Unlock the Power of Transformer Types: Essential Insights

Introduction: Navigating the Global Market for transformer types

In the ever-evolving landscape of global commerce, understanding the intricacies of transformer types is crucial for B2B buyers seeking to optimize their sourcing strategies. Transformers are not merely components; they are vital elements in the electrical infrastructure that drive industries forward, particularly in emerging markets across Africa, South America, the Middle East, and Europe. With diverse applications—from power generation to renewable energy integration—selecting the right transformer type can significantly impact operational efficiency and cost-effectiveness.

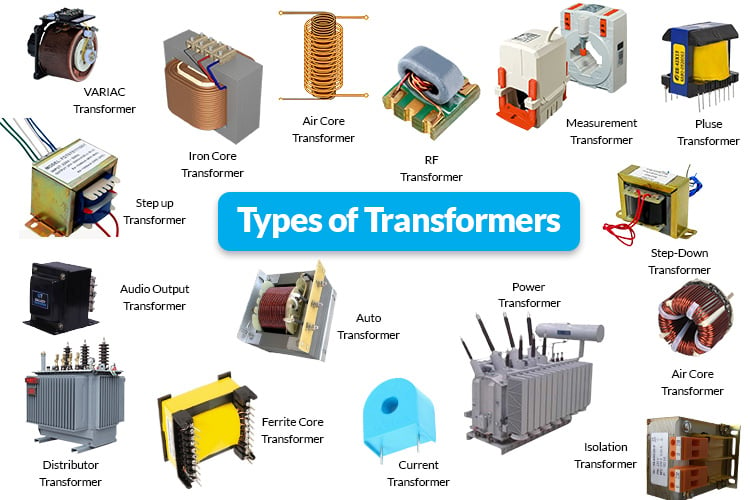

Illustrative Image (Source: Google Search)

This comprehensive guide delves into the various transformer types, examining their specifications, materials, and manufacturing processes, as well as quality control measures that ensure reliability. Additionally, we will explore the landscape of suppliers, offering insights into regional and global players, and provide a detailed analysis of cost factors associated with different transformer types.

By addressing frequently asked questions and clarifying common misconceptions, this guide serves as an essential resource for international B2B buyers. It empowers you to make informed decisions tailored to your unique market needs and challenges. Whether you are looking to enhance your supply chain, increase your technical knowledge, or identify strategic partners, this guide will equip you with the tools and insights necessary to navigate the global transformer market with confidence.

Understanding transformer types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Power Transformers | High voltage, large capacity, step-up/step-down | Power generation and distribution | Pros: Efficient for long-distance transmission. Cons: High initial cost and maintenance. |

| Distribution Transformers | Lower voltage, smaller size, used for local distribution | Commercial and residential applications | Pros: Cost-effective for local use. Cons: Limited capacity compared to power transformers. |

| Isolation Transformers | Provides galvanic isolation, reduces noise | Sensitive equipment, medical devices | Pros: Enhances safety and equipment longevity. Cons: Can be more expensive than standard types. |

| Auto Transformers | Single winding for both primary and secondary, compact | Industrial applications, motor drives | Pros: Smaller and lighter than traditional transformers. Cons: Less electrical isolation. |

| Three-Phase Transformers | Designed for three-phase systems, efficient | Industrial power systems | Pros: Efficient for large-scale power distribution. Cons: More complex installation and maintenance. |

