Master Sourcing Quality 55 Gallon Burn Barrels for Optimal

Introduction: Navigating the Global Market for 55 gallon burn barrel

In today’s global marketplace, the 55-gallon burn barrel stands out as a crucial asset for various industries, from waste management to agriculture and beyond. These versatile containers provide effective solutions for burning waste materials safely and efficiently, making them indispensable in regions where waste disposal options are limited. As international B2B buyers from Africa, South America, the Middle East, and Europe seek reliable suppliers, understanding the nuances of the burn barrel market becomes essential.

This comprehensive guide explores the different types of 55-gallon burn barrels, their construction materials, manufacturing processes, and quality control standards. It also delves into the landscape of suppliers, cost considerations, and the market dynamics influencing availability and pricing. By addressing frequently asked questions, we aim to equip buyers with the knowledge needed to make informed sourcing decisions.

Navigating the complexities of this market can empower businesses to optimize their waste management practices while ensuring compliance with local regulations. Whether you’re in Germany, the UAE, or any other region, this guide will help you understand the critical factors that influence your purchasing strategy, enabling you to source high-quality burn barrels that meet your specific operational needs. With this information, buyers can confidently engage with suppliers, negotiate favorable terms, and ultimately enhance their operational efficiency.

Understanding 55 gallon burn barrel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Steel Barrel | Made from heavy-gauge steel; often unpainted | Waste management, agricultural burning | Pros: Durable, reusable; Cons: Heavier, may rust over time. |

| Painted/Coated Barrel | Available in various colors; protective coating | Industrial waste disposal, landscaping | Pros: Aesthetic appeal, corrosion-resistant; Cons: Coating may degrade over time. |

| Drum with Lid | Features a secure lid to contain embers and smoke | Residential use, outdoor heating | Pros: Enhanced safety, reduces smoke escape; Cons: More expensive, may require additional fittings. |

| Portable Burn Barrel | Lightweight design with handles for easy transport | Camping, outdoor events | Pros: Easy to move, versatile; Cons: Limited capacity, less durable. |

| Customizable Burn Barrel | Tailored designs with modifications for specific needs | Manufacturing, construction waste management | Pros: Meets specific requirements, can include safety features; Cons: Higher initial investment, longer lead time. |

