Master Sourcing Strategies for Crates Plastic to Boost Your

Introduction: Navigating the Global Market for crates plastic

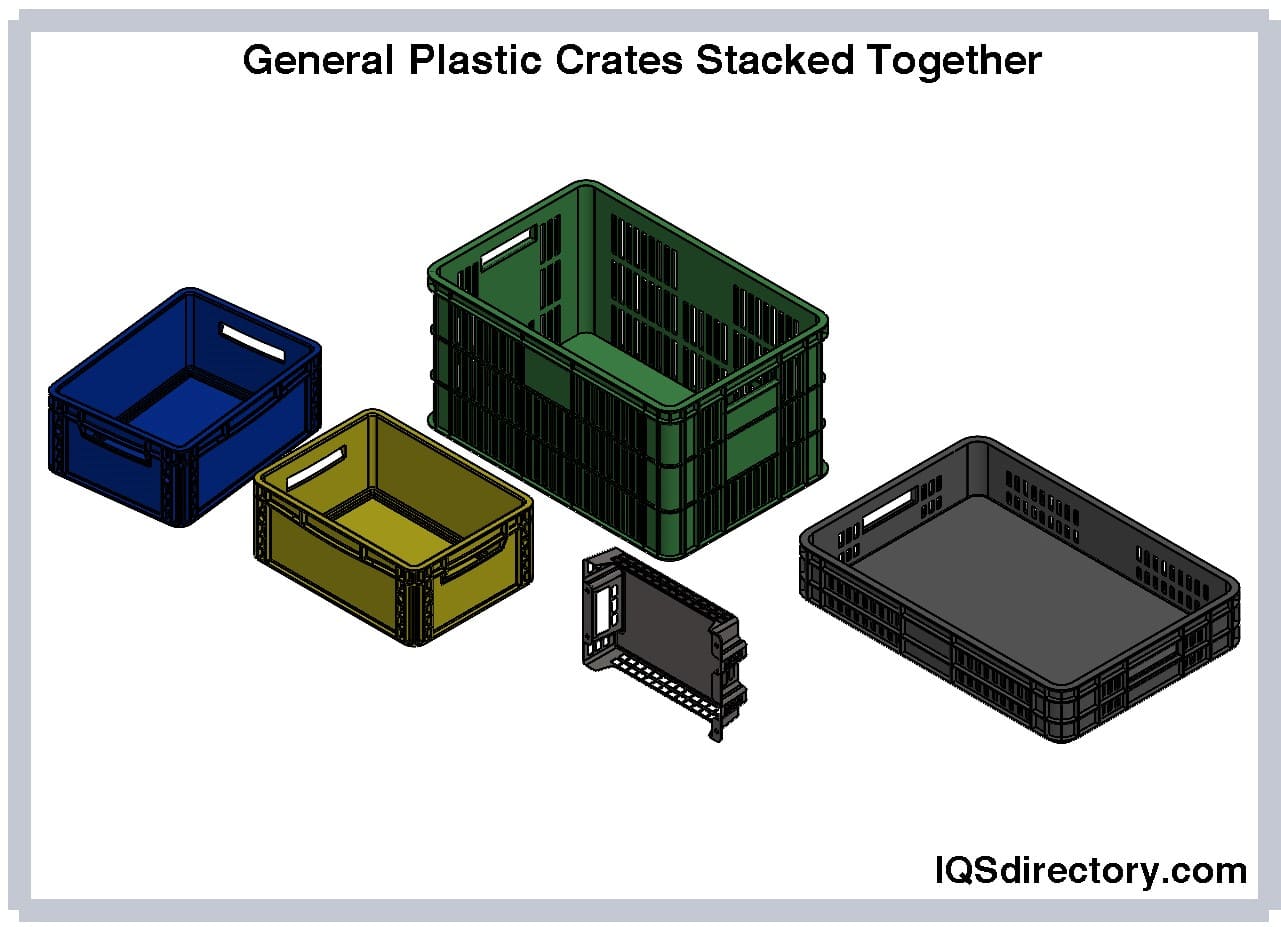

In today’s fast-paced global economy, the demand for durable and versatile packaging solutions has never been higher. Plastic crates have emerged as a crucial component in various industries, including agriculture, logistics, and retail, due to their ability to enhance efficiency and reduce waste. These containers not only ensure the safe transport of goods but also contribute to sustainable practices by being reusable and recyclable.

