Your Ultimate Guide to Sourcing Technical Plating Inc

Introduction: Navigating the Global Market for technical plating inc

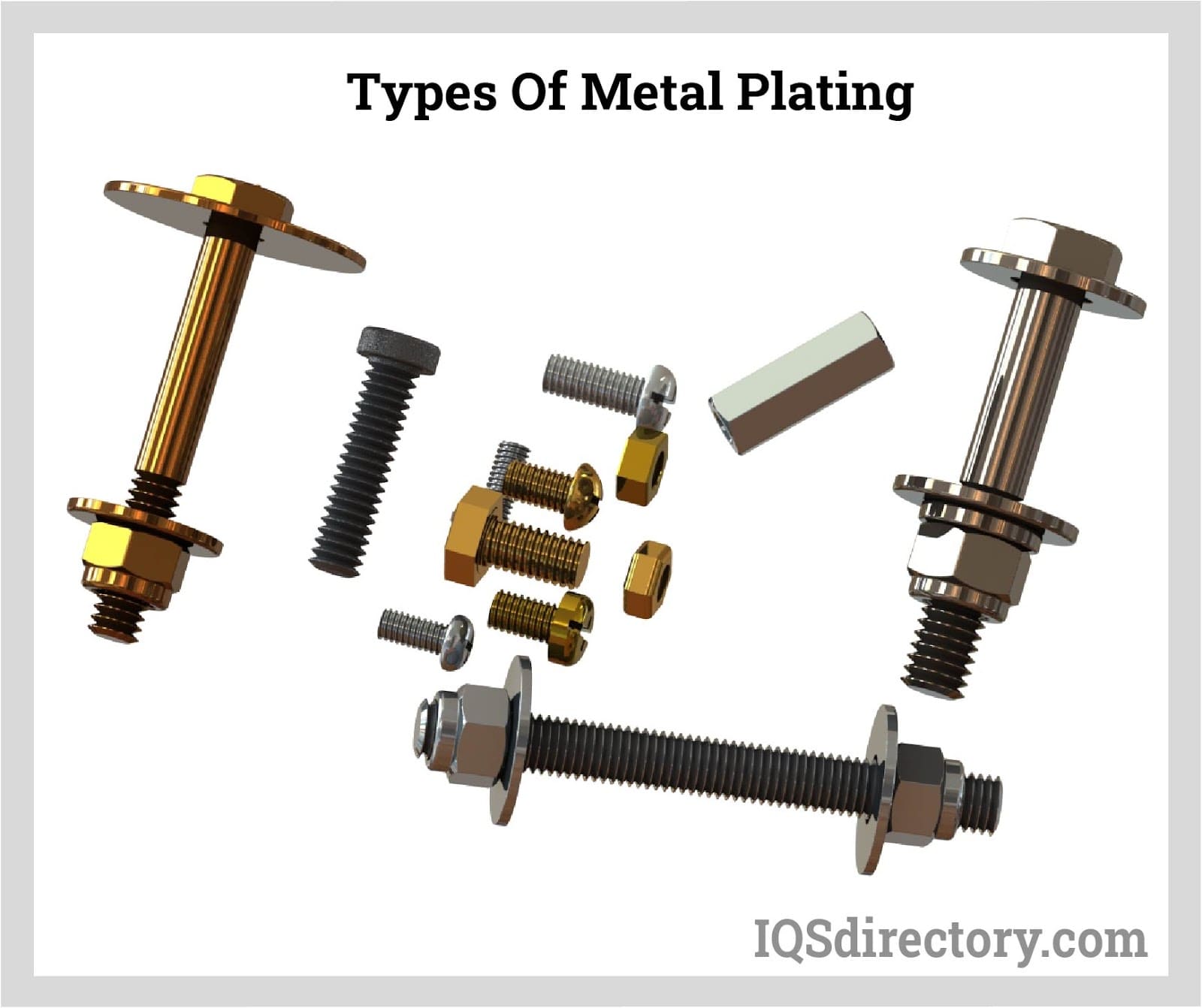

Navigating the intricate landscape of technical plating is essential for international B2B buyers seeking reliable and high-quality metal finishing solutions. Technical Plating Inc. has established itself as a vital player in this market, offering diverse plating services that enhance the durability and aesthetic appeal of various components. As global industries continue to expand, the demand for specialized plating services—such as tin, zinc, silver, and nickel plating—has surged, making informed sourcing decisions more critical than ever.