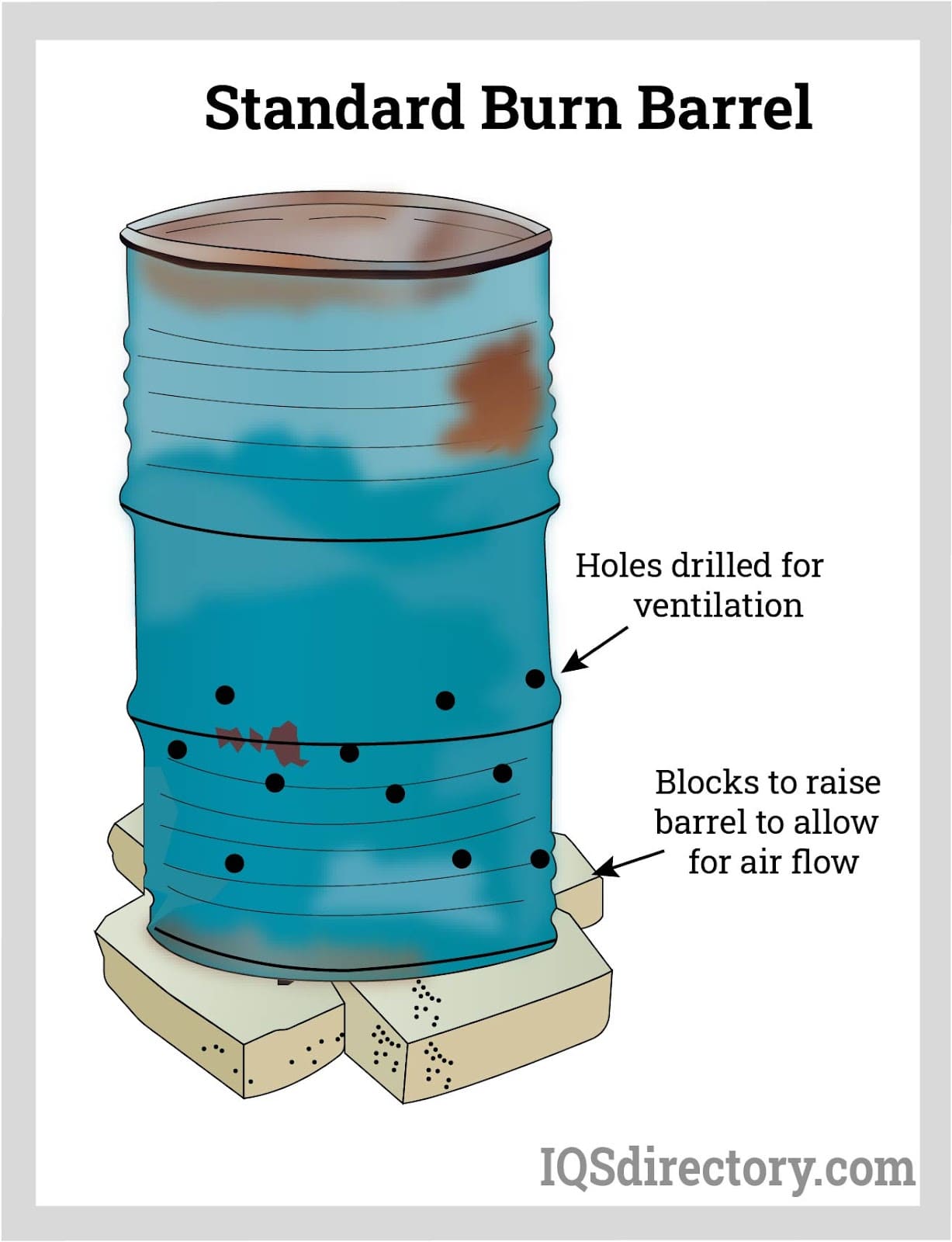

Standard Steel Barrel

The standard steel burn barrel is the most commonly used type, characterized by its heavy-gauge steel construction. It is ideal for various applications, particularly in waste management and agricultural burning. Buyers should consider the barrel’s weight and potential rusting over time, as these factors can impact longevity. For businesses in industries with stringent safety regulations, ensuring the barrel meets local compliance is crucial.

Painted/Coated Barrel

These barrels come with a protective coating that enhances durability and aesthetic appeal. They are often utilized in industrial waste disposal and landscaping applications. While they resist corrosion better than uncoated barrels, buyers should be aware that the coating may degrade over time, especially under harsh environmental conditions. This type is suitable for businesses looking for both functionality and visual appeal.

Drum with Lid

Featuring a secure lid, this burn barrel is designed to contain embers and smoke, making it safer for residential use and outdoor heating. Its lid can significantly reduce the risk of fire hazards and is beneficial for businesses prioritizing safety. However, the added safety features may come at a higher cost, and buyers should assess whether the additional investment aligns with their operational needs.

Portable Burn Barrel

Lightweight and equipped with handles, the portable burn barrel is designed for easy transport, making it ideal for camping and outdoor events. While its mobility is a significant advantage, the limited capacity may not meet the needs of larger operations. Businesses focused on flexibility and ease of use may find this type appealing, but they should also consider the trade-off in durability.

Customizable Burn Barrel

This type allows for modifications to suit specific operational needs, making it a great option for businesses in manufacturing and construction waste management. Custom features can include enhanced safety measures and tailored designs. While the initial investment may be higher, the ability to meet unique requirements can lead to long-term savings and improved efficiency. Buyers should weigh the benefits of customization against the potential for longer lead times and higher costs.

Related Video: Burn Barrel Ideas – 55 Gallon Drums

Key Industrial Applications of 55 gallon burn barrel

| Industry/Sector | Specific Application of 55 Gallon Burn Barrel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Waste Management | Incineration of Non-Hazardous Waste | Reduces waste volume and minimizes landfill use | Ensure compliance with local environmental regulations |

| Agriculture | Disposal of Agricultural Waste | Efficiently manages crop residues and reduces pests | Assess local regulations on burning practices |

| Construction | Burning of Scrap Wood and Materials | Cost-effective waste disposal and site cleanliness | Source durable barrels that meet safety standards |

| Oil and Gas | Disposal of Contaminated Materials | Safely incinerates hazardous waste, ensuring compliance | Verify that barrels are suitable for high-temperature use |

| Emergency Services | Field Waste Disposal in Disaster Zones | Provides a portable solution for waste management | Consider transportability and ease of setup |

Waste Management

In waste management, 55-gallon burn barrels serve as an incineration solution for non-hazardous waste. They effectively reduce waste volume and minimize landfill use, making them a valuable asset for municipalities and waste management companies. International B2B buyers should ensure compliance with local environmental regulations regarding emissions and waste disposal methods, as these can vary significantly across regions, including Africa and Europe.

