Master Sheet Perforation Sourcing: Boost Efficiency and Cut

Introduction: Navigating the Global Market for sheet perforation

In the dynamic world of manufacturing, sheet perforation stands as a critical process that enhances both functionality and aesthetics across various industries. As an essential technique for creating holes or patterns in sheet materials, it plays a pivotal role in applications ranging from automotive components to architectural designs. For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding the nuances of sheet perforation is paramount to making informed sourcing decisions.

This guide delves into the multifaceted landscape of sheet perforation, covering key areas such as types of perforation, materials used, and manufacturing quality control practices. Buyers will gain insights into the various suppliers available globally, helping them identify reliable partners that meet their specific needs. Additionally, an analysis of cost structures and market trends will equip buyers with the knowledge to negotiate effectively and optimize their procurement strategies.

By addressing frequently asked questions and clarifying complex concepts, this comprehensive resource empowers B2B buyers to navigate the global market with confidence. Whether you are seeking innovative solutions or cost-effective materials, understanding sheet perforation is crucial for enhancing your operational efficiency and staying competitive in today’s marketplace.

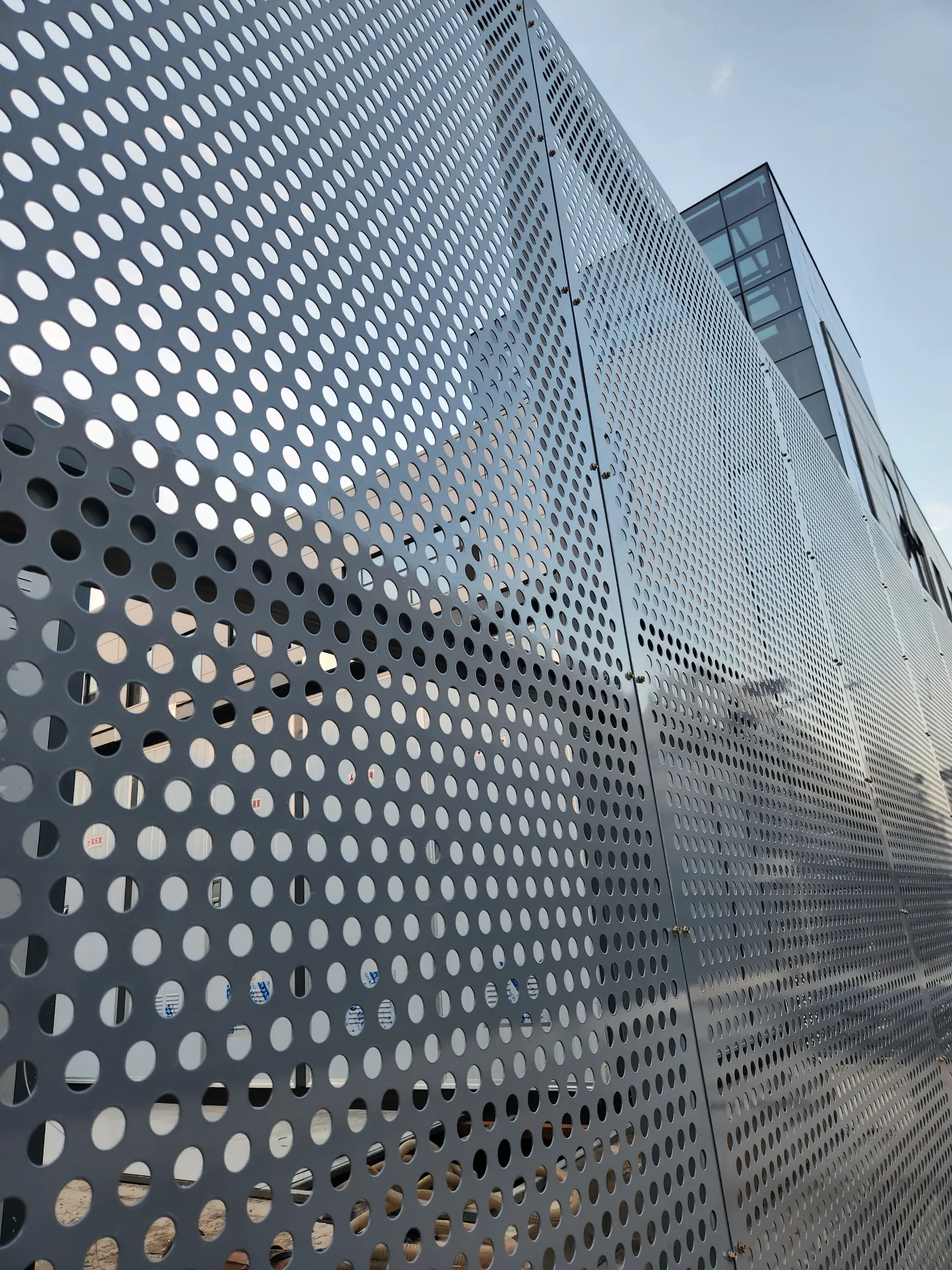

Illustrative Image (Source: Google Search)

Understanding sheet perforation Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Perforation | Uniform hole size and spacing | Packaging, printing, and textiles | Pros: Cost-effective, easy to source. Cons: Limited customization options. |

| Custom Perforation | Tailored hole shapes and patterns | Specialty packaging, filters | Pros: High customization, meets specific needs. Cons: Higher costs and longer lead times. |

| Micro Perforation | Very small holes for enhanced functionality | Medical, electronics, and filters | Pros: Precision and functionality. Cons: More complex manufacturing process. |

| Decorative Perforation | Aesthetic designs with functional benefits | Retail displays, signage, and decor | Pros: Enhances visual appeal. Cons: May compromise structural integrity. |

| Heavy-Duty Perforation | Larger holes for strength and durability | Industrial applications, construction | Pros: Robust and durable. Cons: Heavier and may be more expensive. |

Standard Perforation

Standard perforation is characterized by its uniform hole size and consistent spacing, making it a popular choice for various applications such as packaging, printing, and textiles. This type is highly cost-effective and readily available, which is crucial for businesses looking to maintain budget constraints. However, the lack of customization options may limit its suitability for specialized projects, making it essential for buyers to assess their specific needs before opting for this solution.

Custom Perforation

