Master Metal Heat Treatment Services: Essential Insights

Introduction: Navigating the Global Market for metal heat treatment services

Navigating the complexities of the global market for metal heat treatment services is crucial for international B2B buyers, particularly in regions experiencing rapid industrial growth such as Africa, South America, the Middle East, and Europe. As industries increasingly rely on high-performance metal components, understanding the significance of heat treatment processes has never been more vital. Metal heat treatment not only enhances the mechanical properties of metals—such as strength, ductility, and hardness—but also plays a pivotal role in ensuring the longevity and reliability of end products.

This comprehensive guide delves into the various types of heat treatment available, from hardening and tempering to annealing and quenching, providing insights into the specific materials and alloys best suited for different applications. We will explore essential manufacturing and quality control practices that guarantee consistent results, as well as strategies for evaluating and selecting reliable global suppliers. Additionally, the guide will address cost drivers, market trends, and regional pricing dynamics that influence sourcing decisions.

By equipping international buyers with actionable insights and expert analysis, this guide empowers you to make informed sourcing decisions. Whether you are upgrading equipment, seeking new suppliers, or expanding into new markets, understanding the nuances of metal heat treatment services will turn complexity into clarity and opportunities into tangible results.

Understanding metal heat treatment services Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hardening | Involves heating followed by rapid cooling (quenching) | Tool manufacturing, automotive components | Increases hardness and strength; may reduce ductility. |

| Tempering | Heating post-hardening to reduce brittleness | Structural steel, machinery parts | Balances hardness and ductility; requires careful control. |

| Annealing | Slow heating and cooling to relieve stresses | Aerospace, automotive, and general fabrication | Enhances ductility; may lower strength. |

| Solution Heat Treatment | High-temperature heating followed by rapid quenching | Aerospace, automotive, and structural applications | Maximizes strength; requires precise control. |

| Aging | Controlled heating after quenching to enhance properties | High-performance components, fasteners | Improves strength; can add complexity to the process. |

Hardening

Characteristics: Hardening is a heat treatment process where metal is heated to a high temperature, typically between 800-900°C, and then rapidly cooled using quenching mediums like water, oil, or brine. This method significantly increases the hardness and strength of steel.

Suitability: It is particularly suitable for tool manufacturing and automotive components where high wear resistance and strength are critical.

Key B2B Considerations: Buyers should consider the potential trade-off between increased hardness and reduced ductility. It is essential to ensure that the hardened metal meets the specific performance requirements of its intended application.

Tempering

Characteristics: Tempering involves reheating hardened steel to a lower temperature, generally between 125-700°C, followed by air cooling. This process alleviates internal stresses and reduces brittleness while maintaining a good balance of hardness.

Suitability: It is widely used in structural steel and machinery parts where a combination of strength and ductility is necessary for functionality.

Key B2B Considerations: Buyers must ensure that the tempering process is accurately controlled to achieve the desired mechanical properties. Understanding the tempering temperatures and their effects on material performance is crucial for selecting the right service provider.

Annealing

Characteristics: Annealing entails heating metal to a specific temperature and then allowing it to cool slowly. This process relieves internal stresses, enhances ductility, and improves workability.

Suitability: It is ideal for applications in aerospace and automotive sectors where parts require extensive forming or are prone to cracking during machining.

Key B2B Considerations: Buyers should specify annealing requirements when sourcing components that need high formability. The potential reduction in strength post-annealing should be factored into the overall design and application considerations.

Solution Heat Treatment

Characteristics: This process involves heating aluminum alloys just below their melting point and then rapidly quenching them. This creates a supersaturated solid solution that maximizes ductility and prepares the metal for aging.

Suitability: It is essential for high-performance applications in aerospace, automotive, and structural components where strength is paramount.

Key B2B Considerations: Buyers need to evaluate suppliers for their ability to maintain precise temperature control and rapid quenching. Certification and traceability are vital for safety-sensitive applications, making supplier reliability a top priority.

Aging

Characteristics: Aging can be either natural or artificial and involves heating the metal after quenching to enhance its mechanical properties. Natural aging occurs at room temperature, while artificial aging is done at elevated temperatures.

Suitability: This process is particularly relevant for high-performance components and fasteners that require improved strength and durability.

Key B2B Considerations: Buyers should consider the operational complexity that aging may introduce into the production process. Understanding the specific aging requirements for different alloys is critical for ensuring product compatibility and performance.

