Master Sourcing Plastic Baggies: Your Comprehensive B2B

Introduction: Navigating the Global Market for plastic baggies

In the dynamic landscape of global trade, plastic baggies have emerged as essential tools for a myriad of industries, from food packaging to logistics and retail. Their versatility, cost-effectiveness, and ability to provide secure and hygienic storage solutions make them indispensable for businesses operating across continents. As international B2B buyers, understanding the nuances of sourcing plastic baggies is critical not only for operational efficiency but also for maintaining competitive advantages in diverse markets.

This comprehensive guide delves deep into the world of plastic baggies, covering a wide array of topics crucial for informed decision-making. Buyers will explore the various types of baggies available, from standard polyethylene options to specialized biodegradable variants. The guide also outlines the materials used, manufacturing processes, and quality control standards that ensure product reliability. Furthermore, it identifies trusted suppliers and offers insights into pricing strategies and market trends, tailored specifically for regions including Africa, South America, the Middle East, and Europe.

By equipping procurement professionals with actionable insights and a clear understanding of the global market, this resource empowers you to navigate the complexities of sourcing plastic baggies effectively. Whether you are looking to optimize costs, enhance sustainability, or ensure compliance with regional regulations, this guide serves as your roadmap to successful sourcing in the ever-evolving world of plastic products.

Understanding plastic baggies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Plastic Baggies | Made from low-density polyethylene (LDPE) or polypropylene (PP) | General packaging, food storage, retail | Pros: Cost-effective, widely available, versatile. Cons: Limited durability for heavy items, not suitable for long-term storage. |

| Zipper Seal Baggies | Feature a resealable zipper closure | Food packaging, medical supplies, retail items | Pros: Reusable, provides an airtight seal, enhances product freshness. Cons: Slightly higher cost than standard bags, potential for zipper malfunction. |

| Heavy-Duty Baggies | Thicker materials designed for durability | Industrial applications, construction, waste management | Pros: Strong and tear-resistant, suitable for heavy loads. Cons: Higher cost, may not be necessary for lighter applications. |

| Biodegradable Baggies | Made from materials that break down more easily in the environment | Eco-friendly packaging, food service, retail | Pros: Supports sustainability initiatives, compliance with environmental regulations. Cons: Generally more expensive, limited shelf life compared to traditional options. |

| Custom Printed Baggies | Tailored designs with branding or specific dimensions | Marketing, promotional items, specialized packaging | Pros: Enhances brand visibility, tailored to specific needs. Cons: Higher minimum order quantities, longer lead times for production. |

Standard Plastic Baggies

Standard plastic baggies are typically made from low-density polyethylene (LDPE) or polypropylene (PP). These baggies are cost-effective and widely used for general packaging, food storage, and retail applications. B2B buyers should consider their versatility and availability but be aware that they may not provide sufficient durability for heavier items or long-term storage needs. Ensuring compliance with food safety standards is crucial for businesses in the food industry.

Zipper Seal Baggies

Zipper seal baggies come with a resealable closure, making them ideal for applications that require repeated access, such as food packaging and medical supplies. Their ability to create an airtight seal helps maintain freshness and prevent contamination. B2B buyers should weigh the benefits of reusability and enhanced product protection against the slightly higher cost compared to standard bags. Reliability of the zipper mechanism is also a key consideration in procurement.

Heavy-Duty Baggies

Heavy-duty baggies are constructed from thicker materials to withstand demanding conditions, making them suitable for industrial applications, construction sites, and waste management. Their strength and tear resistance make them ideal for carrying heavy loads. Buyers should evaluate the necessity of these baggies based on their specific applications, as the higher cost may not be justified for lighter products. Understanding the weight capacity and durability requirements is essential for effective purchasing.