Custom perforation allows for tailored hole shapes and patterns, catering to niche requirements in specialty packaging and filtration systems. This flexibility provides significant advantages for businesses that need specific designs to enhance functionality or branding. While the ability to customize perforation patterns can lead to better product performance, buyers should be aware that these solutions often come with higher costs and longer lead times, necessitating careful planning and budget allocation.

Micro Perforation

Micro perforation involves creating very small holes, offering enhanced functionality such as breathability in medical products or precision in electronic components. This type of perforation is ideal for applications that require a high degree of accuracy and performance. However, the manufacturing process can be more complex and costly, which may impact the overall budget for procurement. Buyers should evaluate the trade-offs between precision and cost-effectiveness when considering micro perforation.

Decorative Perforation

Decorative perforation combines aesthetic design with functional benefits, making it suitable for retail displays, signage, and decorative items. This type enhances visual appeal while maintaining some level of functionality. However, it may compromise structural integrity, so buyers must consider the balance between aesthetics and durability based on their specific application needs. Understanding the end use is crucial to ensure that decorative perforation aligns with overall project goals.

Heavy-Duty Perforation

Heavy-duty perforation features larger holes designed to provide strength and durability, making it ideal for industrial applications and construction materials. This type is particularly advantageous in environments that require robust solutions. While heavy-duty perforation offers significant strength, it can also result in increased weight and cost. Buyers should assess the specific demands of their projects to determine if the benefits of heavy-duty perforation justify the potential downsides.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of sheet perforation

| Industry/Sector | Specific Application of sheet perforation | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Lightweight structural components | Reduces vehicle weight, enhancing fuel efficiency and performance | Quality control of perforation patterns; adherence to safety regulations |

| Construction | Ventilation and acoustic panels | Improves air flow and sound absorption, enhancing indoor comfort | Material durability; compliance with local building codes |

| Electronics | Heat dissipation elements in devices | Prevents overheating, prolonging device lifespan | Precision in hole sizes; compatibility with electronic components |

| Packaging | Custom packaging solutions | Enhances product visibility and reduces material waste | Sustainability of materials; cost-effectiveness in production |

| Agriculture | Soil aeration sheets | Promotes healthier plant growth through improved aeration | Resistance to environmental conditions; material sourcing reliability |

