Your Ultimate Guide to Sourcing Power Press Machine

Introduction: Navigating the Global Market for power press machine

In the rapidly evolving landscape of global manufacturing, power press machines stand as essential assets, driving efficiency and precision in production processes. These versatile machines are integral to a range of industries, including automotive, aerospace, and consumer electronics, where they facilitate the shaping, cutting, and forming of materials with unparalleled accuracy. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to enhance their manufacturing capabilities, understanding the nuances of power press technology becomes critical.

Illustrative Image (Source: Google Search)

This guide offers a comprehensive exploration of power press machines, covering key aspects such as types, material compatibility, manufacturing processes, quality control measures, and supplier selection. Buyers will find detailed insights into the costs associated with different models, as well as an analysis of the current market trends affecting procurement decisions.

Moreover, this resource addresses frequently asked questions, empowering decision-makers to navigate the complexities of sourcing power press machines effectively. By equipping buyers with the knowledge necessary to make informed choices, this guide facilitates strategic investments that can significantly enhance operational productivity and competitiveness in the global market. As you embark on your journey to optimize your manufacturing processes, let this guide serve as your trusted resource for understanding the power press machine landscape.

Understanding power press machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Press | Operates via a flywheel; high-speed production | Metal stamping, punching, bending | Pros: Fast operation, cost-effective. Cons: Limited force range compared to hydraulic. |

| Hydraulic Press | Uses hydraulic fluid for force; versatile | Molding, crushing, forming | Pros: High force application, flexible. Cons: Slower than mechanical presses. |

| Pneumatic Press | Operates with compressed air; lightweight | Assembly, punching, clinching | Pros: Quick operation, minimal maintenance. Cons: Limited to lighter tasks. |

| Multi-Station Press | Integrates multiple operations in one machine | High-volume production lines | Pros: Increased efficiency, reduced handling. Cons: Higher initial investment. |

