Your Ultimate Guide to Sourcing Roller Tables

Introduction: Navigating the Global Market for roller tables

In today’s dynamic global market, roller tables stand out as essential components for various industrial applications, ranging from manufacturing to logistics. These versatile systems facilitate the smooth movement of goods and materials, enhancing operational efficiency and productivity. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the nuances of roller tables is crucial for making informed sourcing decisions.

This comprehensive guide delves into the diverse types of roller tables available, including manual and motorized options, and explores the various materials used in their construction, such as aluminum and steel. Buyers will benefit from insights into the manufacturing processes and quality control standards that ensure product reliability and performance. Additionally, the guide outlines key suppliers and manufacturers, helping buyers identify reputable sources that can meet their specific needs.

Furthermore, we provide a detailed analysis of cost factors, enabling buyers to evaluate their investment effectively. The market landscape is examined, highlighting trends and opportunities that can influence purchasing decisions. To address common concerns, an FAQ section offers clarity on maintenance, installation, and customization options.

By equipping international B2B buyers with this wealth of information, this guide empowers them to navigate the global market for roller tables confidently, ensuring they select the best solutions to drive their business forward.

Understanding roller tables Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gravity Roller Tables | Utilizes gravity to move items; no power source required. | Material handling, assembly lines, shipping. | Pros: Low maintenance, cost-effective. Cons: Limited control over speed and direction. |

| Powered Roller Tables | Equipped with electric motors for controlled movement. | Automated warehouses, distribution centers. | Pros: High efficiency, adjustable speed. Cons: Higher initial investment, requires power supply. |

| Ball Transfer Tables | Features multiple ball bearings for multidirectional movement. | Packaging, sorting applications. | Pros: Versatile, allows easy product rotation. Cons: Less effective for heavy loads. |

| Flat Top Roller Tables | Flat surface allows for stable load movement. | Manufacturing, assembly processes. | Pros: Stable for delicate items, easy to clean. Cons: Limited to flat-bottomed products. |

| Custom Roller Tables | Tailored design to specific operational needs. | Unique applications across various industries. | Pros: Optimized for specific tasks, flexible design. Cons: Longer lead times, potentially higher costs. |

Gravity Roller Tables

Gravity roller tables are designed to leverage gravitational force to facilitate the movement of goods. They consist of a series of rollers mounted on a slight incline, allowing products to roll down without the need for power. These tables are ideal for environments where a simple, low-maintenance solution is required, such as in material handling, assembly lines, and shipping areas. B2B buyers should consider the limitations of gravity rollers, particularly in controlling speed and direction, which can impact efficiency in high-demand operations.

Powered Roller Tables

Powered roller tables incorporate electric motors to provide controlled movement of products. This type of roller table is particularly beneficial in automated warehouses and distribution centers, where speed and efficiency are paramount. Buyers should evaluate their operational needs against the higher initial investment and power requirements associated with these systems. The ability to adjust speed and direction enhances productivity, making them a valuable investment for businesses looking to streamline logistics.

Ball Transfer Tables

Ball transfer tables feature a series of ball bearings that allow items to move in any direction with minimal effort. This design is especially useful in packaging and sorting applications, where products need to be rotated or repositioned frequently. B2B buyers should consider the load capacity and the types of products being handled, as ball transfer tables are less effective for heavier items. Their versatility makes them an excellent choice for dynamic work environments.

Flat Top Roller Tables

Flat top roller tables provide a stable surface for transporting items, making them suitable for various manufacturing and assembly processes. This design is particularly advantageous for delicate products that require a steady platform during movement. Buyers should assess the compatibility of their products with flat-bottom designs, as this type of table may not accommodate irregularly shaped items. The ease of cleaning and maintenance is an added benefit for industries requiring high hygiene standards.

Custom Roller Tables

Custom roller tables are designed to meet specific operational requirements, offering tailored solutions for unique applications across various industries. These tables allow businesses to optimize their workflow and enhance productivity. However, B2B buyers must consider the potential for longer lead times and higher costs associated with custom designs. Engaging with manufacturers early in the purchasing process can help ensure that the final product aligns with operational needs and budget constraints.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of roller tables

| Industry/Sector | Specific Application of Roller Tables | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Assembly Line Automation | Increases efficiency and reduces labor costs | Ensure compatibility with existing machinery and load capacity requirements. |

| Logistics & Warehousing | Material Handling and Transportation | Enhances product flow and minimizes handling time | Assess durability and maintenance needs for long-term operation. |

| Automotive | Precision Component Positioning for Assembly | Improves accuracy in assembly processes | Focus on precision specifications and supplier reliability. |

| Food & Beverage | Conveyor Systems for Product Movement | Streamlines operations and reduces product damage | Evaluate hygiene standards and ease of cleaning. |

| Electronics | Testing and Inspection Stations for Components | Facilitates quality control and reduces defect rates | Look for customization options to fit specific testing needs. |