This guide serves as a comprehensive resource, detailing various aspects of technical plating, including types of plating processes, materials used, manufacturing and quality control standards, and a thorough analysis of suppliers. It will also provide insights into cost considerations and current market trends, empowering B2B buyers from regions like Africa, South America, the Middle East, and Europe—such as South Africa and Mexico—to make strategic purchasing choices.

By delving into frequently asked questions, buyers will gain clarity on common concerns and best practices related to technical plating. Whether you are a seasoned procurement professional or new to the field, this guide is designed to equip you with actionable insights, enabling you to navigate the global market with confidence and precision.

Understanding technical plating inc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tin Plating | Provides excellent solderability and corrosion resistance. | Electronics, automotive components, and connectors. | Pros: Cost-effective, good for soldering. Cons: Less durable under mechanical stress. |

| Zinc Plating | Offers good corrosion protection and can be chromate treated for added durability. | Fasteners, automotive parts, and construction hardware. | Pros: Economical, versatile. Cons: Limited high-temperature performance. |

| Nickel Plating | Provides a hard, wear-resistant finish with excellent corrosion resistance. | Aerospace, automotive, and industrial applications. | Pros: High durability, good for high-stress environments. Cons: Higher cost compared to zinc and tin. |

| Silver Plating | Offers superior conductivity and a bright finish; typically used in specialized applications. | Electronics, jewelry, and high-end connectors. | Pros: Excellent conductivity, aesthetic appeal. Cons: Expensive, tarnishes over time. |

| Electroless Nickel | Uniform coating without the need for electrical current; offers excellent corrosion resistance. | Aerospace, oil and gas industries, and automotive. | Pros: Consistent thickness, excellent wear resistance. Cons: More complex process, higher cost. |

Tin Plating

Tin plating is a popular choice in industries requiring solderable surfaces, such as electronics and automotive components. Its primary advantage is its excellent solderability, making it ideal for applications where components need to be joined together. However, while it is cost-effective, tin plating may not withstand significant mechanical stress, which can limit its use in heavy-duty applications.

Zinc Plating

Zinc plating is widely used for its effective corrosion protection. It can be treated with chromates to enhance durability, making it suitable for fasteners and automotive parts. The process is economical, and the versatility of zinc plating allows it to be applied in various industries. However, it has limitations in high-temperature environments, which buyers should consider when selecting this type of plating.

Nickel Plating

Nickel plating is known for its robust and wear-resistant finish, making it suitable for high-stress applications in aerospace and automotive sectors. It provides excellent corrosion resistance and durability, which are crucial in demanding environments. Although it tends to be pricier than other plating options, the long-term benefits often justify the investment for B2B buyers.

Silver Plating

Silver plating is primarily used in electronics and high-end connectors due to its superior conductivity and aesthetic qualities. It provides a bright finish and is favored in applications where electrical performance is critical. However, the higher cost and tendency to tarnish over time can deter some buyers, particularly in industries where budget constraints are significant.