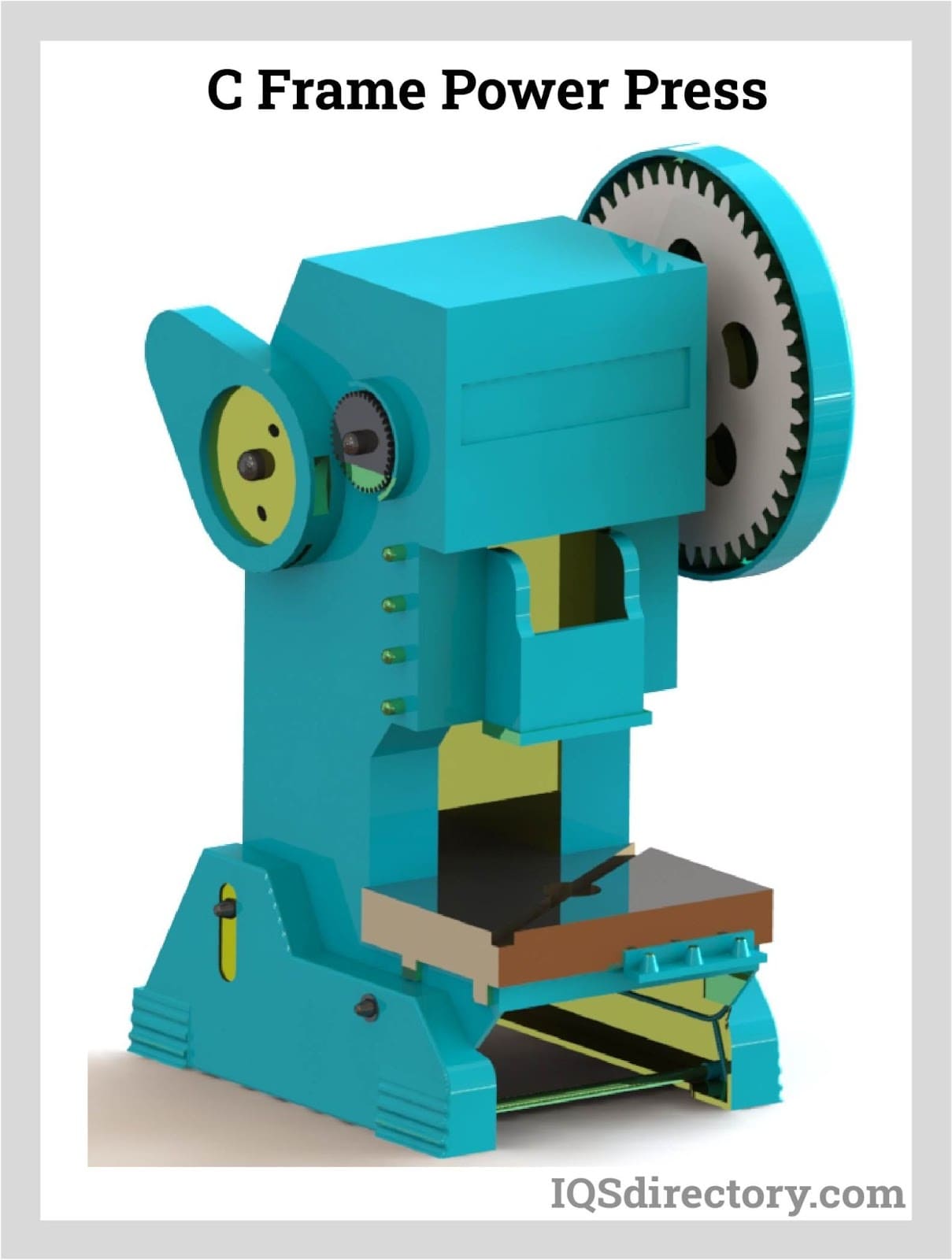

| C-Frame Press | C-shaped frame for easy access | Small to medium production runs | Pros: Simple setup, versatile. Cons: Limited to smaller operations. |

Mechanical Press

Mechanical presses are characterized by their use of a flywheel mechanism, allowing for high-speed operations that are ideal for mass production. They excel in applications such as metal stamping and bending due to their efficiency and cost-effectiveness. When considering a mechanical press, buyers should evaluate the volume of production and the specific types of materials being processed, as these factors influence the press’s performance and longevity.

Hydraulic Press

Hydraulic presses utilize hydraulic fluid to generate force, making them suitable for tasks that require significant pressure, such as molding and crushing. Their versatility allows them to handle a wide range of materials, including metals and plastics. For B2B buyers, it is essential to assess the force requirements of their applications and the complexity of the shapes being produced, as hydraulic presses can provide the necessary flexibility and control.

Pneumatic Press

Pneumatic presses operate using compressed air, making them lightweight and fast. They are commonly used in assembly and punching applications, where speed is crucial. Buyers should consider the operational environment and the types of tasks to be performed, as pneumatic presses are best suited for lighter applications and may require additional air supply infrastructure.

Multi-Station Press

Multi-station presses combine several operations into one machine, significantly enhancing production efficiency. This type of press is particularly beneficial for high-volume production environments, as it reduces handling time and increases output. Buyers should weigh the initial investment against the potential for increased productivity and lower operational costs in the long run.

C-Frame Press

C-frame presses feature a C-shaped design that allows easy access to the working area, making them ideal for small to medium production runs. They are straightforward to set up and operate, which is advantageous for businesses looking for flexibility. When purchasing a C-frame press, buyers should consider the size of the components being produced and the intended production volume to ensure the machine meets their needs.

Related Video: Machine Learning in 2024 – Beginner’s Course

Key Industrial Applications of power press machine

| Industry/Sector | Specific Application of power press machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Stamping and forming metal body parts | High-volume production with precision and consistency | Ensure compatibility with existing production lines and safety standards. |

| Aerospace | Precision forming of structural components | Enhanced safety and compliance with strict regulations | Look for advanced control systems and durability under high-stress conditions. |

| Consumer Electronics | Molding and shaping parts for electronic devices | Faster production cycles and reduced material waste | Assess the machine’s versatility to handle various materials and designs. |

| Heavy Machinery | Fabrication of parts for machinery assembly | Improved efficiency and reduced lead times | Evaluate the machine’s force capacity and adaptability to different manufacturing processes. |

| Metal Fabrication | Punching, shearing, and bending metal sheets | Cost-effective mass production and high accuracy | Consider the machine’s operational speed and ease of maintenance. |

Automotive Industry

In the automotive sector, power press machines are vital for stamping and forming metal body parts, such as chassis and panels. These machines enable manufacturers to achieve high-volume production while maintaining precision and consistency, crucial for vehicle safety and performance. For international buyers, especially in emerging markets like Nigeria and Mexico, it is essential to ensure that the selected machinery complies with local safety standards and integrates seamlessly with existing production lines to minimize downtime.

Aerospace

Aerospace manufacturing relies heavily on power press machines for the precision forming of structural components, such as wing frames and fuselage sections. The ability to maintain tight tolerances is critical in this sector to meet stringent safety regulations. Buyers from regions like the Middle East and Europe should prioritize sourcing machines equipped with advanced control systems that can handle the complexities of aerospace applications, ensuring durability and reliability under high-stress conditions.