Detailed Applications of Roller Tables

Manufacturing

In manufacturing environments, roller tables are essential for assembly line automation. They facilitate the smooth movement of products between workstations, significantly increasing efficiency and reducing labor costs. By implementing roller tables, businesses can streamline production processes, minimize bottlenecks, and enhance overall workflow. For international buyers, it is crucial to verify that the roller tables can integrate seamlessly with existing machinery and meet specific load capacity requirements to ensure optimal performance.

Logistics & Warehousing

In logistics and warehousing, roller tables are utilized for material handling and transportation of goods. They enhance product flow, allowing for quicker loading and unloading of items, which minimizes handling time and improves warehouse efficiency. For businesses in Africa and South America, where logistics can be challenging, investing in durable roller tables can mitigate delays and optimize inventory management. Buyers should consider the durability of the roller tables and their maintenance needs to ensure long-term operational reliability.

Automotive

The automotive industry relies heavily on roller tables for precision component positioning during assembly. These tables provide the necessary accuracy to ensure that parts are aligned correctly, which is vital for quality control in vehicle manufacturing. For B2B buyers in Europe, particularly in Poland where automotive manufacturing is significant, sourcing roller tables that meet precision specifications is essential. Additionally, selecting a reliable supplier can greatly impact production efficiency and product quality.

Food & Beverage

In the food and beverage sector, roller tables are commonly used in conveyor systems for product movement. They help streamline operations, reduce manual handling, and minimize product damage during transport. For businesses in the Middle East, where hygiene standards are paramount, it is important to evaluate the hygiene specifications of roller tables and ensure they are easy to clean. This not only complies with health regulations but also maintains product integrity.

Electronics

In the electronics industry, roller tables serve as testing and inspection stations for components. They enable precise positioning of products, which is crucial for quality control and reducing defect rates. Buyers from South America should look for roller tables that offer customization options to fit specific testing needs, ensuring that they can accommodate various product sizes and types. This adaptability can significantly enhance operational efficiency and product reliability.

Related Video: Roller Conveyors | How It’s Made

Strategic Material Selection Guide for roller tables

When selecting materials for roller tables, international B2B buyers must consider various factors that affect performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in the manufacturing of roller tables, focusing on their properties, advantages, disadvantages, and implications for specific applications.

Aluminum

Aluminum is a lightweight and corrosion-resistant material, making it an ideal choice for roller tables used in environments where weight and resistance to oxidation are critical. It typically has a temperature rating of up to 150°C and is suitable for medium loads.

Pros:

– Excellent corrosion resistance, which is beneficial in humid or chemically aggressive environments.

– Lightweight, facilitating easier handling and installation.

– Good thermal and electrical conductivity.

Cons:

– Lower load-bearing capacity compared to steel.

– More expensive than some other materials like plastic or mild steel.

– Can be prone to deformation under high stress.

Impact on Application:

Aluminum roller tables are well-suited for applications involving light to medium loads and environments requiring resistance to corrosion. They are commonly used in food processing and pharmaceutical industries.

Considerations for International Buyers:

Buyers in Africa and South America should consider local availability and costs, as aluminum can be more expensive. Compliance with standards such as ASTM for material specifications is crucial for ensuring product quality.