Agriculture

In the agricultural sector, burn barrels are utilized for the disposal of agricultural waste, such as crop residues and diseased plants. This method helps manage waste efficiently while reducing pest populations and disease spread. Buyers in this sector should evaluate local regulations on burning practices, as some areas may have restrictions to protect air quality. Understanding these regulations is crucial for compliance and sustainable operations.

Construction

Construction companies often use 55-gallon burn barrels for the burning of scrap wood and other combustible materials on-site. This practice not only helps in waste disposal but also maintains site cleanliness and safety. For international buyers, sourcing durable barrels that meet safety standards is essential, especially in regions where construction regulations are stringent. Ensuring the barrels are robust enough to withstand the rigors of construction sites is also a key consideration.

Oil and Gas

In the oil and gas industry, 55-gallon burn barrels are employed for the safe disposal of contaminated materials. They provide an effective way to incinerate hazardous waste, ensuring compliance with environmental regulations. Buyers should verify that the barrels are suitable for high-temperature use and designed to handle the specific types of waste generated in this sector. This is particularly important in regions like the Middle East, where oil production is prevalent.

Emergency Services

Emergency services utilize 55-gallon burn barrels for field waste disposal in disaster zones. These barrels offer a portable solution for managing waste, allowing first responders to maintain hygiene and safety in challenging environments. When sourcing these barrels, buyers should consider factors such as transportability and ease of setup, ensuring they can be deployed quickly and efficiently in emergency situations.

Related Video: ONE OF A KIND! BBQ Grill Made with a 55 Gallon Barrel | Full Build

Strategic Material Selection Guide for 55 gallon burn barrel

When selecting materials for a 55-gallon burn barrel, it is essential to consider the properties, advantages, and limitations of various materials. This ensures optimal performance and compliance with regional standards, particularly for international B2B buyers from diverse markets such as Africa, South America, the Middle East, and Europe. Below is an analysis of four common materials used in the construction of burn barrels.

Steel

Key Properties:

Steel is known for its high strength and durability, withstanding high temperatures and pressures. It typically has a temperature rating of up to 1,500°F (815°C) and offers excellent corrosion resistance when properly treated.

Pros & Cons:

The primary advantage of steel is its robustness, making it ideal for heavy-duty applications. However, it can be more expensive than other materials and is prone to rust if not adequately coated or maintained. Manufacturing complexity is moderate, requiring welding and finishing processes.

Impact on Application:

Steel is suitable for burning a variety of materials, including wood and paper, due to its ability to handle high heat without deformation. However, it may not be compatible with corrosive substances without additional protective coatings.

Considerations for International Buyers:

Steel burn barrels must comply with local regulations regarding emissions and safety. Buyers should look for products that meet standards like ASTM in the U.S. or DIN in Germany, ensuring they are suitable for their specific market.

Plastic

Key Properties:

Plastic burn barrels are lightweight and resistant to corrosion, with a typical temperature rating of around 180°F (82°C). They are not suitable for high-heat applications but are effective for lower-temperature uses.

Pros & Cons:

The key advantage of plastic is its low cost and ease of handling. However, its lower strength and heat resistance limit its applications, making it unsuitable for high-temperature burning. Manufacturing is generally simpler, involving molding processes.

Impact on Application:

Plastic barrels are best for burning non-combustible materials or for use in applications where temperatures do not exceed its limits. They should not be used for burning wood or other high-heat materials.

Considerations for International Buyers:

Plastic barrels must comply with safety standards for burning materials, particularly in regions with strict environmental regulations. Buyers should verify compliance with local standards, as some countries may restrict the use of plastic for burn applications.

Fiber-Reinforced Polymer (FRP)

Key Properties:

FRP combines high strength with lightweight properties, offering excellent resistance to corrosion and chemicals. Its temperature rating can vary, but it generally withstands up to 300°F (149°C).

Pros & Cons:

FRP is highly durable and resistant to environmental factors, making it a long-lasting option. However, it tends to be more expensive than steel or plastic and can be challenging to repair if damaged.

Impact on Application:

FRP is suitable for burning non-toxic materials and can handle moderate temperatures. Its chemical resistance makes it ideal for applications involving corrosive substances, but it is not recommended for high-heat burning.

Considerations for International Buyers:

Buyers should ensure that FRP burn barrels meet international safety and environmental standards. In regions like Europe, compliance with regulations such as REACH may be necessary.

Aluminum

Key Properties:

Aluminum is lightweight and resistant to corrosion, with a temperature rating of approximately 1,200°F (649°C). It is less durable than steel but offers good thermal conductivity.