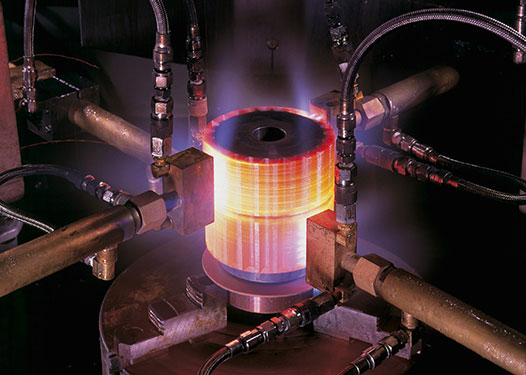

Related Video: Heat Treatment – Types (Including Annealing), Process and Structures (Principles of Metallurgy)

Key Industrial Applications of metal heat treatment services

| Industry/Sector | Specific Application of metal heat treatment services | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Heat treatment of titanium and aluminum components | Enhances strength-to-weight ratio, critical for flight safety | Supplier certification and compliance with aerospace standards |

| Automotive | Quenching and tempering of steel for gear components | Increases durability and performance under stress | Supplier reliability and capability for high-volume production |

| Construction | Annealing of structural steel beams | Improves workability and reduces brittleness | Quality control measures and adherence to local building codes |

| Oil & Gas | Heat treatment of drill bits and casing | Extends tool life and improves resistance to wear | Material traceability and compliance with industry regulations |

| Consumer Electronics | Heat treatment of aluminum housings | Enhances corrosion resistance and aesthetic finish | Cost-effectiveness and supplier capacity for rapid delivery |

Aerospace

In the aerospace industry, metal heat treatment services are essential for processing titanium and aluminum components, which are crucial for aircraft and spacecraft. These treatments enhance the strength-to-weight ratio, ensuring that parts can withstand extreme conditions while maintaining safety. International buyers must ensure that suppliers comply with stringent aerospace standards, including AS9100 certifications, to guarantee the quality and reliability of components.

Automotive

The automotive sector relies heavily on heat treatment processes such as quenching and tempering to enhance the durability of steel gear components. This treatment improves wear resistance and performance under high-stress conditions, ultimately contributing to vehicle longevity. Buyers should prioritize suppliers that demonstrate reliability and can meet high-volume production demands, as automotive applications often require consistent quality across large orders.

Construction

In construction, annealing of structural steel beams is a common application of metal heat treatment services. This process alleviates internal stresses and improves the metal’s workability, making it easier to shape and install. For international buyers, it is crucial to consider suppliers that adhere to local building codes and provide robust quality control measures to ensure the safety and integrity of structures.

Oil & Gas

The oil and gas industry benefits significantly from heat treatment services applied to drill bits and casing materials. These treatments enhance the lifespan of tools and improve their resistance to wear in harsh environments. Buyers in this sector should emphasize material traceability and ensure that suppliers comply with industry regulations, as these factors are critical for operational safety and efficiency.

Consumer Electronics

In the consumer electronics field, heat treatment of aluminum housings is vital for improving corrosion resistance and achieving a desirable aesthetic finish. This process allows manufacturers to produce lightweight yet durable components that meet consumer expectations. Buyers should focus on cost-effectiveness and assess suppliers’ capacities for rapid delivery, as the fast-paced nature of the electronics market demands agility in the supply chain.

Related Video: Heat treatment of metals | Types. Process, Applications

Strategic Material Selection Guide for metal heat treatment services

When selecting materials for metal heat treatment services, international B2B buyers must consider various factors, including the properties of the materials, their suitability for specific applications, and the implications of sourcing these materials from different regions. Below is an analysis of four common materials used in metal heat treatment services, focusing on their key properties, advantages, disadvantages, and specific considerations for international buyers.

Steel

Key Properties:

Steel is known for its high tensile strength and versatility. It can withstand high temperatures and pressures, making it suitable for a wide range of applications. Different alloying elements can enhance its corrosion resistance and toughness.

Pros & Cons:

Steel is durable and cost-effective, making it a popular choice for many industries. However, its susceptibility to corrosion requires additional treatments or coatings, which can increase manufacturing complexity and costs.

Impact on Application:

Steel is compatible with various media, including water and oil, depending on the heat treatment method used. Its properties can be tailored through processes like hardening and tempering, allowing it to meet specific application requirements.

