping | Burning of yard waste (leaves, branches, grass clippings) | Provides a cost-effective method for waste disposal and land clearing | Ensuring compliance with local burning ordinances and fire safety measures |

| Municipal Services | Controlled burning of illegal dumping sites | Improves community cleanliness and reduces fire hazard from illegal waste | Collaborating with local authorities for permits and safety compliance |

Wood Processing

In the wood processing industry, burn barrels serve as an effective solution for disposing of scrap wood, bark, and other unusable byproducts. By incinerating these materials rather than sending them to landfills, businesses can significantly reduce waste management costs and comply with environmental regulations. Buyers should prioritize sourcing food-grade drums to ensure safety and minimize toxic emissions during combustion. Furthermore, understanding local laws regarding open burning is crucial to avoid potential fines.

Agriculture

Agricultural operations frequently generate substantial waste, such as crop residues and untreated plant material. Utilizing burn barrels for incineration allows farmers to manage this waste effectively, returning valuable nutrients to the soil in the form of ash while also controlling pests and diseases. International buyers must be aware of local agricultural waste regulations and obtain the necessary permits to ensure compliance. Selecting a durable burn barrel that can withstand frequent use and harsh conditions is also essential.

Construction

In the construction sector, burn barrels provide a practical means for disposing of construction debris, particularly untreated wood and paper waste. This method not only streamlines waste management processes but also helps reduce costs associated with landfill disposal. Buyers in this sector should consider barrels with larger capacities to accommodate the volume of waste generated. Additionally, it is vital to comply with local regulations regarding the types of materials that can be burned and the safety measures that must be in place.

Landscaping

Landscaping businesses often deal with significant amounts of yard waste, including leaves, branches, and grass clippings. Using burn barrels allows for a controlled and efficient method of disposing of this waste, enabling land clearing and reducing disposal costs. Buyers should ensure that the burn barrels they choose meet local burning ordinances, particularly regarding emissions and safety features. Incorporating a spark arrester and a lid can further enhance safety and compliance with environmental standards.

Municipal Services

Municipalities can utilize burn barrels to address the challenges posed by illegal dumping sites. Controlled burning of illegally discarded waste helps improve community aesthetics and reduces fire hazards associated with accumulated refuse. For municipal buyers, collaboration with local authorities is critical to secure the necessary permits and ensure compliance with safety regulations. Investing in burn barrels that are durable and designed for frequent use can provide a long-term solution to waste management challenges in urban areas.

Related Video: 10 Nifty Uses for Oscillating Multitool Saws

Strategic Material Selection Guide for burn barrel

When selecting materials for burn barrels, international B2B buyers must consider various factors that influence performance, compliance, and cost-effectiveness. Below is an analysis of four common materials used in burn barrel construction, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from regions such as Africa, South America, the Middle East, and Europe.

Steel

Key Properties:

Steel is renowned for its high tensile strength and durability. It can withstand high temperatures, typically rated up to 1,200°F (649°C) without deforming. Steel also offers good corrosion resistance when treated with protective coatings.

Pros & Cons:

The primary advantage of steel is its robustness and longevity, making it suitable for repeated use. However, untreated steel may rust over time, especially in humid environments, which can lead to structural failure. The cost of steel can vary, but it generally falls in the medium range.

Impact on Application:

Steel burn barrels are effective for incinerating various waste types, including yard debris and untreated wood. The material’s strength allows for efficient combustion, but buyers must ensure proper ventilation to prevent smoke accumulation.

Considerations for International Buyers:

Compliance with local regulations regarding emissions and safety standards is crucial. Buyers should look for steel barrels that meet ASTM standards, especially in regions like Europe where environmental regulations are stringent.

Aluminum

Key Properties:

Aluminum is lightweight and has excellent corrosion resistance, making it ideal for environments prone to moisture. It can handle temperatures up to 1,000°F (538°C) without significant degradation.