This guide serves as a comprehensive resource for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, such as Argentina and Colombia. It covers a wide array of topics essential for informed sourcing decisions, including:

- Types of Crates: Understanding the various designs and functionalities available to meet specific industry needs.

- Materials: Insight into the different plastics used in crate manufacturing, their benefits, and environmental impacts.

- Manufacturing and Quality Control: Best practices for ensuring product integrity and compliance with international standards.

- Suppliers: Key players in the global market, including tips for evaluating and selecting reliable partners.

- Cost Considerations: Factors influencing pricing and strategies for cost-effective procurement.

- Market Trends: Current and emerging trends shaping the future of the plastic crate market.

- FAQs: Addressing common queries to facilitate a smoother purchasing experience.

By leveraging the insights and knowledge contained within this guide, B2B buyers will be empowered to make strategic decisions that enhance their operations and drive business growth in an increasingly interconnected marketplace.

Understanding crates plastic Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High-Density Polyethylene (HDPE) | Durable, resistant to impact and chemicals, UV-stabilized | Agriculture, food processing, logistics | Pros: Lightweight, strong, recyclable. Cons: Can be more expensive than other plastics. |

| Polypropylene (PP) | Flexible, resistant to fatigue and chemicals | Packaging, automotive, textiles | Pros: Cost-effective, excellent chemical resistance. Cons: Lower impact resistance compared to HDPE. |

| Polyvinyl Chloride (PVC) | Rigid, good chemical resistance, available in various colors | Construction, plumbing, signage | Pros: Versatile, durable. Cons: Environmental concerns during production and disposal. |

| Expanded Polypropylene (EPP) | Lightweight, shock-absorbing, thermal insulation | Automotive, electronics packaging | Pros: Excellent cushioning properties, recyclable. Cons: Higher cost, limited color options. |

| Polystyrene (PS) | Rigid, lightweight, good insulation properties | Food service, consumer goods | Pros: Inexpensive, easy to mold. Cons: Brittle, not suitable for heavy-duty applications. |

High-Density Polyethylene (HDPE)

HDPE crates are known for their exceptional durability and resistance to impact, making them ideal for demanding environments. Their UV stabilization allows for outdoor usage without significant degradation. B2B buyers in sectors like agriculture and food processing value HDPE for its hygiene and easy cleaning properties. When purchasing, consider the crate’s weight capacity and whether the price aligns with your budget, as HDPE can be pricier than alternatives but offers longevity.

Polypropylene (PP)

Polypropylene crates are characterized by their flexibility and resistance to fatigue, making them suitable for applications requiring repetitive use. They are often employed in packaging and automotive industries due to their lightweight nature and cost-effectiveness. For B2B buyers, it’s important to evaluate the specific chemical resistance needed for their applications, as PP excels in this area but may not withstand heavy impacts like HDPE.

Polyvinyl Chloride (PVC)

PVC crates are highly versatile and come in various colors, making them suitable for branding and aesthetic applications. Their rigidity and good chemical resistance make them popular in construction and plumbing. However, B2B buyers should be aware of environmental concerns associated with PVC production and disposal. It’s crucial to weigh the benefits of durability against the potential regulatory implications when sourcing PVC crates.

Expanded Polypropylene (EPP)

EPP crates are recognized for their lightweight and excellent cushioning properties, making them ideal for packaging sensitive electronics and automotive components. Their shock-absorbing qualities provide additional protection during transport. Buyers should consider the higher cost of EPP crates and the limited color options, but the benefits in terms of product safety and recyclability can justify the investment.

Polystyrene (PS)

Polystyrene crates are lightweight and cost-effective, making them popular in food service and consumer goods sectors. Their easy molding capabilities allow for custom shapes and designs. However, B2B buyers must consider the limitations of PS, such as its brittleness and unsuitability for heavy-duty applications. When selecting PS crates, assess the specific needs of your application and whether the low cost outweighs potential durability issues.