Electroless Nickel

Electroless nickel plating is a unique process that creates a uniform coating without the use of electrical current. This method is particularly beneficial in industries such as aerospace and oil and gas, where consistent thickness and excellent wear resistance are paramount. While the process can be more complex and costly, the benefits often outweigh these drawbacks, especially in specialized applications where performance is critical.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of technical plating inc

| Industry/Sector | Specific Application of Technical Plating Inc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Corrosion-resistant coatings for components | Enhanced durability and extended lifespan of parts | Compliance with automotive standards and regulations |

| Aerospace | Lightweight plating for structural components | Improved fuel efficiency and performance | Certification for aerospace applications and material safety |

| Electronics | Tin and silver plating for circuit boards | Increased conductivity and reliability | Precision in thickness and uniformity of plating |

| Power Generation | Plating for connectors and switches | Enhanced electrical performance and corrosion resistance | ROHS compliance and compatibility with existing systems |

| Industrial Machinery | Protective coatings for machine parts | Reduced wear and tear, leading to lower maintenance costs | Ability to meet specific industry standards and specifications |

Automotive Applications

In the automotive sector, Technical Plating Inc. provides corrosion-resistant coatings for various components, such as brackets, fasteners, and chassis parts. These coatings enhance the durability of parts exposed to harsh environments, prolonging their lifespan and reducing the need for replacements. For international buyers, especially in regions like South Africa and Mexico, it is crucial to ensure that the plating processes comply with local automotive standards, such as ISO/TS 16949, to avoid supply chain disruptions.

Aerospace Applications

In aerospace, lightweight plating solutions are essential for structural components like frames and engine parts. Technical Plating Inc. specializes in providing coatings that not only reduce weight but also improve fuel efficiency and overall performance of aircraft. Buyers from the Middle East and Europe must prioritize suppliers with certifications that meet stringent aerospace safety and performance standards, such as AS9100, to ensure compliance and safety in their operations.

Electronics Applications

For the electronics industry, Technical Plating Inc. offers tin and silver plating services for circuit boards and electronic components. These coatings enhance conductivity and reliability, which are critical for the performance of electronic devices. International buyers should consider the precision in plating thickness and uniformity, as these factors directly affect the functionality and longevity of electronic products, particularly in competitive markets in South America and Africa.

Power Generation Applications

In the power generation sector, Technical Plating Inc. supplies plating for connectors and switches, which are vital for ensuring enhanced electrical performance and corrosion resistance. This application is crucial for maintaining the efficiency and reliability of power systems. Buyers should ensure that the plating services comply with ROHS regulations and are compatible with existing infrastructure to avoid operational inefficiencies and maintain regulatory compliance.

Industrial Machinery Applications

Technical Plating Inc. provides protective coatings for various machine parts used in industrial machinery, significantly reducing wear and tear. This leads to lower maintenance costs and increased operational efficiency. Buyers in Europe and Africa must ensure that the supplier can meet specific industry standards and specifications, such as ISO 9001, to guarantee quality and reliability in their machinery operations.

Related Video: 10 Nifty Uses for Oscillating Multitool Saws

Strategic Material Selection Guide for technical plating inc

When selecting materials for technical plating, understanding the properties, advantages, and limitations of various substrates is crucial for international B2B buyers. Below is a detailed analysis of four common materials used in technical plating, focusing on their performance characteristics, application impacts, and considerations for buyers from regions such as Africa, South America, the Middle East, and Europe.

Tin Plating

Key Properties: Tin plating offers excellent corrosion resistance and is non-toxic, making it suitable for food and electronic applications. It has a relatively low melting point, which allows for easy application.

Pros & Cons: Tin is durable and provides good solderability, but its hardness is lower compared to other metals, which may lead to wear in high-friction applications. The cost is generally low, but the manufacturing process can be complex due to the need for precise thickness control.

Impact on Application: Tin is compatible with various media, including water and food products, making it ideal for the food processing and electronics industries. However, it may not perform well in high-temperature environments.

Considerations for International Buyers: Compliance with food safety standards (e.g., FDA regulations) is essential, especially for buyers in the food industry. Buyers should also ensure adherence to local regulations regarding tin usage in electronics, such as RoHS in Europe.

Zinc Plating

Key Properties: Zinc plating provides excellent corrosion resistance, particularly in humid environments. It offers a sacrificial layer, protecting underlying metals from corrosion.