Steel

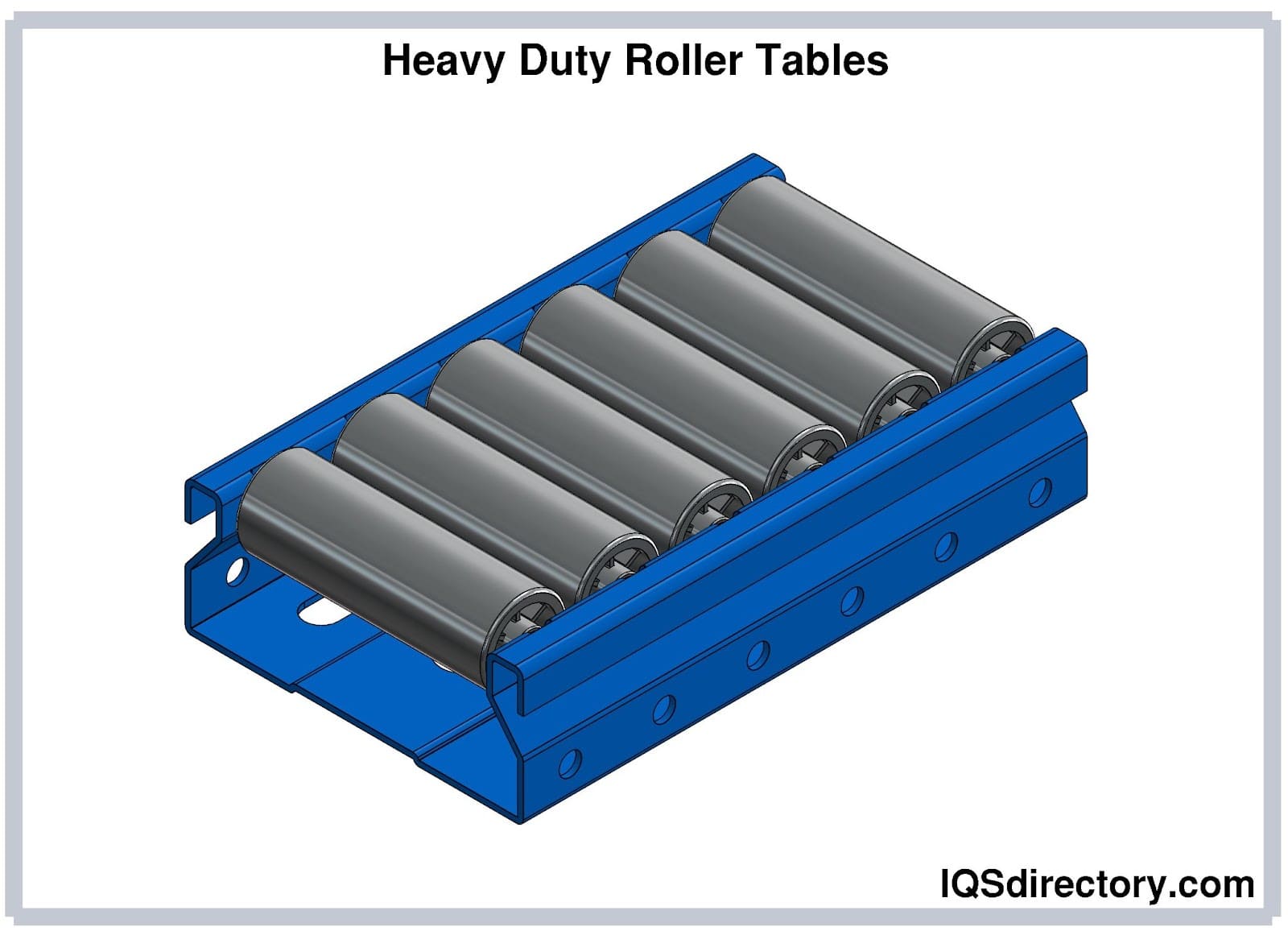

Steel is a traditional choice for roller tables due to its high strength and durability. It can handle heavy loads and is typically rated for temperatures up to 300°C.

Pros:

– Exceptional load-bearing capacity, making it suitable for heavy-duty applications.

– Cost-effective for large-scale production.

– High durability and resistance to wear.

Cons:

– Susceptible to corrosion unless treated or coated.

– Heavier than aluminum, which may complicate installation.

– Requires more energy for manufacturing and processing.

Impact on Application:

Steel roller tables are ideal for manufacturing and logistics applications where heavy loads are common. They are often used in automotive and heavy machinery sectors.

Considerations for International Buyers:

In regions like the Middle East, where humidity can lead to corrosion, buyers should consider galvanized or coated steel options. Compliance with DIN standards is essential for ensuring compatibility with European manufacturing practices.

Plastic

Plastic roller tables, often made from high-density polyethylene (HDPE) or polypropylene, offer a lightweight and corrosion-resistant alternative. They are suitable for applications with lower load requirements and can typically withstand temperatures up to 80°C.

Pros:

– Lightweight and easy to handle, reducing shipping costs.

– Excellent resistance to chemicals and moisture.

– Cost-effective for low-load applications.