Consumer Electronics

In the consumer electronics industry, power press machines are employed for molding and shaping parts for devices like smartphones and tablets. These machines facilitate faster production cycles and help reduce material waste, which is vital for maintaining competitive pricing in a rapidly evolving market. International B2B buyers should assess the machine’s versatility to handle various materials and designs, ensuring that it meets the diverse needs of electronic manufacturing.

Heavy Machinery

Power press machines are also utilized in the fabrication of parts for heavy machinery assembly, such as gears and housings. The efficiency gained from using these machines translates to reduced lead times and improved overall productivity. For businesses in South America and Africa, evaluating the machine’s force capacity and adaptability to different manufacturing processes is crucial, as it can greatly impact operational efficiency and cost-effectiveness.

Metal Fabrication

In metal fabrication, power press machines are essential for operations like punching, shearing, and bending metal sheets. These applications allow for cost-effective mass production while ensuring high accuracy and quality of finished products. Buyers should consider the operational speed and ease of maintenance when sourcing power press machines, as these factors significantly influence productivity and long-term investment returns in competitive markets.

Related Video: Power press punching stamping machine automatic feeder feeding robot arm

Strategic Material Selection Guide for power press machine

When selecting materials for power press machines, it is essential to consider their properties, advantages, disadvantages, and how they impact specific applications. Below is an analysis of four common materials used in the construction of power press machines, tailored for international B2B buyers.

Steel

Key Properties: Steel is renowned for its high strength-to-weight ratio and excellent durability. It typically exhibits good temperature resistance (up to 500°C) and can withstand significant pressure, making it ideal for heavy-duty applications.

Pros & Cons: The primary advantage of steel is its strength and durability, which contributes to the longevity of power press machines. However, it can be susceptible to corrosion if not properly treated, which may lead to increased maintenance costs. Manufacturing complexity is moderate, as steel can be easily welded and machined.

Impact on Application: Steel is suitable for high-stress applications, such as automotive and aerospace manufacturing, where precision and reliability are critical. Its compatibility with various media makes it versatile for different manufacturing processes.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM and DIN for steel quality. Additionally, sourcing from local suppliers may reduce costs and lead times.

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has a good thermal conductivity rating. It can withstand temperatures up to 400°C without significant deformation.

Pros & Cons: The lightweight nature of aluminum allows for easier handling and reduced energy consumption during operation. However, it is generally less durable than steel and may not be suitable for high-stress applications. The manufacturing process can be more complex due to aluminum’s tendency to deform under pressure.

Impact on Application: Aluminum is ideal for applications requiring lightweight components, such as in consumer electronics and automotive parts. Its corrosion resistance makes it suitable for environments where moisture is a concern.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of the specific grades of aluminum required for their applications, adhering to standards like JIS and EN. Sourcing aluminum from local suppliers may also help mitigate import tariffs.

Cast Iron

Key Properties: Cast iron is characterized by its excellent wear resistance and ability to dampen vibrations. It can handle high temperatures and pressures, making it suitable for heavy machinery.

Pros & Cons: The primary advantage of cast iron is its durability and ability to absorb shock, which enhances the machine’s operational stability. However, it is brittle and can crack under extreme stress, limiting its application in high-impact scenarios. The manufacturing process is straightforward but can be costly due to the need for specialized molds.

Impact on Application: Cast iron is commonly used in the bases and frames of power press machines, providing stability and support. Its vibration-damping properties are particularly beneficial in high-speed operations.

Considerations for International Buyers: Buyers should ensure compliance with local casting standards and consider the availability of skilled labor for maintenance and repair. Regions like Nigeria may have specific requirements for cast iron quality that must be met.

Composite Materials

Key Properties: Composites are engineered materials that combine two or more constituent materials to achieve enhanced properties, such as increased strength and reduced weight.

Pros & Cons: The primary advantage of composites is their tailored properties, which can be designed for specific applications. They are resistant to corrosion and have a high strength-to-weight ratio. However, the manufacturing process can be complex and costly, and they may not be as widely available as traditional materials.

Impact on Application: Composites are suitable for specialized applications where weight reduction is critical, such as in aerospace. Their versatility allows for innovative designs that can improve machine performance.

Considerations for International Buyers: Buyers should be aware of the specific composite materials available in their region and their compliance with international standards. In regions like South America, sourcing may be limited, necessitating partnerships with specialized suppliers.