Biodegradable Baggies

Biodegradable baggies are crafted from materials designed to decompose more readily in the environment. They are increasingly popular in eco-friendly packaging solutions for food service and retail sectors. B2B buyers should consider these baggies as part of their sustainability initiatives, especially in markets with strict environmental regulations. However, they typically come at a higher price point and may have a shorter shelf life compared to conventional plastic options, requiring careful inventory management.

Custom Printed Baggies

Custom printed baggies allow businesses to incorporate branding or specific dimensions tailored to their needs. These baggies are often used in marketing and promotional contexts, enhancing brand visibility. B2B buyers should be prepared for higher minimum order quantities and longer lead times associated with custom production. Understanding the balance between promotional impact and cost-effectiveness is vital when deciding on custom options, especially in competitive markets.

Related Video: The Attention Mechanism in Large Language Models

Key Industrial Applications of plastic baggies

| Industry/Sector | Specific Application of Plastic Baggies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Packaging fresh produce and snacks | Enhances product freshness and shelf life | Compliance with food safety regulations and certifications |

| Pharmaceuticals | Containment of medical samples and products | Ensures product integrity and safety | Material specifications for chemical resistance and sterility |

| Retail | Display and sale of small consumer goods | Increases visibility and ease of handling | Customization options for branding and size variations |

| Agriculture | Storage of seeds and fertilizers | Protects products from moisture and pests | Durability and UV resistance for outdoor conditions |

| E-commerce & Logistics | Packaging for shipping and product returns | Reduces shipping costs and improves customer satisfaction | Cost-effective solutions with reliable supply chains |

Food and Beverage

In the food and beverage industry, plastic baggies are commonly used for packaging fresh produce, snacks, and other perishable items. These baggies help to maintain product freshness and extend shelf life by providing a barrier against moisture and contaminants. For international buyers, especially in regions with varying climate conditions like Africa and South America, sourcing baggies that comply with local food safety regulations is crucial. Additionally, buyers should ensure that suppliers can provide certifications proving that materials are food-grade and suitable for direct contact with consumables.

Pharmaceuticals

Plastic baggies play a critical role in the pharmaceutical sector, where they are used to contain medical samples, medications, and other sensitive products. These baggies ensure product integrity and safety, which are paramount in this industry. Buyers in the Middle East and Europe must focus on sourcing materials that meet stringent regulations for chemical resistance and sterility. Understanding the specific requirements for packaging materials, such as barrier properties and durability, is essential for maintaining compliance and ensuring product efficacy.

Retail

In retail, plastic baggies are utilized for displaying and selling small consumer goods, such as jewelry, cosmetics, and snacks. They not only enhance product visibility but also facilitate easier handling for consumers. For B2B buyers in Europe and South America, customization options for branding and size variations can significantly influence purchasing decisions. It is important to work with suppliers who can provide high-quality printing and design options to create eye-catching packaging that aligns with brand identity.

Agriculture

Plastic baggies are increasingly used in agriculture for the storage of seeds, fertilizers, and other agricultural products. They protect these items from moisture, pests, and environmental factors that could compromise their quality. For buyers in regions with challenging climates, such as parts of Africa and South America, sourcing durable and UV-resistant baggies is vital. Additionally, buyers should look for suppliers who can provide baggies that are suited for both indoor and outdoor storage, ensuring long-term protection for agricultural inputs.

E-commerce & Logistics

With the rise of e-commerce, plastic baggies serve a vital function in packaging products for shipping and returns. They help reduce shipping costs by minimizing weight while also improving customer satisfaction through easy handling and secure packaging. International B2B buyers must consider cost-effective solutions that also ensure reliable supply chains, especially in regions like Argentina and the Middle East where logistics can be complex. It is essential to partner with suppliers who can offer consistent quality and timely delivery to meet the demands of fast-paced e-commerce environments.

Related Video: 25 Amazing Uses for IBC Totes

Strategic Material Selection Guide for plastic baggies

When selecting materials for plastic baggies, B2B buyers must consider various factors that influence performance, cost, and compliance with regional standards. Below is an analysis of four common materials used in the production of plastic baggies, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers, particularly in Africa, South America, the Middle East, and Europe.