Considerations for International Buyers:

Buyers should ensure compliance with relevant standards such as ASTM or DIN, especially when sourcing steel from different regions. Understanding local market conditions and pricing dynamics is crucial, particularly in emerging markets like Africa and South America.

Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity. Its mechanical properties can be significantly enhanced through heat treatment processes like solution heat treatment and aging.

Pros & Cons:

Aluminum’s low density makes it ideal for applications where weight reduction is critical, such as in the automotive and aerospace industries. However, its lower strength compared to steel can limit its use in high-stress applications.

Impact on Application:

Aluminum is compatible with various environments, but its performance can vary significantly based on the heat treatment process employed. For instance, solution heat treatment maximizes strength, while annealing improves ductility.

Considerations for International Buyers:

Buyers should focus on suppliers’ capabilities regarding precise temperature control and rapid quenching, especially for critical applications. Compliance with international standards and certifications is essential, particularly in regions with stringent safety regulations.

Titanium

Key Properties:

Titanium is renowned for its high strength-to-weight ratio and excellent corrosion resistance, making it suitable for demanding applications in aerospace and medical industries.

Pros & Cons:

While titanium offers superior performance characteristics, it is more expensive than steel and aluminum. Its manufacturing processes can also be complex, requiring specialized equipment and expertise.

Impact on Application:

Titanium’s compatibility with harsh environments, including high temperatures and corrosive media, makes it an excellent choice for applications like aerospace components and medical implants.

Considerations for International Buyers:

Buyers must assess the availability of titanium and its alloys in their regions, as sourcing can be more challenging. Understanding the cost implications and ensuring compliance with international standards is vital for successful procurement.

Nickel Alloys

Key Properties:

Nickel alloys exhibit excellent corrosion resistance and high-temperature stability, making them suitable for extreme environments, such as those found in chemical processing and aerospace applications.

Pros & Cons:

These alloys provide exceptional durability and performance under harsh conditions. However, they are typically more expensive than other materials, and their processing can be complex.

Impact on Application:

Nickel alloys are compatible with various aggressive media, making them ideal for applications in chemical processing where corrosion resistance is critical.

Considerations for International Buyers:

Buyers should be aware of the specific alloy grades suitable for their applications and the associated costs. Compliance with standards like ASTM or ASME is essential, particularly in regions with stringent regulatory frameworks.

Summary Table

| Material | Typical Use Case for metal heat treatment services | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Automotive parts, machinery components | High strength and versatility | Susceptible to corrosion | Medium |

| Aluminum | Aerospace, automotive, construction | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Titanium | Aerospace components, medical implants | High strength-to-weight ratio | High cost and complex processing | High |

| Nickel Alloys | Chemical processing, aerospace applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

This guide provides a framework for B2B buyers to make informed decisions when selecting materials for metal heat treatment services, ensuring they consider both performance characteristics and regional market dynamics.

In-depth Look: Manufacturing Processes and Quality Assurance for metal heat treatment services

Manufacturing Processes for Metal Heat Treatment Services

Understanding the manufacturing processes involved in metal heat treatment is crucial for B2B buyers aiming to procure high-quality components. The heat treatment process typically consists of several stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring that the final product meets the required specifications and standards.

Material Preparation

The first step in the heat treatment process involves preparing the raw materials, which typically include various grades of steel and non-ferrous metals. This stage includes:

- Material Selection: Choosing the right alloy based on the desired properties such as hardness, ductility, and tensile strength.

- Surface Cleaning: Ensuring that the material is free from contaminants such as oil, rust, or dirt. Techniques such as shot blasting, acid cleaning, or ultrasonic cleaning are commonly employed.

- Cutting and Shaping: The material is cut into specified dimensions using methods like sawing, shearing, or laser cutting to prepare for the heat treatment process.

Forming

Once the materials are prepared, the next stage involves forming, which may include processes such as forging, rolling, or casting. The goal here is to shape the material into the desired form before heat treatment. Key techniques include:

- Hot Forming: Involves shaping metals at high temperatures, which can enhance ductility and reduce the risk of cracking.

- Cold Forming: Shaping metals at room temperature, which can increase strength but may require subsequent heat treatment to relieve stresses.