Pros & Cons:

The main advantage of aluminum is its lightweight nature, which makes transportation easier. However, it is less durable than steel and may warp or melt under extreme heat, limiting its use for high-temperature applications. The cost of aluminum is generally higher than that of steel.

Impact on Application:

Aluminum burn barrels are suitable for light-duty applications, such as burning paper waste or dry leaves. However, they are not recommended for heavy-duty burning of wood or other dense materials due to their lower heat tolerance.

Considerations for International Buyers:

Buyers should ensure that aluminum barrels comply with local fire safety regulations. In regions like the UAE, where high temperatures are common, selecting high-quality aluminum that can withstand local conditions is essential.

Fiberglass

Key Properties:

Fiberglass is known for its excellent chemical resistance and lightweight nature. It can withstand moderate temperatures, typically up to 400°F (204°C), making it suitable for specific applications.

Pros & Cons:

The advantage of fiberglass is its resistance to corrosion and chemicals, which makes it ideal for certain waste types. However, its lower temperature threshold limits its use for traditional burn barrel applications. The cost of fiberglass is generally high due to manufacturing complexity.

Impact on Application:

Fiberglass burn barrels are more suited for incinerating non-combustible materials or low-temperature applications. They are not ideal for typical wood waste due to their temperature limitations.

Considerations for International Buyers:

Buyers should verify compliance with local environmental regulations, especially in regions with strict waste management laws. Fiberglass may not be widely accepted in areas where traditional materials are preferred.

Composite Materials

Key Properties:

Composite materials, which combine various materials for enhanced properties, can offer high strength and resistance to corrosion and heat. Their temperature ratings vary widely depending on the composition.

Pros & Cons:

The primary advantage of composites is their customizable properties, allowing for tailored solutions. However, they can be expensive and complex to manufacture, leading to higher costs.

Impact on Application:

Composite burn barrels can be designed for specific applications, such as burning hazardous materials, but their effectiveness depends on the formulation used.

Considerations for International Buyers:

Buyers must ensure that composite materials meet local safety and environmental standards. In Europe, for instance, compliance with REACH regulations is critical for materials used in waste management.

Summary Table

| Material | Typical Use Case for burn barrel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Yard debris, untreated wood | High durability and strength | Prone to rust without treatment | Medium |

| Aluminum | Light-duty waste (paper, leaves) | Lightweight and corrosion-resistant | Lower heat tolerance | High |

| Fiberglass | Non-combustible or low-temp waste | Excellent chemical resistance | Limited high-temperature use | High |

| Composite | Specialized applications | Customizable properties | High manufacturing complexity | High |

In-depth Look: Manufacturing Processes and Quality Assurance for burn barrel

Manufacturing Processes for Burn Barrels

The production of burn barrels involves several key stages, each crucial to ensuring the final product is effective, safe, and compliant with industry standards. Here’s a detailed look at the typical manufacturing process.

Material Preparation

The primary material used in burn barrel manufacturing is steel, commonly in the form of repurposed 55-gallon drums. The preparation stage involves:

- Sourcing Materials: Suppliers must ensure that the drums are food-grade and have not been previously used for hazardous substances. This minimizes the risk of toxic fumes during combustion.

- Cleaning: Drums must be thoroughly cleaned to remove any residual materials. This can involve chemical cleaning processes or high-pressure washing to ensure safety and compliance.

- Inspection: Each drum undergoes a quality inspection to check for rust, structural integrity, and any signs of previous hazardous use.

Forming

The forming stage shapes the prepared materials into functional burn barrels. Key techniques include:

- Cutting: The drums are often modified to include ventilation holes and a bottom cut-out to facilitate airflow and enhance combustion efficiency.

- Welding: If additional structural components such as legs or supports are added, welding techniques are employed to ensure stability and durability.

- Finishing Treatments: Some manufacturers apply protective coatings to prevent rust and increase the barrel’s lifespan. This may include powder coating or galvanization.

Assembly

During the assembly phase, any additional components are integrated into the burn barrel:

- Airflow Mechanisms: Adjustable vents or additional mesh screens may be added to enhance airflow and reduce smoke emissions.