Cons:

– Limited load capacity compared to metal options.

– Lower temperature resistance can restrict application use.

– Potential for wear and tear over time.

Impact on Application:

Plastic roller tables are commonly used in packaging, assembly lines, and other applications where weight and corrosion resistance are priorities but where heavy loads are not a concern.

Considerations for International Buyers:

Buyers from Europe and Africa should ensure that plastic materials comply with environmental regulations regarding recyclability and safety standards.

Composite Materials

Composite materials, such as fiberglass-reinforced plastics, combine the benefits of both metals and plastics. They offer high strength-to-weight ratios and can withstand temperatures up to 120°C.

Pros:

– High strength while remaining lightweight.

– Good resistance to corrosion and chemicals.

– Versatile for various applications.

Cons:

– Generally more expensive than traditional materials.

– Manufacturing complexity can lead to longer lead times.

– May require specific handling during installation.

Impact on Application:

Composite roller tables are suitable for specialized applications in aerospace, automotive, and high-tech industries where performance and weight are critical.

Considerations for International Buyers:

Buyers should be aware of the specific certifications required for composite materials in their region, as standards can vary significantly between Africa, South America, and Europe.

Summary Table

| Material | Typical Use Case for roller tables | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Food processing, pharmaceuticals | Excellent corrosion resistance | Lower load-bearing capacity | Medium |

| Steel | Manufacturing, logistics | Exceptional load-bearing capacity | Susceptible to corrosion | Low |

| Plastic | Packaging, assembly lines | Lightweight and cost-effective | Limited load capacity | Low |

| Composite | Aerospace, automotive | High strength-to-weight ratio | Generally more expensive | High |

This guide provides a comprehensive overview of material selection for roller tables, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for roller tables

Manufacturing Processes for Roller Tables

When it comes to the manufacturing of roller tables, several critical stages ensure that the final product meets the rigorous demands of various industries. Understanding these processes helps B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, make informed decisions when sourcing roller tables.

1. Material Preparation

The first stage in manufacturing roller tables involves selecting the right materials. Common materials include:

- Steel: Known for its strength and durability.

- Aluminum: Lightweight and resistant to corrosion, ideal for applications requiring mobility.

- Plastic: Used in applications where weight reduction and cost efficiency are priorities.

Once the materials are selected, they undergo a series of processes, including cutting and shaping, to prepare them for the next stage. Laser cutting and CNC machining are popular techniques that ensure precision and reduce waste.

2. Forming

The forming stage involves shaping the prepared materials into the desired configurations. Key techniques include:

- Welding: For joining metal components, ensuring structural integrity.

- Bending: Often used for creating the frame or support structures of the roller tables.

- Injection Molding: Common for plastic roller tables, allowing for complex shapes and designs.

These methods are chosen based on the material properties and the specific design requirements of the roller tables being produced.

3. Assembly

Once the components are formed, they proceed to the assembly stage. This process typically involves:

- Integration of Components: Aligning and securing rollers, bearings, and frames.

- Use of Fasteners: Bolts, screws, and other hardware are used to ensure a robust assembly.

- Quality Control Checks: Initial checks are performed to ensure that components fit correctly and function as intended.

Effective assembly processes can significantly impact the performance and lifespan of roller tables.

4. Finishing

The finishing stage is crucial for enhancing the appearance and performance of roller tables. Common finishing processes include:

- Coating: Powder coating or painting provides a protective layer against wear and corrosion.

- Surface Treatment: Techniques such as anodizing (for aluminum) or galvanization (for steel) enhance durability.

- Polishing: This provides a smooth surface finish, reducing friction and improving aesthetic appeal.

These finishing touches not only improve functionality but also ensure that the product meets industry standards for appearance and durability.

Quality Assurance in Roller Table Manufacturing

Quality assurance (QA) is a critical aspect of roller table manufacturing, ensuring that products meet international standards and customer expectations. B2B buyers should be aware of the following components of the QA process:

Illustrative Image (Source: Google Search)

International Standards

To ensure consistency and reliability, manufacturers often adhere to international quality standards such as:

- ISO 9001: A quality management system standard that emphasizes continuous improvement and customer satisfaction.

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Standards: Relevant for manufacturers producing roller tables for the oil and gas industry, ensuring products meet specific operational requirements.

These certifications not only enhance product credibility but also facilitate smoother trade across borders.