Related Video: 7 Different Types of Plastic and Their Uses | Orange Plastics Academy

Key Industrial Applications of crates plastic

| Industry/Sector | Specific Application of crates plastic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Harvesting and Transport of Produce | Reduces spoilage, enhances efficiency in logistics | Durability, UV resistance, compliance with food safety standards |

| Food and Beverage | Storage and Distribution of Bottled Goods | Ensures product integrity and hygiene during transit | Stackability, ease of cleaning, compatibility with automation systems |

| Pharmaceuticals | Transport of Medical Supplies | Safeguards sensitive products, maintains compliance | Temperature control capabilities, anti-static features, certification for medical use |

| Retail | Display and Storage of Consumer Goods | Increases visibility and organization in stores | Aesthetic design, lightweight yet robust, customization options |

| E-commerce | Packaging for Direct-to-Consumer Shipments | Reduces shipping costs, enhances customer experience | Sustainability features, protective qualities, size variability |

Agriculture

In the agriculture sector, plastic crates are pivotal for the harvesting and transport of produce. These crates minimize spoilage and damage during transit, significantly improving the efficiency of logistics operations. International buyers should prioritize crates that are durable and UV resistant to withstand harsh environmental conditions. Compliance with food safety standards is crucial, especially for buyers in regions like Africa and South America, where agricultural practices may vary.

Food and Beverage

For the food and beverage industry, plastic crates are essential for the storage and distribution of bottled goods. They ensure product integrity and hygiene during transit, which is vital for maintaining quality and compliance with health regulations. Buyers should look for crates that are stackable and easy to clean, as well as those that can integrate seamlessly into automated processes. This is particularly important in European markets, where efficiency and sustainability are increasingly prioritized.

Pharmaceuticals

In pharmaceuticals, plastic crates serve a critical role in the transport of medical supplies. They protect sensitive products and help maintain compliance with stringent regulations. Buyers in this sector must consider crates with temperature control capabilities and anti-static features to safeguard medications and other sensitive items. Certification for medical use is a non-negotiable requirement for international buyers, particularly in the Middle East and Europe.

Retail

In retail, plastic crates are used for both the display and storage of consumer goods. They enhance product visibility and organization, which can lead to increased sales. International B2B buyers should focus on crates that offer aesthetic design while being lightweight yet robust. Customization options can also be beneficial, allowing businesses to tailor their crates to specific branding needs, especially in diverse markets across South America and Africa.

Illustrative Image (Source: Google Search)

E-commerce

For e-commerce businesses, plastic crates are vital for packaging direct-to-consumer shipments. They help reduce shipping costs and enhance the overall customer experience by providing robust protection during transit. Buyers should consider crates with sustainability features and protective qualities to minimize environmental impact and ensure product safety. Size variability is also important, as it allows for flexibility in packing different types of products, catering to varying demands in international markets.

Strategic Material Selection Guide for crates plastic

When selecting materials for plastic crates, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. Here, we analyze four common materials used in the production of plastic crates, highlighting their properties, advantages, limitations, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Polypropylene (PP)

Polypropylene is widely used in the manufacture of plastic crates due to its excellent balance of properties. It has a high melting point (around 160°C) and exhibits good chemical resistance, making it suitable for various applications, including food storage and logistics.

Pros:

– Durability: Resistant to impact and stress, making it long-lasting.

– Cost-Effective: Generally lower production costs compared to other plastics.

– Lightweight: Facilitates easier handling and transportation.

Cons:

– Temperature Sensitivity: Not suitable for extreme temperatures; can become brittle in cold conditions.

– UV Degradation: Prolonged exposure to sunlight can weaken the material.

Impact on Application:

Polypropylene crates are ideal for dry goods and non-perishable items. However, they may not be suitable for products requiring refrigeration or exposure to direct sunlight.

Considerations for International Buyers:

Compliance with food safety standards is crucial, particularly in regions with strict regulations. Buyers should also be aware of local recycling capabilities for polypropylene, as this can affect long-term sustainability practices.

