Your Ultimate Guide to Sourcing Injection Molders

Introduction: Navigating the Global Market for injection molders

In an era where globalization shapes the dynamics of manufacturing, selecting the right injection molder is a critical decision that can define the success of your projects. For international B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, understanding the intricacies of the injection molding landscape is essential. Injection molders play a pivotal role in producing high-quality plastic components that meet the demands of various industries, from automotive to consumer goods.

This guide serves as an authoritative resource, meticulously crafted to equip you with the knowledge necessary for informed sourcing decisions. We delve into a variety of injection molding processes, highlight the range of materials available—including innovative engineering plastics and sustainable options—and emphasize the importance of stringent quality control measures to adhere to international standards.

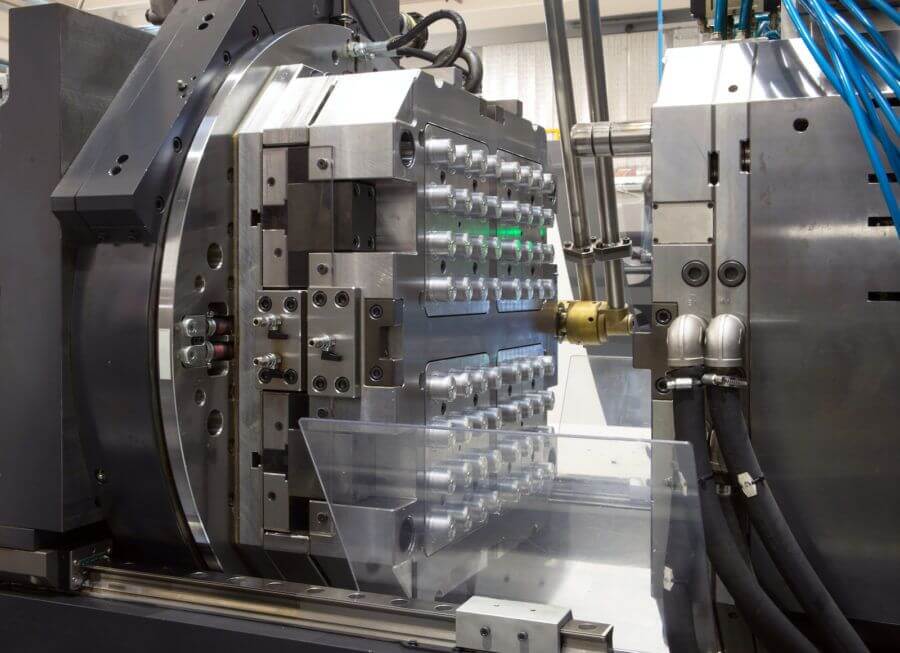

Illustrative Image (Source: Google Search)

Moreover, we provide actionable insights into evaluating potential suppliers, understanding cost drivers, and navigating the unique market dynamics across different regions. As you explore the comprehensive sections of this guide, you will find answers to frequently asked questions, enabling you to forge strategic partnerships that enhance quality, reduce costs, and accelerate your time-to-market. By leveraging the insights contained within, you can confidently align your sourcing strategies with your project goals and the evolving demands of the global market.

Understanding injection molders Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| In-House (Vertical Integration) | Fully equipped internal facilities; direct production control | Custom, high-volume components | Pros: High quality control, confidentiality. Cons: Higher initial investment. |

| Contract Manufacturing (OEM) | External firms producing parts based on specifications | Consumer electronics, automotive | Pros: Cost-effective, flexible. Cons: Less control over quality. |

| Rapid Prototyping & Short-Run | Quick turnaround for small batches; additive techniques | Product development, niche markets | Pros: Fast delivery, low upfront costs. Cons: Higher per-unit costs. |

| High-Precision Molders | Advanced equipment for intricate parts; tight tolerances | Aerospace, medical devices | Pros: Exceptional accuracy. Cons: Higher prices, longer setup times. |

| Eco-Friendly Molders | Focus on sustainable practices and materials | Eco-conscious brands, packaging | Pros: Aligns with environmental standards. Cons: Higher material costs. |

In-House (Vertical Integration)

In-house injection molding facilities provide comprehensive control over the manufacturing process, allowing businesses to manage quality, lead times, and intellectual property effectively. This model is particularly suitable for large corporations that produce custom, high-volume components and require stringent quality assurance. B2B buyers should weigh the advantages of confidentiality and quality control against the higher initial investment and ongoing operational costs, which can be justified for strategic, long-term projects.

