Master Sourcing Capacitive Touch Displays: A Strategic B2B

Introduction: Navigating the Global Market for capacitive touch display

In today’s digital landscape, capacitive touch displays have become integral to a wide array of devices, from smartphones and tablets to interactive kiosks and industrial equipment. Their ability to deliver a seamless user experience through responsive touch capabilities has transformed how businesses engage with technology and consumers alike. As global demand for these displays continues to soar, understanding their intricacies becomes essential for international B2B buyers aiming to stay competitive.

This comprehensive guide is designed to empower buyers from diverse regions, including Africa, South America, the Middle East, and Europe, with critical insights into the capacitive touch display market. We will explore the various types of touch displays, the raw materials used in their construction, and the intricate manufacturing and quality control processes that ensure their reliability. Additionally, we will delve into key topics such as sourcing suppliers, evaluating cost structures, and understanding market trends.

By equipping yourself with this knowledge, you will make informed sourcing decisions that not only enhance product offerings but also improve operational efficiency. Whether you are looking to integrate touch technology into new products or seeking reliable suppliers, this guide serves as a valuable resource to navigate the complexities of the capacitive touch display market. Together, let us unlock the potential of touch technology and leverage it for business growth and innovation.

Understanding capacitive touch display Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Projected Capacitive | Multi-touch capabilities, high durability, and accuracy | Smartphones, tablets, kiosks | Pros: Excellent responsiveness and clarity; Cons: Higher cost compared to resistive displays. |

| Surface Capacitive | Single touch detection, lower production cost | ATMs, industrial controls | Pros: Cost-effective for simple applications; Cons: Limited multi-touch functionality. |

| Self-Capacitance | Measures each electrode individually, allowing for multi-touch | Gaming devices, tablets | Pros: Highly sensitive and accurate; Cons: More complex and potentially more expensive to manufacture. |

| Mutual-Capacitance | Detects touch through a grid of electrodes | Interactive displays, automotive interfaces | Pros: Supports multi-touch and gestures; Cons: More susceptible to noise and interference. |

| Glass Touch Panels | High durability with a sleek design | Consumer electronics, automotive displays | Pros: Aesthetic appeal and robustness; Cons: Heavier and can be more expensive. |

Projected Capacitive

Projected capacitive displays are renowned for their multi-touch capabilities and high durability, making them ideal for smartphones, tablets, and interactive kiosks. These displays utilize a grid of sensors to detect touch, providing excellent responsiveness and clarity. For B2B buyers, the key considerations include the initial investment, as these displays tend to be more expensive. However, the long-term benefits in terms of user experience and durability often justify the cost.

Surface Capacitive

Surface capacitive touch displays are characterized by their single touch detection and lower production costs. Commonly found in ATMs and industrial control systems, they are suitable for applications requiring basic touch functionality. While they are more budget-friendly, B2B buyers should consider the limitations of single touch detection, which may not meet the needs of more interactive applications.

Illustrative Image (Source: Google Search)

Self-Capacitance

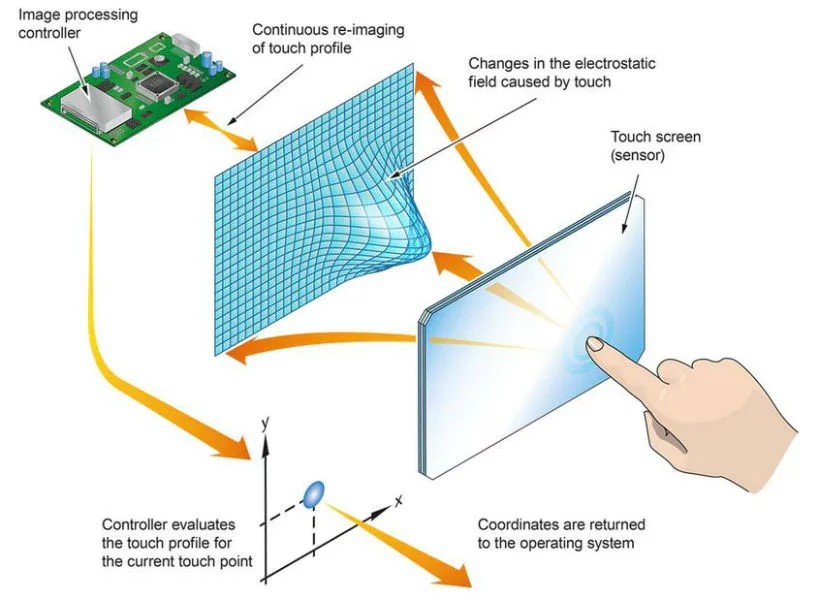

Self-capacitance displays measure the capacitance at each electrode individually, allowing for accurate multi-touch detection. They are commonly used in gaming devices and tablets, where high sensitivity is crucial. B2B buyers should weigh the benefits of responsiveness against potential manufacturing complexities and costs, as self-capacitance displays can be more intricate to produce.