High-Density Polyethylene (HDPE)

HDPE is another popular choice for plastic crates, known for its strength and resistance to various chemicals. It can withstand temperatures up to 120°C and is often used in applications involving liquids.

Pros:

– Chemical Resistance: Excellent for storing a wide range of substances, including acids and bases.

– Robustness: Highly resistant to impact and stress, ensuring longevity.

– Recyclability: Widely accepted in recycling programs, enhancing sustainability.

Cons:

– Higher Cost: Generally more expensive than polypropylene.

– Weight: Heavier than other plastic options, which can increase shipping costs.

Impact on Application:

HDPE crates are particularly effective for transporting liquids and hazardous materials. Their durability makes them suitable for heavy-duty applications.

Considerations for International Buyers:

Buyers must ensure compliance with regional safety regulations, especially when dealing with hazardous materials. Understanding local standards for chemical compatibility is essential for safe usage.

Polyvinyl Chloride (PVC)

PVC is known for its versatility and can be used in various applications, including crates. It offers good chemical resistance and can be formulated for specific needs, such as flexibility or rigidity.

Pros:

– Versatile: Can be tailored for specific applications, including flexibility or rigidity.

– Cost-Effective: Generally lower cost than HDPE, making it a budget-friendly option.

– Good Chemical Resistance: Suitable for many industrial applications.

Cons:

– Environmental Concerns: Production and disposal can have negative environmental impacts.

– Temperature Limitations: Can become brittle at low temperatures.

Impact on Application:

PVC crates are often used in industrial settings where chemical exposure is a concern. However, they may not be suitable for food applications without proper certification.

Considerations for International Buyers:

Buyers should be aware of environmental regulations regarding PVC in their regions. Compliance with local standards, such as ASTM or DIN, is crucial for ensuring product safety and acceptance.

Polystyrene (PS)

Polystyrene is a lightweight and cost-effective material commonly used for disposable crates. It is known for its rigidity and ability to be molded into various shapes.

Pros:

– Lightweight: Easy to handle and transport, reducing shipping costs.

– Low Cost: One of the most affordable plastic options available.

– Moldability: Can be easily shaped for specific applications.

Cons:

– Brittleness: Prone to cracking under stress or impact.

– Limited Chemical Resistance: Not suitable for all chemical environments.

Impact on Application:

Polystyrene crates are often used for temporary storage solutions or in environments where durability is less critical. They are commonly found in retail and food service applications.

Considerations for International Buyers:

Buyers should consider the environmental impact of polystyrene, particularly in regions with strict waste management policies. Compliance with local standards for food safety is also essential.

Summary Table

| Material | Typical Use Case for crates plastic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene (PP) | Food storage, logistics | Cost-effective and durable | Temperature sensitivity | Low |

| High-Density Polyethylene (HDPE) | Liquid transport, hazardous materials | Excellent chemical resistance | Higher cost | Medium |

| Polyvinyl Chloride (PVC) | Industrial applications | Versatile and cost-effective | Environmental concerns | Low |

| Polystyrene (PS) | Disposable crates, retail | Lightweight and low cost | Brittleness and limited chemical resistance | Low |

This guide aims to equip international B2B buyers with the necessary insights to make informed decisions regarding the selection of materials for plastic crates, ensuring compliance with regional standards and suitability for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for crates plastic

Overview of Manufacturing Processes for Plastic Crates

When considering the purchase of plastic crates, understanding the manufacturing processes can provide critical insights into product quality and supplier reliability. The production of plastic crates typically involves several main stages, each employing specific techniques to ensure durability, usability, and compliance with international standards.

1. Material Preparation

The initial step in the manufacturing process is material preparation. Plastic crates are predominantly made from high-density polyethylene (HDPE) or polypropylene (PP), chosen for their strength, resistance to impact, and recyclability.

- Material Selection: Buyers should ensure that the supplier uses virgin resin or recycled materials that meet industry standards. Specifications should be checked against applicable norms such as ASTM or ISO.

- Quality Control of Raw Materials: Suppliers often conduct incoming quality control (IQC) checks to assess the quality of the raw materials before processing. This step is crucial to prevent defects in the final product.

2. Forming

The forming stage typically involves techniques such as injection molding or blow molding, which are essential for creating the shape and structure of the crates.

