Your Ultimate Guide to Sourcing Thomasnet Reviews

Introduction: Navigating the Global Market for thomasnet reviews

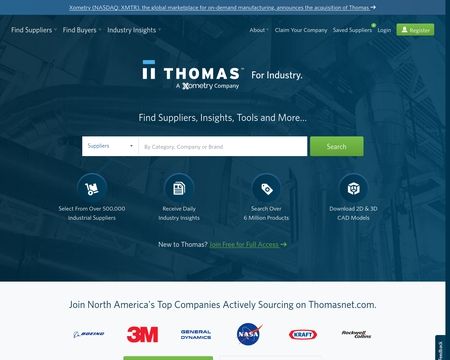

In today’s interconnected world, sourcing reliable suppliers is crucial for businesses aiming to thrive in competitive markets. ThomasNet reviews serve as a vital resource for international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe. This platform not only connects manufacturers with potential partners but also offers insights into supplier capabilities, quality control processes, and market trends.

Understanding the nuances of ThomasNet is essential for making informed sourcing decisions. This guide delves deep into the platform’s features, including its extensive supplier database, advanced search functionalities, and the overall user experience. Buyers will benefit from a comprehensive analysis of various factors such as types of suppliers, materials available, manufacturing and quality control standards, and cost considerations. Additionally, we address frequently asked questions to ensure clarity and confidence in your sourcing strategy.

With a focus on empowering businesses in emerging markets, this guide equips B2B buyers with actionable insights and critical evaluations of ThomasNet. By leveraging these reviews, companies can navigate the complexities of global sourcing, foster fruitful partnerships, and ultimately enhance their operational efficiency. Whether you are in Nigeria seeking local suppliers or in the UAE looking for international connections, understanding ThomasNet reviews is your first step towards successful procurement.

Understanding thomasnet reviews Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Supplier Reviews | Focus on individual supplier performance and reliability. | Supplier selection and risk management. | Pros: Insightful feedback; Cons: Limited scope. |

| Product Reviews | Evaluation of specific products offered by suppliers. | Product procurement and sourcing decisions. | Pros: Detailed product insights; Cons: May lack comprehensive comparisons. |

| Platform Usability Reviews | Assessments of user experience with the ThomasNet platform. | Platform selection and user training. | Pros: Highlights ease of use; Cons: Subjective experiences vary. |

| Customer Support Reviews | Feedback on the responsiveness and effectiveness of support. | Critical for operational continuity and support. | Pros: Helps gauge support quality; Cons: May not reflect overall platform performance. |

| Market Analysis Reviews | Insights into industry trends and supplier market positioning. | Strategic sourcing and market entry strategies. | Pros: Broad market insights; Cons: Requires external verification for accuracy. |

Supplier Reviews

Supplier reviews are essential for B2B buyers looking to evaluate the reliability and performance of potential partners. These reviews often focus on aspects like product quality, delivery times, and overall service satisfaction. For international buyers, especially from regions like Africa and South America, understanding supplier reputation can mitigate risks associated with cross-border transactions. When considering supplier reviews, businesses should prioritize verified feedback and look for consistent patterns in performance to make informed decisions.

Product Reviews

Product reviews provide detailed evaluations of specific items available on ThomasNet, helping buyers assess the suitability of products for their needs. These reviews often include user experiences, specifications, and performance metrics. For B2B buyers in the Middle East and Europe, leveraging product reviews can streamline the procurement process by highlighting key features and potential drawbacks. Buyers should consider the relevance of reviews to their specific applications and seek out diverse opinions to gain a well-rounded view of product performance.

Platform Usability Reviews

Usability reviews focus on the user experience within the ThomasNet platform, assessing features such as navigation, search capabilities, and integration with other systems. For international B2B buyers, understanding how easy it is to use the platform can significantly affect operational efficiency and team productivity. Companies should pay attention to usability feedback, especially if they plan to onboard multiple users or integrate the platform into their existing workflows. A user-friendly interface can facilitate quicker decision-making and enhance overall procurement efficiency.