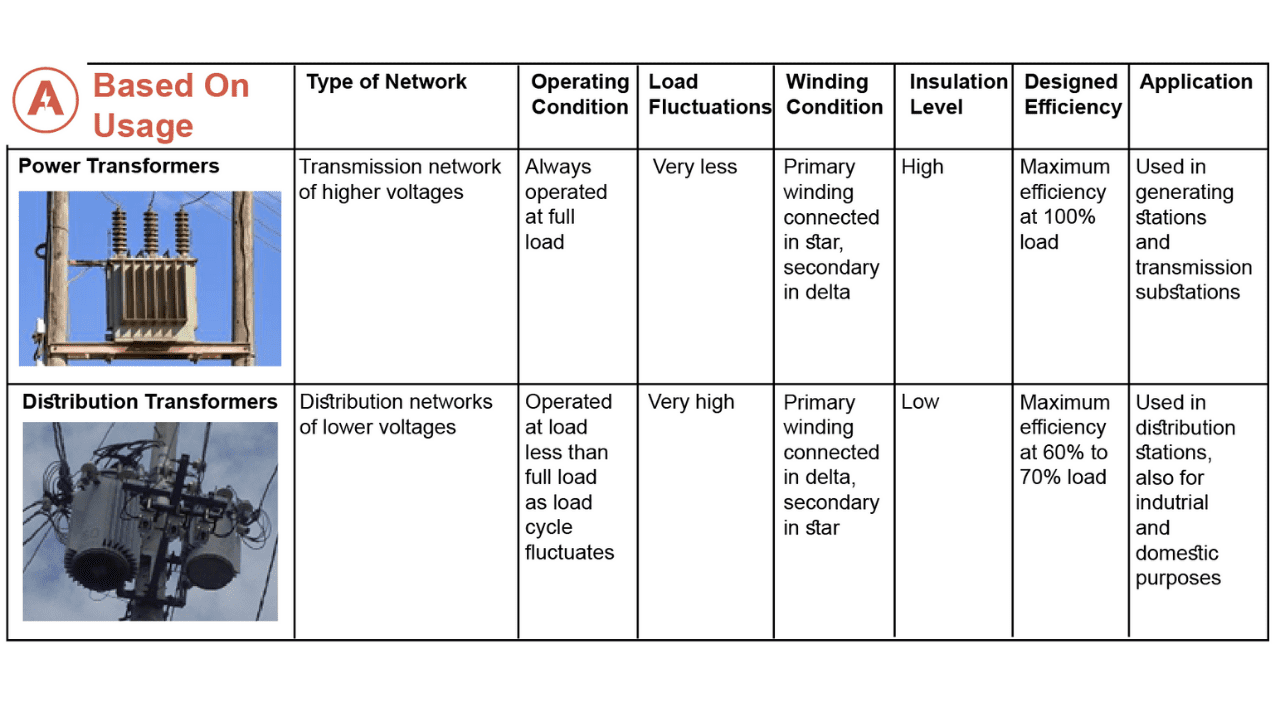

Power Transformers

Power transformers are essential for high voltage applications, allowing for efficient transmission of electricity over long distances. They are typically used in power generation and distribution systems. Buyers should consider their capacity needs, as these transformers are more expensive upfront but can lead to significant savings in energy costs over time. Maintenance is crucial due to their complexity and size.

Distribution Transformers

Distribution transformers are smaller and operate at lower voltages, making them ideal for local electricity distribution in commercial and residential settings. They are more cost-effective than power transformers and require less space, which can be beneficial in urban environments. However, buyers should be mindful of their capacity limitations and ensure that they match the local demand for electricity.

Isolation Transformers

Isolation transformers are designed to provide electrical isolation between circuits, which is vital for protecting sensitive equipment from noise and surges. They are commonly used in medical devices and laboratories. While they enhance safety and reliability, their cost can be a deterrent for some buyers. Organizations should evaluate their need for protection against electrical noise to justify the investment.

Auto Transformers

Auto transformers utilize a single winding for both primary and secondary circuits, making them more compact and lightweight compared to traditional transformers. They are often used in industrial applications, particularly for motor drives. Buyers should weigh the benefits of reduced size and weight against the lack of full electrical isolation, which may not be suitable for all applications.

Three-Phase Transformers

Three-phase transformers are designed to handle the demands of three-phase electrical systems, which are common in industrial settings. They provide efficient power distribution and are essential for large-scale operations. While they can be more complex to install and maintain, the efficiency gains can justify the investment for businesses with significant power needs. Buyers should consider their specific power distribution requirements and the complexities involved in installation.