Mutual-Capacitance

Mutual-capacitance displays feature a grid of electrodes that detect touch through changes in capacitance, enabling multi-touch and gesture recognition. These displays are popular in interactive displays and automotive interfaces. Buyers should consider the enhanced functionality they offer, balanced against potential susceptibility to noise and interference, which could impact performance in certain environments.

Glass Touch Panels

Glass touch panels combine aesthetic appeal with high durability, making them a popular choice for consumer electronics and automotive displays. Their sleek design enhances the visual aspect of devices, but they may come at a higher price point and increased weight. For B2B buyers, the decision often hinges on the trade-off between aesthetics and budget, especially in industries where product appearance is paramount.

Related Video: The Attention Mechanism in Large Language Models

Key Industrial Applications of capacitive touch display

| Industry/Sector | Specific Application of capacitive touch display | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Smartphones and Tablets | Enhanced user experience through responsive touch interfaces. | Quality of materials, responsiveness, and durability of touch panels. |

| Healthcare | Medical Equipment (e.g., patient monitoring systems) | Improved user interaction and data visualization for medical staff. | Compliance with health regulations, ease of cleaning, and reliability. |

| Automotive | Infotainment Systems | Intuitive controls that enhance driver and passenger engagement. | Environmental resistance and compatibility with automotive standards. |

| Retail | Point of Sale (POS) Systems | Faster transactions and better customer engagement at checkout. | Integration capabilities with existing systems and durability. |

| Industrial Automation | Control Panels for Machinery | Streamlined operations and real-time data access for operators. | Robustness, resistance to environmental factors, and ease of maintenance. |

Consumer Electronics

Capacitive touch displays are integral to smartphones and tablets, providing a seamless and intuitive user interface. These displays enable multi-touch capabilities, allowing users to interact with applications through gestures. For B2B buyers in this sector, sourcing high-quality materials and ensuring responsiveness and durability are critical. Manufacturers must balance cost with technology advancements to meet consumer expectations in fast-paced markets across regions like Europe and South America.

Healthcare

In the healthcare sector, capacitive touch displays are utilized in medical equipment, such as patient monitoring systems and diagnostic devices. These displays facilitate user interaction, enabling healthcare professionals to access and manipulate data efficiently. Key considerations for international buyers include compliance with health regulations, ease of cleaning to maintain hygiene, and reliability under various operational conditions. Suppliers must ensure that their products meet stringent industry standards, particularly in regions with varying regulatory environments.

Automotive

Capacitive touch displays have revolutionized infotainment systems in vehicles, providing intuitive controls for navigation, music, and vehicle settings. These displays enhance user engagement, allowing drivers to interact safely while on the move. For buyers in the automotive sector, sourcing displays that are resistant to environmental factors, such as temperature fluctuations and humidity, is vital. Additionally, compatibility with automotive standards is crucial for ensuring integration into existing systems.

Retail

In retail environments, capacitive touch displays are employed in point-of-sale (POS) systems, enabling faster transactions and enhancing customer engagement. These displays allow for quick product lookups and payment processing, improving the overall shopping experience. For B2B buyers in this sector, considerations include the integration capabilities of the touch displays with existing systems and their durability under frequent use. Suppliers should also focus on providing solutions that enhance the aesthetic appeal of retail spaces.

Industrial Automation

Capacitive touch displays are increasingly used in control panels for machinery within industrial automation. These displays enable operators to access real-time data and control machinery efficiently, streamlining operations. Buyers in this sector need to prioritize robustness and resistance to environmental factors, such as dust and moisture, which can impact performance. Furthermore, ease of maintenance and long-term reliability are critical factors for suppliers to address, ensuring that their products can withstand the rigors of industrial environments.