Customer Support Reviews

Customer support reviews are critical for businesses that rely on ThomasNet for sourcing and procurement activities. Feedback on the responsiveness and effectiveness of customer support can inform buyers about the level of assistance they can expect when issues arise. For companies in regions with different time zones, such as Nigeria or the UAE, understanding support availability is crucial. Buyers should weigh the quality of support against their operational needs, ensuring they can access timely help when required.

Market Analysis Reviews

Market analysis reviews provide insights into industry trends, supplier performance, and competitive positioning within the ThomasNet ecosystem. These reviews can be invaluable for strategic sourcing and market entry decisions, especially for B2B buyers looking to expand into new regions. Understanding market dynamics through these reviews can help companies anticipate changes and adapt their procurement strategies accordingly. Buyers should complement these insights with their research to validate findings and ensure alignment with their business objectives.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of thomasnet reviews

| Industry/Sector | Specific Application of thomasnet reviews | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Supplier Evaluation and Selection | Increases reliability and quality of sourced materials | Supplier certifications, production capabilities, lead times |

| Construction | Project Procurement and Material Sourcing | Streamlines sourcing process, reduces project delays | Local supplier availability, compliance with regulations |

| Oil & Gas | Equipment and Service Provider Assessment | Ensures access to specialized services and equipment | Industry certifications, service history, geographic proximity |

| Electronics | Component Sourcing and Supplier Relationship Management | Enhances product innovation and reduces time-to-market | Quality assurance processes, technology compatibility |

| Agriculture | Machinery and Parts Procurement | Improves operational efficiency and reduces downtime | Supplier reliability, after-sales support, delivery timelines |

In the manufacturing sector, international B2B buyers utilize ThomasNet reviews to evaluate and select suppliers based on their reliability and product quality. By accessing a comprehensive database of suppliers, businesses can make informed decisions that enhance the quality of sourced materials. Buyers should consider supplier certifications, production capabilities, and lead times to ensure they align with their operational requirements.

For the construction industry, ThomasNet reviews aid in project procurement and material sourcing. The platform simplifies the identification of suppliers who can meet specific project needs, thereby minimizing delays and improving project timelines. Buyers need to prioritize local supplier availability and compliance with local regulations, particularly in regions such as Africa and the Middle East, where local standards can vary significantly.

In the oil and gas industry, ThomasNet reviews serve as a critical tool for assessing equipment and service providers. Buyers can leverage the platform to find specialized services that meet the unique needs of their operations, ensuring access to high-quality equipment and support. Key considerations include verifying industry certifications, reviewing service history, and assessing the geographic proximity of suppliers to reduce logistical challenges.

For the electronics sector, ThomasNet reviews facilitate component sourcing and supplier relationship management. By utilizing the platform, companies can enhance product innovation and reduce time-to-market by connecting with reliable suppliers. Buyers should focus on quality assurance processes and technology compatibility to ensure that components meet their specific needs and standards.

In the agriculture industry, ThomasNet reviews are instrumental in machinery and parts procurement. The platform helps businesses improve operational efficiency and reduce downtime by connecting them with reputable suppliers. It is essential for buyers to evaluate supplier reliability, after-sales support, and delivery timelines to maintain smooth operations, especially in regions where agricultural cycles are critical to business success.

Related Video: Who Uses Thomasnet.com® To Source?

Strategic Material Selection Guide for thomasnet reviews

When selecting materials for industrial applications, international B2B buyers must consider a variety of factors that impact performance, cost, and compliance. Below are analyses of four common materials frequently referenced in ThomasNet reviews, focusing on their properties, pros and cons, application impacts, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Steel

Key Properties: Steel is known for its high tensile strength and durability. It can withstand high temperatures and pressures, making it suitable for various industrial applications. Corrosion resistance can be enhanced through galvanization or alloying with elements like chromium.

Pros & Cons: Steel is relatively inexpensive and widely available, making it a popular choice for construction and manufacturing. However, it can be heavy and may require additional treatments to prevent rust, which can increase overall costs and complexity in manufacturing.

Impact on Application: Steel’s compatibility with various media, including water and gases, makes it versatile. However, its susceptibility to corrosion in certain environments (e.g., coastal areas) can limit its use without proper treatment.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM in the U.S. or EN in Europe. Additionally, understanding the specific grades of steel available in their region can help in selecting the right material for their needs.