Pros & Cons:

The primary advantage of aluminum is its lightweight nature, making it easy to transport. However, it is less robust than steel and can be more expensive. Manufacturing can be complex due to the need for specialized welding techniques.

Impact on Application:

Aluminum barrels are suitable for burning materials at moderate temperatures but may not withstand prolonged high-heat applications. They are ideal for lighter burning tasks, such as yard waste.

Considerations for International Buyers:

Aluminum products must comply with local regulations regarding burning and emissions. Buyers should check for compliance with industry standards such as ISO or ASTM.

Summary Table

| Material | Typical Use Case for 55 gallon burn barrel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-temperature burning of wood and paper | High strength and durability | Prone to rust without treatment | Medium |

| Plastic | Low-temperature burning of non-combustibles | Lightweight and low cost | Limited heat resistance | Low |

| Fiber-Reinforced Polymer (FRP) | Burning of non-toxic materials | Excellent corrosion resistance | Higher cost and difficult to repair | High |

| Aluminum | Moderate-temperature burning of lighter materials | Lightweight and easy to transport | Less robust than steel | Medium |

This guide provides critical insights into material selection for 55-gallon burn barrels, enabling B2B buyers to make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 55 gallon burn barrel

Manufacturing Processes for 55 Gallon Burn Barrels

When considering the procurement of 55-gallon burn barrels, understanding the manufacturing processes is essential for ensuring quality and compliance with international standards. The production of these barrels involves several key stages, each critical to the performance and safety of the final product.

1. Material Preparation

The first stage of manufacturing involves sourcing high-quality materials, typically steel, which is favored for its strength and durability.

- Material Selection: The steel should be of appropriate gauge, generally between 16 to 18, to withstand high temperatures and resist corrosion. It is crucial to avoid drums made from recycled materials that may have previously contained hazardous substances.

- Inspection: Incoming materials undergo inspection (Incoming Quality Control, IQC) to ensure they meet specified standards and are free from defects.

2. Forming

Once materials are approved, the forming process begins.