Pros & Cons: Zinc is relatively inexpensive and easy to apply, making it a popular choice for various applications. However, it can be prone to white rust if not properly passivated, and its mechanical properties may not be suitable for high-stress applications.

Impact on Application: Zinc-plated components are commonly used in automotive and construction applications due to their durability and resistance to environmental factors. However, they may not be suitable for extreme temperature conditions.

Considerations for International Buyers: Buyers should verify that the zinc plating meets international standards such as ASTM B633 or ISO 2081. Additionally, awareness of local environmental regulations regarding zinc discharge during manufacturing is crucial.

Nickel Plating

Key Properties: Nickel plating is known for its hardness and resistance to wear and corrosion. It can withstand high temperatures and is often used as a barrier layer for other coatings.

Pros & Cons: The durability and aesthetic appeal of nickel make it a preferred choice for decorative applications. However, the cost of nickel is higher, and the plating process can be more complex, requiring specialized equipment and expertise.

Impact on Application: Nickel plating is widely used in the aerospace and automotive industries due to its strength and corrosion resistance. It is also effective in applications involving harsh chemicals.

Considerations for International Buyers: Compliance with nickel regulations, such as those outlined in REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) in Europe, is essential. Buyers should also consider the implications of nickel allergies in consumer products.

Silver Plating

Key Properties: Silver plating offers exceptional electrical conductivity and thermal properties, making it ideal for electronic components. It also has good corrosion resistance.

Pros & Cons: The primary advantage of silver plating is its conductivity, which is critical in electronic applications. However, silver is one of the more expensive plating materials, and it can tarnish over time, requiring maintenance.

Impact on Application: Silver plating is commonly used in connectors, circuit boards, and other electronic components. It is also suitable for decorative applications due to its luster.

Considerations for International Buyers: Buyers must ensure compliance with international standards for electronic components, such as IPC-A-610. Additionally, understanding the market dynamics for precious metals pricing is crucial for cost management.

Summary Table

| Material | Typical Use Case for technical plating inc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Tin | Food processing, electronics | Excellent corrosion resistance | Lower hardness | Low |

| Zinc | Automotive, construction | Inexpensive and easy to apply | Prone to white rust | Low |

| Nickel | Aerospace, automotive | High durability and corrosion resistance | Higher cost and complex process | High |

| Silver | Electronics, decorative applications | Exceptional conductivity | High cost and tarnishing | High |

This guide provides international B2B buyers with the necessary insights to make informed decisions regarding material selection for technical plating applications, ensuring compliance with relevant standards and optimizing product performance.

In-depth Look: Manufacturing Processes and Quality Assurance for technical plating inc

Manufacturing Processes at Technical Plating Inc.

Technical Plating Inc. employs a systematic approach to manufacturing that ensures high-quality metal finishing services. Understanding the stages of their manufacturing process can help international B2B buyers make informed decisions.

Main Stages of Manufacturing

-

Material Preparation

– This initial stage involves selecting the appropriate substrate material, which can include metals like aluminum, steel, or copper. The choice of substrate is crucial as it affects the adhesion and performance of the plating.

– Materials undergo cleaning to remove any contaminants, such as oils, dust, or oxides. Common cleaning methods include ultrasonic cleaning and chemical baths to ensure a pristine surface. -

Forming

– In this phase, the prepared materials are shaped into the desired forms using techniques such as CNC machining, stamping, or bending. Precision in this stage is vital to ensure that the final product meets specified tolerances.

– Forming is often complemented by heat treatments to enhance the mechanical properties of the substrates, particularly when they will undergo plating. -

Plating

– This is the core of Technical Plating’s offerings. Various plating techniques are employed, including:- Electroplating: A process where metal ions are deposited onto the substrate using an electric current. This method is ideal for achieving a uniform coating thickness.

- Electroless Plating: A non-electric method that provides a consistent coating, particularly useful for complex geometries.