Automotive

In the automotive industry, sheet perforation is utilized for lightweight structural components, such as body panels and frames. By incorporating perforated sheets, manufacturers can significantly reduce vehicle weight, which enhances fuel efficiency and overall performance. International buyers must ensure that their suppliers maintain stringent quality control over perforation patterns to meet safety regulations and performance standards, especially considering the varying automotive regulations across regions like Europe and South America.

Construction

In construction, perforated sheets are commonly used in ventilation and acoustic panels. These panels facilitate improved airflow and sound absorption in buildings, contributing to enhanced indoor comfort. Buyers in this sector should prioritize material durability and compliance with local building codes, particularly in regions with specific environmental conditions, such as the Middle East or Africa, where weather resistance may be crucial.

Electronics

The electronics sector employs sheet perforation for heat dissipation elements in devices. Perforated sheets allow for efficient airflow, preventing overheating and thereby prolonging the lifespan of electronic components. B2B buyers should focus on precision in hole sizes and ensure compatibility with various electronic components, which can vary across regions like Europe and South America, where different standards may apply.

Packaging

In the packaging industry, sheet perforation is leveraged for creating custom packaging solutions that enhance product visibility while reducing material waste. Perforated packaging can improve the aesthetics of products on shelves and contribute to sustainability goals. Buyers should consider the sustainability of materials used and the cost-effectiveness of production processes, especially in competitive markets such as Africa and South America, where pricing can be a significant factor.

Agriculture

In agriculture, perforated soil aeration sheets are employed to promote healthier plant growth by improving aeration in the soil. These sheets help prevent compaction, allowing for better water drainage and root development. Buyers in this field should ensure that the materials used are resistant to environmental conditions and that suppliers can reliably source these materials, which is particularly important in regions prone to extreme weather.

Related Video: Forming Sheet Metal & Metal Forming Tools – Uses Explained By Gene Winfield at SEMA

Strategic Material Selection Guide for sheet perforation

When selecting materials for sheet perforation, it is essential to consider the properties, advantages, and limitations of each material type. Below are analyses of four common materials used in sheet perforation, focusing on their performance characteristics and implications for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and durability. It can withstand high temperatures and pressures, making it suitable for various applications, including food processing and chemical industries.

Pros & Cons:

The primary advantage of stainless steel is its longevity and resistance to rust and staining. However, it is more expensive than other materials, which can impact overall project costs. Additionally, the manufacturing complexity is higher due to its toughness, which may require specialized equipment.

Impact on Application:

Stainless steel is compatible with a wide range of media, including acidic and alkaline substances, making it a versatile choice for industries requiring stringent hygiene and safety standards.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A240 or DIN 1.4301. The higher cost may be justified in regions with strict regulations on material safety and environmental impact.

2. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal and electrical conductivity. It is easy to machine and can be anodized for enhanced surface protection.

Pros & Cons:

Aluminum’s lightweight nature makes it ideal for applications where weight reduction is crucial. However, it has a lower strength-to-weight ratio compared to stainless steel, which may limit its use in high-stress applications. The cost is moderate, making it accessible for various projects.

Impact on Application:

Aluminum is suitable for applications involving moisture and mild chemicals but may not perform well in highly corrosive environments.

Considerations for International Buyers:

Buyers in regions like Europe should consider compliance with EN standards for aluminum alloys. The cost-effectiveness of aluminum can be appealing, but it’s essential to evaluate the specific requirements of the application.

3. Carbon Steel

Key Properties:

Carbon steel is known for its high tensile strength and hardness. It is less expensive than stainless steel and aluminum but is more susceptible to corrosion.