Aluminum

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance due to its natural oxide layer. It has a lower melting point than steel, making it easier to work with in manufacturing processes.

Pros & Cons: The primary advantage of aluminum is its weight, which can lead to cost savings in shipping and handling. However, it is generally more expensive than steel and has lower tensile strength, which may limit its use in heavy-duty applications.

Impact on Application: Aluminum is compatible with various media, including chemicals and moisture, making it suitable for packaging and transportation industries. Its lightweight nature can enhance product performance in applications where weight is a critical factor.

Considerations for International Buyers: Compliance with standards such as ISO and ASTM is crucial. Additionally, buyers should be aware of the recycling capabilities of aluminum in their region, as this can influence sustainability practices.

Stainless Steel

Key Properties: Stainless steel is an alloy known for its exceptional corrosion resistance, high strength, and ability to withstand extreme temperatures. It is available in various grades, each suited for different applications.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and staining, making it ideal for food processing and medical applications. However, it is more expensive than regular steel and can be challenging to machine.

Impact on Application: Stainless steel is highly compatible with various media, including acidic and alkaline substances, making it suitable for chemical processing. Its longevity reduces the need for frequent replacements, which can be cost-effective in the long run.

Considerations for International Buyers: Buyers must ensure that the stainless steel grades comply with local regulations and standards, such as AISI or ASTM. Understanding the specific environment in which the material will be used is also essential to select the appropriate grade.

Plastic (Polypropylene)

Key Properties: Polypropylene is a thermoplastic polymer known for its chemical resistance, low density, and flexibility. It can withstand a range of temperatures and is often used in applications requiring lightweight materials.

Pros & Cons: The key advantage of polypropylene is its cost-effectiveness and versatility. It is resistant to many chemicals and is easy to mold into various shapes. However, it has lower strength compared to metals and may not be suitable for high-stress applications.

Impact on Application: Polypropylene is compatible with a variety of media, including acids and bases, making it ideal for containers and packaging. Its lightweight nature can enhance efficiency in transportation.

Considerations for International Buyers: Buyers should be aware of compliance with standards such as ASTM and ISO for plastics. Additionally, understanding the recycling options available in their region can inform sustainable procurement practices.

Summary Table

| Material | Typical Use Case for thomasnet reviews | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Construction, manufacturing | High strength and durability | Corrosion susceptibility | Medium |

| Aluminum | Packaging, transportation | Lightweight and corrosion resistant | Higher cost than steel | High |

| Stainless Steel | Food processing, medical applications | Exceptional corrosion resistance | More expensive and machining complexity | High |

| Plastic (Polypropylene) | Containers, packaging | Cost-effective and versatile | Lower strength compared to metals | Low |

This guide provides a comprehensive overview of material selection considerations for B2B buyers utilizing ThomasNet. By understanding the properties, advantages, and limitations of each material, buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for thomasnet reviews

When evaluating suppliers through platforms like ThomasNet, understanding their manufacturing processes and quality assurance (QA) practices is crucial for B2B buyers. This knowledge not only ensures that products meet required standards but also fosters trust and reliability in business relationships. Below is a detailed exploration of typical manufacturing processes, quality control measures, relevant international standards, and actionable insights for B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

Manufacturing Processes

Main Stages of Manufacturing

-

Material Preparation

– Description: This initial stage involves selecting and preparing raw materials needed for production. Processes may include cutting, shaping, or treating materials to ensure they meet specific requirements.

– Key Techniques:- Cutting: Techniques such as laser cutting or waterjet cutting for precision.

- Treatment: Chemical processes to enhance material properties, like heat treatment for metals.

-

Forming

– Description: In this stage, raw materials are shaped into parts or components through various methods.

– Key Techniques:- Casting: Pouring molten material into molds.

- Molding: Using molds for plastics and other materials.

- Machining: Removing material to achieve desired dimensions and finishes.

-

Assembly

– Description: This process involves putting together various components to create the final product. It can be manual or automated, depending on the complexity of the product.