- Zinc and Tin Plating: Common for corrosion resistance, these processes involve dipping the substrate into molten metal or applying it through an electroplating method.

- Each plating type has specific parameters, such as temperature, pH, and deposition time, that are meticulously controlled to ensure quality.

-

Finishing

– After plating, components undergo several finishing processes to enhance their surface properties. This includes passivation, polishing, and applying protective coatings.

– Quality checks during this stage ensure that the finished products meet industry standards and customer specifications.

Quality Assurance Protocols

Quality assurance at Technical Plating Inc. is integral to maintaining the high standards expected by international clients. The company adheres to several international and industry-specific standards to ensure compliance and quality.

Illustrative Image (Source: Google Search)

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent product quality and customer satisfaction. Adhering to ISO 9001 allows buyers to trust that Technical Plating Inc. has established processes that meet international quality standards.

- CE Marking: Particularly important for products sold in the European market, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Certification: For clients in the oil and gas sectors, API certifications ensure that products meet the rigorous standards required in these industries.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Materials are inspected upon arrival to ensure they meet specified criteria. This initial checkpoint helps in identifying any defects or non-conformities before production begins. -

In-Process Quality Control (IPQC)

– Throughout the manufacturing process, regular inspections are conducted to monitor the plating thickness, adherence, and overall quality of the coatings. This proactive approach helps in mitigating defects before they escalate. -

Final Quality Control (FQC)

– The final inspection involves thorough testing of the finished products against customer specifications and industry standards. This can include:- XRF Thickness Measurement: A non-destructive testing method that accurately measures the thickness of the plating.

- Adhesion Testing: Ensures that the plating will adhere properly to the substrate under various conditions.

Verification of Supplier Quality Control

B2B buyers, especially those from Africa, South America, the Middle East, and Europe, should consider several strategies to verify the quality control processes of Technical Plating Inc.:

- Audits: Conducting onsite audits can provide insights into the manufacturing processes and quality control measures in place. This direct assessment helps build trust and ensures that the supplier meets the buyer’s standards.

- Quality Reports: Requesting detailed quality assurance reports can provide transparency into the QC processes. These reports should include results from IQC, IPQC, and FQC checks.

- Third-Party Inspections: Engaging independent third-party inspectors to evaluate the manufacturing processes and final products can further validate the supplier’s quality claims. This adds an extra layer of assurance for international buyers.

Quality Control Nuances for International Buyers

International B2B buyers should be aware of specific nuances regarding quality control:

- Cultural and Regional Standards: Different regions may have varying quality expectations and regulatory requirements. Understanding these nuances is crucial for buyers, especially in regions like Africa and South America, where local standards may differ significantly from European norms.

- Documentation and Compliance: It is essential for buyers to ensure that suppliers provide proper documentation, including compliance certifications and quality control records. This documentation should be readily available and understandable to facilitate international trade.

By understanding the manufacturing processes and quality assurance protocols at Technical Plating Inc., B2B buyers can make informed decisions that align with their quality expectations and regulatory requirements, ultimately fostering successful partnerships.

Related Video: Mercedes C-Class CAR FACTORY – HOW IT’S MADE Assembly Production Line Manufacturing Making of

Comprehensive Cost and Pricing Analysis for technical plating inc Sourcing

When sourcing from Technical Plating Inc., understanding the cost structure and pricing dynamics is essential for international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe. Below is a comprehensive analysis of the cost components, price influencers, and actionable buyer tips.

Cost Components

-

Materials: The cost of raw materials, such as tin, zinc, silver, and nickel, significantly impacts the overall pricing. Prices for these metals fluctuate based on market conditions, which can affect the cost of the final product. Buyers should keep an eye on commodity markets to anticipate price changes.

-

Labor: Labor costs encompass the wages of skilled workers involved in the plating process. Given the specialized nature of metal finishing, labor costs can vary based on the region and the expertise required. For instance, labor in the United States may be higher compared to labor in developing regions.