Pros & Cons:

The primary advantage of carbon steel is its cost-effectiveness, making it a popular choice for large-scale projects. However, its susceptibility to rust means that protective coatings or regular maintenance are necessary, which can increase long-term costs.

Impact on Application:

Carbon steel is suitable for applications where strength is crucial, but it may not be ideal for environments exposed to moisture or corrosive substances.

Considerations for International Buyers:

Buyers should be aware of standards such as ASTM A36. In regions with high humidity, additional protective measures should be taken to prevent corrosion, affecting the overall cost and maintenance strategy.

4. Plastic (Polypropylene or PVC)

Key Properties:

Plastics like polypropylene and PVC are lightweight, corrosion-resistant, and have good chemical resistance. They are easy to fabricate and can be produced in various colors.

Pros & Cons:

The main advantage of plastic is its low cost and versatility in applications. However, it may not withstand high temperatures or heavy loads, limiting its use in structural applications.

Impact on Application:

Plastic is suitable for applications involving chemicals and moisture but may not be ideal for high-temperature environments.

Considerations for International Buyers:

Buyers should check for compliance with standards such as ASTM D638 for plastics. The lower cost can be attractive, but it’s crucial to assess the suitability of plastic for specific applications, especially in industrial settings.

Summary Table

| Material | Typical Use Case for sheet perforation | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, chemical industries | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Aluminum | Automotive, aerospace components | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Carbon Steel | Construction, heavy machinery | Cost-effective, high strength | Susceptible to corrosion | Low |

| Plastic (PVC) | Chemical storage, lightweight structures | Low cost, versatile | Limited temperature tolerance | Low |

This guide provides a foundational understanding of material selection for sheet perforation, emphasizing the importance of aligning material properties with application requirements and compliance standards specific to different regions.

In-depth Look: Manufacturing Processes and Quality Assurance for sheet perforation

The manufacturing process for sheet perforation involves several key stages, each crucial for ensuring quality and efficiency. B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be familiar with these processes to make informed decisions when sourcing perforated sheets.

Manufacturing Process

1. Material Preparation

The first step in the sheet perforation process is the selection and preparation of raw materials. Common materials used include stainless steel, aluminum, and various alloys. The choice of material depends on the intended application, such as construction, automotive, or consumer goods.

- Material Inspection: Prior to processing, materials undergo rigorous inspection to ensure they meet specifications. This can include checking for defects, thickness, and tensile strength.

- Cutting: Sheets are then cut to the required dimensions, often using laser cutting or shearing techniques, which provide precision and reduce waste.

2. Forming

Once the materials are prepared, the next stage involves the actual perforation.

- Perforating Techniques: The most common methods include:

- Punching: A punch press is used to create holes in the sheet. This method is efficient for high-volume production.

- Laser Perforation: Laser technology allows for more intricate designs and smaller holes, making it suitable for specialized applications.

- Water Jet Cutting: This method uses high-pressure water mixed with abrasives to cut through materials without generating heat, which can alter the material properties.

3. Assembly

In many cases, perforated sheets are part of larger assemblies.

- Joining Techniques: Depending on the end product, sheets may be welded, riveted, or bonded to other components. Ensuring compatibility and structural integrity during this stage is vital.

- Custom Fabrication: Some suppliers offer custom fabrication services, allowing buyers to specify unique designs or features tailored to their applications.

4. Finishing

The final stage involves treating the sheets to enhance durability and aesthetics.

- Surface Treatments: Common finishing processes include powder coating, anodizing, or galvanizing. These treatments help prevent corrosion and improve the visual appeal of the final product.

- Quality Checks: Final inspections are conducted to ensure the finished product meets all specifications and quality standards.

Quality Assurance

Quality assurance (QA) is essential in the manufacturing of perforated sheets, ensuring that products meet both international and industry-specific standards.

International Standards

B2B buyers should verify that suppliers adhere to recognized quality standards such as:

- ISO 9001: This standard emphasizes a process approach to quality management, ensuring consistent product quality and customer satisfaction.