- Safety Features: Features such as spark arresters and lids are installed to comply with safety regulations and enhance user safety.

- Final Inspection: A thorough inspection is conducted to ensure that all components are securely assembled and that the barrel meets design specifications.

Finishing

The finishing stage enhances the appearance and functionality of the burn barrels:

- Surface Treatment: This may include painting or applying rust-resistant coatings. Aesthetic aspects can also be considered, especially for products marketed in urban areas.

- Quality Testing: Each barrel undergoes final quality control checks to ensure compliance with safety and performance standards.

Quality Assurance Processes

Quality assurance is critical in the production of burn barrels to ensure safety, performance, and compliance with international regulations. Here’s how quality is typically assured:

Relevant International Standards

B2B buyers should ensure their suppliers adhere to recognized international quality standards, such as:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent product quality.

- CE Marking: Indicates compliance with European safety, health, and environmental protection standards.

- API Standards: For manufacturers in regions like the Middle East, adherence to American Petroleum Institute (API) standards may be relevant, particularly for barrels intended for industrial applications.

Quality Control Checkpoints

Effective quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC):

– Inspection of raw materials upon arrival to ensure they meet specifications.

– Verification of material certifications and compliance with safety standards. -

In-Process Quality Control (IPQC):

– Continuous monitoring during the manufacturing process.

– Random sampling and testing of barrels to check for structural integrity and design compliance. -

Final Quality Control (FQC):

– Comprehensive inspection of finished products before they are shipped.

– Testing for functionality, safety features, and compliance with specified standards.

Common Testing Methods

Manufacturers often employ various testing methods to validate the quality and safety of burn barrels:

- Pressure Testing: To ensure the barrel can withstand the combustion process without deformation or failure.

- Burn Tests: Conducted to evaluate the efficiency of combustion and emissions produced.

- Durability Tests: Assess the barrel’s resistance to wear, rust, and environmental factors over time.

Verifying Supplier Quality Control

For B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial. Here are actionable steps:

- Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes and quality control measures. This includes reviewing their adherence to international standards and local regulations.

- Quality Reports: Request detailed quality assurance reports that document compliance with relevant standards and testing outcomes.

- Third-party Inspections: Consider engaging third-party inspection services to independently verify the quality of burn barrels before finalizing purchases. This adds an additional layer of assurance.

Quality Control Nuances for International Buyers

International buyers must navigate various nuances when sourcing burn barrels:

- Regulatory Compliance: Understand the specific regulations in your region regarding burn barrels, including safety standards and environmental regulations.

- Cultural Considerations: Be aware of local practices and preferences, which may influence the design and functionality of burn barrels.

- Shipping Regulations: Ensure that the barrels comply with international shipping standards, particularly regarding hazardous materials.

In conclusion, B2B buyers must engage in thorough due diligence when sourcing burn barrels. Understanding the manufacturing processes, quality assurance standards, and verification methods will empower buyers to make informed decisions that align with their operational needs and regulatory requirements.

Comprehensive Cost and Pricing Analysis for burn barrel Sourcing

Understanding the Cost Structure of Burn Barrel Sourcing

When sourcing burn barrels, international B2B buyers must navigate a complex cost structure that encompasses various components. Understanding these costs can lead to more informed purchasing decisions and improved negotiation outcomes.

Cost Components

1. Materials: The primary material for burn barrels is typically steel, with 55-gallon drums being the most common. Prices for new barrels range from $80 to $150, while used food-grade drums may cost between $20 to $50. The choice of material can significantly affect the overall cost, especially when considering durability and compliance with safety standards.

-

Labor: Manufacturing labor costs vary by region. In regions with lower labor costs, such as parts of Africa and South America, buyers may find competitive pricing. Conversely, labor costs in Europe and the Middle East might be higher, impacting the final product price.

-

Manufacturing Overhead: This includes expenses related to the production facility, utilities, and equipment maintenance. Overhead can vary widely based on the supplier’s location and operational efficiency.