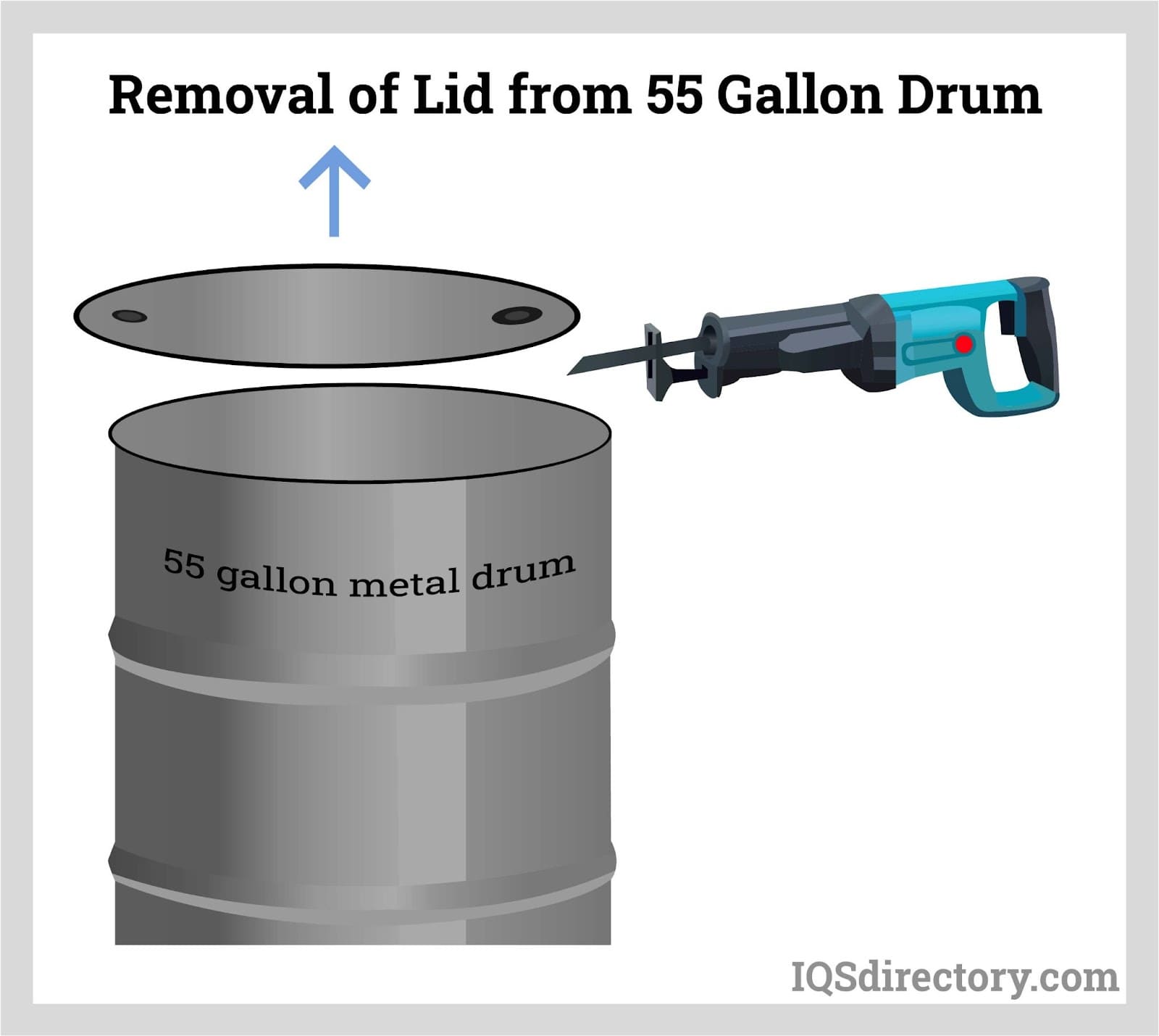

- Cutting: Steel sheets are cut to size using laser cutting or shearing techniques to ensure precision.

- Bending: The sheets are then bent to form the cylindrical shape of the barrel. This is typically done using a hydraulic press, which ensures uniformity and strength in the seams.

- Welding: After forming, the ends of the cylinder are welded together. Techniques such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding are commonly used to create strong, leak-proof joints.

3. Assembly

After the barrels are formed, they undergo assembly.

- Adding Components: This stage involves attaching any necessary components, such as lids, handles, and ventilation systems, which are essential for safe operation.

- Quality Checks: Throughout the assembly process, In-Process Quality Control (IPQC) measures are taken to ensure that each component fits properly and meets design specifications.

4. Finishing

The final stage of manufacturing is finishing, which enhances the durability and aesthetic appeal of the burn barrels.

- Surface Treatment: Barrels typically undergo surface treatment processes such as sandblasting, which removes any surface imperfections, followed by a protective coating (e.g., paint or galvanization) to prevent rust and corrosion.

- Final Inspection: Finished products are subject to Final Quality Control (FQC), where each barrel is inspected for overall quality, ensuring it meets both aesthetic and functional requirements.

Quality Assurance Standards

Quality assurance is paramount in the manufacturing of 55-gallon burn barrels, especially for international B2B buyers. Ensuring compliance with relevant international and industry-specific standards is crucial.

International Standards

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is applicable to any organization, regardless of its size or the industry. Certification to ISO 9001 indicates that a manufacturer has established a QMS that consistently meets customer and regulatory requirements.

Industry-Specific Standards

- CE Marking: Required for products sold within the European Economic Area, CE marking ensures that products meet safety, health, and environmental protection standards.

- API Standards: The American Petroleum Institute (API) has established standards relevant to the design and manufacturing of barrels used in the petroleum industry.

Quality Control Checkpoints

Quality control is integrated throughout the manufacturing process, with several checkpoints to maintain high standards.

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet the required specifications.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to catch any defects early.

- Final Quality Control (FQC): A thorough inspection of the finished product to ensure it meets all specifications and standards before shipping.

Common Testing Methods

B2B buyers should be aware of the various testing methods employed to ensure product quality:

- Hydrostatic Testing: This method checks for leaks by filling the barrel with water and pressurizing it.

- Visual Inspection: A thorough visual examination for any defects or inconsistencies in the structure or finish of the barrel.

- Material Testing: Testing the material properties, including tensile strength and resistance to corrosion, to ensure they meet specified standards.

Verifying Supplier Quality Control

International buyers can take several steps to verify the quality control processes of potential suppliers:

- Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures.

- Request Quality Assurance Reports: Suppliers should be able to provide documentation of their quality assurance processes, including results from IQC, IPQC, and FQC.

- Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the manufacturing processes and the quality of the finished products.

Nuances for International B2B Buyers

For buyers in Africa, South America, the Middle East, and Europe, understanding the nuances of quality assurance in different regions is vital:

- Regulatory Variations: Different countries have varying regulations regarding manufacturing standards and environmental compliance. Buyers should familiarize themselves with local laws and standards.