- CE Marking: For products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

Industry-Specific Standards

Depending on the application, additional certifications may be required:

- API Standards: For perforated sheets used in the oil and gas industry, adherence to American Petroleum Institute (API) standards ensures reliability and safety.

- ASTM Standards: The American Society for Testing and Materials (ASTM) provides specifications for materials, testing methods, and performance criteria.

Quality Control Checkpoints

Effective quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Regular checks during production to identify and rectify issues early.

- Final Quality Control (FQC): Comprehensive inspections of finished products, including dimensional checks, visual inspections, and functional testing.

Common Testing Methods

To verify the quality of perforated sheets, suppliers may employ various testing methods:

- Tensile Testing: Measures the strength and ductility of the material.

- Hardness Testing: Assesses the material’s resistance to deformation.

- Dimensional Inspection: Ensures that the perforated patterns and overall dimensions meet specifications.

Verifying Supplier Quality Control

B2B buyers can take proactive steps to ensure that suppliers maintain high-quality standards:

- Supplier Audits: Conducting regular audits helps assess the supplier’s compliance with quality standards and their manufacturing processes.

- Quality Reports: Requesting detailed quality control reports can provide insights into the supplier’s QA processes and any issues encountered during production.

- Third-Party Inspections: Engaging independent inspectors can offer an unbiased evaluation of the supplier’s quality practices and product reliability.

Quality Certification Nuances for International Buyers

When sourcing internationally, buyers should be aware of the nuances in quality certifications:

- Documentation: Ensure that all quality certifications are documented and verifiable. This includes understanding the validity and scope of certifications.

- Regulatory Compliance: Different regions may have specific regulatory requirements. For example, products sold in the European market must comply with EU regulations, while those in the Middle East may adhere to different standards.

- Cultural Considerations: Understanding the cultural context of suppliers can aid in establishing effective communication regarding quality expectations.

By comprehensively understanding the manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions that align with their operational needs and market requirements.

Related Video: Mercedes C-Class CAR FACTORY – HOW IT’S MADE Assembly Production Line Manufacturing Making of

Comprehensive Cost and Pricing Analysis for sheet perforation Sourcing

Understanding the Cost Structure of Sheet Perforation

In the realm of sheet perforation, a clear understanding of cost components is essential for B2B buyers aiming to make informed sourcing decisions. The primary cost components involved in sheet perforation include:

-

Materials: The type of sheet material used (e.g., steel, aluminum, plastic) significantly impacts the overall cost. Higher-quality materials generally lead to higher prices but can also improve the longevity and performance of the final product.

-

Labor: Labor costs vary depending on the complexity of the perforation process and the skill level required. Skilled labor, particularly in regions with higher wage standards (like parts of Europe), can drive up costs.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help reduce overhead, thereby lowering the overall cost.

-

Tooling: Tooling costs are critical, especially for custom perforation designs. The creation of specialized dies and tools can be a significant upfront expense.

-

Quality Control (QC): Investing in quality control ensures that products meet specified standards, which can prevent costly reworks or returns. However, this also adds to the overall cost.

-

Logistics: Transportation and warehousing costs must be factored in, especially for international buyers. The choice of shipping methods and the distance from suppliers can greatly influence logistics expenses.

-

Margin: Suppliers will typically include a profit margin in their pricing, which can vary based on competition, demand, and market conditions.

Key Price Influencers

Several factors can influence the pricing of sheet perforation services:

-

Volume/MOQ (Minimum Order Quantity): Larger orders can lead to significant discounts. Suppliers often have set pricing tiers based on volume, so negotiating for higher quantities can result in lower per-unit costs.

-

Specifications/Customization: Custom designs or specific perforation patterns may incur additional costs. Standard designs are typically more cost-effective.

-

Material Choices: The choice of material not only affects the cost but also the performance. Buyers should consider the balance between cost and material specifications.

-

Quality and Certifications: Products that meet certain quality standards or certifications (ISO, ASTM, etc.) may come at a premium. However, these certifications can also enhance the product’s marketability.

-

Supplier Factors: The supplier’s reputation, location, and capabilities can impact pricing. Established suppliers with proven track records may charge more for their services.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) can help buyers evaluate total costs effectively. These terms define who bears the shipping risks and costs.