Related Video: ESP32 with display, 7inch lcd, capacitive touch, supports wifi & bluetooth

Strategic Material Selection Guide for capacitive touch display

When selecting materials for capacitive touch displays, understanding the properties, advantages, and limitations of each material is crucial for B2B buyers. Below are analyses of four common materials used in the manufacturing of capacitive touch displays, focusing on their performance characteristics and implications for international buyers.

1. Indium Tin Oxide (ITO)

Key Properties:

ITO is a transparent conductive oxide with excellent electrical conductivity and optical transparency. It typically has a high temperature rating, making it suitable for various applications. However, it can be brittle and prone to cracking under mechanical stress.

Pros & Cons:

The primary advantage of ITO is its superior transparency and conductivity, which are essential for touch sensitivity. However, its fragility can lead to durability issues, particularly in rugged environments. The manufacturing process can be complex and costly, especially when ensuring uniform coating thickness.

Impact on Application:

ITO is compatible with a wide range of media, including glass and plastic substrates, making it versatile for different display technologies. However, its brittleness can limit its use in flexible or handheld devices.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and JIS. Additionally, sourcing ITO can be challenging due to geopolitical factors affecting indium supply, particularly for buyers in Africa and South America.

2. Glass Substrates

Key Properties:

Glass substrates are known for their rigidity, excellent optical clarity, and resistance to environmental factors. They can withstand high temperatures and pressures, making them suitable for various applications.

Pros & Cons:

The durability and aesthetic appeal of glass substrates are significant advantages. However, they are heavier and can be more expensive than alternative materials like plastics. The manufacturing process involves careful handling to avoid breakage, which can increase costs.

Impact on Application:

Glass substrates provide a premium feel and are ideal for high-end devices. However, their weight can be a disadvantage in portable applications, impacting user experience.

Considerations for International Buyers:

Buyers should consider local availability and transportation costs, especially in regions with limited infrastructure. Compliance with safety standards is also essential, particularly in Europe where regulations are stringent.

3. Polyethylene Terephthalate (PET)

Key Properties:

PET is a lightweight and flexible plastic with good chemical resistance and moderate temperature tolerance. It is less brittle than glass, making it suitable for applications requiring durability.

Pros & Cons:

The flexibility and lower cost of PET make it an attractive option for manufacturers. However, it does not offer the same level of optical clarity or scratch resistance as glass or ITO, which can affect the end product’s quality.

Impact on Application:

PET is compatible with various touch technologies and is often used in consumer electronics. Its lower durability compared to glass can be a concern in high-use environments.

Considerations for International Buyers:

Buyers should be aware of the recycling standards for plastics in their regions, particularly in Europe where environmental regulations are stringent. Understanding the local market’s acceptance of plastic materials is also crucial.

4. Conductive Silver Ink

Key Properties:

Conductive silver ink is used to create flexible circuits and is known for its excellent conductivity. It can be printed onto various substrates, allowing for innovative design possibilities.

Pros & Cons:

The ability to print conductive patterns offers design flexibility and can reduce manufacturing costs. However, the long-term durability of conductive inks can be a concern, especially in high-wear applications.

Impact on Application:

Conductive silver ink is ideal for applications requiring lightweight and flexible displays. However, its performance can degrade over time, impacting the reliability of touch functionality.

Considerations for International Buyers:

Buyers should evaluate the ink’s compatibility with local printing technologies and standards. Additionally, they should consider the sourcing of silver, which can be affected by market fluctuations.

Summary Table

| Material | Typical Use Case for capacitive touch display | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Indium Tin Oxide (ITO) | Touch sensors in smartphones and tablets | High transparency and conductivity | Brittle and prone to cracking | High |

| Glass Substrates | High-end touch displays | Excellent durability and optical clarity | Heavier and more expensive | Medium |

| Polyethylene Terephthalate (PET) | Consumer electronics | Lightweight and flexible | Lower optical clarity and scratch resistance | Low |

| Conductive Silver Ink | Flexible touch sensors | Design flexibility and lower manufacturing costs | Durability concerns over time | Medium |

This guide provides a comprehensive overview for B2B buyers, enabling informed decisions when selecting materials for capacitive touch displays. Each material’s unique properties and implications for specific applications should be carefully considered to align with business needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for capacitive touch display

The manufacturing of capacitive touch displays involves a complex series of processes and quality assurance measures to ensure that the final product meets the high standards required by modern technology. Understanding these processes can aid international B2B buyers in making informed decisions when selecting suppliers.