– Key Techniques:- Fastening: Using bolts, screws, or adhesives.

- Welding: Fusing materials together using heat.

-

Finishing

– Description: The final stage focuses on enhancing the product’s appearance and performance.

– Key Techniques:- Coating: Painting or applying protective layers.

- Polishing: Smoothing surfaces for aesthetic and functional purposes.

Illustrative Image (Source: Google Search)

Quality Assurance (QA)

International Standards

For B2B buyers, understanding and verifying compliance with international quality standards is essential. Key standards include:

- ISO 9001: A widely recognized standard that ensures organizations meet customer and regulatory requirements consistently.

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Certification: Relevant for companies in the oil and gas industry, ensuring products meet specific performance criteria.

Quality Control Checkpoints

Quality control is typically implemented at several stages of the manufacturing process:

-

Incoming Quality Control (IQC)

– Purpose: To inspect and verify the quality of raw materials before production.

– Common Practices: Visual inspections, dimensional checks, and material testing. -

In-Process Quality Control (IPQC)

– Purpose: To monitor the production process to ensure compliance with quality standards.

– Common Practices: Periodic sampling, process monitoring, and real-time inspections. -

Final Quality Control (FQC)

– Purpose: To conduct a final inspection of the finished product before delivery.

– Common Practices: Functional testing, packaging inspections, and documentation checks.

Common Testing Methods

To ensure product quality, various testing methods may be employed:

- Destructive Testing: Evaluates material properties by testing until failure (e.g., tensile testing).

- Non-Destructive Testing: Inspects materials without causing damage (e.g., ultrasonic testing).

- Visual Inspection: Basic checks for defects or inconsistencies.

Verifying Supplier Quality Control

For international B2B buyers, particularly those from diverse regions, verifying the quality control processes of suppliers is paramount. Here are some actionable strategies:

-

Audits: Conduct regular audits of suppliers’ facilities to assess compliance with quality standards and practices. This can be done by in-house teams or third-party agencies.

-

Quality Reports: Request detailed quality reports that outline testing results, certifications, and any non-conformance issues. This transparency can build trust.

-

Third-Party Inspections: Engage third-party inspection services to perform independent assessments of supplier products. This is particularly useful when dealing with suppliers in regions with varying regulatory standards.

Quality Control and Certification Nuances

B2B buyers must be aware of specific nuances related to quality control and certifications, especially when dealing with suppliers from Africa, South America, the Middle East, and Europe:

-

Regional Standards: Different regions may have distinct quality standards that may not be universally recognized. Buyers should familiarize themselves with local regulations and certifications.

-

Cultural Differences: Understand that cultural perceptions of quality may vary. Building relationships and trust with suppliers can help bridge these gaps.

-

Documentation: Ensure that suppliers provide all necessary documentation, including compliance certificates, test results, and quality assurance policies. This documentation is critical for import/export regulations.

Conclusion

In summary, a thorough understanding of manufacturing processes and quality assurance practices is essential for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control checkpoints and verification methods, buyers can make informed decisions. This not only minimizes risks but also enhances the reliability of their supply chains, fostering successful business partnerships globally.

Related Video: The Production Planning Process

Comprehensive Cost and Pricing Analysis for thomasnet reviews Sourcing

In the realm of B2B sourcing, understanding the cost structure and pricing dynamics is essential for making informed purchasing decisions. For buyers utilizing platforms like ThomasNet, it is crucial to grasp the various components that contribute to the total cost of procurement as well as the factors influencing pricing.

Cost Components

-

Materials: The type and quality of materials sourced significantly impact costs. Buyers should evaluate the material specifications required for their products and consider sourcing from suppliers that offer competitive pricing without compromising quality.

-

Labor: Labor costs can vary widely based on the supplier’s location and the complexity of the manufacturing process. International buyers should account for potential wage disparities and labor regulations in different regions, which may affect overall pricing.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and administrative expenses incurred by suppliers during production. Understanding a supplier’s overhead can provide insight into their pricing strategy and help buyers identify more cost-effective options.

-

Tooling: Custom tooling can add to initial costs but may lead to better long-term value. Buyers should assess whether investing in custom tooling is justified based on their volume and specific product needs.