Buyer Tips for Cost-Efficiency

-

Negotiate Effectively: Leverage your purchasing power by negotiating terms, especially on volume discounts. Building a long-term relationship with suppliers can also yield better pricing over time.

-

Consider Total Cost of Ownership (TCO): Rather than just focusing on upfront costs, assess the long-term costs associated with maintenance, durability, and performance. This holistic view can lead to better purchasing decisions.

-

Research Pricing Nuances: International buyers should be aware of regional pricing trends and fluctuations due to local economic conditions. For instance, currency exchange rates can significantly affect costs.

-

Optimize Specifications: Standardize specifications where possible to avoid unnecessary customization costs. This can simplify the sourcing process and lead to cost savings.

-

Evaluate Multiple Suppliers: Don’t settle for the first quote. Comparing different suppliers can provide insights into competitive pricing and highlight potential savings.

Disclaimer

The prices discussed in this analysis are indicative and may vary based on market conditions, supplier negotiations, and other variables. Buyers are encouraged to conduct thorough research and obtain multiple quotes to ensure they are making the best financial decisions for their specific needs.

Spotlight on Potential sheet perforation Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘sheet perforation’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for sheet perforation

Critical Technical Properties of Sheet Perforation

When engaging in sheet perforation, understanding the technical specifications is essential for making informed purchasing decisions. Here are some key properties to consider:

-

Material Grade

– Definition: The quality and type of material used for perforation, such as stainless steel, aluminum, or specialized alloys.

– Importance: The material grade affects durability, corrosion resistance, and application suitability. For example, stainless steel is often preferred for its strength and resistance to rust, making it ideal for outdoor applications. -

Hole Size and Shape

– Definition: The dimensions and geometric configuration of the perforations made in the sheet.

– Importance: Different applications require specific hole sizes and shapes. For instance, larger holes might be needed for drainage, while smaller, precise holes are often required for filtration. Understanding these requirements ensures optimal performance in the intended application. -

Tolerance

– Definition: The allowable variation in the dimensions of the perforated sheet, typically expressed in millimeters or inches.

– Importance: Tight tolerances are crucial in applications where precision is paramount, such as in automotive or aerospace industries. Knowing the tolerance levels helps buyers ensure that the perforated sheets will fit correctly in their applications. -

Thickness

– Definition: The gauge or thickness of the sheet material before perforation.

– Importance: The thickness impacts the sheet’s strength and weight. Thicker materials can withstand more stress and are suitable for heavy-duty applications, while thinner sheets may be more cost-effective for less demanding uses. -

Perforation Pattern

– Definition: The arrangement and spacing of holes in the sheet, which can be uniform or varied.

– Importance: The pattern affects the sheet’s functionality and aesthetics. For instance, a uniform pattern might be necessary for specific industrial applications, while varied patterns may be used for decorative purposes.

Common Trade Terminology in Sheet Perforation

Familiarity with industry jargon can facilitate smoother transactions and clearer communication. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding whether a supplier is an OEM can impact sourcing decisions, especially when quality and compatibility are critical in B2B partnerships. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ is crucial for budgeting and inventory management. Buyers must ensure that they can meet the supplier’s MOQ without overcommitting resources. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to solicit price quotes for specific products or services.

– Relevance: Submitting an RFQ allows buyers to compare prices and terms from multiple suppliers, leading to more informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers.

– Relevance: Familiarity with Incoterms is vital for understanding shipping responsibilities, costs, and risk management, which can significantly affect overall project costs and timelines. -

Lead Time

– Definition: The time taken from placing an order to its delivery.

– Relevance: Knowing the lead time is essential for planning and scheduling production processes. Longer lead times can impact project timelines and inventory levels, making this a critical factor in procurement strategies.