Low-Density Polyethylene (LDPE)

Key Properties: LDPE is known for its flexibility, low-density structure, and excellent moisture barrier properties. It performs well in temperatures up to 80°C and has good chemical resistance, making it suitable for various applications.

Pros & Cons: LDPE is durable and resistant to impact, which is beneficial for packaging fragile items. It is also cost-effective due to its widespread availability and simple manufacturing process. However, LDPE is less suitable for high-temperature applications and can be less rigid compared to other plastics.

Impact on Application: LDPE baggies are ideal for food packaging, retail, and general-purpose storage, as they effectively protect contents from moisture and dust.

Considerations for International Buyers: Buyers should ensure compliance with food safety regulations, particularly in regions like Europe, where standards such as EU 10/2011 must be met. Additionally, sourcing from suppliers with ISO certifications can enhance reliability.

Polypropylene (PP)

Key Properties: Polypropylene is characterized by its high melting point (up to 100°C), excellent chemical resistance, and good tensile strength. It is also lightweight and has a high resistance to fatigue.

Pros & Cons: PP baggies are more rigid than LDPE, making them suitable for applications requiring structural integrity. They are also recyclable, which can appeal to environmentally conscious buyers. However, the manufacturing process is more complex and may lead to higher costs.

Impact on Application: PP is often used for packaging medical supplies, food items, and other products requiring a higher degree of protection and durability.

Considerations for International Buyers: Buyers should be aware of recycling regulations and standards in their respective regions, as compliance can vary significantly. For example, European markets have stringent recycling directives that must be adhered to.

Polyethylene Terephthalate (PET)

Key Properties: PET is known for its excellent clarity, high strength, and resistance to impact and moisture. It can withstand temperatures up to 70°C and is highly resistant to various chemicals.

Pros & Cons: The clarity of PET makes it an attractive option for retail packaging, as it allows consumers to see the product inside. It is also highly recyclable, which can enhance a brand’s sustainability profile. However, PET can be more expensive than LDPE and PP, and its production process is more energy-intensive.

Impact on Application: PET baggies are commonly used for packaging food items, beverages, and consumer products that benefit from visibility and durability.

Considerations for International Buyers: Buyers should ensure that PET products comply with the relevant food safety standards, such as those set by the FDA in the U.S. or EFSA in Europe. Additionally, understanding local recycling capabilities is essential for sustainable sourcing.

Biodegradable Plastics

Key Properties: Biodegradable plastics are designed to break down more quickly than traditional plastics, often within a few months to a few years, depending on environmental conditions. They can be made from renewable resources, such as cornstarch.

Pros & Cons: The primary advantage of biodegradable plastics is their reduced environmental impact, appealing to eco-conscious consumers and businesses. However, they can be more expensive than conventional plastics and may require specific conditions for effective degradation.

Impact on Application: These materials are increasingly used in packaging applications where sustainability is a priority, such as in food service items and shopping bags.

Considerations for International Buyers: Buyers should verify the certifications of biodegradable products to ensure they meet local environmental regulations. Understanding the disposal infrastructure in the target market is also crucial, as not all regions have the facilities to process biodegradable materials effectively.

Summary Table

| Material | Typical Use Case for plastic baggies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Low-Density Polyethylene (LDPE) | Food packaging, retail storage | Flexible and moisture-resistant | Less rigid and lower temperature tolerance | Low |

| Polypropylene (PP) | Medical supplies, food packaging | High durability and recyclability | Higher manufacturing complexity | Medium |

| Polyethylene Terephthalate (PET) | Food and beverage packaging | Excellent clarity and strength | Higher cost and energy-intensive production | High |

| Biodegradable Plastics | Eco-friendly packaging | Reduced environmental impact | Higher cost and specific disposal needs | Medium |

This analysis provides B2B buyers with actionable insights into selecting the right materials for plastic baggies, ensuring they can make informed decisions that align with their operational needs and sustainability goals.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic baggies

Manufacturing Processes for Plastic Baggies

The manufacturing of plastic baggies involves several critical stages designed to ensure efficiency and high-quality output. Understanding these processes can help international B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation

The first step in manufacturing plastic baggies is material preparation. Typically, polyethylene (PE) or polypropylene (PP) is used due to their favorable properties such as flexibility, moisture resistance, and durability.