- Injection Molding: This is the most common method for producing plastic crates. The process involves melting plastic granules and injecting them into a mold. This technique allows for high precision and repeatability, which is vital for bulk orders.

- Blow Molding: Used primarily for hollow crates, this method involves inflating a heated plastic tube into a mold. Buyers should inquire about the forming method used by suppliers, as it impacts crate strength and design flexibility.

3. Assembly

After forming, the crates may require assembly, especially if they consist of multiple parts or features such as handles and lids.

- Automated vs. Manual Assembly: Many manufacturers utilize automated assembly lines to enhance consistency and efficiency. Understanding the assembly process can help buyers evaluate the potential for production errors or delays.

- Quality Checks During Assembly: In-process quality control (IPQC) is crucial at this stage to ensure that all components fit correctly and function as intended.

4. Finishing

The finishing stage involves processes that improve the aesthetics and functionality of the crates.

- Surface Treatment: This may include processes like UV stabilization or anti-microbial treatments, especially important for crates used in food and pharmaceutical industries.

- Final Inspection: Final quality control (FQC) checks are conducted to ensure that the crates meet the required specifications and standards before packaging.

Quality Assurance Standards

For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, understanding quality assurance is crucial for ensuring product reliability.

International Standards

- ISO 9001: This is a widely recognized standard for quality management systems. Suppliers with ISO 9001 certification indicate a commitment to maintaining high-quality processes.

- CE Marking: For products sold in Europe, CE marking signifies compliance with health, safety, and environmental protection standards.

- API Certification: For crates used in specific industries, such as oil and gas, look for suppliers with API certification, indicating adherence to industry-specific standards.

Quality Control Checkpoints

B2B buyers should be aware of the critical quality control checkpoints that suppliers should implement:

- Incoming Quality Control (IQC): Assessing raw materials before they enter production.

- In-Process Quality Control (IPQC): Monitoring production processes to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product to ensure it meets all specifications.

Common Testing Methods

Suppliers typically utilize various testing methods to verify the integrity and performance of plastic crates:

- Mechanical Testing: Includes tests for tensile strength, impact resistance, and flexibility.

- Environmental Testing: Evaluates how crates perform under different temperature and humidity conditions.

- Chemical Testing: Ensures that the materials used are safe and compliant with relevant regulations, especially for food-grade applications.

Verifying Supplier Quality Control

To ensure that suppliers maintain high-quality standards, B2B buyers can take several steps:

- Supplier Audits: Conducting on-site audits can provide insights into manufacturing processes and quality control practices.

- Requesting Quality Reports: Suppliers should be willing to provide documentation of their quality control processes and results.

- Third-party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality assurance practices.

Considerations for International Buyers

When sourcing plastic crates from suppliers in different regions, B2B buyers should consider the following nuances:

- Regulatory Compliance: Different regions may have varying regulations regarding materials and safety standards. Buyers should ensure that their suppliers comply with local regulations in their target markets.

- Cultural Differences: Understanding cultural nuances can enhance communication and negotiation with suppliers from diverse backgrounds.

- Logistics and Supply Chain: Assess the supplier’s ability to meet delivery timelines and manage logistics, which is particularly important for international transactions.

Conclusion

Understanding the manufacturing processes and quality assurance practices related to plastic crates is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, along with adhering to international quality standards, buyers can make informed decisions that align with their operational needs and compliance requirements. Engaging in thorough supplier verification processes will further ensure a reliable and high-quality supply chain.

Related Video: Plastic Bag Mass Production Factory in Korea. Plastic Bag Manufacturing Process.

Comprehensive Cost and Pricing Analysis for crates plastic Sourcing

Understanding the Cost Structure of Plastic Crates

When sourcing plastic crates, international B2B buyers must navigate a multifaceted cost structure. Key components include:

-

Materials: The type of plastic used significantly impacts costs. High-density polyethylene (HDPE) and polypropylene are common choices, with varying price points based on market fluctuations and availability. Buyers should consider sourcing materials locally where possible to reduce expenses.