By grasping these properties and terms, international B2B buyers can navigate the complexities of sheet perforation more effectively, ensuring they make choices that align with their operational needs and strategic goals.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the sheet perforation Sector

Market Overview & Key Trends

The sheet perforation sector is experiencing significant transformation driven by various global factors. Key drivers include the rapid advancement of technology, increasing demand for customized solutions, and the push for efficiency in manufacturing processes. With the rise of Industry 4.0, B2B buyers are now leveraging digital tools such as artificial intelligence (AI) and the Internet of Things (IoT) to enhance production capabilities and optimize supply chains.

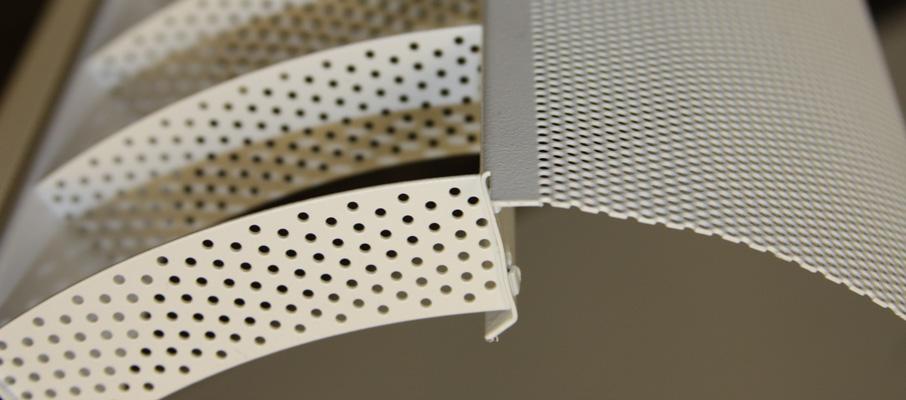

Illustrative Image (Source: Google Search)

Emerging trends such as automation and the integration of smart technologies are reshaping sourcing strategies. For instance, buyers are increasingly adopting automated perforation systems that not only enhance precision but also reduce waste and lead times. This shift towards digital procurement processes enables buyers from regions like Africa, South America, the Middle East, and Europe to engage with suppliers more effectively, ensuring that they receive timely and tailored solutions.

Furthermore, the growing emphasis on sustainability is influencing sourcing decisions. Buyers are actively seeking suppliers who can demonstrate eco-friendly practices and materials. As businesses become more interconnected, international buyers must consider geopolitical factors and supply chain resilience, particularly in light of recent disruptions due to global events. This landscape necessitates a proactive approach to sourcing, where understanding market dynamics and leveraging technology can unlock significant value.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal concern in the sheet perforation sector, influencing purchasing decisions and supplier selection. The environmental impact of manufacturing processes is under scrutiny, prompting buyers to seek out suppliers that prioritize sustainable practices. This includes minimizing waste during production, utilizing renewable energy sources, and implementing recycling initiatives for scrap materials.

Ethical sourcing is equally crucial, as businesses face increasing pressure from consumers and regulators to ensure their supply chains are transparent and responsible. Buyers should prioritize suppliers who adhere to internationally recognized standards and certifications, such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety. These certifications not only enhance credibility but also foster trust among stakeholders.

In addition, the demand for ‘green’ materials is on the rise. Buyers are encouraged to explore options such as recycled metals or eco-friendly coatings in their perforation projects. Implementing sustainable practices not only addresses environmental concerns but also provides a competitive edge, as customers increasingly favor businesses that demonstrate a commitment to sustainability.

Brief Evolution/History

The sheet perforation industry has evolved significantly over the past few decades. Initially, perforation techniques were rudimentary, relying heavily on manual processes. However, with advancements in technology, the introduction of automated systems and CNC (Computer Numerical Control) machines has revolutionized the sector. These innovations have improved precision, efficiency, and scalability, allowing manufacturers to meet the growing demands of diverse industries, from automotive to consumer goods.

Today, the focus has shifted towards integrating smart technologies and sustainable practices, ensuring that the sheet perforation sector remains relevant in a rapidly changing market landscape. As international buyers navigate this evolving space, understanding historical trends can provide valuable insights into future opportunities and challenges.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of sheet perforation

-

How can I effectively vet suppliers for sheet perforation?