Manufacturing Processes

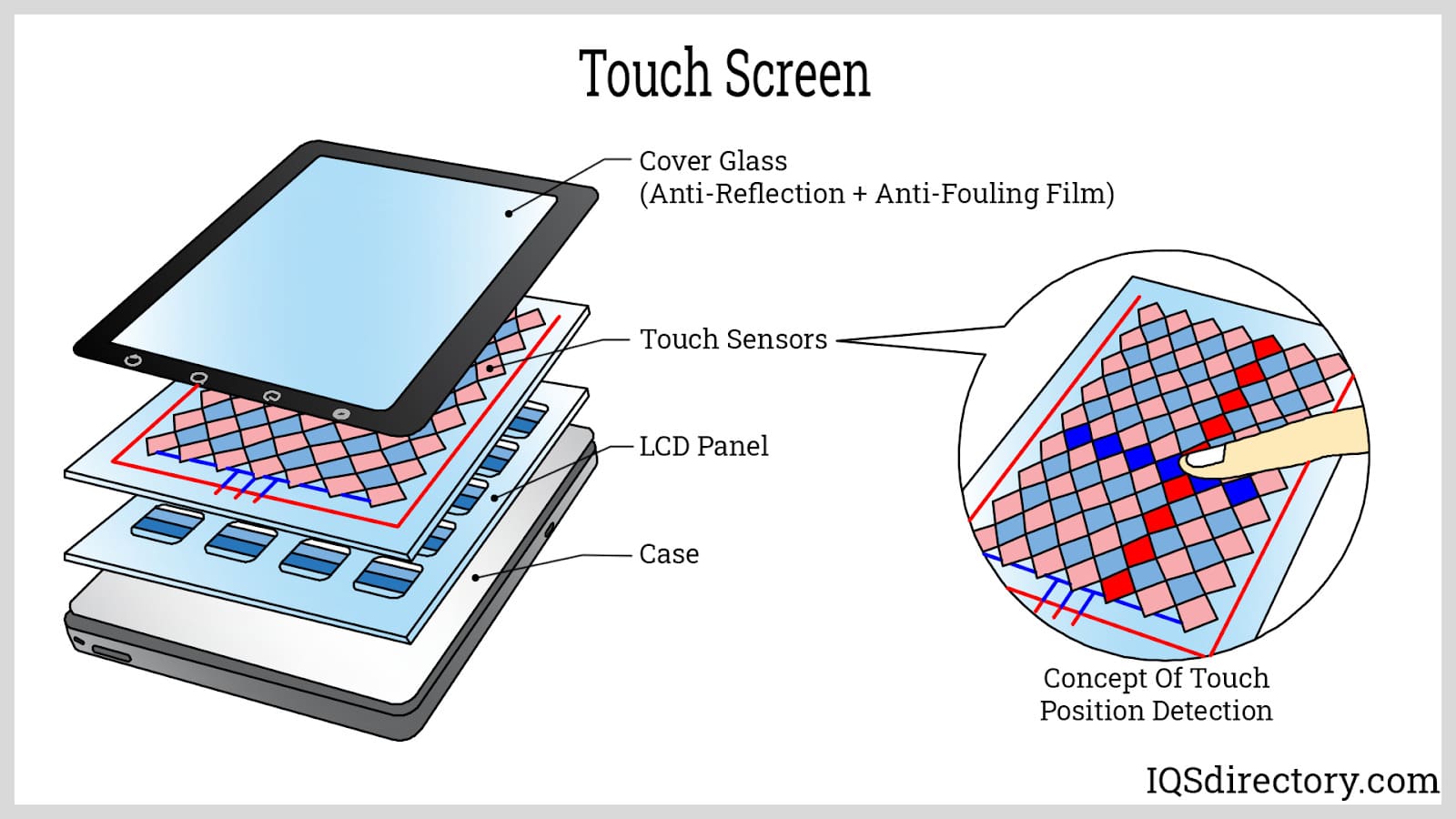

1. Material Preparation

The initial stage of capacitive touch display manufacturing involves sourcing high-quality raw materials. The primary materials include:

- Glass Substrate: This serves as the base layer and must be free of defects.

- Indium Tin Oxide (ITO): Used for creating the transparent conductive layers essential for touch sensitivity.

- Photoresist: A light-sensitive material applied during the etching process to form precise patterns.