Summary Table

| Material | Typical Use Case for power press machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Lightweight components | Lightweight and corrosion-resistant | Less durable under high stress | Medium |

| Cast Iron | Machine bases and frames | Excellent wear resistance | Brittle and can crack under stress | High |

| Composite Materials | Specialized applications | Tailored properties and lightweight | Complex and costly manufacturing | High |

This material selection guide provides actionable insights for international B2B buyers, helping them make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for power press machine

In the manufacturing of power press machines, a systematic approach is essential to ensure both efficiency and quality. Understanding the typical manufacturing processes and quality assurance protocols is crucial for B2B buyers, particularly those operating in diverse regions like Africa, South America, the Middle East, and Europe. This section will explore the main stages of manufacturing, key techniques, relevant international standards, and how buyers can effectively verify supplier quality control (QC).

Illustrative Image (Source: Google Search)

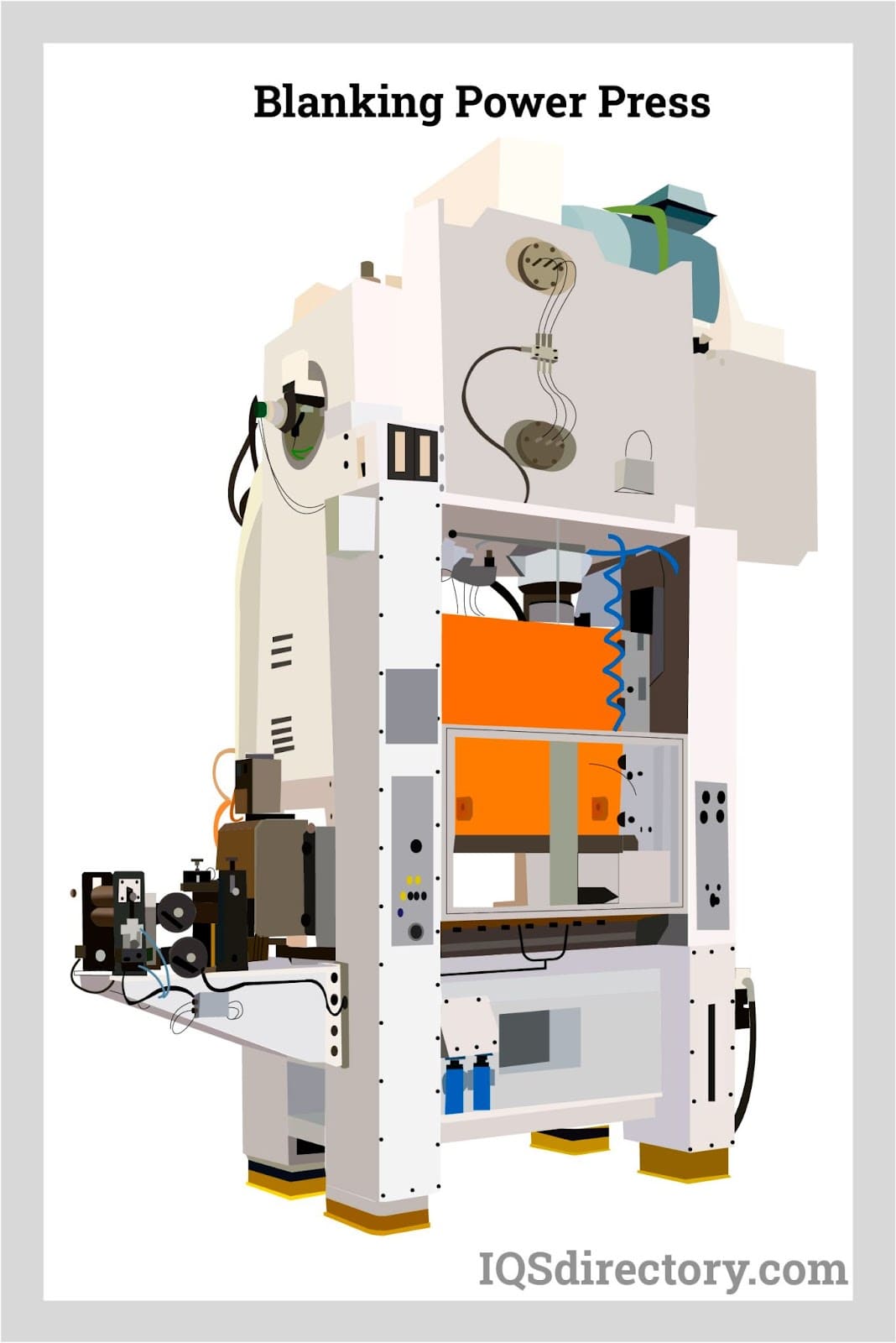

Manufacturing Processes

The manufacturing of power press machines can be broken down into four main stages: material preparation, forming, assembly, and finishing. Each stage plays a significant role in ensuring the final product meets stringent quality and performance standards.