-

Quality Control (QC): Robust QC processes may increase upfront costs but are essential for ensuring product reliability and compliance with industry standards. Buyers should weigh the benefits of enhanced QC against potential risks associated with lower-quality suppliers.

-

Logistics: Shipping and transportation costs can fluctuate based on distance, mode of transport, and current market conditions. Buyers should consider proximity to suppliers and potential logistics partners to optimize shipping costs.

-

Margin: Supplier profit margins vary based on market competition, product demand, and negotiation power. Understanding these margins can help buyers negotiate better deals.

Price Influencers

-

Volume and Minimum Order Quantity (MOQ): Prices often decrease with larger order volumes. Buyers should negotiate MOQs that align with their purchasing capabilities to leverage better pricing.

-

Specifications and Customization: Customized products typically incur higher costs. Buyers need to clearly define their specifications to avoid unexpected expenses during the manufacturing process.

-

Quality Certifications: Suppliers with recognized quality certifications may charge premium prices. However, these certifications often assure higher product reliability, which can be crucial for international buyers.

-

Supplier Factors: The reputation, reliability, and experience of suppliers can influence pricing. Established suppliers may offer higher prices due to their proven track record but might also deliver superior service and quality.

-

Incoterms: Understanding International Commercial Terms (Incoterms) is vital for managing logistics costs and responsibilities. Different Incoterms can affect pricing and liability, so buyers should clarify these terms during negotiations.

Buyer Tips

-

Negotiation Strategies: Engage suppliers in open discussions about pricing, emphasizing long-term partnerships. Leverage competitive quotes from multiple suppliers to negotiate better terms.

-

Cost-Efficiency: Consider not just the purchase price but also the total cost of ownership (TCO), which includes maintenance, shipping, and potential downtime costs. This holistic view can reveal more cost-effective options.

-

International Pricing Nuances: For buyers from regions like Africa, South America, the Middle East, and Europe, currency fluctuations and import tariffs can significantly impact costs. Stay informed about the economic climate and negotiate terms that account for these variables.

-

Research and Comparison: Utilize ThomasNet’s extensive supplier database to compare prices, services, and reviews. This research can empower buyers to make well-informed decisions.

Disclaimer

Prices and costs mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough due diligence when sourcing from international suppliers.

Spotlight on Potential thomasnet reviews Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘thomasnet reviews’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for thomasnet reviews

Key Technical Properties for B2B Procurement

Understanding essential technical properties is crucial for international B2B buyers when navigating the ThomasNet platform. Here are several critical specifications that can significantly impact procurement decisions:

-

Material Grade

Material grade refers to the classification of materials based on their properties and performance. For instance, metals can be graded based on tensile strength, corrosion resistance, and chemical composition. This specification is vital for buyers, as selecting the wrong material grade can lead to product failure, increased costs, and potential safety hazards. -

Tolerance

Tolerance defines the permissible limits of variation in a physical dimension. For example, in machining, if a component has a tolerance of ±0.01 mm, it indicates that the actual size can vary within that range. Tolerances are crucial in ensuring that components fit together correctly, impacting the overall functionality and reliability of assemblies, particularly in industries like aerospace and automotive. -

Surface Finish

Surface finish describes the texture of a material’s surface, which can affect its appearance, adhesion, corrosion resistance, and wear. A smoother finish might be required for aesthetic components, while rougher finishes can enhance bonding in coatings. Understanding surface finish requirements helps in achieving desired product performance and longevity. -

Load Capacity

Load capacity indicates the maximum load a component can safely bear without failure. This specification is particularly critical for structural components in construction and machinery. Buyers need to ensure that the selected suppliers can provide components that meet or exceed the required load specifications to prevent operational failures. -

Compatibility

Compatibility refers to the ability of different components or systems to work together without issues. In B2B procurement, it is essential to ensure that the materials or components sourced from various suppliers can integrate seamlessly, particularly in industries like electronics and manufacturing. -

Certifications

Certifications, such as ISO or CE markings, validate that products meet specific standards of quality and safety. These credentials are important for buyers, as they provide assurance of compliance with regulatory requirements and industry standards, reducing risks associated with procurement.