The quality of these materials is critical, as impurities can lead to defects in the final product. Buyers should prioritize suppliers who can provide certificates of analysis for their materials.

2. Forming

This stage includes several key techniques:

- Sputtering: A process where ITO is deposited onto the glass substrate under vacuum conditions. This ensures a uniform coating, essential for touch sensitivity.

- Etching: Using laser or chemical methods, microscopic patterns are created on the coated glass. These patterns are crucial for detecting touch inputs.

- Lamination: Multiple layers, including the touch sensor and the LCD panel, are bonded together using optical adhesives. This step is vital for maintaining the display’s integrity and performance.

Each forming technique must be executed with precision. B2B buyers should inquire about the technologies and equipment used by potential suppliers to ensure they meet industry standards.

3. Assembly

In this stage, the various components come together:

- Integration of Layers: The laminated layers are aligned and bonded, ensuring that the optical and electrical properties are maintained.

- Final Assembly: This involves adding the protective cover glass and ensuring all components are securely fitted.

Proper assembly is critical for the durability and functionality of the capacitive touch display. Buyers should assess suppliers’ assembly capabilities and workforce training programs.

4. Finishing

The finishing stage includes several processes that enhance the product’s performance:

- Coating: Application of anti-reflective or oleophobic coatings to improve user experience.

- Quality Inspection: Each unit undergoes a thorough inspection to identify defects or inconsistencies.

This stage is crucial for ensuring that the touch display meets customer expectations. Buyers should request information about the finishing techniques employed by suppliers.

Quality Assurance

To ensure that capacitive touch displays are manufactured to the highest standards, suppliers must adhere to international and industry-specific quality assurance protocols.

Relevant International Standards

- ISO 9001: This standard outlines the requirements for a quality management system. Suppliers certified to this standard demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with safety, health, and environmental protection standards.

- API Standards: For suppliers involved in specific industries, adherence to American Petroleum Institute standards may also be relevant.

B2B buyers should verify the certifications held by their suppliers to ensure compliance with these standards.

Quality Control Checkpoints

Quality control is integrated throughout the manufacturing process, with several checkpoints established:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet predefined specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing to identify issues early.

- Final Quality Control (FQC): Comprehensive inspections are conducted before shipment to ensure the final product meets all quality standards.

Buyers should request detailed quality control reports from suppliers to understand how these checkpoints are implemented.

Common Testing Methods

Several testing methods are commonly employed to assess the quality of capacitive touch displays:

- Functionality Testing: Ensures that the touch sensors respond accurately to inputs.

- Durability Testing: Evaluates the resistance of the display to scratches and impacts.

- Environmental Testing: Assesses performance under various temperature and humidity conditions.

B2B buyers should inquire about the specific testing protocols used by potential suppliers.

Verifying Supplier Quality Control

To ensure that suppliers maintain high-quality standards, international B2B buyers can take several steps:

- Supplier Audits: Conduct on-site audits to assess manufacturing processes, equipment, and quality control measures.

- Request Quality Reports: Ask for detailed reports on past quality issues and how they were resolved.

- Third-Party Inspections: Engage third-party inspection services to evaluate the manufacturing process and product quality before shipment.

These actions can help mitigate risks associated with sourcing from international suppliers.

Quality Control and Certification Nuances

When dealing with suppliers from Africa, South America, the Middle East, and Europe, it’s important to consider regional variations in quality standards and certifications. Each region may have specific regulations and practices that affect manufacturing and quality assurance processes.

- Local Regulations: Understand the local regulatory environment that impacts manufacturing practices.

- Cultural Differences: Be aware of cultural factors that may influence quality management practices and supplier relationships.

- Language Barriers: Ensure that communication is clear and effective to avoid misunderstandings regarding quality expectations.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for capacitive touch displays is essential for B2B buyers. By focusing on material quality, manufacturing techniques, and robust quality control systems, buyers can ensure that they select suppliers capable of delivering high-quality products that meet their needs.

Related Video: Factory IO – Production Line Project ( Programmed using Control IO and Tia Portal )

Comprehensive Cost and Pricing Analysis for capacitive touch display Sourcing

When sourcing capacitive touch displays, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This section breaks down the critical cost components and price influencers, providing actionable insights to facilitate informed purchasing decisions.