1. Material Preparation

The first stage involves selecting and preparing raw materials, which typically include high-strength steel and other alloys. Key activities in this stage include:

- Material Selection: Choosing the right material based on the desired strength, ductility, and resistance to wear.

- Cutting and Shaping: Raw materials are cut into manageable sizes using techniques such as shearing or laser cutting.

- Surface Treatment: To enhance durability and resistance to corrosion, materials may undergo surface treatments like galvanization or powder coating.

2. Forming

In this stage, the prepared materials are transformed into specific components of the power press machine. Common techniques include:

- Stamping and Punching: Utilizing mechanical or hydraulic presses to shape materials into desired forms.

- Bending: Applying pressure to create angles or curves in metal sheets.

- Welding: Joining different components together using techniques such as MIG or TIG welding, ensuring strong and durable connections.

3. Assembly

Once the individual components are formed, they are assembled into the final power press machine. This stage typically involves:

- Sub-assembly: Grouping similar parts together for easier handling and integration.

- Main Assembly: Combining all sub-assemblies and components, including the drive mechanism, control systems, and safety features.

- Alignment and Calibration: Ensuring all components are properly aligned and calibrated for optimal performance.

4. Finishing

The final stage involves applying any necessary finishes and conducting pre-delivery inspections. Key processes include:

- Surface Finishing: Techniques such as painting, powder coating, or anodizing to enhance aesthetics and protect against environmental factors.

- Quality Checks: Conducting thorough inspections to ensure all parts meet specifications and perform as intended.

Quality Assurance (QA)

Quality assurance is a critical aspect of manufacturing power press machines, ensuring that products meet industry standards and customer expectations. Internationally recognized standards, along with industry-specific certifications, guide these processes.

Relevant International Standards

- ISO 9001: This standard outlines the criteria for a quality management system (QMS) and is applicable to any organization. Compliance with ISO 9001 demonstrates a commitment to quality and continuous improvement.

- CE Marking: Required for products sold in the European Economic Area (EEA), CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For power presses used in industries such as oil and gas, adherence to American Petroleum Institute (API) standards ensures reliability and safety.

QC Checkpoints

Effective quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials upon delivery to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify and rectify defects early.

- Final Quality Control (FQC): Comprehensive testing of finished products to confirm they meet all performance and safety specifications.

Common Testing Methods

To ensure quality, various testing methods are employed, including:

- Dimensional Inspection: Verifying the dimensions of components against specifications using tools like calipers and micrometers.

- Functional Testing: Assessing the performance of the power press under operational conditions to ensure it meets required performance standards.

- Safety Testing: Checking safety features and emergency shutdown mechanisms to ensure compliance with safety regulations.

Verification of Supplier QC

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. Here are actionable steps to ensure supplier reliability:

- Conduct Audits: Regular audits of suppliers’ facilities can provide insights into their manufacturing processes and adherence to quality standards.

- Request Quality Reports: Suppliers should be able to provide documentation of their QC processes, including results of IQC, IPQC, and FQC.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased evaluation of the supplier’s quality control practices and product reliability.

Quality Control and Certification Nuances for International Buyers

International B2B buyers must be aware of regional nuances in quality control and certification:

- Understanding Local Regulations: Different regions may have specific regulations that impact the certification process. Buyers should familiarize themselves with local standards and compliance requirements.

- Navigating Language Barriers: Communication is key; ensure that suppliers can provide documentation and support in a language that is clear and understandable.

- Cultural Considerations: Be mindful of cultural differences that may affect business practices, including negotiation styles and expectations regarding quality.

In summary, the manufacturing processes and quality assurance protocols for power press machines are complex yet essential. By understanding these elements, international B2B buyers can make informed decisions, ensuring they source high-quality machinery that meets their operational needs and complies with relevant standards.

Related Video: Amazing factories | Manufacturing method and top 4 processes | Mass production process

Comprehensive Cost and Pricing Analysis for power press machine Sourcing

Understanding the cost structure and pricing dynamics of power press machines is crucial for international B2B buyers. A clear grasp of these factors will empower buyers to make informed decisions, optimize procurement strategies, and ultimately enhance their competitive edge in the market.