-

Tooling: Initial tooling costs for custom designs or modifications can be significant. Buyers seeking specialized burn barrels should factor in these costs when requesting quotes.

-

Quality Control (QC): Ensuring that burn barrels meet safety and environmental standards is crucial. QC processes add to the overall cost but are essential for compliance with local regulations.

-

Logistics: Shipping costs can be a major contributor to the total expense, especially for international shipments. Factors such as distance, shipping mode (air, sea, or land), and Incoterms will influence logistics costs.

Illustrative Image (Source: Google Search)

- Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary depending on the supplier’s pricing strategy and market competition.

Price Influencers

Several factors influence the pricing of burn barrels, which buyers should consider when sourcing:

-

Volume/MOQ: Bulk purchases often yield better pricing. Buyers should negotiate minimum order quantities (MOQs) to benefit from volume discounts.

-

Specifications/Customization: Custom features, such as spark arresters or specific dimensions, can increase costs. Buyers should clearly define their requirements to receive accurate quotes.

-

Materials: The choice between new and used barrels, as well as the quality of materials, can significantly affect pricing.

-

Quality/Certifications: Certifications for safety and environmental compliance can add to the cost but are essential for legal operation.

-

Supplier Factors: Reputation, reliability, and experience of the supplier can impact pricing. Established suppliers may charge more but often provide better quality and service.

-

Incoterms: Understanding Incoterms is crucial for international buyers as they define responsibilities for shipping, insurance, and tariffs, which can all affect the total cost.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers about pricing. Leverage potential volume purchases to negotiate better terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, shipping, maintenance, and disposal costs. This approach can uncover hidden costs and lead to more strategic purchasing decisions.

-

Pricing Nuances: Be aware of regional pricing differences. For example, prices may vary significantly between suppliers in the UAE and those in Spain due to differing market conditions and regulations.

-

Regulatory Compliance: Ensure that suppliers can provide burn barrels that meet local regulations. Non-compliance can lead to fines and additional costs.

-

Supplier Relationships: Cultivating strong relationships with suppliers can lead to better pricing, priority service, and additional support.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential burn barrel Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘burn barrel’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for burn barrel

Key Technical Properties of Burn Barrels

When considering the procurement of burn barrels, understanding their essential technical properties is crucial for ensuring compliance, safety, and efficiency in waste disposal. Here are some of the critical specifications:

-

Material Grade

– Definition: Burn barrels are typically made from steel, with 55-gallon drums being the most common. The steel must be corrosion-resistant and capable of withstanding high temperatures.

– B2B Importance: Selecting high-quality steel ensures durability and reduces the risk of structural failure during operation. This is particularly important for businesses in regions with fluctuating weather conditions. -

Capacity

– Definition: The standard capacity for burn barrels is usually 55 gallons, but smaller or larger options may be available depending on specific needs.

– B2B Importance: Understanding capacity helps businesses manage waste volumes effectively. Companies that generate significant waste will benefit from larger barrels, while smaller operations may opt for compact sizes to save space. -

Airflow Design

– Definition: Effective burn barrels feature a design that allows for proper airflow to facilitate combustion. This may include holes drilled for ventilation or an elevated base.

– B2B Importance: A well-designed airflow system minimizes smoke production and ensures more complete combustion, aligning with environmental regulations and reducing air quality issues. -

Spark Arrestor Compliance

– Definition: A spark arrestor is a mesh screen that prevents embers from escaping the burn barrel during combustion.

– B2B Importance: Compliance with local fire safety standards is critical to avoid legal penalties and ensure safety. Businesses must ensure their burn barrels are equipped with spark arrestors, especially in fire-prone areas. -

Lid Type

– Definition: Burn barrels may come with a lid that can be secured to contain fire and control emissions.

– B2B Importance: A secure lid enhances safety by preventing accidental fires and controlling smoke release. It is essential for operations in populated areas where smoke regulations are strict.