- Resin Selection: Suppliers often begin by sourcing high-quality resin pellets, which are then dried to remove any moisture that could affect processing.

- Additives Inclusion: Depending on the desired characteristics, additives may be blended into the resin. This could include colorants, UV stabilizers, or anti-static agents, enhancing the baggie’s functionality.

2. Forming

The forming stage is where the actual shape of the baggie is created. There are several key techniques used in this process:

- Blown Film Extrusion: This is the most common method for producing plastic baggies. The resin is heated until it melts, then extruded through a circular die to form a tube. Air is blown into the tube, expanding it into a film. The film is then cooled and flattened.

- Cast Film Extrusion: An alternative method where the melted resin is extruded into a flat sheet, which is then cooled and cut into the desired dimensions. This method can produce thinner films with a more uniform thickness.

3. Assembly

Once the film is prepared, it is cut and sealed to form individual baggies.

- Cutting: The film is cut to the specified size, depending on the intended use of the baggies.

- Sealing: The edges of the baggie are sealed using heat sealing methods, which involve applying heat and pressure to join the edges together. This ensures a strong seal that can withstand various stresses.

4. Finishing

The final stage involves finishing touches to enhance the baggie’s usability and aesthetic appeal.

- Printing: If branding or information is required, the baggies may undergo flexographic or gravure printing processes, allowing for high-quality designs.

- Quality Inspection: Finally, a quality inspection is conducted to ensure that all baggies meet the required specifications before packaging.

Quality Assurance (QA) Standards

Quality assurance is paramount in the manufacturing of plastic baggies, especially for international B2B transactions. Buyers must ensure that their suppliers adhere to recognized standards that guarantee product quality and safety.

International Standards

- ISO 9001: This standard ensures that suppliers maintain a quality management system (QMS) that consistently meets customer and regulatory requirements. B2B buyers should verify that their suppliers are certified, indicating a commitment to quality.

- CE Marking: For products sold within the European Economic Area, the CE mark indicates compliance with health, safety, and environmental protection standards. Buyers from Europe should ensure that their suppliers provide CE-certified products.

Industry-Specific Standards

- API (American Petroleum Institute): For baggies used in the oil and gas sector, compliance with API standards ensures that products meet industry-specific safety and quality requirements.

- FDA Compliance: For food-grade plastic baggies, suppliers must comply with FDA regulations, which dictate that materials used are safe for food contact.

Quality Control Checkpoints

A robust quality control process includes several checkpoints throughout the manufacturing cycle:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival. Suppliers should conduct tests to confirm that the materials meet specified standards before processing.

- In-Process Quality Control (IPQC): During manufacturing, ongoing checks are performed to ensure that the production process adheres to quality standards. This includes monitoring temperature, pressure, and seal strength.

- Final Quality Control (FQC): Once production is complete, a final inspection is conducted. This includes testing for seal integrity, dimensions, and any defects in the baggies.

Common Testing Methods

To maintain quality, various testing methods are employed:

- Tensile Strength Testing: Measures the force required to break the baggie, ensuring it can withstand normal handling.

- Thickness Measurement: Ensures that the baggies are produced within the specified thickness range.

- Seal Strength Testing: Evaluates the strength of the seals to prevent leakage or breakage during use.

Verifying Supplier Quality Control

B2B buyers should take proactive steps to verify the quality control measures of potential suppliers:

- Conduct Audits: Regular audits of supplier facilities can provide insights into their manufacturing processes and adherence to quality standards.