-

Manufacturing Overhead: This includes costs related to utilities, maintenance, and depreciation of equipment. Efficient production processes can help reduce overhead, but buyers should inquire about how these costs are managed by the supplier.

-

Tooling: Custom tooling for specific plating processes can incur significant upfront costs. This is particularly relevant for custom projects requiring unique specifications. Buyers should discuss tooling costs upfront to avoid surprises later in the project.

-

Quality Control (QC): QC measures ensure that the plating meets industry standards and specifications. The cost of QC processes can vary depending on the level of inspection required. Buyers should assess the supplier’s QC practices to ensure they align with their quality expectations.

-

Logistics: Shipping costs can add to the total price, particularly for international buyers. Factors such as distance, mode of transport, and Incoterms significantly influence logistics costs.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding the standard margins in the industry can help buyers negotiate better deals.

Price Influencers

-

Volume/MOQ: Pricing often benefits from economies of scale. Higher order volumes may lead to lower per-unit costs. Buyers should consider consolidating orders to maximize savings.

-

Specifications/Customization: Custom specifications can lead to higher costs due to the need for specialized processes or materials. Clear communication about requirements can help manage costs effectively.

-

Materials: As mentioned, the choice of materials directly affects pricing. Buyers should assess alternative materials that may offer cost savings without compromising quality.

-

Quality/Certifications: Products that meet specific quality standards or certifications may incur higher costs. Buyers should evaluate the necessity of these certifications against their application requirements.

-

Supplier Factors: The supplier’s reputation, reliability, and service quality can influence pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: Different shipping terms can affect the overall cost structure. Buyers should understand the implications of Incoterms on their pricing, including who bears the risk and cost of transportation.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers about pricing structures. Don’t hesitate to ask for breakdowns of costs to identify areas where savings can be achieved.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes all costs associated with purchasing, shipping, and maintaining the products over time. This approach can lead to more informed purchasing decisions.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and their impact on pricing. Additionally, tariffs and trade agreements may also affect costs.

-

Local Partnerships: Establishing relationships with local representatives or distributors can enhance communication and potentially lead to better pricing and service.

Disclaimer

Prices can vary widely based on market conditions and specific project requirements. It is advisable to obtain quotes directly from Technical Plating Inc. or other suppliers for the most accurate and indicative pricing.

Illustrative Image (Source: Google Search)

Spotlight on Potential technical plating inc Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘technical plating inc’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for technical plating inc

Key Technical Properties for Technical Plating

Understanding the essential technical properties of plating services is crucial for B2B buyers in sectors such as automotive, aerospace, and electronics. Here are some critical specifications to consider:

-

Material Grade: The quality of the metal substrate being plated is paramount. Common grades include stainless steel, aluminum, and brass. Each material has unique characteristics that affect corrosion resistance, strength, and conductivity. For example, stainless steel is often preferred in high-corrosion environments due to its durability.

-

Plating Thickness: This specification indicates the depth of the plating layer applied to the substrate. It is vital for ensuring adequate protection against corrosion and wear. Typical thicknesses range from a few microns to several hundred microns, depending on the application. Ensuring the correct thickness can prevent failures in critical components, thus reducing costs associated with rework or replacement.

-

Tolerance: This refers to the allowable deviation from a specified dimension during the plating process. Tight tolerances are essential for parts that require precise fitment, such as those in automotive assemblies. Understanding the tolerance levels can help in selecting suppliers who can meet stringent manufacturing requirements.

-

Adhesion Strength: The bond between the plating and the substrate must be strong enough to withstand various operational stresses. Adhesion strength is typically tested using methods like cross-hatch adhesion tests. Poor adhesion can lead to flaking and failure of the plated surface, impacting product reliability.

-

Corrosion Resistance: This property measures how well the plated surface can withstand corrosive environments. It is particularly important for applications in marine, chemical, and outdoor settings. Buyers should request corrosion test results to ensure that the plating meets industry standards for longevity.