Contract Manufacturing (OEM)

Contract manufacturers, or OEMs, serve as external suppliers that produce components according to client specifications. This approach is advantageous for businesses seeking flexibility and cost savings without significant capital investment. Ideal for industries like consumer electronics and automotive, buyers must ensure robust quality assurance processes are in place to mitigate risks associated with reduced direct oversight. Establishing clear communication channels with OEM partners is crucial to maintain quality standards.

Rapid Prototyping & Short-Run Molding

Focusing on quick turnaround times, rapid prototyping and short-run molding services are ideal for businesses needing small batch production or prototypes. Utilizing advanced techniques such as 3D printing, these suppliers enable fast development cycles for product testing and market validation. While this approach offers lower upfront costs and quick delivery, B2B buyers should note that per-unit costs can be higher, making it less suitable for large-scale production. This option is best during early development phases or niche market entries.

High-Precision Molders

High-precision molders utilize state-of-the-art equipment to manufacture intricate components with tight tolerances, catering to sectors such as aerospace and medical devices. For B2B buyers, the ability to produce exceptionally accurate parts is a significant advantage, particularly when quality is non-negotiable. However, the costs associated with precision manufacturing and longer setup times may be a consideration. This type of supplier is best suited for high-value projects where quality and accuracy are paramount.

Eco-Friendly Molders

Eco-friendly injection molders prioritize sustainable manufacturing practices by using recycled materials and energy-efficient processes. This approach appeals to brands focused on sustainability and compliance with environmental standards. While these suppliers may command higher material costs, the potential for eco-labeling and alignment with corporate social responsibility initiatives can be compelling benefits for B2B buyers. Engaging with eco-friendly molders can enhance brand reputation and meet the growing consumer demand for sustainable products.

Related Video: Lecture 1 Two compartment models

Key Industrial Applications of injection molders

| Industry/Sector | Specific Application of injection molders | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of interior and exterior components | High-volume production, cost efficiency, and durability | Supplier certifications (IATF 16949), tooling capabilities, and lead times |

| Consumer Electronics | Manufacturing casings and components for devices | Precision, aesthetic quality, and rapid prototyping | Design support, quality control processes, and material options |

| Medical Devices | Creation of surgical instruments and housings | Compliance with strict regulatory standards and reliability | ISO certifications, engineering support, and in-house tooling |

| Packaging | Production of custom packaging solutions | Enhanced brand visibility, sustainability options | Eco-friendly materials, design versatility, and cost-effectiveness |

| Aerospace | Fabrication of complex components for aircraft | Lightweight and high-strength materials, precision engineering | High-precision molding capabilities, certifications, and long-term partnerships |

Automotive Industry

Injection molders play a crucial role in the automotive sector by producing various interior and exterior components such as dashboards, bumpers, and trim pieces. These components must meet strict durability and performance standards, making high-volume production essential. International buyers should prioritize suppliers with IATF 16949 certification to ensure compliance with automotive quality management standards. Additionally, tooling capabilities and lead times are critical factors, as delays can significantly impact vehicle production schedules.

Consumer Electronics

In the consumer electronics industry, injection molders are used to manufacture casings and components for devices like smartphones, tablets, and wearables. The need for precision and aesthetic quality is paramount, as these products often compete on design appeal. B2B buyers should seek suppliers that offer robust design support and have rigorous quality control processes in place to ensure that components meet the necessary specifications. Material options, including engineering plastics, can also influence the performance and durability of the final products.

Medical Devices

The medical sector relies heavily on injection molding for the creation of surgical instruments, housings, and other critical components. Given the stringent regulatory standards that govern this industry, it is essential for buyers to partner with molders who hold relevant ISO certifications, such as ISO 13485. Engineering support during the design phase can help optimize product performance and compliance. Furthermore, in-house tooling capabilities are vital to maintaining quality and minimizing rework, which is crucial in this high-stakes environment.