Common Trade Terminology

Familiarity with industry jargon is vital for effective communication and negotiation in the procurement process. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships helps buyers identify reliable suppliers and assess the quality of the burn barrels based on the original manufacturer’s reputation. -

MOQ (Minimum Order Quantity)

– Definition: MOQ refers to the minimum number of units a supplier is willing to sell in a single order.

– Importance: Knowing the MOQ helps businesses manage inventory and cash flow effectively, ensuring they do not overcommit resources while securing the necessary equipment. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers requesting a price quote for specific products or services.

– Importance: Issuing an RFQ allows buyers to compare prices and terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of international rules that define the responsibilities of sellers and buyers in global trade, particularly concerning shipping and delivery.

– Importance: Familiarity with Incoterms ensures that international buyers understand their liabilities and obligations, helping to prevent misunderstandings during the shipping process. -

Lead Time

– Definition: Lead time is the time taken from placing an order to the delivery of goods.

– Importance: Understanding lead times is essential for businesses to plan their operations effectively, especially when dealing with waste disposal and processing schedules. -

Compliance Standards

– Definition: These are regulations and guidelines that govern the safety and environmental impact of using burn barrels.

– Importance: Knowledge of compliance standards helps buyers ensure that their operations align with local laws, mitigating risks of fines or legal issues related to improper waste disposal.

By comprehensively understanding these properties and terms, international B2B buyers can make informed decisions that enhance operational efficiency and compliance in waste management practices.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the burn barrel Sector

Market Overview & Key Trends

The burn barrel market is witnessing significant growth, driven by rising environmental awareness and regulatory changes concerning waste management. In regions like Africa and South America, where waste disposal infrastructure may be limited, burn barrels provide a practical solution for managing combustible waste. The Middle East, particularly in urban areas, is increasingly adopting burn barrels due to stringent waste management policies that discourage open burning. In Europe, regulations are tightening, leading to a shift towards more efficient and eco-friendly burning methods.

Emerging B2B technology trends include the development of smart burn barrels equipped with sensors that monitor combustion efficiency and emissions. These innovations help users optimize burning practices while adhering to local regulations. Additionally, the market is seeing a rise in the demand for customized burn barrels that cater to specific waste types, such as yard debris or industrial waste. This customization not only enhances safety but also improves operational efficiency. International buyers should pay attention to these trends to leverage better sourcing opportunities and align with regional compliance requirements.

Sustainability & Ethical Sourcing in B2B

As sustainability becomes a cornerstone of global business practices, the burn barrel sector is no exception. The environmental impact of improper waste disposal is significant, contributing to air pollution and deforestation. B2B buyers must prioritize suppliers who adhere to ethical sourcing practices and utilize materials that minimize ecological footprints. This includes sourcing burn barrels made from recycled materials or those that meet green certification standards, such as ISO 14001 for environmental management.

Moreover, ethical supply chains are crucial in ensuring that suppliers practice responsible manufacturing methods. B2B buyers should seek partnerships with manufacturers who demonstrate transparency in their sourcing and production processes. Certifications such as the Forest Stewardship Council (FSC) and Green Seal can serve as indicators of a supplier’s commitment to sustainability. By focusing on these aspects, international buyers can not only improve their corporate responsibility profiles but also enhance their brand reputation in an increasingly eco-conscious marketplace.

Brief Evolution/History

Historically, burn barrels were simple repurposed metal drums used primarily in rural areas for waste disposal. The practice of open burning was common, but with increasing awareness of environmental issues, the use of burn barrels has evolved. Today, they are manufactured with safety features and designed to comply with various regulations. This evolution reflects a broader shift in waste management practices, where efficiency and environmental considerations are paramount. As the burn barrel sector continues to innovate, it presents new opportunities for B2B buyers to engage with sustainable solutions tailored to modern waste disposal challenges.

Related Video: Global trade will never be the same again, says Christine Lagarde | Power & Politics

Frequently Asked Questions (FAQs) for B2B Buyers of burn barrel

-

What should I consider when vetting suppliers for burn barrels?