When vetting suppliers, prioritize those with established reputations and positive reviews from previous clients. Request references and case studies that demonstrate their expertise in sheet perforation. Utilize platforms like Alibaba or ThomasNet to find verified suppliers. Conduct on-site visits if possible, or use virtual tours to assess their facilities. Additionally, check for industry certifications (e.g., ISO 9001) to ensure adherence to quality standards. -

What customization options are typically available for sheet perforation?

Many suppliers offer customization options, including hole size, shape, and spacing, as well as the type of material used. Discuss your specific requirements upfront to ensure the supplier can meet your needs. Consider requesting prototypes or samples to evaluate the quality of the perforation. Collaboration with the supplier during the design phase can lead to more efficient production and potentially lower costs. -

What are the common minimum order quantities (MOQ) and lead times for sheet perforation?

MOQs for sheet perforation can vary significantly based on the supplier and the complexity of your order. Generally, MOQs may range from 100 to 1,000 units. Lead times typically depend on the order size and customization level, averaging between 2 to 6 weeks. Always clarify these details in advance to avoid delays, and negotiate terms that suit your operational timeline. -

What payment terms should I expect when sourcing sheet perforation?

Payment terms can vary by supplier and region, but common practices include a 30% deposit with the order and the remaining balance before shipping. Some suppliers may offer net 30 or net 60 terms based on your creditworthiness. Always clarify payment methods accepted (e.g., wire transfer, PayPal) and ensure secure transactions. Consider using letters of credit for larger orders to protect both parties. -

What quality assurance measures should I look for in sheet perforation suppliers?

Suppliers should have comprehensive quality assurance processes, including regular inspections and testing of raw materials and finished products. Request documentation of their QA protocols, such as inspection reports and compliance certificates. Certifications like ISO 9001 or specific industry standards provide assurance of their commitment to quality. Discuss the possibility of third-party inspections if necessary. -

How can I ensure compliance with international shipping and logistics?

When sourcing internationally, it’s crucial to understand the logistics involved, including shipping methods, customs regulations, and import duties. Work with suppliers who have experience in international trade and can provide Incoterms (e.g., FOB, CIF) that clarify responsibility for shipping costs and risks. Partnering with a reliable freight forwarder can streamline the process and help navigate complex customs requirements. -

What should I do in case of disputes with my supplier?

To prevent disputes, establish clear terms in your contract, including delivery schedules, quality standards, and payment terms. In the event of a disagreement, initiate open communication with your supplier to resolve the issue amicably. If necessary, refer to the dispute resolution clause in your contract, which may include mediation or arbitration. Keeping detailed records of all communications and transactions can also help support your case. -

How can I stay informed about industry trends and changes affecting sheet perforation?

Staying updated on industry trends is vital for making informed purchasing decisions. Subscribe to industry publications, attend trade shows, and participate in relevant online forums or groups. Following key suppliers and industry experts on social media platforms can also provide insights into new technologies and market shifts. Networking with peers in your industry can offer valuable perspectives on challenges and innovations in sheet perforation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for sheet perforation

As the global market for sheet perforation continues to evolve, international B2B buyers must recognize the critical importance of strategic sourcing in maximizing value and efficiency. By leveraging advanced sourcing techniques, organizations can transform their procurement processes into powerful tools for cost reduction and quality enhancement. Key takeaways for buyers include the necessity of engaging in supplier collaboration, utilizing data analytics for informed decision-making, and adopting innovative procurement technologies.

Investing in a robust strategic sourcing strategy not only mitigates risks associated with supply chain disruptions but also positions companies to capitalize on emerging market opportunities. Buyers should focus on building long-term partnerships with suppliers who demonstrate reliability and innovation, particularly in regions like Africa, South America, the Middle East, and Europe, where diverse sourcing options are increasingly available.

Looking ahead, the emphasis on sustainability and efficiency will only grow stronger. International B2B buyers are encouraged to proactively seek out suppliers that align with these values, ensuring their sourcing strategies are not only effective today but also resilient for the future. Engage with your suppliers now to explore how strategic sourcing can unlock new avenues for growth and success in the sheet perforation market.