Common Trade Terms in Technical Plating

Familiarity with industry jargon is essential for effective communication and negotiation in the plating sector. Here are some terms frequently encountered:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts that are used in another company’s end product. OEMs often require specific plating services to meet their quality and performance standards.

-

MOQ (Minimum Order Quantity): This is the smallest amount of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory costs and ensure they can meet production demands without over-purchasing.

-

RFQ (Request for Quotation): An RFQ is a document that a buyer sends to potential suppliers to request pricing and terms for specific products or services. Including detailed specifications in an RFQ can help suppliers provide accurate quotes, enabling better comparison and decision-making.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in global trade. Understanding Incoterms is essential for clarifying who bears the costs and risks associated with shipping, such as delivery points, insurance, and customs clearance.

-

Passivation: A post-plating process that enhances the corrosion resistance of metals, especially stainless steel. This treatment is crucial for applications where long-term durability is required, and buyers should inquire about the passivation methods employed by suppliers.

-

Electroless Plating: A method of plating that does not require an external electrical current. This technique is often used for intricate shapes and provides uniform coating thickness. Understanding this process can help buyers select the appropriate plating method for their specific needs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement strategies and ensure the reliability of their products.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the technical plating inc Sector

Market Overview & Key Trends

The technical plating sector is experiencing notable growth driven by several global factors. Increasing demand for high-quality metal finishing in industries such as automotive, aerospace, and electronics is propelling the market forward. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers that can offer specialized plating services, such as nickel, zinc, and silver plating.

Emerging trends in the B2B sourcing landscape include the integration of advanced technologies like Artificial Intelligence (AI) and the Internet of Things (IoT) in manufacturing processes. These technologies enhance operational efficiency, reduce waste, and improve product quality. Additionally, the rise of e-commerce platforms for industrial goods is transforming how buyers source plating services, offering greater transparency and access to a broader range of suppliers.

Another important dynamic is the shift towards local sourcing, particularly in response to geopolitical uncertainties and supply chain disruptions. Buyers are now more inclined to partner with suppliers within their regions to mitigate risks associated with long-distance logistics. This trend is especially relevant for buyers in Africa and South America, where local suppliers are becoming increasingly competitive in terms of pricing and quality.

Sustainability & Ethical Sourcing in B2B

Sustainability has emerged as a critical consideration for B2B buyers in the technical plating sector. The environmental impact of metal finishing processes, including chemical waste and energy consumption, necessitates a focus on sustainable practices. Buyers are increasingly prioritizing suppliers who demonstrate commitment to reducing their ecological footprint. This includes adopting cleaner technologies, recycling waste materials, and minimizing the use of harmful chemicals.

Ethical sourcing is equally important, with a growing emphasis on supply chain transparency. Buyers are encouraged to seek suppliers that hold certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety). These certifications signify a supplier’s dedication to maintaining environmentally friendly practices and ensuring the safety of their workforce.

Furthermore, the adoption of ‘green’ materials and processes, such as trivalent chromates instead of hexavalent chromates, is becoming a standard requirement. This shift not only aligns with regulatory compliance (e.g., REACH and RoHS) but also enhances the brand image of buyers committed to sustainability.

Brief Evolution/History

The technical plating sector has evolved significantly since its inception in the mid-20th century. Initially dominated by traditional plating techniques, the industry has witnessed substantial advancements in technology and materials science. The introduction of automated systems and precision plating methods has improved efficiency and consistency in metal finishing.

Over the years, regulatory pressures regarding environmental standards have transformed the industry, pushing companies to innovate and adopt sustainable practices. Today, the focus is on high-quality finishes that not only enhance product performance but also comply with stringent environmental regulations. As a result, suppliers in this sector are now better positioned to meet the diverse needs of international B2B buyers, ensuring a competitive edge in the global market.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of technical plating inc

-

What should I consider when vetting suppliers for technical plating services?