Cost Components

-

Materials: The cost of raw materials, such as steel or aluminum, significantly impacts the overall pricing of power press machines. Higher quality materials often lead to increased costs but can enhance durability and performance.

-

Labor: Labor costs vary by region and can significantly affect the price. Skilled labor in manufacturing countries like Germany or Japan may command higher wages compared to emerging markets in Africa or South America. This factor is essential when considering the total cost of ownership.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Overhead costs can vary significantly based on the manufacturer’s location and efficiency.

-

Tooling: Tooling costs are associated with the design and creation of molds or dies used in the production of parts. Custom tooling can elevate costs significantly, particularly for specialized applications.

-

Quality Control (QC): Rigorous QC processes ensure that machines meet industry standards and specifications. Investing in quality assurance can reduce long-term costs by minimizing defects and improving reliability.

-

Logistics: Shipping and handling costs are crucial, especially for international buyers. These costs can fluctuate based on distance, transportation modes, and current fuel prices.

-

Margin: Suppliers typically add a profit margin to cover business expenses and earn a profit. Understanding the typical margins in your target market can aid in negotiation.

Price Influencers

-

Volume/MOQ: Manufacturers often offer better pricing for larger orders due to economies of scale. Understanding minimum order quantities (MOQs) is vital for negotiating favorable terms.

-

Specifications/Customization: Custom features or specifications can lead to higher costs. Buyers should clearly define their requirements to avoid unexpected expenses during the manufacturing process.

-

Materials: The choice of materials directly affects both the performance and price of power press machines. Buyers should balance between cost and quality based on their operational needs.

-

Quality/Certifications: Machines that meet international quality standards or have specific certifications may come at a premium. However, investing in certified equipment can lead to long-term savings through enhanced reliability and reduced downtime.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a history of quality and service may charge more, but they often provide greater peace of mind.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) can impact the total cost by determining who bears responsibility for shipping, insurance, and tariffs. Understanding these terms is essential for accurate cost estimation.

Buyer Tips

-

Negotiation: Always negotiate pricing. Leverage your purchasing power and market knowledge to secure better deals. Consider discussing long-term partnerships for more favorable terms.

-

Cost Efficiency: Assess the total cost of ownership (TCO) rather than just the initial purchase price. Factors such as maintenance, operational costs, and potential downtime should be included in your calculations.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and import duties, which can significantly impact final costs. Establish clear communication with suppliers to understand all potential fees.

-

Research Local Markets: Buyers from Africa, South America, the Middle East, and Europe should research local suppliers and manufacturers, as regional differences can lead to significant price variations.

Disclaimer

Prices for power press machines can vary widely based on the aforementioned factors. It is advisable to obtain multiple quotes and conduct thorough market research to ensure the best deal tailored to your specific needs. Always consult with industry experts or procurement specialists when navigating complex purchasing decisions.

Spotlight on Potential power press machine Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘power press machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for power press machine

When considering the purchase of a power press machine, understanding its technical properties and industry terminology is crucial for making informed decisions. This knowledge not only aids in selecting the right machine but also facilitates smoother negotiations and communications with suppliers. Below are essential specifications and terms that every international B2B buyer should be familiar with.

Key Technical Properties of Power Press Machines

-

Material Grade

– Definition: Refers to the quality and type of materials used in the construction of the power press, typically involving steel grades like A36 or S235.

– B2B Importance: Higher-grade materials enhance durability and performance, reducing maintenance costs and downtime. Buyers should ensure the machine’s material grade aligns with their operational requirements. -

Press Capacity

– Definition: Measured in tons, this indicates the maximum force the power press can exert on a workpiece.

– B2B Importance: Understanding press capacity is vital for determining if the machine can handle specific materials and thicknesses. A higher capacity often translates to more versatility in applications. -

Stroke Length

– Definition: The distance the ram travels during operation, which influences the depth of the workpiece being processed.

– B2B Importance: Buyers need to match stroke length with the intended applications. For instance, deeper strokes are necessary for bending or forming thicker materials. -

Speed (Strokes per Minute)

– Definition: This indicates how many times the ram can complete a full cycle in one minute.

– B2B Importance: High-speed presses are suitable for mass production, while slower speeds may be preferable for detailed work. Understanding speed helps in aligning the machine’s capabilities with production demands. -

Tolerance

– Definition: The acceptable range of deviation from a specified dimension, crucial for precision engineering.