Key Quality Control Checkpoints

Quality control (QC) is integrated into various stages of the manufacturing process, with specific checkpoints:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify and rectify defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished roller tables before shipment to verify performance and compliance with specifications.

Common Testing Methods

Manufacturers employ various testing methods to ensure quality, including:

- Load Testing: To verify the load-bearing capacity of roller tables.

- Durability Testing: Simulating operational conditions to assess wear and tear over time.

- Dimensional Inspection: Using tools like calipers and micrometers to ensure precise dimensions.

These tests help guarantee that the roller tables will perform reliably in their intended applications.

Verifying Supplier Quality Control

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality is essential. Here are actionable steps to ensure the supplier’s QC processes meet your standards:

- Conduct Audits: Regularly audit suppliers to assess their manufacturing processes, quality control systems, and compliance with international standards.

- Request Quality Reports: Suppliers should provide documentation of their QC processes, including inspection reports and test results.

- Engage Third-Party Inspectors: Consider hiring third-party inspection services to conduct unbiased assessments of the manufacturing facility and products.

- Review Certifications: Ensure that suppliers possess the necessary certifications that align with your industry requirements.

Conclusion

Understanding the manufacturing processes and quality assurance practices for roller tables is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, as well as the importance of adhering to international standards and implementing robust QC measures, buyers can make informed decisions. This knowledge not only aids in selecting the right suppliers but also ensures that the roller tables meet the high standards necessary for operational success in diverse applications.

Related Video: Business English Vocabulary : VV 47 – Manufacturing & Production Process (1) | English Vocabulary

Comprehensive Cost and Pricing Analysis for roller tables Sourcing

When sourcing roller tables, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. The cost components that contribute to the final price include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

Cost Components

-

Materials: The primary materials used in roller tables typically include steel, aluminum, and various polymers. The choice of material significantly impacts both the performance and the cost. For instance, high-grade steel may enhance durability but can increase costs.

-

Labor: Labor costs vary by region and can be influenced by local wage standards. In countries with lower labor costs, such as those in parts of Africa and South America, you might find more competitive pricing. However, this can sometimes come with trade-offs in quality or delivery times.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help lower these overhead costs.

-

Tooling: Custom tooling for specialized roller tables can add to the initial investment. For standard models, tooling costs are generally amortized over larger production runs, which can lower the per-unit cost.

-

Quality Control (QC): Investing in robust QC processes ensures the reliability of the roller tables. This can involve additional costs but is essential for maintaining quality, especially for critical applications.

-

Logistics: Shipping costs can vary significantly based on the destination, mode of transport, and current global shipping rates. Buyers should consider Incoterms that best suit their shipping needs, as they define who bears the cost and risk at each stage of transportation.

-

Margin: Supplier margin is influenced by market competition and the supplier’s operational efficiencies. Buyers should research multiple suppliers to understand the typical markup in their region.

Price Influencers

Several factors can influence the pricing of roller tables:

-

Volume/MOQ: Larger orders often qualify for bulk pricing discounts. It’s beneficial to negotiate minimum order quantities (MOQs) to achieve better rates.

-

Specifications/Customization: Customized roller tables tailored to specific applications will generally come at a premium. Clearly defining your requirements can help suppliers provide more accurate quotes.

-

Materials: The choice of materials can affect both cost and performance. Higher quality or specialized materials may increase the price but can lead to greater longevity and reduced maintenance.

-

Quality/Certifications: Suppliers with recognized quality certifications (such as ISO) may command higher prices, but this often translates into greater reliability and lower Total Cost of Ownership (TCO).

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can all impact pricing. Engaging with reputable suppliers can mitigate risks associated with quality and delivery.

-

Incoterms: Understanding Incoterms is crucial for international buyers. They determine the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect total costs.

Buyer Tips

-

Negotiation: Always negotiate pricing and terms. Suppliers may have flexibility in pricing, especially for larger orders or long-term contracts.

-

Cost-Efficiency: Consider the Total Cost of Ownership rather than just the upfront price. Evaluate maintenance, durability, and operational efficiencies over the lifespan of the roller tables.

-

Pricing Nuances: Be aware of fluctuations in raw material prices and shipping costs, as these can affect quotes and final pricing. Establishing relationships with multiple suppliers can provide leverage during negotiations.

Disclaimer

Prices can vary widely based on market conditions, supplier capabilities, and specific project requirements. It is advisable for buyers to conduct thorough market research and request quotes from multiple suppliers to ascertain competitive pricing.