- Request Quality Reports: Suppliers should provide documentation of their quality control processes, including test results and certifications.

- Third-Party Inspections: Engaging third-party inspectors can provide an unbiased assessment of a supplier’s quality assurance practices, ensuring compliance with international standards.

Nuances for International Buyers

For B2B buyers in Africa, South America, the Middle East, and Europe, understanding local regulations and market expectations is crucial:

- Regional Compliance: Different regions may have varying regulations regarding plastic products. Buyers should familiarize themselves with local standards, particularly in Africa and South America, where regulations may be less stringent.

- Sustainability Practices: Increasingly, buyers are prioritizing suppliers who demonstrate commitment to sustainable practices, such as using recycled materials or reducing waste during manufacturing.

Conclusion

By comprehensively understanding the manufacturing processes and quality assurance measures involved in producing plastic baggies, international B2B buyers can make informed sourcing decisions. Prioritizing suppliers that adhere to recognized standards and maintaining rigorous quality control will ensure that the products meet market demands and regulatory requirements, ultimately supporting long-term business success.

Related Video: Plastic Bag Mass Production Factory in Korea. Plastic Bag Manufacturing Process.

Comprehensive Cost and Pricing Analysis for plastic baggies Sourcing

In the sourcing of plastic baggies, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This analysis focuses on the key cost components, price influencers, and strategic buyer tips that can enhance procurement efficiency and effectiveness.

Cost Components

-

Materials: The primary cost driver in plastic baggies is the raw materials used, typically polyethylene (PE) or polypropylene (PP). Prices fluctuate based on oil market trends, impacting overall costs. Sustainable materials, while offering eco-friendly benefits, often come at a premium.

-

Labor: Labor costs vary significantly by region. In countries with lower labor costs, such as certain areas in Africa and South America, total production costs can be lower, while higher labor costs in Europe may increase the price per unit.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, rent, and equipment maintenance. Efficient operations can reduce these costs, impacting the overall pricing structure.

-

Tooling: For custom or specialized baggies, tooling costs can be substantial. Buyers should consider the amortization of these costs over the production volume to understand their impact on unit pricing.

-

Quality Control (QC): Ensuring product quality is essential, especially for buyers in regulated markets. QC processes can add to production costs but are necessary for compliance with safety standards and certifications.

-

Logistics: Transportation and handling costs can vary widely based on distance, shipping methods, and local infrastructure. Buyers should evaluate the total logistics cost as part of their overall procurement strategy.

-

Margin: Supplier margins can differ based on market conditions, competition, and supplier reputation. Understanding the typical margin in the industry can help buyers negotiate better pricing.

Price Influencers

-

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQ) to maximize cost efficiency.

-

Specifications/Customization: Custom features or specifications can increase costs significantly. Buyers should weigh the benefits of customization against the potential price increases.

-

Materials: The choice of materials directly influences pricing. Eco-friendly options may offer long-term savings but can have higher upfront costs.

-

Quality/Certifications: Higher-quality products or those with specific certifications (such as food safety standards) may command higher prices. Buyers must assess the value of these features in relation to their needs.

-

Supplier Factors: Supplier reputation, reliability, and service levels can affect pricing. Established suppliers may charge more for the assurance of quality and service.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) can impact overall costs, including who bears responsibility for shipping, insurance, and customs duties.

Buyer Tips

-

Negotiation: Engage in discussions with suppliers to explore flexible pricing structures, especially for long-term contracts or larger orders.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not only the purchase price but also logistics, storage, and disposal costs over the product lifecycle.

-

Regional Considerations: Understand local market conditions and supplier capabilities in Africa, South America, the Middle East, and Europe. Tailoring your approach to regional specifics can yield better pricing and service.

-

Pricing Nuances: Stay informed about market trends and global economic factors that may affect plastic prices. Regularly review supplier quotes and compare them against market benchmarks.