– B2B Importance: Tight tolerances are essential in industries like aerospace and automotive, where precision is critical. Buyers must verify that the power press can achieve their required tolerances. -

Control System

– Definition: Refers to the technology used to operate the machine, which can be manual, semi-automated, or fully automated.

– B2B Importance: An advanced control system can enhance efficiency and safety. Buyers should assess whether the control system aligns with their workforce capabilities and production needs.

Common Trade Terms in Power Press Transactions

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding whether the power press is an OEM product can influence quality assurance and service options. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their budgets and inventory. It can also affect the cost-effectiveness of the purchase. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting a price quote for specific products or services.

– Importance: Issuing an RFQ allows buyers to compare pricing and terms from multiple suppliers, ensuring they get the best deal.

-

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of sellers and buyers in international transactions.

– Importance: Familiarity with Incoterms is crucial for understanding shipping responsibilities, costs, and risks associated with the transportation of the power press. -

Lead Time

– Definition: The time it takes from placing an order to receiving the product.

– Importance: Understanding lead time helps buyers plan their production schedules and manage inventory effectively. -

Warranty

– Definition: A guarantee provided by the manufacturer regarding the condition and performance of the machine.

– Importance: A robust warranty can protect buyers from defects and failures, reducing long-term costs associated with repairs and replacements.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of power press procurement with greater confidence and strategic insight. This knowledge empowers them to make choices that align with their production goals and operational standards.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the power press machine Sector

Market Overview & Key Trends

The power press machine sector is witnessing significant transformation driven by advancements in technology and changing market dynamics. Global drivers such as the increasing demand for precision-engineered components, especially in the automotive and aerospace industries, are propelling growth. Emerging markets in Africa, South America, and the Middle East are particularly vital, as they seek to enhance their manufacturing capabilities and reduce reliance on imports. Notably, countries like Nigeria and Mexico are investing heavily in local manufacturing, which presents substantial opportunities for international suppliers.

Current and emerging B2B tech trends include the integration of automation and smart technologies in power press machines. Manufacturers are increasingly adopting Industry 4.0 principles, utilizing IoT devices to enhance operational efficiency and data analytics for predictive maintenance. This shift not only improves productivity but also extends the lifespan of machinery. Furthermore, there is a growing trend towards customization, as businesses seek to tailor machines to specific production needs, enhancing their competitive edge.

Market dynamics indicate a shift towards strategic partnerships and collaborations. International buyers are encouraged to engage with local manufacturers to leverage their understanding of regional market conditions and regulatory environments. Additionally, the rise of e-commerce platforms is facilitating easier access to suppliers, enabling B2B buyers to compare products and prices more effectively. As such, fostering relationships with reliable partners in these emerging markets can yield long-term benefits.

Sustainability & Ethical Sourcing in B2B

As sustainability becomes a focal point in global manufacturing, the power press machine sector is not left behind. The environmental impact of manufacturing processes, particularly energy consumption and waste generation, is under scrutiny. Therefore, international buyers must prioritize sustainable sourcing practices. This includes selecting suppliers that demonstrate a commitment to reducing their carbon footprint and implementing eco-friendly manufacturing processes.

Ethical supply chains are increasingly important, with buyers looking for transparency in sourcing materials. Engaging suppliers who adhere to ethical labor practices and fair trade principles not only enhances brand reputation but also mitigates risks associated with supply chain disruptions. Furthermore, buyers should seek out green certifications, such as ISO 14001 or LEED, which indicate a supplier’s commitment to sustainability.

Green materials in the manufacturing of power press machines, such as recyclable metals and biodegradable lubricants, are gaining traction. By opting for suppliers that utilize these materials, businesses can significantly reduce their environmental impact while meeting consumer demand for sustainability. This approach not only aligns with global sustainability goals but also opens up new market opportunities as eco-conscious consumers increasingly favor brands that prioritize ethical practices.

Brief Evolution/History

The evolution of power press machines dates back to the mid-19th century when they were first introduced to enhance metalworking capabilities. Initially, mechanical presses dominated the market due to their speed and efficiency in mass production. However, the advent of hydraulic technology in the 20th century revolutionized the industry by enabling machines to apply greater force and flexibility, allowing for more complex shaping and forming processes.

In recent years, the integration of automation and digital technologies has further transformed the sector, leading to smarter, more efficient machines that can adapt to various manufacturing needs. This historical progression highlights the ongoing innovation within the power press machine sector, making it essential for B2B buyers to stay informed about technological advancements and their implications for production efficiency and sustainability.