Spotlight on Potential roller tables Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘roller tables’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for roller tables

Roller tables are critical components in various industries, facilitating the efficient movement of materials and products. Understanding their essential technical properties and relevant trade terminology is crucial for international B2B buyers looking to make informed purchasing decisions.

Key Technical Properties of Roller Tables

-

Material Grade

– The material used in roller tables, such as steel, aluminum, or plastic, significantly affects durability and load capacity. Higher-grade materials typically offer increased strength and longevity, making them suitable for heavy-duty applications. Buyers should assess the environmental conditions (e.g., humidity, temperature) to select the appropriate material. -

Load Capacity

– This specification indicates the maximum weight the roller table can support. It’s crucial for buyers to match the load capacity with their operational requirements to prevent equipment failure. Overloading can lead to safety hazards and increased maintenance costs. -

Tolerance

– Tolerance refers to the allowable deviation from specified dimensions. For roller tables, maintaining tight tolerances ensures accurate positioning and smooth operation. Precision is essential in applications requiring high accuracy, such as in robotics or automated systems. -

Roller Diameter and Spacing

– The size and arrangement of rollers affect how easily items can move across the table. Larger rollers typically allow for smoother movement and can support heavier loads. Proper spacing is also vital to prevent jamming and ensure consistent performance. -

Surface Finish

– The finish of the roller table’s surface impacts friction and wear. A smoother surface reduces drag, facilitating easier movement of goods. Buyers should consider the nature of the items being transported; for example, delicate products may require a specific finish to avoid damage. -