-

Labor: Labor costs can vary widely by region. In countries with higher wage standards, manufacturers may face increased labor costs. Understanding local labor rates can aid buyers in negotiating better pricing.

-

Manufacturing Overhead: This encompasses costs related to factory maintenance, utilities, and indirect labor. Manufacturers with efficient operations often pass on savings to buyers, making it essential to assess potential suppliers’ operational efficiency.

-

Tooling: Initial costs for tooling can be significant, especially for custom crates. Buyers should inquire about tooling costs upfront, as these can be amortized over large orders, reducing per-unit expenses.

-

Quality Control (QC): Investing in QC processes ensures product reliability and compliance with international standards. While this may add to upfront costs, it can minimize long-term risks and enhance buyer confidence.

-

Logistics: Shipping and handling costs can fluctuate based on distance, mode of transport, and fuel prices. Understanding Incoterms will help clarify who bears these costs, which can influence overall pricing.

-

Margin: Suppliers will include their profit margin in the final pricing. This margin can vary based on competition and perceived value, making it a critical area for negotiation.

Influencers on Pricing

Several factors can influence the pricing of plastic crates:

-

Volume/MOQ: Larger orders often qualify for bulk pricing, significantly lowering unit costs. Buyers should assess their needs to maximize order sizes without overcommitting.

-

Specifications/Customization: Custom designs or specifications can lead to higher costs. Buyers should weigh the necessity of customization against the potential price increase.

-

Material Quality/Certifications: Crates that meet specific quality standards or certifications may command higher prices. Buyers must evaluate whether these certifications are essential for their applications.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more, but they often provide better service and quality assurance.

-

Incoterms: Understanding Incoterms is crucial for managing logistics costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who pays for shipping and insurance, impacting overall costs.

Buyer Tips for Cost Efficiency

To optimize sourcing strategies, consider the following tips:

-

Negotiate: Always negotiate pricing and terms with suppliers. Leverage volume commitments or long-term contracts to secure better rates.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but all associated costs, including logistics, maintenance, and potential waste. This approach can reveal the true cost of sourcing decisions.

-

Research Pricing Nuances: Be aware that pricing can vary by region. Factors like tariffs, local demand, and currency fluctuations can influence costs, especially for buyers in Africa, South America, the Middle East, and Europe.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and service. Trust and reliability often translate into more favorable terms.

Disclaimer

The prices discussed in this analysis are indicative and can fluctuate based on market conditions, regional economic factors, and specific supplier negotiations. Buyers are encouraged to conduct thorough market research and consult multiple suppliers to obtain the most accurate pricing for their needs.

Spotlight on Potential crates plastic Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘crates plastic’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for crates plastic

Key Technical Properties of Plastic Crates

Understanding the technical properties of plastic crates is crucial for international B2B buyers, as these specifications directly impact functionality, durability, and compliance with industry standards. Here are the essential properties to consider:

-

Material Grade: This refers to the specific type of plastic used in manufacturing crates, typically High-Density Polyethylene (HDPE) or Polypropylene (PP). The material grade affects the crate’s strength, flexibility, and resistance to chemicals and UV light. For buyers, selecting the right material grade ensures the crates meet their operational requirements and environmental conditions.

-

Load Capacity: This specification indicates the maximum weight a crate can safely hold without deforming or breaking. Understanding load capacity is vital for buyers to ensure that the crates can handle their intended products without risk of damage. It also helps in optimizing storage and transportation logistics.

-

Dimensional Tolerances: Tolerances refer to the permissible limits of variation in the dimensions of the crates (length, width, height). Tight tolerances ensure that crates stack properly and fit standard handling equipment. For B2B buyers, knowing the tolerances can prevent compatibility issues with existing systems and reduce operational inefficiencies.

-

Impact Resistance: This property measures the crate’s ability to withstand sudden shocks or drops without cracking or breaking. High impact resistance is critical for buyers in industries like food and beverage, where crates may undergo rough handling. Selecting crates with adequate impact resistance minimizes product loss and enhances safety.

-

Temperature Resistance: This defines the range of temperatures within which the crates can operate effectively without losing structural integrity. For international buyers, especially in regions with extreme weather, understanding temperature resistance is essential to ensure that products remain safe during storage and transportation.