When vetting suppliers, focus on their experience in the industry, the quality of their products, and customer reviews. Check for compliance with local and international safety standards, as well as certifications such as ISO or CE. It’s beneficial to request samples to evaluate the construction and functionality of the burn barrels. Additionally, inquire about their production capacity and the materials used, ensuring they align with your needs and environmental regulations in your region. -

Can I customize burn barrels to meet specific requirements?

Yes, many suppliers offer customization options for burn barrels. This can include modifications in size, design, and features such as spark arresters or lids. Customization may also involve branding or specific color requirements. Discuss your needs directly with potential suppliers, and ensure they have the capability to meet your specifications without compromising on safety standards or delivery timelines. -

What are the typical minimum order quantities (MOQ) and lead times for burn barrels?

Minimum order quantities can vary significantly among suppliers, ranging from a few units for smaller manufacturers to larger quantities for mass producers. Lead times typically depend on the supplier’s production capacity and your order size, usually ranging from 2 to 8 weeks. Always confirm these details before finalizing your order to ensure they align with your project timelines and budget constraints. -

What payment options should I expect when sourcing burn barrels internationally?

International suppliers often accept various payment methods, including bank transfers, letters of credit, and online payment platforms. It’s crucial to discuss payment terms upfront, including deposits and payment schedules. Ensure that you understand any potential transaction fees and currency conversion costs. Establishing a clear agreement on payment terms can help avoid disputes later in the transaction. -

How can I ensure the quality and safety of the burn barrels I purchase?

To ensure quality, request documentation of quality assurance processes, including relevant certifications and testing results. Look for suppliers who adhere to international safety standards and can provide proof of compliance. It’s also advisable to conduct a factory visit or rely on third-party inspections, especially for large orders, to verify the manufacturing processes and materials used in the burn barrels. -

What logistics considerations should I keep in mind when importing burn barrels?

Logistics can be complex, especially for bulky items like burn barrels. Consider the shipping methods available, including sea freight or air freight, and assess the costs associated with each. Be aware of import duties, taxes, and any regulatory requirements specific to your country. Collaborating with a reliable freight forwarder can streamline the process, helping you navigate customs clearance and delivery logistics effectively. -

How should I handle disputes with suppliers regarding burn barrel orders?

Dispute resolution should begin with clear communication. Document all transactions, agreements, and communications to have a reference point. If issues arise, reach out to the supplier to discuss the problem and seek an amicable solution. If direct negotiations fail, refer to the contract for any specified dispute resolution mechanisms, such as mediation or arbitration. Engaging a legal expert familiar with international trade can also be beneficial in resolving significant disputes.

Illustrative Image (Source: Google Search)

- What are the environmental regulations I need to consider when using burn barrels?

Environmental regulations vary widely by region. Before using burn barrels, familiarize yourself with local laws regarding waste disposal and open burning. Some areas may have restrictions on materials that can be burned or require permits for operation. Adhering to these regulations not only avoids legal penalties but also demonstrates your commitment to sustainable practices. Consult local environmental agencies for detailed guidelines relevant to your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for burn barrel

In conclusion, the strategic sourcing of burn barrels presents significant opportunities for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. By understanding the diverse applications of burn barrels—from managing wood waste in rural areas to complying with stringent regulations in urban settings—buyers can make informed decisions that align with both operational efficiency and environmental sustainability.

Key Takeaways:

- Cost-Effectiveness: Utilizing burn barrels can drastically reduce waste management costs, particularly in areas lacking comprehensive disposal services.

- Regulatory Compliance: Awareness of local regulations is crucial. Buyers should prioritize burn barrels that meet safety and environmental standards to avoid legal complications.

- Customization: Different burn barrel designs cater to specific needs, including those for yard waste or industrial applications, enhancing overall efficiency and safety.

As the global market evolves, international buyers are encouraged to explore innovative sourcing strategies and establish partnerships with reputable suppliers. By doing so, they can not only optimize their waste disposal processes but also contribute to a more sustainable future. Embrace the potential of burn barrels in your operations and take proactive steps towards responsible waste management today.