Drive Mechanism

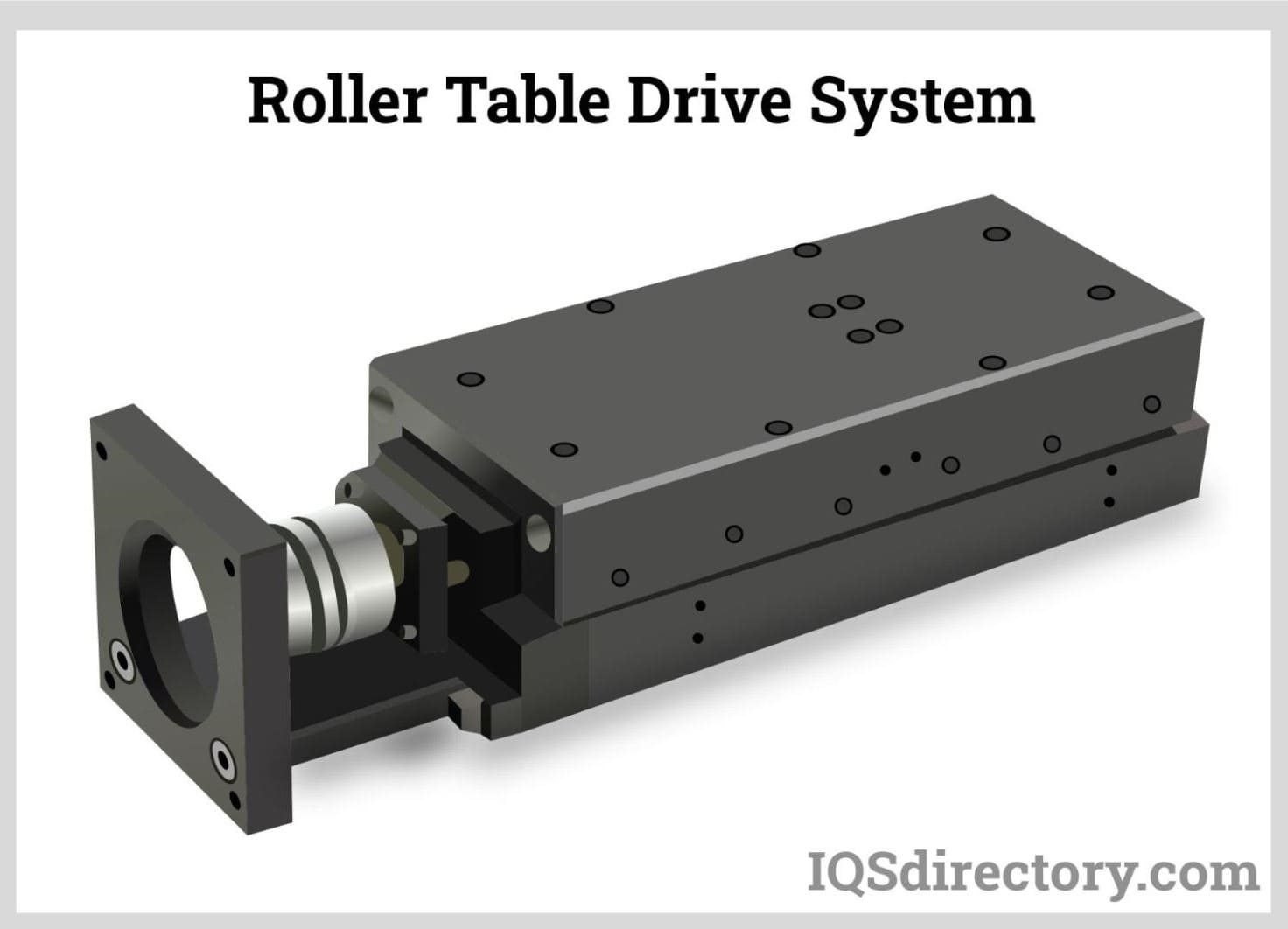

– Roller tables can be powered by different mechanisms, such as electric motors, hydraulic systems, or manual operation. The choice of drive mechanism influences operational efficiency and maintenance requirements. Buyers should evaluate the available power sources and their compatibility with the intended application.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce components that are used in another company’s end products. For buyers, partnering with OEMs can ensure quality and compatibility when sourcing roller tables. -

MOQ (Minimum Order Quantity)

– This is the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for buyers to plan their procurement strategy and manage inventory effectively, especially for businesses with limited storage capabilities. -

RFQ (Request for Quotation)

– An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. For international buyers, issuing an RFQ can facilitate competitive bidding and ensure they receive the best value for roller tables. -

Incoterms (International Commercial Terms)

– These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for buyers to understand their obligations and risks in cross-border transactions. -

Lead Time

– Lead time refers to the time it takes from placing an order to receiving the goods. Buyers must consider lead times when planning their production schedules and inventory levels, particularly when sourcing from international suppliers. -

Warranty

– A warranty is a supplier’s promise regarding the quality and longevity of their product. Understanding the warranty terms is vital for buyers to assess the risk associated with their investment in roller tables and to ensure they are protected against defects.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of roller table procurement, ensuring they select the right products for their operational needs while minimizing risks and costs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the roller tables Sector

Global demand for roller tables continues to rise, driven by the increasing need for automation in manufacturing and logistics. As industries embrace Industry 4.0, roller tables are pivotal in enhancing operational efficiency and reducing labor costs. Key trends include the integration of smart technologies, such as IoT-enabled sensors that monitor load capacities and performance, allowing for real-time adjustments and predictive maintenance. Additionally, there is a growing trend towards modular designs, which offer flexibility in configurations to meet diverse operational needs.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding regional market dynamics is essential. In Europe, for instance, there is a strong emphasis on advanced engineering and precision manufacturing, which influences sourcing decisions. In contrast, emerging markets in Africa and South America may prioritize cost-effectiveness and scalability. Buyers should also consider supplier capabilities in customization and quick turnaround times, as these factors can significantly impact operational efficiency.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

The roller table sector is increasingly recognizing the importance of sustainability and ethical sourcing. As environmental regulations tighten globally, companies are under pressure to minimize their ecological footprint. Environmental impacts of roller table production include energy consumption, waste generation, and the use of non-recyclable materials. B2B buyers must evaluate suppliers based on their sustainability practices, such as using recycled materials and adopting energy-efficient manufacturing processes.

Moreover, the significance of ethical supply chains cannot be overstated. Buyers should seek suppliers that adhere to fair labor practices and have transparent sourcing strategies. Certifications such as ISO 14001 for environmental management systems and other ‘green’ certifications can provide assurance regarding a supplier’s commitment to sustainability. Utilizing materials that are sustainably sourced, such as recycled metals or eco-friendly coatings, can not only reduce environmental impact but also enhance brand reputation in the marketplace.

Brief Evolution/History

Roller tables have evolved significantly since their inception, transitioning from simple mechanical devices to sophisticated systems integrated with advanced technology. Early roller tables were primarily used in manual assembly lines, facilitating the movement of goods. Over time, as automation took center stage, these tables adapted to accommodate automated processes, becoming essential components in modern manufacturing and logistics. This evolution reflects broader trends in industry, where efficiency, adaptability, and sustainability have become critical in meeting the demands of a globalized market. As technology continues to advance, the roller table sector is poised for further innovation, offering new solutions for B2B buyers.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of roller tables

-

What factors should I consider when vetting suppliers of roller tables?