- Cultural Considerations: Building relationships with suppliers can be essential in regions where personal relationships and trust play a significant role in business transactions.

- Logistical Challenges: Consider the logistics of shipping and handling, particularly when dealing with heavy steel products like burn barrels, which can incur additional costs.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance standards for 55-gallon burn barrels is essential for B2B buyers. By focusing on these aspects, buyers can ensure they procure high-quality products that meet their specific needs while complying with relevant regulations and standards.

Related Video: The Ultimate DIY Burn Barrel Guide

Comprehensive Cost and Pricing Analysis for 55 gallon burn barrel Sourcing

The sourcing of 55-gallon burn barrels involves a complex cost structure that varies significantly based on numerous factors. Understanding these components is crucial for international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe.

Cost Components

- Materials: The primary material for manufacturing burn barrels is steel, often sourced from local suppliers. The cost can vary based on steel prices, which are influenced by global market trends. Additionally, the use of high-quality or certified materials may increase costs but can enhance durability and safety.

Illustrative Image (Source: Google Search)

-

Labor: Labor costs depend on the manufacturing location. Regions with lower labor costs may offer competitive pricing, while countries with stringent labor laws and higher wages may see increased manufacturing expenses.

-

Manufacturing Overhead: This encompasses the costs associated with utilities, equipment maintenance, and factory operations. Efficient manufacturing processes can help reduce overhead costs, which may be passed on to buyers.

-

Tooling: The initial investment in tooling for production can be significant, particularly for custom or specialized burn barrels. Buyers should inquire about tooling costs if they require unique specifications.

-

Quality Control (QC): Ensuring that each burn barrel meets safety and performance standards is essential. The costs associated with QC processes can vary based on the complexity of the product and regulatory requirements.

-

Logistics: Transportation costs can be a substantial part of the total cost, especially for international shipments. Factors such as distance, shipping method, and freight charges can greatly influence the final price.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on their market position, competition, and overall business strategy.

Price Influencers

Several factors can influence the pricing of 55-gallon burn barrels:

-

Volume/MOQ: Larger orders often result in reduced per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their needs.

-

Specifications/Customization: Custom designs or specific features can increase costs. Clear communication about requirements can help suppliers provide accurate quotes.

-

Materials: The choice of materials impacts both performance and pricing. For instance, barrels made from higher-grade steel may cost more but offer greater longevity.

-

Quality/Certifications: Products that meet international standards or possess specific certifications may command higher prices but provide assurance regarding safety and performance.

-

Supplier Factors: The reliability and reputation of the supplier can affect pricing. Established suppliers may offer better quality assurance but at a premium price.

-

Incoterms: The agreed terms for shipping and handling can impact overall costs. Buyers should understand the implications of different Incoterms on pricing, delivery timelines, and responsibilities.

Buyer Tips

-

Negotiation: Always negotiate pricing and terms. Suppliers may have flexibility in their margins, especially for larger orders or long-term contracts.

-

Cost-Efficiency: Assess total cost of ownership, which includes not just the purchase price but also shipping, handling, and long-term maintenance costs. This analysis can reveal the true value of a supplier’s offer.

-

Pricing Nuances for International Buyers: Understand local market conditions, currency fluctuations, and regional regulations that may impact pricing. Buyers in Africa, South America, the Middle East, and Europe should consider these factors to avoid unexpected costs.

-

Quality Over Price: While it can be tempting to opt for the lowest price, consider the long-term implications of quality. Investing in higher-quality barrels can reduce maintenance and replacement costs over time.

-

Stay Informed: Regularly monitor market trends and raw material prices to better understand the timing for purchases and potential cost fluctuations.

Disclaimer

Pricing for 55-gallon burn barrels can vary widely based on the aforementioned factors. Buyers should obtain multiple quotes and conduct thorough market research to ensure they are making informed purchasing decisions.

Spotlight on Potential 55 gallon burn barrel Manufacturers and Suppliers

This section looks at several manufacturers active in the ’55 gallon burn barrel’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for 55 gallon burn barrel

Key Technical Properties of 55 Gallon Burn Barrels

Understanding the essential technical properties of 55-gallon burn barrels is crucial for international B2B buyers. Here are some critical specifications that buyers should consider:

-

Material Grade: The most common material used for burn barrels is carbon steel. A higher material grade (like ASTM A1011 or A36) indicates better durability and resistance to corrosion. This is vital for longevity, especially in harsh environmental conditions typical in regions like Africa and the Middle East.