Packaging

Injection molders are increasingly being utilized in the packaging industry to produce custom packaging solutions, including containers and closures. This application not only enhances brand visibility but also allows for the incorporation of sustainable materials. Buyers should consider suppliers that offer eco-friendly options and demonstrate design versatility to meet specific branding needs. Cost-effectiveness is also a significant factor, especially for businesses looking to scale production without sacrificing quality.

Aerospace

In the aerospace industry, injection molders are tasked with fabricating complex components that require lightweight yet high-strength materials. Precision engineering is critical, as any failure in components can have serious implications for safety and performance. B2B buyers should focus on suppliers with high-precision molding capabilities and the necessary certifications to comply with aerospace standards. Establishing long-term partnerships can also provide stability and support for ongoing projects and innovations in this highly regulated field.

Strategic Material Selection Guide for injection molders

When selecting materials for injection molding, B2B buyers must consider various factors that influence product performance, cost, and application suitability. Below, we analyze four common materials used in injection molding, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

Polypropylene (PP)

Key Properties: Polypropylene is known for its excellent chemical resistance, low density, and high melting point (around 160°C). It has good fatigue resistance and can perform well under moderate temperatures.

Pros & Cons: One of the key advantages of polypropylene is its durability and lightweight nature, making it suitable for a variety of applications, including packaging, automotive parts, and consumer goods. However, it has a lower impact resistance compared to other plastics and may not be suitable for high-stress applications.

Impact on Application: Polypropylene is compatible with various media, including acids and bases, which makes it ideal for containers and automotive components. However, it is not recommended for applications requiring high-temperature resistance or structural integrity.

Considerations for International Buyers: Buyers should ensure that their suppliers comply with relevant standards such as ASTM D4101 for polypropylene. Additionally, understanding the material’s recyclability can be crucial for eco-conscious markets in Europe and South America.

Acrylonitrile Butadiene Styrene (ABS)

Key Properties: ABS is a thermoplastic known for its toughness and impact resistance, with a temperature range of -20°C to 80°C. It offers good dimensional stability and is easy to machine.

Pros & Cons: The key advantage of ABS is its high impact strength and surface finish, making it suitable for consumer electronics, automotive interiors, and toys. However, it has lower chemical resistance and can be susceptible to UV degradation if not treated properly.

Impact on Application: ABS is widely used in applications where aesthetics and durability are essential, such as in household appliances and automotive components. Its poor chemical resistance limits its use in harsh environments.

Considerations for International Buyers: Buyers should verify compliance with safety standards like ISO 9001 and ensure that ABS products meet specific regional regulations, particularly in Europe, where consumer safety is heavily regulated.

Polycarbonate (PC)

Key Properties: Polycarbonate is a high-performance plastic known for its exceptional impact resistance and optical clarity, with a glass transition temperature around 147°C. It is also resistant to UV light and has good dimensional stability.

Pros & Cons: The primary advantage of polycarbonate is its strength and ability to withstand high temperatures, making it suitable for applications like eyewear lenses, safety equipment, and electronic housings. However, it is more expensive than other materials and can be challenging to process due to its high viscosity.

Impact on Application: Polycarbonate’s transparency and durability make it ideal for applications requiring visibility and protection, such as safety shields and light covers. Its susceptibility to scratching can be a limitation in some applications.

Considerations for International Buyers: Buyers should ensure that polycarbonate products comply with standards such as ASTM D635 and consider the implications of sourcing from suppliers with certifications for environmental safety, especially in regions with strict regulations.

Nylon (Polyamide)

Key Properties: Nylon is known for its excellent mechanical properties, including high tensile strength and abrasion resistance. It has a melting point of around 220°C and offers good chemical resistance.

Pros & Cons: The key advantage of nylon is its versatility and ability to perform well in demanding environments, making it suitable for automotive parts, industrial components, and consumer goods. However, it can absorb moisture, which may affect its dimensional stability and mechanical properties.

Impact on Application: Nylon is ideal for applications requiring high strength and durability, such as gears and bearings. Its moisture absorption can limit its use in applications exposed to high humidity.