Common Trade Terminology

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms related to plastic crates:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For B2B buyers, partnering with OEMs can provide access to high-quality products and custom solutions tailored to specific needs.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory costs and production planning. Buyers should negotiate MOQs that align with their operational needs and budget constraints.

-

RFQ (Request for Quotation): An RFQ is a formal request sent to suppliers to obtain price quotes for specific products or services. For buyers, issuing an RFQ is an effective way to compare prices and terms from multiple suppliers, ensuring they secure the best deal.

-

Incoterms (International Commercial Terms): These are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their liabilities and rights in international transactions, thereby mitigating risks.

-

Lead Time: This term refers to the time it takes from placing an order to receiving the goods. For B2B buyers, understanding lead times is vital for planning inventory and production schedules. Buyers should consider lead times when evaluating suppliers to ensure timely delivery and maintain operational efficiency.

By grasping these technical properties and industry terminology, B2B buyers can make informed decisions, streamline procurement processes, and foster successful partnerships in the global plastic crate market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the crates plastic Sector

Market Overview & Key Trends

The global crates plastic market is experiencing significant growth, driven by increased demand from various sectors including agriculture, food and beverage, and logistics. In particular, the rise of e-commerce and food delivery services has led to a surge in demand for durable, lightweight, and stackable plastic crates. International B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe, should take note of the following key trends shaping the market:

Illustrative Image (Source: Google Search)

-

Technological Advancements: The integration of smart technologies, such as RFID tagging and IoT-enabled tracking, is revolutionizing the way crates are managed in supply chains. This allows for enhanced inventory management and reduces losses due to misplacement.

-

Customization and Flexibility: Manufacturers are increasingly offering customizable crate solutions tailored to specific industries. Buyers should look for suppliers that can provide bespoke designs that meet unique operational needs, whether for agricultural produce or retail goods.

-

Circular Economy Initiatives: With a growing emphasis on sustainability, many companies are adopting circular economy principles, focusing on recycling and reusing plastic materials. This trend not only reduces waste but also creates cost efficiencies for businesses.

-

Regulatory Compliance: Buyers must stay informed about local and international regulations regarding plastic usage and recycling. Compliance with these regulations can influence sourcing decisions and operational practices.

By understanding these dynamics, B2B buyers can make informed decisions that align with market demands and operational efficiency.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal concern in the crates plastic sector, as businesses face pressure to minimize their environmental footprint. The production and disposal of plastic crates can significantly impact ecosystems, leading to pollution and waste management challenges. Therefore, B2B buyers must prioritize suppliers who demonstrate a commitment to sustainability.

Importance of Ethical Supply Chains: Establishing ethical supply chains not only enhances brand reputation but also fosters consumer trust. Buyers should seek out suppliers who adhere to responsible sourcing practices, ensuring that raw materials are sourced sustainably and ethically. This can include transparency in the supply chain, fair labor practices, and community engagement.

Green Certifications and Materials: Look for suppliers that offer crates made from recycled plastics or bioplastics, which have a lower environmental impact. Certifications such as ISO 14001 (Environmental Management) and certifications from recognized organizations like the Forest Stewardship Council (FSC) can indicate a supplier’s commitment to sustainability. Additionally, investing in crates that can be easily recycled at the end of their lifecycle will further enhance a company’s sustainability profile.

Incorporating these sustainable practices into sourcing strategies not only meets regulatory requirements but also aligns with the growing consumer demand for environmentally responsible products.

Brief Evolution/History

The evolution of plastic crates dates back to the mid-20th century when the introduction of synthetic materials revolutionized packaging and transportation. Initially designed for the agricultural sector, plastic crates offered a lightweight, durable alternative to traditional wooden crates. Over the decades, their versatility has led to widespread adoption across various industries, including retail, logistics, and food service.

The late 20th century saw significant advancements in manufacturing techniques, allowing for mass production and customization. As global awareness of environmental issues grew, the industry began shifting towards more sustainable practices, paving the way for the current focus on ethical sourcing and recycling. Today, the crates plastic sector is poised to continue evolving, driven by technological innovations and a commitment to sustainability, providing B2B buyers with ample opportunities for growth and responsible sourcing.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of crates plastic

-

How can I effectively vet suppliers of plastic crates?