Cost Components

-

Materials: The primary materials for capacitive touch displays include substrate glass, indium tin oxide (ITO) for conductive layers, and various adhesives and coatings. These materials are subject to market fluctuations, especially ITO, which can significantly affect overall costs.

-

Labor: Labor costs vary widely depending on the manufacturing location. Regions with lower labor costs, such as parts of South America and Africa, may offer competitive pricing, but this must be weighed against potential quality issues.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and general administrative costs. Buyers should consider suppliers with efficient manufacturing processes to minimize overhead costs.

-

Tooling: The initial setup for production, including molds and specialized machinery, can represent a significant upfront investment. Custom tooling for specific display configurations can increase costs but may be necessary for unique applications.

-

Quality Control (QC): Ensuring high standards through rigorous QC processes is vital. This includes testing for responsiveness, durability, and compliance with international standards, which can add to the overall cost.

-

Logistics: Shipping costs, customs duties, and storage fees must be factored into the total cost of ownership. Buyers should consider the impact of geographic distance and the chosen shipping method on logistics costs.

-

Margin: Suppliers will add a margin on top of their costs, influenced by their positioning in the market and the perceived value of their products. Understanding typical margins in the industry can aid buyers in negotiating better prices.

Price Influencers

-

Volume/MOQ: Pricing often varies based on the minimum order quantity (MOQ). Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should assess their needs carefully to balance inventory levels and cost savings.

-

Specifications/Customization: Custom specifications can increase costs. Buyers should clearly define their requirements, as additional features or modifications may involve more complex manufacturing processes.

-

Materials: The choice of materials can significantly influence pricing. Higher quality or specialty materials will typically incur higher costs. Buyers should evaluate whether the benefits justify the additional expenditure.

-

Quality/Certifications: Products that meet specific international standards or certifications may carry a premium price. Buyers in regulated industries should prioritize certified suppliers to ensure compliance, even if the upfront costs are higher.

-

Supplier Factors: Supplier reputation, reliability, and location can influence pricing. Established suppliers may offer higher prices due to perceived value and reliability, while newer entrants may be more competitive but less proven.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. They define responsibilities regarding shipping, insurance, and tariffs, which can impact total costs.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers to negotiate better terms. Leveraging relationships and demonstrating long-term potential can lead to favorable pricing.

-

Cost-Efficiency: Evaluate total cost of ownership rather than just upfront costs. Consider factors like lifespan, warranty, and maintenance when assessing value.

-

Pricing Nuances: Be aware that pricing may vary significantly across regions due to local economic conditions, import/export duties, and currency fluctuations. Buyers should conduct market research to benchmark prices effectively.

-

Regional Considerations: For buyers in Africa, South America, the Middle East, and Europe, understanding local market dynamics can provide leverage in negotiations. Tailoring approaches to specific regional conditions can enhance sourcing strategies.

Disclaimer

The prices discussed in this analysis are indicative and can vary based on the market conditions, supplier negotiations, and specific project requirements. It is advisable for buyers to conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential capacitive touch display Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘capacitive touch display’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for capacitive touch display

Key Technical Properties of Capacitive Touch Displays

When evaluating capacitive touch displays for B2B applications, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some of the key specifications to consider:

-

Material Grade

– Capacitive touch displays typically utilize Indium Tin Oxide (ITO) as a conductive material. The grade of ITO affects the display’s transparency and conductivity. Higher-grade materials provide better performance, which is vital for touch sensitivity and durability.

– B2B Importance: Choosing the right material grade ensures product reliability and longevity, minimizing replacement costs and enhancing user satisfaction. -

Thickness

– The thickness of the glass substrate and the touch sensor layer can vary between displays. Common thicknesses range from 0.5 mm to 3 mm. Thinner displays are often more sensitive and lighter but may be less durable.

– B2B Importance: Understanding the thickness is essential for integration into devices, affecting both the product’s aesthetics and its operational lifespan. -

Tolerance

– Tolerance refers to the allowable deviation in dimensions and performance of the touch display. High tolerance levels (±0.1 mm) ensure that components fit together correctly and function as intended.

– B2B Importance: Precision in manufacturing is crucial for device compatibility and performance. Poor tolerances can lead to malfunctions and increased warranty claims. -

Response Time

– This is the time taken for the display to register a touch input, typically measured in milliseconds. A lower response time indicates a more responsive touch experience.