Common Trade Terminology

Familiarity with industry jargon enhances communication and understanding in B2B transactions. Here are some common terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers, as it often impacts product quality, warranty, and support services. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to manage inventory costs effectively and negotiate favorable terms, especially when sourcing from international suppliers. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. Utilizing RFQs can help buyers compare offers systematically, ensuring they receive competitive pricing and suitable conditions for their procurement needs. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms is vital for buyers to understand their obligations and manage logistics effectively. -

Lead Time

Lead time is the time taken from placing an order to receiving the goods. Understanding lead times helps buyers plan their inventory and production schedules, ensuring they meet market demands without excess stock. -

Sourcing

Sourcing refers to the process of finding and selecting suppliers for goods and services. Effective sourcing strategies are essential for optimizing costs, enhancing quality, and ensuring timely delivery, making this a critical aspect of the procurement process.

By grasping these technical properties and trade terminologies, international B2B buyers can navigate the ThomasNet platform more effectively, ensuring informed purchasing decisions that align with their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the thomasnet reviews Sector

Market Overview & Key Trends

The B2B sourcing landscape is rapidly evolving, driven by globalization, technological advancements, and shifting buyer preferences. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly leveraging platforms like ThomasNet to enhance their sourcing strategies. Key trends influencing this market include the rise of digital procurement tools, which streamline processes and improve efficiency. For instance, advanced search and filtering capabilities on platforms like ThomasNet allow businesses to quickly identify suitable suppliers based on specific criteria, such as certifications and geographical location.

Another significant trend is the growing emphasis on supplier diversity and local sourcing. Companies are recognizing the importance of building resilient supply chains that can withstand global disruptions, prompting a shift towards engaging with suppliers from diverse backgrounds. This is particularly relevant for buyers in emerging markets, where establishing strong local partnerships can lead to competitive advantages.

Furthermore, the integration of AI and machine learning into sourcing platforms is enhancing predictive analytics, enabling buyers to make data-driven decisions. These technologies can identify trends and forecast market demands, helping businesses stay ahead of the curve. As international buyers navigate these market dynamics, they must remain agile and informed about emerging technologies and sourcing strategies to optimize their procurement processes.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a pivotal factor in B2B procurement decisions. Buyers are increasingly aware of the environmental impacts associated with their supply chains and are actively seeking suppliers that prioritize sustainable practices. In this context, platforms like ThomasNet are becoming vital as they provide access to a comprehensive database of suppliers who adhere to sustainability standards.

The importance of ethical sourcing cannot be overstated. Companies are now expected to demonstrate transparency in their supply chains, ensuring that materials are sourced responsibly and that suppliers maintain fair labor practices. Buyers should look for suppliers with recognized certifications, such as ISO 14001 for environmental management or Fair Trade certifications, which indicate a commitment to ethical sourcing.

In addition, the demand for green materials is on the rise. Buyers should prioritize suppliers that offer sustainable products, such as those made from recycled materials or bio-based alternatives. This not only helps mitigate environmental impact but also enhances brand reputation among increasingly eco-conscious consumers.

Brief Evolution/History

ThomasNet has evolved from a traditional industrial directory to a sophisticated digital marketplace, reflecting the broader shifts in B2B procurement. Initially established to connect manufacturers with buyers, the platform has integrated advanced technological features to meet the changing needs of international B2B buyers. Over the years, it has expanded its supplier database significantly, now boasting over 500,000 profiles, which aids in simplifying complex sourcing processes.

As the demand for digital solutions in procurement has surged, ThomasNet has adapted by enhancing its search capabilities and supplier communication tools. This evolution highlights the importance of staying relevant in a competitive market, particularly for international buyers seeking reliable partners in an increasingly interconnected global economy.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of thomasnet reviews

-

How can I vet suppliers on ThomasNet effectively?

To vet suppliers on ThomasNet, start by utilizing the comprehensive supplier database that includes over 500,000 profiles. Look for suppliers with relevant industry certifications and positive customer reviews. Engage with suppliers through the integrated messaging system to ask specific questions about their capabilities and previous projects. Additionally, request references or case studies that demonstrate their reliability and performance. Cross-reference this information with external platforms to ensure a holistic view of their reputation. -

Is customization of products available through ThomasNet suppliers?