Assembly

For components that require assembly, this stage involves joining different parts using methods such as welding, bolting, or adhesive bonding. Proper alignment and fit are critical to ensure that the heat treatment will not adversely affect the assembled structure. Buyers should consider:

- Tolerances: Ensuring that parts are assembled within specified tolerances to avoid deformation during heat treatment.

- Joint Design: Selecting appropriate joint designs that can withstand the thermal stresses introduced during heat treatment.

Finishing

The final stage involves various finishing processes that enhance the surface quality and performance of the heat-treated parts. This may include:

- Machining: Precision machining to achieve the final dimensions and surface finish.

- Coating: Applying protective coatings to improve corrosion resistance or reduce friction.

- Surface Hardening: Techniques such as nitriding or carburizing can be applied post-heat treatment to further enhance surface properties.

Quality Assurance in Metal Heat Treatment Services

Quality assurance (QA) is a critical aspect of the metal heat treatment process. It ensures that the treated components meet international and industry-specific standards, thus providing confidence to B2B buyers.

Relevant International Standards

B2B buyers should be aware of the following international standards that govern quality assurance in heat treatment:

- ISO 9001: A globally recognized quality management standard that outlines requirements for an effective quality management system (QMS). Certification indicates that a supplier has a consistent process for ensuring quality.

- API Standards: For buyers in the oil and gas sector, adherence to API standards ensures that heat-treated components meet safety and performance requirements.

- CE Marking: Indicates compliance with EU safety, health, and environmental protection legislation, which is essential for products sold in European markets.

Quality Control Checkpoints

Effective quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing monitoring during the manufacturing process, including temperature checks during heat treatment and dimensional checks after forming.

- Final Quality Control (FQC): Comprehensive inspection of finished products, including mechanical property testing and surface integrity checks.

Common Testing Methods

Testing is crucial to validate the effectiveness of heat treatment. B2B buyers should look for suppliers that employ the following methods:

- Hardness Testing: To measure the hardness of the treated material, commonly using Rockwell or Brinell scales.

- Tensile Testing: To evaluate the strength and ductility of the material.

- Microstructural Analysis: Utilizing techniques like metallography to assess the microstructure and confirm that desired transformations have occurred.

Verifying Supplier Quality Control

To ensure that suppliers maintain robust quality assurance practices, B2B buyers can take several steps:

- Supplier Audits: Conduct regular audits of potential suppliers to evaluate their processes, facilities, and adherence to quality standards.

- Requesting Quality Reports: Suppliers should provide documentation of their quality control processes, including test results and certifications.

- Third-Party Inspections: Engaging independent inspectors can provide an unbiased evaluation of a supplier’s adherence to quality standards.

QC and Certification Nuances for International Buyers

B2B buyers from Africa, South America, the Middle East, and Europe should be aware of specific nuances when dealing with international suppliers:

- Regional Standards: Different regions may have varying standards and certifications. It’s essential to ensure that suppliers are compliant with local regulations and industry-specific requirements.

- Cultural and Language Barriers: Effective communication is vital to ensure that quality requirements are clearly understood and met. Buyers should consider using local representatives or consultants who can bridge these gaps.

- Logistical Challenges: Understand the logistics involved in transporting heat-treated components, as improper handling can affect quality. Buyers should discuss packaging and shipping methods with suppliers to mitigate these risks.

By understanding the manufacturing processes and quality assurance practices associated with metal heat treatment services, B2B buyers can make informed decisions, ensuring that they procure components that meet their specifications and standards. This knowledge will not only enhance their procurement strategies but also strengthen their overall supply chain resilience.

Related Video: The Steel Heat Treatment Process

Comprehensive Cost and Pricing Analysis for metal heat treatment services Sourcing

When sourcing metal heat treatment services, international B2B buyers must navigate a complex cost structure influenced by various factors. Understanding these components is critical for making informed purchasing decisions that align with organizational goals.

Cost Components of Metal Heat Treatment Services

-

Materials: The type of metal being treated significantly affects costs. Ferrous metals, such as steel, typically have different pricing dynamics compared to non-ferrous metals like aluminum or titanium. The quality of raw materials also plays a crucial role; higher-grade metals may incur additional costs but yield better performance.

-

Labor: Skilled labor is essential for effective heat treatment processes. Labor costs can vary significantly based on geographic location, with regions like Europe and North America generally facing higher wages compared to parts of Africa or South America. The complexity of the heat treatment process also influences labor costs; processes requiring specialized skills or certifications tend to be more expensive.