When vetting suppliers for technical plating services, evaluate their industry experience, customer reviews, and certifications. Check their compliance with international standards such as ISO and ROHS, which indicate quality and environmental responsibility. Request references from similar businesses and inquire about their production capacity and technology used. Also, consider their ability to provide customization and quick turnaround times, which are crucial for maintaining your supply chain efficiency. -

Can I customize plating services to meet my specific needs?

Yes, many plating suppliers offer customization options to meet unique specifications. You can discuss your specific requirements regarding thickness, material compatibility, and finish type. Ensure that the supplier has experience with the materials you are using and can produce the desired results without compromising quality. It’s advisable to request samples of their work to verify that they can meet your expectations before placing a large order. -

What are the typical minimum order quantities (MOQs) and lead times for plating services?

Minimum order quantities vary by supplier and can depend on the type of plating and customization required. Generally, MOQs can range from a few hundred units to several thousand. Lead times typically range from one week to several weeks, depending on the complexity of the order and the supplier’s current workload. Always clarify these details before placing an order to ensure they align with your project timelines and inventory needs. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary significantly between suppliers, especially in international trade. Common practices include upfront deposits (20-50% of the total order value) with the balance due upon completion or before shipping. Some suppliers may offer credit terms for established relationships. It’s important to discuss payment methods (e.g., wire transfer, credit card, letters of credit) and ensure that terms are clearly outlined in the purchase agreement to avoid misunderstandings. -

How can I ensure quality assurance and certifications from my supplier?

To ensure quality assurance, request detailed documentation of the supplier’s quality management system, including certifications such as ISO 9001. Ask for specific quality assurance procedures they follow, such as XRF thickness measurement and other testing methods. Regular audits and checks should be part of their process. Additionally, inquire about their approach to handling defects or non-conformance to ensure a reliable supply chain. -

What logistics considerations should I keep in mind when sourcing plating services internationally?

Logistics plays a crucial role in international sourcing. Consider the supplier’s location and the associated shipping costs, which can significantly impact your total expenses. Discuss shipping methods, expected delivery times, and customs clearance processes to avoid delays. Ensure that the supplier can provide necessary export documentation and consider partnering with a freight forwarder who understands international trade regulations to streamline the process. -

How do I handle disputes or issues with my plating supplier?

Establish a clear communication protocol with your supplier from the outset to facilitate resolving any disputes. Maintain thorough documentation of all transactions, specifications, and communications. If issues arise, first attempt to resolve them directly through discussion. If that fails, refer to the terms outlined in your contract regarding dispute resolution, which may include mediation or arbitration. Consider involving legal counsel if necessary, particularly for larger disputes. -

What are the best practices for establishing a long-term relationship with a plating supplier?

Building a long-term relationship with a plating supplier requires clear communication, trust, and mutual understanding. Regularly provide feedback on their services and quality, and encourage them to do the same. Engage in joint planning sessions to align on future needs and potential innovations. Establishing a collaborative approach can lead to better pricing, priority service, and improved quality as both parties grow together in the business relationship.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for technical plating inc

In conclusion, effective strategic sourcing is essential for international B2B buyers seeking to leverage the capabilities of Technical Plating Inc. By understanding the diverse plating services offered—such as tin, zinc, and silver plating—buyers can make informed decisions that align with their specific industry requirements. The emphasis on quality assurance, compliance with ROHS standards, and competitive pricing positions Technical Plating Inc. as a trusted partner in the metal finishing sector.

For buyers in Africa, South America, the Middle East, and Europe, the potential for collaboration with Technical Plating Inc. is significant. Establishing strong supplier relationships can lead to enhanced product durability, improved supply chain efficiency, and ultimately, greater market competitiveness.

As industries evolve, the demand for high-quality metal finishing continues to rise. It is crucial for international buyers to engage proactively with Technical Plating Inc. to explore innovative solutions that meet their unique needs. Take the next step—reach out today for a consultation or quote, and discover how Technical Plating Inc. can support your business growth in a competitive landscape.