Many suppliers on ThomasNet offer customization options for their products, but this can vary significantly by industry and supplier. When reaching out to potential suppliers, clearly articulate your customization needs and inquire about their capabilities. It’s advisable to discuss lead times and any additional costs associated with custom orders upfront to avoid surprises later. Be sure to request samples or prototypes when possible to assess the quality of customized products. -

What are the typical minimum order quantities (MOQs) and lead times for suppliers?

Minimum order quantities (MOQs) and lead times on ThomasNet can vary widely depending on the supplier and the type of product. Generally, suppliers will specify their MOQs on their profiles. When negotiating, clarify the lead times for production and delivery to ensure they align with your project timelines. If you are a smaller buyer, some suppliers may be willing to negotiate MOQs, particularly if you express a commitment to ongoing orders. -

How do I ensure quality assurance and certifications from suppliers?

To ensure quality assurance, check that the suppliers on ThomasNet possess relevant industry certifications, such as ISO or ASTM standards. You can often find this information in their profiles or by directly contacting them. Request documentation that verifies their quality control processes and any third-party inspections they may undergo. Additionally, consider visiting the supplier’s facility if possible, or request a third-party audit report to gain further insights into their quality management practices. -

What logistics support can I expect from ThomasNet suppliers?

Logistics capabilities vary among suppliers on ThomasNet, so it’s crucial to discuss these aspects early in your communication. Inquire about their shipping options, delivery timelines, and whether they handle customs clearance for international shipments. Many suppliers can provide insights into the best shipping practices to minimize costs and delays. Additionally, confirm if they offer tracking services for shipments and how they manage returns or damaged goods.

Illustrative Image (Source: Google Search)

-

How should I handle disputes with suppliers sourced from ThomasNet?

In the event of a dispute with a supplier, begin by documenting all communications and agreements. Engage the supplier directly to address the issue, as many disputes can be resolved through open dialogue. If needed, refer to the terms and conditions outlined in your agreement for guidance. Should the situation escalate, consider mediation or arbitration as a means to resolve the conflict. It’s advisable to establish clear terms regarding dispute resolution in your initial contracts to streamline this process. -

What payment methods are typically accepted by ThomasNet suppliers?

Payment methods accepted by suppliers on ThomasNet can vary. Common options include bank transfers, credit cards, and letters of credit, particularly for international transactions. When discussing payment, clarify the terms (e.g., upfront deposits, payment on delivery) to ensure mutual understanding. Be cautious with payment methods that offer little recourse in case of disputes, and consider using escrow services for larger transactions to safeguard your investment. -

How can I assess supplier performance over time?

To assess supplier performance, establish key performance indicators (KPIs) such as on-time delivery rates, product quality, and responsiveness to inquiries. Utilize ThomasNet’s supplier communication tools to maintain regular contact and gather feedback. Implement a periodic review process to evaluate supplier performance against these KPIs. Additionally, solicit feedback from your team who interacts with the supplier to gain insights into their reliability and service quality, allowing you to make informed decisions about future partnerships.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for thomasnet reviews

The strategic sourcing landscape continues to evolve, presenting significant opportunities for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. ThomasNet stands out as a powerful platform, facilitating connections between manufacturers and businesses through its extensive supplier database and advanced search capabilities. By leveraging these tools, companies can enhance their procurement processes, ultimately driving productivity and fostering robust partnerships.

For buyers in diverse markets, strategic sourcing is not just about finding suppliers, but about establishing relationships that can lead to long-term growth and innovation. The feedback from users highlights the importance of thorough supplier evaluation and the necessity of integrating efficient communication tools to streamline procurement operations.

As we look to the future, embracing platforms like ThomasNet can significantly impact your sourcing strategy. By tapping into its vast resources, international buyers can position themselves favorably in the competitive landscape. We encourage B2B buyers to explore the potential of strategic sourcing today, ensuring they not only meet their immediate needs but also set the stage for sustainable growth in their respective markets.