Related Video: Transformer Types – Types of Transformer – Electrical Transformers Types

Key Industrial Applications of transformer types

| Industry/Sector | Specific Application of Transformer Types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Energy and Utilities | Step-up and step-down transformers for power distribution | Improved efficiency in energy transmission and reduced losses | Compliance with local regulations and standards |

| Manufacturing | Isolation transformers for machinery protection | Enhanced equipment safety and reduced downtime | Quality certifications and robust technical support |

| Telecommunications | Transformers for signal transmission and power supply | Reliable network performance and uptime | Supplier reliability and service level agreements |

| Mining and Metals | Custom transformers for heavy machinery and equipment | Increased operational efficiency and equipment lifespan | Ability to provide tailored solutions and quick delivery |

| Construction | Transformers for temporary power supply at construction sites | Cost-effective power solutions and project efficiency | Local availability and logistics support |

Energy and Utilities

In the energy sector, step-up and step-down transformers are critical for effective power distribution. These transformers adjust voltage levels to minimize energy losses during transmission. For international B2B buyers, especially in regions like Africa and the Middle East, understanding local grid requirements and compliance with energy regulations is essential. Buyers should prioritize suppliers who can demonstrate experience in local market conditions and provide transformers that meet international safety and performance standards.

Manufacturing

Isolation transformers are widely used in manufacturing to protect sensitive machinery from electrical surges and noise. By ensuring clean power supply, these transformers help minimize equipment damage and downtime. B2B buyers in South America and Europe should consider sourcing isolation transformers from manufacturers that offer robust technical support and compliance with industry standards. This is crucial to ensure seamless integration into existing production lines and adherence to safety protocols.

Telecommunications

In telecommunications, transformers play a vital role in signal transmission and power supply. They ensure reliable network performance, which is critical for service providers aiming to maintain uptime. International buyers must evaluate suppliers based on their ability to deliver high-quality transformers that meet specific voltage and capacity requirements. Additionally, assessing the supplier’s track record for reliability and service level agreements can significantly impact operational efficiency.

Mining and Metals

The mining and metals industry often requires custom transformers designed for heavy machinery and equipment. These transformers are essential for managing the high power demands of mining operations, ultimately leading to improved efficiency and extended equipment lifespan. B2B buyers should focus on suppliers that can provide tailored solutions, as well as quick delivery times to minimize project delays. Understanding the specific power needs and environmental conditions of the mining site is also crucial.

Construction

Transformers are frequently used for temporary power supply at construction sites, where reliable and cost-effective power solutions are essential for project efficiency. International buyers should consider the local availability of transformers and the logistical support offered by suppliers. It’s important to choose transformers that can handle the fluctuating power demands of construction activities while ensuring compliance with safety regulations. This can help mitigate risks associated with power interruptions during critical project phases.

Illustrative Image (Source: Google Search)

Strategic Material Selection Guide for transformer types

When selecting materials for transformers, international B2B buyers must consider various factors that influence performance, cost, and compliance with regional standards. Below, we analyze four common materials used in transformer construction: silicon steel, copper, aluminum, and composite materials. Each material has distinct properties, advantages, and limitations that can significantly impact transformer performance and suitability for specific applications.

Silicon Steel

Key Properties: Silicon steel is known for its excellent magnetic properties, which enhance efficiency in transformer cores. It typically has a temperature rating of up to 150°C and offers good resistance to oxidation and corrosion.

Pros & Cons:

– Advantages: Silicon steel is durable and has low hysteresis losses, making it ideal for energy-efficient transformers. Its manufacturing process is well-established, leading to relatively lower costs.

– Disadvantages: While it is durable, silicon steel can be brittle and may require careful handling during installation. Additionally, it may not perform as well in high-frequency applications.

Impact on Application: Silicon steel is suitable for oil-immersed transformers and is often used in medium to high voltage applications due to its magnetic efficiency.

Considerations for International Buyers: Buyers from regions such as Africa and the Middle East should ensure compliance with international standards like ASTM A677 for electrical steel. Understanding local availability and sourcing options is crucial to avoid supply chain disruptions.