Disclaimer

Pricing for plastic baggies can fluctuate based on various factors, including market demand, raw material costs, and geopolitical influences. The insights provided are indicative and should be validated with suppliers for accurate, current pricing.

Spotlight on Potential plastic baggies Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘plastic baggies’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for plastic baggies

Key Technical Properties of Plastic Baggies

Understanding the technical properties of plastic baggies is crucial for international B2B buyers, as these specifications directly impact product quality, usability, and compliance with regional regulations. Here are several critical specifications to consider:

- Material Grade

– Definition: The specific type of plastic resin used, such as Low-Density Polyethylene (LDPE) or High-Density Polyethylene (HDPE).

– Importance: Different material grades offer varying levels of durability, flexibility, and resistance to chemicals. Choosing the appropriate grade is essential for meeting application requirements, whether for food packaging, medical supplies, or industrial uses.

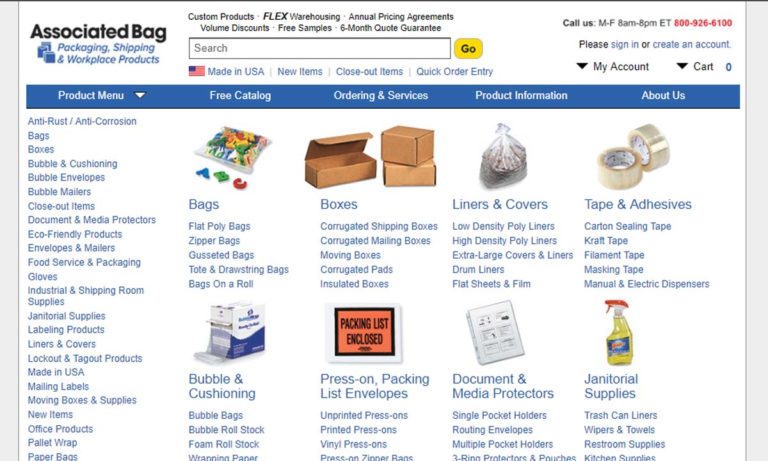

Illustrative Image (Source: Google Search)

-

Thickness

– Definition: Measured in microns or mils, this indicates the density of the plastic baggie.

– Importance: Thickness affects the baggie’s strength and tear resistance. Thicker baggies are typically more durable but may also be more expensive. Buyers should assess their needs based on product weight and handling requirements to ensure cost-effectiveness. -

Tolerance

– Definition: The permissible limit of variation in dimensions and physical properties of the baggie.

– Importance: Tolerances ensure that the baggies fit specific applications or equipment. For instance, if a baggie is intended for automated filling machines, precise tolerances are critical to avoid operational disruptions. -

Seal Strength

– Definition: The strength of the seals used to close the baggie, typically measured in pounds per inch (PPI).

– Importance: Strong seals are essential for maintaining the integrity of the contents, especially for food and medical applications. Buyers should verify seal strength to ensure product safety and reliability during transport and storage. -

Transparency

– Definition: The clarity of the baggie, which can range from completely transparent to opaque.

– Importance: Transparency is important for visibility of contents, especially in retail and food sectors. Buyers should consider the balance between visibility and privacy based on their specific application. -

Temperature Resistance

– Definition: The ability of the plastic baggie to withstand varying temperatures without deforming or losing functionality.

– Importance: Temperature resistance is crucial for applications involving hot or cold products. Buyers in regions with extreme temperatures must ensure that the baggies meet these specifications to avoid product failure.

Common Trade Terminology

Familiarity with industry jargon is vital for effective communication and negotiation in the B2B sector. Here are several key terms relevant to sourcing plastic baggies:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify potential suppliers who can provide customized solutions based on existing product lines. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Buyers must consider MOQs to ensure they can meet their demand without overcommitting financially. This is especially important for startups or smaller businesses in emerging markets. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting a price quote for specific products or services.

– Importance: An RFQ helps buyers compare pricing and terms from different suppliers, enabling informed decisions that can lead to cost savings.