-

Wall Thickness: Typically ranging from 16 to 20 gauge, the wall thickness of a burn barrel affects its heat retention and structural integrity. Thicker walls can withstand higher temperatures and are less prone to warping or failure, making them suitable for continuous use.

-

Capacity: While the standard capacity is 55 gallons, it’s essential to confirm that the barrel is designed to handle the specific volume of waste intended for burning. Overloading can lead to safety hazards and inefficiencies.

-

Safety Features: Look for barrels with built-in safety features like proper venting systems and spark guards. These enhance safety during operation and are crucial for compliance with local regulations.

-

Coating and Finish: The internal and external coatings of the burn barrel can significantly affect its lifespan. Coatings that resist rust and high temperatures prolong the barrel’s usability, making it a more cost-effective investment.

-

Certification: Ensure that the burn barrel meets international safety and environmental standards. Certifications from recognized bodies can assure buyers of the product’s quality and compliance, which is particularly important in regions with strict regulatory frameworks.

Common Trade Terminology for B2B Transactions

Familiarity with industry jargon can streamline communication and negotiations in the procurement process. Here are several key terms relevant to 55-gallon burn barrels:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding whether the barrels are sourced from an OEM can provide insights into quality and reliability.

-

MOQ (Minimum Order Quantity): This is the minimum number of units a supplier is willing to sell. Knowing the MOQ can help buyers plan their purchases and manage inventory effectively, especially when sourcing from different regions like Europe or South America.

-

RFQ (Request for Quotation): An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products. It is a critical step in ensuring competitive pricing and understanding the total cost of ownership, including shipping and duties.

-

Incoterms (International Commercial Terms): These are internationally recognized rules that define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs. Familiarity with Incoterms can help buyers navigate logistics and reduce risks associated with international trade.

-

Lead Time: This refers to the time taken from placing an order to receiving the goods. Understanding lead times is essential for effective supply chain management, especially for businesses that rely on timely deliveries to meet customer demands.

-

Certification of Compliance: This document assures that the product meets specific regulatory standards. For burn barrels, compliance with environmental regulations is critical, especially in regions with stringent waste management laws.

By understanding these technical properties and trade terminologies, international B2B buyers can make more informed decisions when sourcing 55-gallon burn barrels, ultimately leading to better procurement strategies and operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 55 gallon burn barrel Sector

Market Overview & Key Trends

The global market for 55-gallon burn barrels is witnessing significant growth driven by several factors. One primary driver is the increasing need for efficient waste management solutions across various industries, particularly in regions like Africa and South America where traditional waste disposal methods are often inadequate. Additionally, the rise in off-grid living and DIY culture has spurred interest in the use of burn barrels for heating and waste reduction.

Emerging B2B technologies are reshaping how buyers source burn barrels. E-commerce platforms and online marketplaces have made it easier for international buyers to access suppliers from diverse regions, enhancing competition and driving down costs. The trend toward digital procurement tools also facilitates better supply chain transparency, enabling buyers to assess supplier reliability and compliance with industry standards.

Market dynamics are influenced by regional regulations and sustainability initiatives. For instance, the European Union is tightening regulations on emissions from burn barrels, prompting manufacturers to innovate cleaner-burning designs. In the Middle East, where energy costs are high, businesses are increasingly seeking cost-effective heating solutions, further boosting demand for efficient burn barrels. Buyers from Germany and the UAE, in particular, are focused on sourcing high-quality, compliant products that meet both local and international standards.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a core focus for B2B buyers in the burn barrel sector. The environmental impact of burn barrels, particularly concerning emissions and waste, necessitates the adoption of more sustainable practices. Buyers should prioritize suppliers that use eco-friendly materials and adhere to stringent emissions standards. This includes sourcing barrels made from recycled materials and ensuring that their manufacturing processes are energy-efficient.

Ethical supply chains are critical in today’s marketplace. Buyers must consider the environmental and social implications of their sourcing decisions, opting for suppliers that demonstrate a commitment to sustainable practices. Certifications such as ISO 14001 (Environmental Management) and various green labels can serve as indicators of a supplier’s commitment to sustainability.

Moreover, investing in green materials not only minimizes environmental impact but can also enhance brand reputation and customer loyalty. For example, using sustainably sourced steel or certified recycled plastics in burn barrel production can appeal to eco-conscious consumers and businesses alike.

Brief Evolution/History

The 55-gallon burn barrel has its roots in the early 20th century, primarily linked to the oil and chemical industries. Initially standardized by the American Petroleum Institute in 1905, the drum’s size and construction facilitated efficient storage and transportation. Over time, its versatility expanded beyond industrial uses to include residential applications, particularly for waste disposal and heating.