Vetting suppliers is crucial to ensuring quality and reliability. Start by verifying their business credentials, such as registration and certifications. Request references from other clients, particularly those in your industry and region. Conduct online research to assess their reputation, and consider using platforms like Alibaba or Global Sources, which often feature supplier ratings. It’s also beneficial to visit the supplier’s facility, if feasible, to evaluate their production capabilities and quality control measures firsthand. -

What customization options are typically available for plastic crates?

Many suppliers offer customization in terms of size, color, and design. It’s advisable to discuss your specific requirements early in the negotiation process. Some manufacturers can provide tailored solutions to meet your logistics or branding needs. Ensure to request samples of customized products before placing a large order, as this will help you evaluate the quality and suitability of the crates for your intended use. -

What are the common Minimum Order Quantities (MOQs) and lead times?

MOQs vary significantly among suppliers and are influenced by factors like product type and customization. Generally, for standard plastic crates, MOQs can range from 100 to 1,000 units. Lead times can also differ based on the order size and the supplier’s production capacity, typically ranging from 2 to 8 weeks. Always confirm these details upfront to avoid unexpected delays, especially if you’re working on a tight schedule. -

What payment terms should I expect when purchasing plastic crates?

Payment terms can vary by supplier and region. Common practices include a 30% deposit upon order confirmation and the remaining 70% before shipment. For larger orders, some suppliers may offer more flexible terms or financing options. Additionally, consider using secure payment methods such as letters of credit or escrow services to mitigate risks. Always clarify payment terms in your contract to ensure both parties are aligned. -

What quality assurance measures should suppliers provide?

Quality assurance is vital when sourcing plastic crates. Ensure that your supplier adheres to recognized quality standards, such as ISO 9001. Request documentation such as quality control reports and certificates of compliance for materials used. Additionally, ask about their testing procedures for durability and safety. Establishing clear quality benchmarks before production begins can help prevent issues down the line. -

How should I handle logistics and shipping for my orders?

Logistics can be complex, especially for international shipments. Work closely with your supplier to determine the best shipping methods and incoterms (e.g., FOB, CIF) that fit your needs. Consider using a freight forwarder who can assist with customs clearance and logistics planning. Always factor in potential delays due to customs inspections, especially in regions with stricter regulations, and plan accordingly to maintain your supply chain. -

What steps can I take if disputes arise with my supplier?

To mitigate disputes, establish clear communication channels and document all agreements in writing. Should a disagreement occur, first attempt to resolve it directly with the supplier. If that fails, refer to the contract’s dispute resolution clause, which may outline mediation or arbitration processes. Engaging a legal expert familiar with international trade laws can provide guidance on your rights and obligations in such scenarios. -

What certifications should I look for in plastic crates?

Certifications can ensure that the plastic crates meet industry standards for safety and environmental impact. Look for certifications like FDA approval for food-grade materials, ISO certifications, and any regional compliance marks relevant to your market. These certifications not only guarantee quality but can also enhance your brand’s credibility with customers. Always request copies of these certificates before finalizing your purchase.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for crates plastic

In today’s competitive landscape, the strategic sourcing of plastic crates is not just a procurement activity; it is a pivotal part of operational efficiency and sustainability. As B2B buyers from regions like Africa, South America, the Middle East, and Europe engage in sourcing, key takeaways include the necessity for thorough supplier evaluations, understanding regional compliance standards, and the importance of innovation in materials and designs. By aligning sourcing strategies with sustainable practices, companies can not only reduce costs but also enhance their brand reputation in a market increasingly driven by environmental concerns.

The future of plastic crates is promising, with advancements in technology and materials paving the way for more durable and eco-friendly solutions. Buyers are encouraged to explore partnerships with suppliers who prioritize innovation and sustainability, ensuring a competitive edge in their respective markets.

Take action now: Review your current sourcing strategies and consider how you can integrate these insights. Embrace the opportunity to enhance your supply chain resilience and sustainability practices, positioning your business for long-term success in an evolving global market.