Copper

Key Properties: Copper is renowned for its excellent electrical conductivity, thermal conductivity, and resistance to corrosion. It can withstand high temperatures, with ratings often exceeding 200°C.

Pros & Cons:

– Advantages: Copper’s high conductivity leads to lower energy losses, making it a preferred choice for windings in transformers. Its durability and corrosion resistance also contribute to a longer lifespan.

– Disadvantages: The primary drawback of copper is its cost, which is significantly higher than aluminum. Additionally, its weight can complicate installation and transportation.

Impact on Application: Copper is ideal for high-performance transformers where efficiency is paramount, particularly in regions with stringent energy regulations.

Considerations for International Buyers: Buyers in Europe and South America should be aware of fluctuating copper prices and consider long-term contracts to mitigate risks. Compliance with environmental standards related to mining and sourcing is also essential.

Aluminum

Key Properties: Aluminum offers good electrical conductivity (about 60% that of copper) and is lightweight, making it easier to handle. Its temperature rating is similar to copper, typically around 200°C.

Pros & Cons:

– Advantages: The lower cost and lightweight nature of aluminum make it an attractive option for large-scale transformers. It is also resistant to corrosion, particularly in humid environments.

– Disadvantages: Aluminum has lower conductivity compared to copper, which can lead to increased energy losses. Its mechanical strength is also lower, potentially affecting durability in harsh conditions.

Impact on Application: Aluminum is commonly used in lower-voltage transformers and applications where weight is a critical factor, such as in mobile or temporary installations.

Considerations for International Buyers: Buyers from regions like Turkey and Indonesia should evaluate local aluminum production capabilities and standards, such as ISO 9001 for quality management. Understanding the trade-offs between weight and performance is crucial.

Composite Materials

Key Properties: Composite materials, often used in insulation and structural components, offer excellent strength-to-weight ratios and resistance to environmental factors. Their temperature ratings can vary widely based on the specific composition.

Pros & Cons:

– Advantages: Composites can enhance the overall performance of transformers by providing lightweight, durable, and corrosion-resistant options. They also allow for design flexibility.

– Disadvantages: The manufacturing process can be complex and costly, which may lead to higher initial investments. Additionally, not all composites are suitable for high-voltage applications.

Impact on Application: Composites are increasingly used in modern transformer designs, particularly in applications requiring advanced insulation and weight reduction.

Considerations for International Buyers: Buyers in Africa and South America should assess the availability of composite materials and their compliance with international standards like IEC 60076 for power transformers. Understanding local manufacturing capabilities can also influence material selection.

Summary Table

| Material | Typical Use Case for transformer types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Steel | Medium to high voltage transformers | Low hysteresis losses | Brittle, requires careful handling | Medium |

| Copper | High-performance transformers | Excellent conductivity and durability | High cost, heavy | High |

| Aluminum | Lower-voltage transformers | Lightweight and cost-effective | Lower conductivity, less durable | Low |

| Composite Materials | Advanced insulation applications | Lightweight and corrosion-resistant | Complex manufacturing process | Medium to High |

This strategic material selection guide provides essential insights for international B2B buyers, helping them make informed decisions based on performance, cost, and regional compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for transformer types

The manufacturing processes for transformers are intricate and multifaceted, requiring attention to detail at every stage. This section delves into the typical manufacturing processes and quality assurance mechanisms that are crucial for B2B buyers in the international market, particularly those from Africa, South America, the Middle East, and Europe.

Manufacturing Processes

1. Material Preparation

The first step in transformer manufacturing involves the selection and preparation of raw materials. Key materials include:

- Silicon Steel: Used for the core due to its magnetic properties.

- Copper or Aluminum: Used for windings, chosen based on conductivity and cost.

- Insulation Materials: Such as paper, oil, or synthetic materials, which are crucial for safety and performance.

Effective sourcing and quality checks of these materials ensure optimal performance and longevity of the transformers.