-

Manufacturing Overhead: This includes costs associated with facility maintenance, utilities, and equipment depreciation. High overhead can lead to increased service prices, particularly in regions with stringent regulations or high operational costs.

-

Tooling: The need for specialized equipment and tooling for specific heat treatment processes can add to the overall cost. For example, custom tooling designed for unique specifications will raise initial costs but may enhance efficiency and product quality in the long run.

-

Quality Control (QC): Rigorous QC processes are essential for ensuring that heat-treated components meet necessary standards. This often involves testing and certification, which can increase costs. Buyers should prioritize suppliers with robust QC measures to avoid potential failures in the field.

-

Logistics: Transportation costs can vary based on the distance between the supplier and the buyer, as well as the mode of transportation chosen. Incoterms will influence the final price, determining who bears the responsibility for shipping costs and risks.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary widely based on market conditions, competition, and supplier reputation. Buyers should be aware that established suppliers may charge higher margins due to perceived reliability and quality.

Price Influencers

Several factors can impact the pricing of metal heat treatment services:

-

Volume/MOQ: Larger orders often qualify for bulk pricing discounts. Establishing a minimum order quantity (MOQ) can also help manage costs.

-

Specifications/Customization: Highly customized treatments may incur additional costs. Buyers should clearly define specifications to avoid unexpected pricing increases.

-

Materials: The choice of material can drastically alter costs. For instance, heat treatment for high-alloy steels typically costs more than for standard carbon steels.

-

Quality/Certifications: Suppliers with industry certifications (e.g., ISO, AS9100) may charge a premium due to their adherence to strict quality standards.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may offer higher prices but can provide better guarantees and customer service.

-

Incoterms: Understanding shipping terms is crucial. Different Incoterms can significantly impact total landed costs, affecting budgeting and pricing decisions.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers about pricing. Understanding their cost structure can provide leverage during negotiations.

-

Cost-Efficiency: Analyze the total cost of ownership (TCO) rather than just the initial purchase price. Consider factors like potential rework, lead times, and the quality of the final product.

-

Pricing Nuances: For international buyers, be aware of currency fluctuations, tariffs, and trade agreements that may affect pricing. Establishing long-term relationships with suppliers can also lead to better terms and pricing stability.

-

Regional Considerations: Buyers from Africa, South America, the Middle East, and Europe should consider local market dynamics and supplier capabilities, as these can significantly impact both cost and service quality.

Disclaimer

Prices for metal heat treatment services are subject to change based on market conditions, material availability, and regional factors. It is essential for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential metal heat treatment services Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘metal heat treatment services’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for metal heat treatment services

Understanding the essential technical properties and terminology related to metal heat treatment services is crucial for B2B buyers looking to make informed decisions. Here, we break down key specifications and common trade terms that will enhance your sourcing strategy.

Critical Specifications

-

Material Grade

– Definition: This refers to the classification of metals based on their composition and mechanical properties. Common grades for steel, for instance, include ASTM A36 or AISI 4140.

– B2B Importance: Knowing the material grade ensures that the heat-treated metal meets specific performance requirements for applications like automotive, aerospace, or construction. Incorrect grading can lead to failures and increased costs. -

Tolerances

– Definition: Tolerances indicate the permissible limits of variation in a physical dimension or property of a metal part. For instance, a tolerance of ±0.01 mm means the part can vary by that amount from its specified size.

– B2B Importance: Tighter tolerances can lead to higher manufacturing costs but are often necessary for parts that must fit precisely. Understanding tolerance requirements can help buyers negotiate better terms and ensure product compatibility. -

Heat Treatment Process

– Definition: This encompasses the specific method used to alter the properties of metals, such as annealing, quenching, or tempering.

– B2B Importance: Different processes yield different mechanical properties. Buyers should specify the required heat treatment method to ensure the final product meets performance expectations, particularly in high-stress applications. -

Hardness

– Definition: Hardness measures a material’s resistance to deformation, often quantified using scales like Rockwell or Brinell.

– B2B Importance: Hardness is critical in applications where wear resistance is essential. Buyers should clearly define hardness specifications to ensure the treated metal will perform adequately under operational conditions. -

Microstructure

– Definition: This term refers to the internal structure of a metal, which can be affected by heat treatment processes. Key microstructural features include grain size, phase distribution, and inclusions.