– B2B Importance: In sectors like gaming or industrial applications, a quick response time can significantly enhance user experience, making it a critical factor in purchasing decisions. -

Durability Rating

– Displays are often rated for scratch resistance, impact resistance, and environmental factors (like moisture and temperature). Common standards include IP ratings for ingress protection.

– B2B Importance: Understanding durability ratings helps buyers select displays suited for specific environments, such as outdoor applications or industrial settings, reducing the likelihood of damage.

Common Trade Terminology

Familiarity with industry jargon can streamline communication and negotiations in the capacitive touch display market. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

– Refers to companies that produce parts or equipment that may be marketed by another manufacturer. For instance, a company that manufactures capacitive touch displays for smartphones.

– Importance: Knowing OEMs helps buyers identify reliable manufacturers and assess product compatibility with their devices. -

MOQ (Minimum Order Quantity)

– This term indicates the smallest number of units a supplier is willing to sell in a single order. MOQs can vary significantly based on the manufacturer and product type.

– Importance: Understanding MOQs allows buyers to plan inventory and manage cash flow effectively, especially for smaller businesses. -

RFQ (Request for Quotation)

– A formal process where buyers request pricing and terms from suppliers for specific quantities and specifications of products.

– Importance: Issuing RFQs enables buyers to compare prices and terms from multiple suppliers, ensuring they secure the best deal. -

Incoterms (International Commercial Terms)

– A set of predefined international sales terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery responsibilities, facilitating smoother international trade. -

Touch Sensitivity

– This term refers to how well a touch display can detect and respond to touch inputs. It is influenced by the technology used and the quality of materials.

– Importance: High touch sensitivity is essential for applications requiring precision, such as medical devices or industrial controls, impacting user interaction and satisfaction.

Understanding these properties and terms will empower B2B buyers to make informed decisions, ensuring that they select the most suitable capacitive touch displays for their applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the capacitive touch display Sector

Market Overview & Key Trends

The capacitive touch display market is experiencing significant growth, driven by advancements in technology and increasing demand for interactive devices across various sectors. Global drivers include the proliferation of smartphones, tablets, and IoT devices, which are increasingly integrating touch capabilities. According to recent market analyses, the market is expected to expand at a CAGR of over 7% through the next five years, with robust growth in regions such as Africa, South America, the Middle East, and Europe.

Emerging B2B Tech Trends: One of the most notable trends is the shift towards multi-touch technology, enabling more complex interactions on devices. Additionally, flexible and transparent displays are gaining traction, particularly in applications like automotive displays and wearables. As international B2B buyers, understanding these trends is crucial for sourcing products that meet the evolving demands of consumers.

Sourcing Dynamics: Sourcing strategies are also evolving, with a growing emphasis on localization to mitigate supply chain disruptions caused by geopolitical tensions and the pandemic. For buyers in Africa and South America, this means exploring regional manufacturers who can provide high-quality components while reducing lead times. Furthermore, the move towards digital procurement tools is streamlining the sourcing process, allowing for better visibility into supplier performance and inventory management.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of competitive advantage in the capacitive touch display sector. The environmental impact of traditional manufacturing processes, including the use of hazardous materials and high energy consumption, has prompted a shift towards more sustainable practices. For B2B buyers, prioritizing suppliers who demonstrate commitment to sustainability can enhance brand reputation and customer loyalty.

Importance of Ethical Supply Chains: Ethical sourcing is critical, particularly in regions like Africa and the Middle East, where supply chain transparency can be lacking. Buyers should seek partnerships with manufacturers that adhere to international labor standards and environmental regulations. This not only ensures compliance but also fosters goodwill in the communities where suppliers operate.

Green Certifications and Materials: Look for suppliers who offer green certifications, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals), which indicate adherence to environmental standards. Additionally, consider sourcing materials like recycled glass and eco-friendly coatings that reduce the environmental footprint of capacitive touch displays.

Brief Evolution/History

The capacitive touch display technology has evolved significantly since its inception in the early 1980s. Initially limited to niche applications, the technology gained mainstream traction with the advent of smartphones, particularly after Apple’s introduction of the iPhone in 2007. This milestone not only revolutionized user interaction but also spurred innovation in manufacturing processes, leading to higher quality and more responsive touch panels.