2. Forming

This stage involves shaping the raw materials into components:

- Core Formation: The silicon steel sheets are cut, stacked, and assembled to form the core. Techniques such as laser cutting and stamping are commonly used to ensure precision.

- Winding: The wire (copper or aluminum) is wound around the core in precise layers. This process can be automated for consistency and efficiency, utilizing machines that monitor tension and placement.

3. Assembly

In the assembly phase, various components are brought together:

- Component Integration: The windings are connected to the core, and other parts like bushings and terminals are integrated.

- Sealing and Insulation: Insulating materials are applied to prevent electrical leakage. This stage is crucial for ensuring safety and efficiency.

4. Finishing

The final touches to a transformer include:

- Testing: Each unit undergoes rigorous testing to ensure it meets performance standards.

- Painting and Coating: Protective coatings are applied to enhance durability against environmental factors.

- Packaging: Proper packaging is essential for safe transportation, particularly for international shipments.

Quality Assurance

Quality assurance (QA) is a critical component of transformer manufacturing, ensuring that products meet both international standards and customer expectations.

International Standards

B2B buyers should look for manufacturers that adhere to recognized international standards, including:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently produce products that meet customer and regulatory requirements.

- CE Marking: Indicates compliance with European safety standards, crucial for buyers in Europe.

- API Standards: For transformers used in the oil and gas industry, adherence to American Petroleum Institute standards is essential.

Quality Control Checkpoints

Quality control (QC) is typically conducted at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Checks raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing to identify and rectify issues promptly.

- Final Quality Control (FQC): Comprehensive testing of the finished product to ensure it meets all performance and safety standards.

Common Testing Methods

Testing methodologies can include:

- Electrical Testing: Such as insulation resistance tests and power factor tests.

- Thermal Imaging: To identify hotspots that could indicate potential failures.

- Mechanical Testing: Assessing physical durability through vibration and impact tests.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s QC processes is essential to mitigate risks associated with product quality. Here are actionable steps:

-

Conduct Supplier Audits: Regular audits can help assess the manufacturing processes and adherence to quality standards. Request access to audit reports and findings.

-

Request Documentation: Ask for certificates of compliance with international standards (ISO, CE, etc.) and detailed QC reports that outline testing methods and results.

-

Third-Party Inspections: Engage independent inspection agencies to verify manufacturing practices and product quality before shipment. This is particularly beneficial for buyers in regions where local quality assurance may not be as stringent.

QC and Certification Nuances for International Buyers

When sourcing transformers internationally, B2B buyers should be aware of certain nuances:

-

Local Regulations: Each country may have specific regulations regarding electrical equipment. Understanding these can prevent costly compliance issues.

-

Cultural Differences: Different regions may have varying approaches to quality assurance. Familiarize yourself with local manufacturing practices and standards to better evaluate potential suppliers.

-

Language Barriers: Ensure that all communications, contracts, and quality documentation are clear and understandable. Consider hiring local experts if language differences pose a challenge.

Conclusion

Understanding the manufacturing processes and quality assurance mechanisms for transformers is vital for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control practices, buyers can make informed decisions that align with their operational needs. By verifying suppliers through audits, documentation, and third-party inspections, buyers can ensure that they are receiving high-quality products that meet global standards.

Related Video: Extreme Power Transformer Manufacturing Process – How It’s Made

Comprehensive Cost and Pricing Analysis for transformer types Sourcing

When sourcing transformers, understanding the cost structure and pricing dynamics is crucial for international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. A comprehensive analysis of these elements can lead to better negotiation outcomes and cost efficiencies.

Cost Components

-

Materials: The cost of raw materials is a significant portion of transformer pricing. Key components include copper for windings, silicon steel for cores, and insulating materials. Fluctuations in global commodity prices can impact overall costs, making it essential for buyers to monitor market trends.

-

Labor: Labor costs vary by region and can significantly affect the pricing of transformers. In areas with lower labor costs, such as parts of South America and Africa, buyers might find more competitive pricing. However, the skill level and experience of the workforce also play a critical role in production quality.