– B2B Importance: Understanding the desired microstructure helps in selecting the appropriate heat treatment process. It also affects the mechanical properties, influencing factors like strength and ductility.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM produces parts or equipment that may be marketed by another manufacturer.

– Importance: Recognizing OEM suppliers can streamline sourcing, ensuring that parts are made to the original specifications required for compatibility and performance. -

MOQ (Minimum Order Quantity)

– Definition: This is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ can help buyers manage inventory costs and negotiate better terms, especially when sourcing specialized heat-treated components. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers requesting a quote for specific products or services.

– Importance: Utilizing RFQs can facilitate competitive pricing and ensure that suppliers understand exact requirements, thus reducing the risk of misunderstandings. -

Incoterms (International Commercial Terms)

– Definition: These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms helps buyers clarify shipping responsibilities, costs, and risks, which is crucial for effective logistics management. -

Lead Time

– Definition: This refers to the amount of time it takes from placing an order until the product is delivered.

– Importance: Understanding lead times is essential for planning production schedules and managing project timelines, particularly in industries with tight deadlines.

By grasping these technical properties and trade terms, B2B buyers can enhance their decision-making processes, leading to better sourcing outcomes and reduced operational risks in the metal heat treatment sector.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the metal heat treatment services Sector

Market Overview & Key Trends

The metal heat treatment services sector is currently experiencing significant transformation driven by technological advancements, increased demand for high-performance materials, and evolving industrial applications. Key global drivers include the growth of the automotive, aerospace, and construction industries, particularly in emerging markets across Africa, South America, the Middle East, and Europe. As these regions industrialize, the need for heat-treated components that offer enhanced strength, durability, and corrosion resistance is on the rise.

Emerging B2B technology trends, such as automation and digitization, are reshaping sourcing practices. Advanced heat treatment technologies, including vacuum heat treatment and induction heating, are gaining traction due to their efficiency and ability to achieve precise material properties. Additionally, the integration of Industry 4.0 concepts—where IoT devices monitor and optimize heat treatment processes—provides buyers with real-time data, enhancing decision-making capabilities and supplier transparency.

Market dynamics are also influenced by supply chain complexities and regional availability. Buyers are increasingly looking for suppliers that can provide not only high-quality heat treatment services but also demonstrate reliability and flexibility in meeting diverse customer needs. As competition intensifies, establishing long-term relationships with trusted suppliers becomes essential. Buyers should prioritize suppliers with a proven track record in quality control, compliance with international standards, and the capacity to scale operations as demand fluctuates.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the metal heat treatment services sector. The environmental impact of traditional heat treatment processes—including energy consumption, emissions, and waste generation—has prompted a shift towards more sustainable practices. International B2B buyers are increasingly prioritizing suppliers who adopt energy-efficient technologies and practices that minimize their carbon footprint.

Ethical sourcing is equally important, as businesses are held accountable for their supply chains. Buyers should look for suppliers that adhere to ethical labor practices and demonstrate a commitment to sustainable sourcing of materials. Certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) are indicators of a supplier’s dedication to sustainability.

Moreover, the use of ‘green’ materials and processes in heat treatment can enhance a company’s market reputation and appeal to environmentally conscious customers. Techniques such as cryogenic treatment and the use of non-toxic quenching fluids are gaining popularity. These methods not only improve the performance of treated metals but also align with global sustainability goals, making them attractive options for B2B buyers looking to enhance their green credentials.

Brief Evolution/History

The evolution of metal heat treatment services has been marked by significant technological advancements over the centuries. Initially, heat treatment processes were rudimentary, relying heavily on blacksmithing techniques. However, the industrial revolution brought about the introduction of more controlled processes, enabling the precise manipulation of metal properties.

In the 20th century, the development of advanced alloys and the understanding of metallurgical principles led to the refinement of heat treatment processes such as hardening, tempering, and annealing. Today, the sector continues to evolve with innovations in automation, smart manufacturing, and sustainability practices, allowing for more efficient and environmentally friendly heat treatment solutions. This historical progression highlights the industry’s adaptability and responsiveness to changing market demands, positioning it as a vital component of modern manufacturing.

Frequently Asked Questions (FAQs) for B2B Buyers of metal heat treatment services

-

What should I consider when vetting suppliers for metal heat treatment services?