As the market matured, advancements in materials science, such as the development of indium tin oxide (ITO) for transparent conductive films, have enhanced performance and durability. Today, the industry is focused on integrating capacitive touch displays into a wider array of devices, from consumer electronics to industrial applications, reflecting the technology’s versatility and growing importance in the digital landscape. For B2B buyers, understanding this evolution provides valuable context for sourcing decisions and future investment strategies.

Related Video: Global Trends Tutorial: Chapter 3: IPE

Frequently Asked Questions (FAQs) for B2B Buyers of capacitive touch display

-

What criteria should I use to vet suppliers of capacitive touch displays?

When vetting suppliers, prioritize their experience and reputation in the industry. Check for certifications such as ISO 9001 or relevant quality assurance standards. Additionally, evaluate their production capabilities and technology used in manufacturing. Request references from previous clients and assess their financial stability to ensure they can meet your demands consistently. Conducting site visits, if possible, can provide deeper insights into their operations. -

Can capacitive touch displays be customized to meet specific requirements?

Yes, many suppliers offer customization options to meet specific needs. This includes variations in size, shape, touch sensitivity, and surface treatments like anti-glare or anti-fingerprint coatings. Communicate your requirements clearly and request prototypes to test before finalizing orders. It’s advisable to discuss customization capabilities during the supplier selection process to ensure they can deliver what you need. -

What are the typical minimum order quantities (MOQ) and lead times for capacitive touch displays?

MOQs can vary significantly among suppliers, often ranging from 100 to several thousand units, depending on the complexity and customization of the displays. Lead times also depend on the order size and specific customization, typically ranging from 4 to 12 weeks. To optimize your supply chain, negotiate terms that align with your production schedules and explore suppliers that offer flexible MOQs. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should implement rigorous quality assurance processes, including testing for touch sensitivity, durability, and compliance with international standards. Inquire about their QA protocols and whether they conduct inspections at various production stages. Request documentation of quality certifications and any testing results to verify the reliability of their products. -

How can I ensure compliance with international trade regulations?

Familiarize yourself with both your country’s import regulations and those of the supplier’s country. Ensure that the capacitive touch displays meet relevant safety and environmental standards, such as RoHS or CE marking. Collaborate with customs brokers or legal experts specializing in international trade to navigate complex regulations and avoid potential penalties or delays. -

What logistics considerations should I keep in mind when sourcing capacitive touch displays?

Logistics play a crucial role in the timely delivery of displays. Assess the supplier’s shipping options, including air and sea freight, and consider factors such as shipping costs, transit times, and customs clearance. Additionally, discuss packaging methods to prevent damage during transit. Establish a clear communication line for tracking shipments to stay informed about delivery timelines. -

What steps should I take if there’s a dispute with my supplier?

In case of a dispute, start by reviewing your contract and any agreements made regarding quality, delivery, and payment terms. Attempt to resolve the issue through direct communication with the supplier. If necessary, escalate the matter by involving a third-party mediator or arbitration service. Keeping a detailed record of all communications and transactions can support your case if legal action is required. -

What payment terms are common in international B2B transactions for capacitive touch displays?

Payment terms can vary widely, but common practices include a 30% upfront deposit with the remaining balance due upon delivery or a Letter of Credit (LC) arrangement for larger orders. Discuss payment methods, such as wire transfers, PayPal, or trade financing options, to find a mutually agreeable solution. Always ensure that payment terms are clearly outlined in your contract to avoid misunderstandings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for capacitive touch display

In conclusion, the strategic sourcing of capacitive touch displays is essential for international B2B buyers seeking to enhance their product offerings and maintain competitive advantage. By understanding the intricate manufacturing processes, including the critical roles of materials like indium tin oxide and various layering techniques, businesses can make informed decisions that align with their quality standards and budget constraints.

Key Takeaways:

– Quality Assurance: Prioritize suppliers that adhere to stringent quality control measures during production to ensure reliability and performance.

– Supplier Relationships: Foster strong relationships with manufacturers to negotiate better terms and gain insights into innovations in touch display technology.

– Market Trends: Stay updated on emerging trends and technological advancements that can influence sourcing strategies, particularly in fast-growing markets across Africa, South America, the Middle East, and Europe.

As we look to the future, the demand for advanced capacitive touch displays is poised to grow, fueled by innovations in consumer electronics and smart devices. Now is the time for B2B buyers to engage with reputable suppliers, explore collaborative opportunities, and leverage strategic sourcing to capitalize on this dynamic market.

Illustrative Image (Source: Google Search)