-

Manufacturing Overhead: This includes expenses related to facilities, equipment, and utilities. Manufacturers in regions with advanced technology may have higher overhead costs, but this often correlates with better quality and efficiency.

-

Tooling: Custom tooling for specific transformer types can add to the initial costs. Buyers should assess whether the investment in custom tooling will yield long-term savings or operational efficiencies.

-

Quality Control (QC): Ensuring that transformers meet specific standards often involves additional QC costs. Certifications (such as ISO or IEC standards) can enhance reliability but may also increase the price. Buyers should consider the balance between cost and quality assurance.

-

Logistics: Shipping and handling costs can vary significantly based on the destination and shipping terms. Buyers should factor in both domestic and international logistics when calculating total costs.

-

Margin: The manufacturer’s profit margin is influenced by competition, production costs, and market demand. Understanding the typical margins in the industry can help buyers gauge whether a quote is reasonable.

Price Influencers

-

Volume/MOQ: Higher order volumes often lead to reduced per-unit costs. Buyers should negotiate minimum order quantities (MOQs) that balance their needs with cost efficiency.

-

Specifications/Customization: Custom transformers tailored to specific applications can incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality/Certifications: The choice of materials and required certifications will heavily influence pricing. Investing in higher-quality materials can lead to longer-lasting products, impacting the Total Cost of Ownership (TCO).

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium but often provide better service and product quality.

-

Incoterms: The terms of shipping (Incoterms) can significantly affect total costs. Buyers should understand the implications of terms like FOB (Free On Board) versus CIF (Cost, Insurance, and Freight) to ensure clarity in pricing.

Buyer Tips

-

Negotiation: Leverage market research to negotiate better pricing. Understanding the cost structure can provide leverage during discussions.

-

Cost-Efficiency: Focus on TCO rather than just initial purchase price. Consider factors like energy efficiency, maintenance costs, and lifespan when evaluating options.

-

Pricing Nuances: Be aware of regional pricing differences. Factors such as local tariffs, taxes, and supply chain dynamics can impact costs.

-

Market Research: Regularly analyze trends in transformer pricing and materials to stay informed and make strategic purchasing decisions.

Disclaimer

Prices for transformers are indicative and can vary based on multiple factors, including market conditions, supplier negotiations, and specific project requirements. Always consult with suppliers for the most accurate and up-to-date pricing.

Spotlight on Potential transformer types Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘transformer types’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for transformer types

When engaging in international B2B transactions for transformers, understanding the essential technical properties and trade terminology is crucial. This knowledge not only aids in making informed purchasing decisions but also enhances communication with suppliers and partners.

Key Technical Properties

-

Material Grade

The material grade of a transformer, typically related to the core and windings, directly affects efficiency and performance. High-grade silicon steel, for example, reduces energy losses and enhances magnetic properties. For buyers, selecting the right material grade is vital for meeting energy efficiency standards and ensuring long-term reliability. -

Tolerance Levels

Tolerance levels refer to the allowable deviations in dimensions and electrical properties. Tight tolerances are essential for ensuring optimal transformer performance and reliability, especially in precision applications. Buyers should seek suppliers who can meet stringent tolerance requirements to avoid potential operational failures. -

Efficiency Ratings

Efficiency ratings indicate how effectively a transformer converts input energy to output energy, often expressed as a percentage. Higher efficiency ratings mean lower operational costs and reduced energy waste. Understanding these ratings helps buyers assess the long-term cost implications of their purchases and aligns with sustainability goals. -

Temperature Rise

This specification measures the maximum temperature increase that a transformer can withstand during operation. It is critical for ensuring that the transformer operates within safe thermal limits. Buyers should consider the environmental conditions in their region, as high ambient temperatures may necessitate transformers with lower temperature rise ratings. -

Short-Circuit Current Rating (SCCR)