Related Video: Global trade will never be the same again, says Christine Lagarde | Power & Politics

Frequently Asked Questions (FAQs) for B2B Buyers of power press machine

-

What should I consider when vetting suppliers for power press machines?

When vetting suppliers, prioritize their experience in the industry, production capacity, and quality assurance practices. Look for certifications such as ISO 9001, which indicate adherence to international quality standards. It’s also essential to evaluate their customer service responsiveness and support capabilities. Request references from previous clients to gauge reliability. Additionally, consider visiting their manufacturing facilities if possible, or utilize virtual tours to assess their operations firsthand. -

Can power press machines be customized to meet specific production needs?

Yes, many suppliers offer customization options for power press machines to fit unique production requirements. Customizations can include modifications to size, force capacity, or specific tooling configurations. When discussing customization, be clear about your operational needs and expectations. Ensure that the supplier provides a detailed proposal outlining the modifications, timelines, and any additional costs involved. This clarity will help avoid misunderstandings during the manufacturing process. -

What are the typical minimum order quantities (MOQ) and lead times for power press machines?

Minimum order quantities can vary significantly between suppliers, often depending on the machine’s specifications and customization requirements. For standard models, MOQs may range from one unit to several, while custom machines might require higher quantities. Lead times also depend on production schedules and complexity but typically range from 4 to 12 weeks. Always confirm these details with the supplier early in negotiations to align your production schedules accordingly. -

What payment terms are common when purchasing power press machines internationally?

Payment terms can differ widely among suppliers but often include options like a deposit upfront (usually 30-50%) with the balance due before shipment. Some suppliers may offer financing options or extended payment terms for larger orders. It’s crucial to negotiate terms that protect your interests, such as using a letter of credit or escrow services to ensure that funds are only released upon meeting agreed-upon conditions. Clarifying these terms in advance can prevent disputes later. -

How can I ensure quality assurance and certifications for power press machines?

To ensure quality, request copies of the supplier’s certifications, such as ISO 9001 or CE marking, which indicate compliance with international safety and quality standards. Additionally, inquire about their quality control processes, including inspection methods and testing protocols before shipment. It’s advisable to conduct a factory audit if feasible or use third-party inspection services to verify that the machines meet your specifications and quality expectations. -

What logistics considerations should I keep in mind when importing power press machines?

Logistics are critical when importing machinery. Consider the mode of transport (air vs. sea), as it will affect delivery times and costs. Ensure that the supplier provides all necessary shipping documentation, including invoices, packing lists, and customs declarations. Also, factor in local regulations regarding machinery imports, which may require specific certifications or inspections. Engaging a freight forwarder familiar with importing machinery can streamline the process and help avoid delays. -

What steps can I take to resolve disputes with suppliers?

To resolve disputes effectively, first, try to communicate directly with the supplier to discuss the issue and seek a mutually agreeable solution. Document all communications and agreements to establish a clear record. If direct negotiation fails, consider involving a mediator or arbitrator, particularly if you have a contract outlining dispute resolution procedures. Additionally, be aware of the legal framework governing international trade in your agreements, as this may influence the resolution process. -

Are there any specific safety standards I should be aware of when purchasing power press machines?

Yes, safety standards vary by region but typically include compliance with OSHA regulations in the U.S. and CE marking in Europe. Ensure that the machines have safety features like emergency stop buttons, guards, and sensors to protect operators. Familiarize yourself with local regulations regarding the installation and operation of industrial machinery. Request documentation from the supplier confirming adherence to these standards to safeguard your workforce and comply with legal requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for power press machine

As the manufacturing landscape continues to evolve, strategic sourcing of power press machines becomes increasingly vital for businesses aiming to enhance productivity and maintain competitive advantage. Key takeaways for international B2B buyers include understanding the diverse types of power presses—mechanical, hydraulic, pneumatic, and multi-station—and their specific applications across industries such as automotive, aerospace, and consumer electronics. Investing in the right machinery not only ensures operational efficiency but also supports safety and compliance with industry standards.

For buyers in regions like Africa, South America, the Middle East, and Europe, leveraging global supply chains can lead to cost-effective procurement and access to advanced technology. Engaging with reputable suppliers who prioritize innovation and customer support is essential.

Looking ahead, the integration of automation and smart technologies in power press machines will likely reshape production capabilities. Now is the time to evaluate your manufacturing needs and explore partnerships that can drive growth and efficiency. By prioritizing strategic sourcing today, you position your business for success in an increasingly competitive global market.