When vetting suppliers, prioritize their experience in the industry, their reputation, and customer reviews. Request references and check if they have a proven track record with international clients, particularly in your region. Evaluate their manufacturing capabilities, including technology and quality control processes. Ensure they comply with international standards and certifications relevant to your industry. A good supplier should also be open to communication and provide detailed product information, including specifications and materials used. -

Can I customize roller tables to meet my specific needs?

Yes, most reputable manufacturers offer customization options for roller tables. When inquiring about customization, specify your requirements regarding dimensions, load capacity, material, and any special features you may need. It’s essential to discuss these details early in the negotiation process to ensure the supplier can meet your expectations. Be prepared to share your application needs and any relevant technical drawings, which can help the manufacturer provide a tailored solution. -

What are the typical minimum order quantities (MOQs) and lead times for roller tables?

MOQs can vary significantly between suppliers and depend on the customization requirements. For standard models, some suppliers may accept orders as low as 10 units, while customized solutions might have higher MOQs. Lead times generally range from 4 to 12 weeks, depending on the complexity of the order and the supplier’s production capacity. It’s advisable to clarify these details upfront and factor them into your project timelines to avoid delays. -

What payment terms are common when sourcing roller tables internationally?

Payment terms can vary widely based on the supplier and your negotiation. Common practices include a deposit (usually 30-50%) upfront, with the balance payable upon delivery or prior to shipping. Some suppliers may offer letters of credit or escrow services for larger transactions to mitigate risk. Ensure you understand the supplier’s payment policies and negotiate terms that protect your interests, especially when dealing with new partners. -

How can I ensure the quality of roller tables I order?

To ensure quality, request certifications from suppliers, such as ISO 9001 or industry-specific standards. Ask for samples or prototypes to evaluate the quality before placing a larger order. It’s also beneficial to include quality assurance (QA) clauses in your contract, specifying inspection and testing processes. Additionally, consider hiring a third-party inspection service, particularly for large orders or when dealing with unfamiliar suppliers. -

What logistics considerations should I keep in mind when importing roller tables?

Logistics is critical when importing roller tables. Consider the shipping methods, costs, and potential customs duties that may apply. Choose a reliable freight forwarder experienced in handling industrial equipment. Ensure the supplier provides necessary documentation, such as bills of lading and customs invoices, to facilitate smooth customs clearance. It’s also wise to confirm the delivery timeline and plan for any potential delays that may arise during transit. -

What should I do if I encounter disputes with my roller table supplier?

In the event of a dispute, start by reviewing your contract to understand the terms agreed upon. Engage in direct communication with the supplier to resolve the issue amicably. If necessary, involve a mediator or arbitrator to facilitate discussions. It’s beneficial to have a clear dispute resolution clause in your contract outlining the steps to take in such situations. Keeping thorough documentation of all communications and transactions can also support your position during a dispute. -

Are there specific certifications I should look for in roller table suppliers?

Yes, look for certifications relevant to quality management, such as ISO 9001, which demonstrates a commitment to quality processes. Depending on your industry, additional certifications like CE marking (for compliance with European standards) or UL certification (for safety) may be important. Verify if the supplier has undergone third-party audits and can provide documentation of their compliance. This not only ensures product quality but also enhances your credibility when sourcing from international suppliers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for roller tables

In conclusion, the strategic sourcing of roller tables offers significant advantages for international B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. By leveraging a comprehensive understanding of suppliers, product specifications, and market trends, businesses can optimize their procurement processes, ensuring they select high-quality, cost-effective solutions tailored to their operational needs.

Key Takeaways:

- Supplier Diversity: Engage with a wide range of manufacturers to explore innovative designs and features that meet specific industry requirements.

- Customization Opportunities: Many suppliers offer tailored solutions, enabling businesses to source roller tables that align with unique operational demands.

- Cost Efficiency: By comparing quotes and understanding the total cost of ownership, buyers can make informed decisions that enhance profitability.

As industries continue to evolve, the demand for reliable and efficient roller tables will only increase. Now is the time for international B2B buyers to take proactive steps in their sourcing strategies. Embrace the opportunity to enhance operational efficiency and drive competitive advantage through strategic partnerships with leading roller table manufacturers. Engage in dialogue with suppliers today to secure the best solutions for your business needs.