The SCCR indicates the maximum short-circuit current a transformer can endure without damage. This property is essential for safety and compliance with electrical codes. Buyers should ensure that the transformers they purchase have adequate SCCR ratings to protect their systems in case of fault conditions.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers, as it often influences product quality and warranty conditions. Partnering with reputable OEMs can ensure the reliability of the transformers being purchased. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. It is an important consideration for buyers, particularly those in emerging markets, as it can impact inventory management and cash flow. Negotiating favorable MOQs can lead to cost savings and better supply chain efficiency. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting price estimates for specific products or services. This process allows buyers to compare offers from multiple suppliers and make informed purchasing decisions. Crafting a detailed RFQ can lead to better pricing and terms, especially in competitive markets. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for negotiating shipping responsibilities, risk management, and cost allocation. Clear agreements on Incoterms can prevent misunderstandings and disputes. -

Lead Time

Lead time refers to the time it takes for an order to be fulfilled, from placement to delivery. It is critical for planning and scheduling in projects, especially in sectors where transformers are integral to operations. Buyers should inquire about lead times to ensure that they align with project timelines and avoid delays.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of transformer procurement more effectively, ensuring they make informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the transformer types Sector

Market Overview & Key Trends

The transformer types sector is currently experiencing dynamic shifts driven by technological advancements, increasing demand for renewable energy, and the need for efficient power distribution. In regions such as Africa and South America, rapid urbanization and industrial growth are propelling the demand for reliable electrical infrastructure. Meanwhile, Europe and the Middle East are witnessing a transition towards smart grid technologies, which require advanced transformer solutions that enhance efficiency and reduce losses.

Emerging trends in B2B sourcing include the adoption of digital platforms for procurement processes, enabling buyers to access a wider range of suppliers and products. E-commerce in the industrial sector is gaining traction, allowing international buyers to compare prices, specifications, and lead times easily. Additionally, the rise of Industry 4.0 is encouraging the integration of IoT-enabled transformers, which provide real-time data analytics and predictive maintenance capabilities.

For international buyers, understanding the local market dynamics is crucial. In Africa, for instance, the varying regulatory environments and infrastructure challenges necessitate a tailored approach to sourcing transformers. South American countries are increasingly prioritizing energy efficiency, which influences purchasing decisions. In contrast, European buyers are focusing on compliance with stringent environmental regulations, which affects the selection of transformer types and manufacturers.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of strategic sourcing in the transformer types sector. The environmental impact of traditional transformers, particularly in terms of energy losses and greenhouse gas emissions, is prompting a shift towards greener alternatives. B2B buyers are increasingly prioritizing suppliers that utilize sustainable materials and practices, such as recyclable components and low-impact manufacturing processes.

The importance of ethical supply chains cannot be overstated. Buyers are encouraged to engage with suppliers who adhere to international labor standards and promote fair trade practices. This not only enhances brand reputation but also mitigates risks associated with sourcing from regions with weaker labor laws.

Certifications such as ISO 14001 for environmental management and IEC 60076 for transformer efficiency are becoming vital considerations in the procurement process. These certifications provide assurance that suppliers are committed to sustainability and can meet the growing demands for green products. Furthermore, opting for transformers designed with eco-friendly materials, such as bio-based insulation oils, can significantly reduce environmental footprints.

Brief Evolution/History

The transformer industry has evolved significantly over the past century, transitioning from simple step-up and step-down transformers to sophisticated, multifunctional devices. Initially developed to facilitate long-distance power transmission, transformers have now integrated advanced technologies, including smart monitoring systems and enhanced materials that improve energy efficiency.

This evolution is influenced by the growing demand for renewable energy sources and the need for smarter electrical grids. As countries around the globe strive to meet energy demands sustainably, the transformer sector continues to innovate, aligning itself with the broader goals of energy transition and sustainability. For international B2B buyers, understanding this historical context is essential for making informed purchasing decisions that align with future trends.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of transformer types

-

What should I consider when vetting suppliers for transformers?