When vetting suppliers, focus on their experience, certifications, and technological capabilities. Look for companies with ISO certifications, as these indicate adherence to international quality standards. Additionally, assess their production capacity and lead times to ensure they can meet your demands. Reviewing customer testimonials and case studies can provide insights into their reliability and service quality. Lastly, consider their location and logistical capabilities to minimize shipping delays and costs. -

Can I customize heat treatment processes to meet specific requirements?

Yes, many suppliers offer customization options for heat treatment processes. When discussing your needs, provide detailed specifications about the metal type, desired properties, and intended application. This information allows suppliers to tailor their processes, such as adjusting temperature profiles or soaking times, to achieve optimal results. Ensure that the supplier has the necessary flexibility and expertise to accommodate your unique requirements without compromising quality.

Illustrative Image (Source: Google Search)

-

What are the minimum order quantities (MOQs) and lead times for heat treatment services?

MOQs and lead times can vary significantly between suppliers and depend on factors like production capacity and the complexity of the treatment required. Typically, suppliers may have MOQs ranging from a few hundred to several thousand units. Lead times can range from a few days to several weeks, especially for customized treatments. Always clarify these details upfront and negotiate terms that align with your project timelines and inventory management strategies. -

How can I ensure quality assurance and certification for heat-treated products?

Quality assurance is critical in metal heat treatment. Request documentation of the supplier’s quality control processes, including in-process inspections and final testing protocols. Ensure they provide relevant certifications, such as ISO 9001, which indicates a commitment to quality management. Additionally, inquire about traceability measures to track the heat treatment process, which is essential for compliance in industries like aerospace and automotive. -

What logistical considerations should I keep in mind when sourcing heat treatment services internationally?

Logistics play a crucial role in international sourcing. Evaluate shipping options, costs, and delivery times to determine the most efficient route. Consider potential customs regulations and tariffs that may affect the overall cost and timeline. Establish clear communication with your supplier regarding shipping terms (Incoterms) to avoid misunderstandings. It’s also wise to have contingency plans in case of delays or disputes during transportation. -

How should I handle disputes with suppliers regarding heat treatment services?

Establishing clear contracts that outline the scope of work, quality standards, and delivery schedules can prevent disputes. In the event of a disagreement, maintain open communication with the supplier to address concerns promptly. Document all communications and agreements related to the issue. If a resolution cannot be reached, refer to the contract’s dispute resolution clause, which may include mediation or arbitration as options for resolving conflicts without resorting to litigation.

Illustrative Image (Source: Google Search)

-

What are the common payment terms for international heat treatment services?

Payment terms can vary widely among suppliers. Common options include upfront payments, progress payments, or payment upon delivery. For international transactions, consider using secure payment methods like letters of credit or escrow services to protect your investment. Always clarify payment terms in the contract to avoid misunderstandings. Additionally, be aware of currency exchange rates and potential transaction fees that could impact your overall costs. -

How can I assess the overall performance of a heat treatment supplier?

To evaluate a supplier’s performance, consider both quantitative and qualitative metrics. Look at delivery times, defect rates, and adherence to specifications as quantitative indicators. Qualitative assessments can include customer service responsiveness and the supplier’s ability to adapt to changes. Conduct regular reviews of their performance and maintain open lines of communication to foster a collaborative relationship. Gathering feedback from other customers can also provide valuable insights into their reliability and service quality.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for metal heat treatment services

Strategic sourcing in metal heat treatment services is not merely a procurement activity; it is a vital component of ensuring product quality and competitive advantage in the global market. By understanding the various heat treatment processes and their implications on metal properties, international B2B buyers can make informed decisions that enhance the performance of their products. Key takeaways include the necessity of aligning supplier capabilities with specific treatment requirements, assessing cost structures and logistics, and ensuring compliance with international standards.

As industries across Africa, South America, the Middle East, and Europe continue to evolve, the demand for high-quality metal components will only increase. Engaging in strategic sourcing allows buyers to not only secure reliable suppliers but also to foster partnerships that drive innovation and efficiency.

Looking ahead, it is imperative for B2B buyers to remain proactive in their sourcing strategies. By leveraging insights from this guide, buyers can navigate the complexities of the market, optimize their supply chains, and position themselves for growth. Embrace the opportunity to enhance your sourcing strategy today, ensuring you remain at the forefront of your industry.