Illustrative Image (Source: Google Search)

-

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

– Importance: Understanding Incoterms is crucial for managing logistics and ensuring that both parties are clear about their obligations and risks during transit. -

Lead Time

– Definition: The amount of time it takes from placing an order to receiving the goods.

– Importance: Buyers need to understand lead times to effectively manage inventory and meet customer demands. Long lead times may necessitate advanced planning and stockpiling. -

Certification

– Definition: Documentation that verifies that products meet specific regulatory or quality standards.

– Importance: Certifications can enhance product credibility and compliance, especially in regulated markets like food and pharmaceuticals. Buyers should prioritize suppliers with relevant certifications to ensure product safety and quality.

These technical properties and trade terms are essential for international B2B buyers to navigate the complexities of sourcing plastic baggies effectively, ensuring that they make informed decisions that align with their operational needs and market demands.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the plastic baggies Sector

Global drivers are significantly shaping the plastic baggies market, particularly influenced by consumer demand for convenience and the evolving regulatory landscape. The rise in e-commerce and food delivery services has accelerated the need for efficient packaging solutions, driving the demand for plastic baggies across various sectors. Additionally, the increasing focus on hygiene and safety—exacerbated by the COVID-19 pandemic—has led to a surge in single-use plastic products, including baggies.

Emerging trends in B2B technology, such as automation and digital supply chain management, are optimizing sourcing processes for international buyers. Tools like predictive analytics are enabling suppliers to better forecast demand, which is crucial for maintaining a steady supply chain. Moreover, the integration of blockchain technology enhances transparency and traceability, allowing buyers to verify the origin and quality of their plastic products. For buyers in regions such as Africa and South America, where infrastructure challenges exist, these technologies can mitigate risks associated with procurement and logistics.

Market dynamics are also shifting towards regional sourcing strategies. International B2B buyers are increasingly looking to partner with local suppliers to reduce shipping costs and delivery times, especially in regions with varying regulatory environments. This trend aligns with the broader move towards localization in supply chains, which can enhance resilience against global disruptions.

Sustainability & Ethical Sourcing in B2B

The environmental impact of plastic baggies is a pressing concern for today’s B2B buyers. The production and disposal of plastic contribute significantly to pollution and landfill waste, prompting many businesses to seek sustainable alternatives. Ethical sourcing has become paramount, as companies face scrutiny from consumers and regulatory bodies alike. Buyers should prioritize suppliers that adhere to sustainable practices, including the use of recycled materials and compliance with environmental regulations.

Certifications such as ISO 14001 (Environmental Management) and the Global Recycling Standard (GRS) can serve as indicators of a supplier’s commitment to sustainability. Additionally, exploring biodegradable or compostable plastic options can align with corporate social responsibility goals while meeting consumer demand for greener products. By integrating sustainability into their sourcing strategies, international buyers not only enhance their brand reputation but also contribute positively to the environment, ultimately driving long-term business success.

Brief Evolution/History

The evolution of plastic baggies dates back to the mid-20th century when polyethylene was first introduced. Initially used for simple storage solutions, their versatility quickly made them popular across various sectors. Over the decades, advancements in manufacturing processes have led to the development of specialized baggies for specific applications, such as food safety and medical use. The recent push towards sustainability has spurred innovation in materials, with manufacturers now exploring bio-based and recycled content options. This historical context highlights the ongoing transformation within the plastic baggies sector, emphasizing the need for B2B buyers to stay informed about material advancements and sourcing trends.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of plastic baggies

-

What criteria should I use to vet suppliers of plastic baggies?

When vetting suppliers, prioritize their experience in the industry, production capacity, and quality control processes. Request references and assess their compliance with international quality certifications such as ISO 9001. Additionally, evaluate their track record in meeting delivery timelines and responsiveness to inquiries. Conducting a site visit or virtual audit can also provide insights into their operational capabilities and business ethics, ensuring they align with your company’s standards. -

Can I customize plastic baggies to meet specific requirements?