When vetting suppliers, prioritize their industry experience, production capacity, and reputation. Verify certifications such as ISO standards and compliance with local regulations in your region. Request references from previous clients and evaluate their responsiveness and customer service. Conducting a factory audit can also provide insights into their operational standards and quality control processes. Additionally, check for their ability to offer customized solutions to meet specific project requirements. -

Can transformers be customized to fit my specific needs?

Yes, many manufacturers offer customization options for transformers. This can include adjustments to voltage ratings, size, and insulation types, among other features. When discussing customization, provide detailed specifications of your requirements and inquire about the supplier’s previous projects that involved custom solutions. It’s essential to assess any additional costs and lead times associated with custom orders to ensure they align with your project timeline and budget. -

What are the typical minimum order quantities (MOQ) and lead times?

MOQs for transformers can vary widely based on the supplier and type of transformer. Generally, larger orders may reduce the per-unit cost, but smaller orders are often accommodated at a higher price point. Lead times also depend on the complexity of the transformer and the supplier’s current workload. Always clarify these aspects upfront to avoid delays in your project and ensure that your procurement strategy aligns with your operational needs. -

What payment terms should I expect when sourcing transformers internationally?

Payment terms can vary by supplier and region. Common options include upfront payments, letters of credit, and payment on delivery. It’s advisable to negotiate terms that provide sufficient protection for both parties. Consider using an escrow service for larger transactions to ensure that funds are released only upon satisfactory delivery. Additionally, familiarize yourself with currency exchange rates and potential banking fees that could affect your total cost. -

How can I ensure the quality of the transformers I purchase?

To ensure quality, request comprehensive quality assurance documentation, including test reports and certifications. A reputable supplier should provide details about their manufacturing processes, testing protocols, and compliance with international standards. Consider conducting third-party inspections before shipment, especially for large orders. Establishing a clear quality agreement in your contract can also help mitigate risks associated with product quality. -

What certifications should I look for in transformer suppliers?

Key certifications to look for include ISO 9001 for quality management systems, ISO 14001 for environmental management, and specific regional certifications like CE marking in Europe or UL listing in North America. These certifications indicate adherence to international standards and can greatly enhance reliability. Additionally, inquire about compliance with local electrical safety standards relevant to your region to ensure safe and efficient operation. -

What logistics considerations should I keep in mind when importing transformers?

Logistics is a crucial aspect of importing transformers. Consider the mode of transport (air vs. sea) based on your budget and urgency. Factor in customs clearance processes, tariffs, and local regulations that may affect delivery. Work with a freight forwarder experienced in handling heavy equipment to navigate these complexities. Ensure that the packaging is suitable for long-distance transport to prevent damage during transit.

- How should I handle disputes with suppliers?

To effectively manage disputes, establish clear communication channels and a detailed contract that outlines terms, conditions, and expectations. In case of a disagreement, attempt to resolve the issue amicably through direct negotiation. If necessary, consider mediation or arbitration as alternatives to litigation, which can be time-consuming and costly. Keeping thorough documentation of all communications and transactions can also provide critical evidence should the dispute escalate.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for transformer types

In summary, strategic sourcing of transformer types is pivotal for international B2B buyers aiming to optimize their supply chains and enhance operational efficiency. Key takeaways include understanding the diverse types of transformers available, evaluating suppliers based on technical specifications and reliability, and considering the total cost of ownership beyond initial purchase price.

Actionable Insights:

– Market Research: Conduct thorough market analysis to identify reputable suppliers and emerging trends in transformer technology.

– Supplier Relationships: Cultivate strong partnerships with manufacturers and distributors to ensure consistent quality and support.

– Regulatory Compliance: Stay informed about regional regulations and standards, particularly in Africa, South America, the Middle East, and Europe, to avoid costly compliance issues.

As the global energy landscape continues to evolve, embracing innovative transformer solutions will be essential for staying competitive. B2B buyers are encouraged to leverage these insights and actively engage with suppliers to secure the most suitable transformer types for their needs. The future is bright for those who prioritize strategic sourcing in their procurement strategies—now is the time to act decisively and position your business for success.