Today, the evolution of materials—from traditional steel to modern alternatives like plastic and fiber-reinforced polymers—has significantly influenced the burn barrel market. This shift reflects changing industry standards, environmental concerns, and the need for cost-effective solutions, making the 55-gallon burn barrel a staple in both industrial and domestic settings. Understanding this evolution is crucial for B2B buyers as they navigate sourcing decisions that align with current market demands and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of 55 gallon burn barrel

-

What factors should I consider when vetting suppliers for 55-gallon burn barrels?

When vetting suppliers, focus on their reputation, experience, and compliance with international standards. Check for certifications such as ISO 9001, which indicates quality management practices. Additionally, assess their production capabilities, delivery timelines, and customer reviews. Establish direct communication to discuss your requirements and gauge their responsiveness. Inquire about their sourcing of materials to ensure they meet safety and environmental regulations pertinent to your region. -

Can I customize the specifications of the 55-gallon burn barrels?

Yes, many suppliers offer customization options based on your specific needs. This can include variations in thickness, materials used, and additional features such as lids or ventilation systems. It’s essential to communicate your requirements clearly during initial discussions. Customization may impact lead times and pricing, so ensure you understand any implications on your order. -

What are the typical minimum order quantities (MOQs) and lead times for 55-gallon burn barrels?

MOQs can vary widely depending on the supplier and your location. Generally, MOQs range from 50 to 200 units. Lead times can also differ; expect anywhere from 4 to 12 weeks for production and shipping, depending on customization and the supplier’s workload. Always confirm these details before placing an order to avoid unexpected delays. -

What payment options are available for international orders of burn barrels?

Payment terms vary by supplier but typically include options such as wire transfers, letters of credit, and PayPal. For larger orders, negotiating terms like partial payments upfront and the balance upon delivery can be beneficial. Ensure you discuss currency exchange rates and potential fees associated with international transactions to avoid surprises.

Illustrative Image (Source: Google Search)

-

What quality assurance measures should I expect from suppliers?

Reputable suppliers should have a robust quality assurance (QA) process in place. This includes regular inspections during production and testing of finished products to ensure they meet safety standards. Ask for documentation of QA processes and any third-party certifications that validate their compliance with industry regulations. A supplier that prioritizes quality will also be transparent about their procedures. -

How do I handle disputes or issues with the supplier?

Establish clear communication channels with your supplier to address any potential disputes. Having a written contract that outlines the terms of the agreement, including delivery schedules and quality expectations, will help protect your interests. In case of a dispute, approach the supplier professionally, presenting your concerns with supporting documentation. If necessary, consider mediation or arbitration as a resolution method, as these can be less costly than legal action. -

What logistics considerations should I be aware of when importing burn barrels?

Logistics play a critical role in the import process. Research shipping methods that align with your budget and timeline, such as sea freight for bulk orders or air freight for urgent needs. Understand customs regulations in your country, including import duties and taxes applicable to burn barrels. Partnering with a logistics provider experienced in international shipping can streamline the process and help mitigate potential delays. -

Are there specific regulations I need to comply with when importing burn barrels?

Yes, importing burn barrels may be subject to various regulations based on your country’s environmental and safety laws. For example, some regions require compliance with specific emission standards or safety certifications. It’s crucial to conduct thorough research on local regulations or consult with a legal expert to ensure compliance. Failure to adhere to these regulations can result in fines, delays, or even confiscation of your shipment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 55 gallon burn barrel

In conclusion, strategic sourcing for 55-gallon burn barrels presents an array of opportunities for international B2B buyers across Africa, South America, the Middle East, and Europe. Understanding the diverse applications and regulatory considerations associated with burn barrels is crucial for making informed purchasing decisions. Buyers should prioritize sourcing from reputable suppliers who adhere to safety standards and offer durable materials, ensuring the longevity and efficiency of their burn barrels.

Key takeaways include:

– Cost-Effectiveness: Sourcing locally can reduce transportation costs and support regional economies.

– Customization Options: Engaging with manufacturers who offer tailored solutions can better meet specific operational needs.

– Sustainability Practices: Consider suppliers that utilize recycled materials, aligning with global sustainability goals.

As the demand for burn barrels continues to grow, leveraging strategic sourcing will empower businesses to enhance their operational efficiency while maintaining compliance with local regulations. Take action today by exploring partnerships with reliable suppliers and integrating innovative solutions that will position your business for success in this evolving market landscape. The future of burn barrels is bright, and your proactive approach can lead to significant competitive advantages.