Yes, many suppliers offer customization options for plastic baggies, including size, thickness, color, and printing. Discuss your specific needs with potential suppliers to understand their capabilities. Ensure they have the necessary technology and expertise to produce customized solutions. Be prepared to provide detailed specifications, including any regulatory requirements that may apply in your region, to facilitate the design and production process. -

What are the typical minimum order quantities (MOQ) and lead times for plastic baggies?

Minimum order quantities (MOQ) vary by supplier and depend on the customization level and production capabilities. Standardized baggies may have lower MOQs, while customized products typically require larger orders. Lead times can range from a few weeks to several months based on production schedules, material availability, and shipping logistics. Discuss these factors upfront with suppliers to align expectations and plan your procurement strategy effectively. -

What payment terms are commonly offered by suppliers?

Payment terms can vary significantly among suppliers. Common arrangements include upfront payments, letters of credit, or installment payments based on milestones. For international transactions, consider using secure payment methods that offer buyer protection. Negotiate terms that suit your cash flow and risk management strategies while ensuring they are acceptable to the supplier, which can foster a smoother business relationship. -

How can I ensure quality assurance and compliance with certifications?

To ensure quality assurance, request documentation of the supplier’s quality management systems and any relevant certifications (e.g., FDA, CE, or ISO certifications). Conduct regular quality audits and establish clear quality criteria in your contracts. Additionally, consider third-party inspections or testing for critical batches to verify compliance with your specifications and local regulations, especially in regions with stringent safety standards. -

What logistics considerations should I be aware of when sourcing plastic baggies internationally?

When sourcing internationally, consider shipping costs, customs regulations, and lead times. Work with logistics providers experienced in handling plastic products to navigate import/export regulations effectively. Ensure your supplier can accommodate your preferred shipping methods and that they provide clear documentation for customs clearance. Plan for potential delays and build flexibility into your supply chain to mitigate disruptions. -

How should I handle disputes or issues with suppliers?

Establish clear communication channels and conflict resolution protocols before engaging with suppliers. In the event of a dispute, address the issue promptly and professionally, referring to your contract for terms and obligations. Document all communications and agreements. If necessary, consider mediation or arbitration as a means to resolve conflicts amicably without escalating to legal proceedings, which can be costly and damaging to business relationships. -

What trends should I be aware of in the plastic baggies market?

Stay informed about sustainability trends, as there is increasing demand for eco-friendly and biodegradable plastic baggies. Regulatory changes regarding plastic use can impact sourcing decisions, particularly in Europe. Additionally, technological advancements in production processes may enhance customization options and reduce lead times. Keeping abreast of these trends will help you adapt your procurement strategies and maintain a competitive edge in the market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for plastic baggies

In today’s competitive landscape, strategic sourcing of plastic baggies is more crucial than ever for international B2B buyers. Leveraging the right suppliers can enhance product quality, streamline operations, and ensure compliance with regional regulations. By understanding the distinct types of plastic baggies available—ranging from commodity options to sustainable alternatives—buyers can make informed decisions that align with their specific market needs.

Key takeaways include:

– Supplier Relationships: Building long-term partnerships with reliable suppliers can mitigate risks associated with price volatility and supply chain disruptions.

– Customization and Innovation: Engaging with custom plastic fabricators allows for tailored solutions that meet unique specifications, driving product differentiation.

– Sustainability Focus: As global markets increasingly prioritize eco-friendly solutions, sourcing sustainable plastic baggies can enhance brand reputation and compliance with regulatory mandates.

Looking ahead, B2B buyers from Africa, South America, the Middle East, and Europe are encouraged to proactively seek out innovative suppliers who can provide not just products, but also strategic insights into evolving market trends. By embracing a forward-thinking sourcing strategy, businesses can position themselves for sustainable growth and competitive advantage in the global plastics market.