Considerations for International Buyers: Buyers should be aware of the specific grades of nylon available and their compliance with standards like ASTM D4066. Understanding the regional preferences for nylon grades can also influence sourcing decisions, particularly in Europe and the Middle East.

| Material | Typical Use Case for injection molders | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Packaging, automotive parts | Lightweight and durable | Lower impact resistance | Low |

| ABS | Consumer electronics, toys | High impact strength | Poor chemical resistance | Medium |

| Polycarbonate | Safety equipment, eyewear lenses | Exceptional impact resistance | Higher cost and processing difficulty | High |

| Nylon | Automotive parts, industrial components | High strength and durability | Moisture absorption affects stability | Medium |

This guide serves as a strategic resource for international B2B buyers to make informed decisions regarding material selection in injection molding, ensuring alignment with project requirements and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for injection molders

In the world of injection molding, understanding the manufacturing processes and quality assurance mechanisms is crucial for B2B buyers seeking reliable partnerships. This section outlines the typical manufacturing processes involved in injection molding, key techniques utilized, and the quality control measures that ensure product excellence.

Manufacturing Processes

The injection molding process consists of several distinct stages, each critical to achieving high-quality molded parts. Here’s a breakdown of the main stages involved:

-

Material Preparation

– Resin Selection: The first step involves selecting the appropriate thermoplastic or thermosetting resin based on the product requirements. This selection impacts the part’s strength, flexibility, and thermal resistance.

– Drying: Many resins absorb moisture, which can affect the molding process. Drying the material to the manufacturer’s specifications ensures optimal flow characteristics during injection. -

Forming

– Injection: The dried resin is fed into a heated barrel where it is melted and then injected into a mold cavity under high pressure. The design of the mold is vital for achieving the desired part geometry and surface finish.

– Cooling: After injection, the material must cool and solidify in the mold. This phase can take several seconds to minutes, depending on the part thickness and material properties. -

Assembly

– Ejection: Once the part has cooled, it is ejected from the mold. This stage may involve additional mechanisms, such as ejector pins or plates, to ensure that the molded part is removed without damage.

– Post-Processing: This can include trimming excess material, adding inserts, or performing any secondary operations such as painting or assembly with other components. -

Finishing

– Surface Treatment: Depending on the application, parts may undergo further finishing processes such as polishing, plating, or coating to enhance appearance or functionality.

– Quality Inspection: Final inspection occurs at this stage to ensure the parts meet specified tolerances and quality standards.

Key Techniques in Injection Molding

- Multi-Shot Molding: This technique allows for the use of multiple materials in a single part, enhancing functionality and aesthetics.

- Gas-Assisted Injection Molding: Utilizes gas to create hollow sections within a part, reducing material use and weight while maintaining strength.

- Insert Molding: Involves placing a component (like metal or another plastic) into the mold before the injection process, integrating parts into a single molded piece.

Quality Assurance

Quality assurance is paramount in injection molding, as it directly affects the reliability and safety of the final product. The following international standards and industry-specific certifications are essential:

- ISO 9001: A widely recognized standard for quality management systems applicable to all industries, ensuring consistent quality in processes and products.

- ISO 13485: Specific to the medical device industry, ensuring stringent quality control in the design and manufacturing of medical products.

- IATF 16949: Focused on the automotive sector, this standard emphasizes continuous improvement and defect prevention in manufacturing processes.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Materials and components are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to detect any deviations from set standards.

- Final Quality Control (FQC): A thorough inspection of the finished product to confirm compliance with quality requirements and customer specifications.

Common Testing Methods

- Dimensional Inspection: Utilizing calipers and micrometers to verify that molded parts meet specified dimensions.

- Visual Inspection: Checking for surface defects, color consistency, and overall appearance.

- Mechanical Testing: Assessing properties such as tensile strength, impact resistance, and thermal stability through standardized tests.

Verifying Supplier Quality Control

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are some actionable insights:

- Conduct Audits: Regular audits of potential suppliers help assess their manufacturing capabilities and adherence to quality standards. This includes reviewing their quality management systems and production environments.

- Request Quality Reports: Suppliers should provide documentation of their quality control processes, including inspection reports and testing results.

- Engage Third-Party Inspectors: Consider hiring independent inspectors to evaluate the manufacturing process and final products, ensuring an unbiased assessment of quality.

QC and Certification Nuances for International Buyers

B2B buyers must be aware of the nuances in quality control and certification standards across different regions. For example, certifications like CE marking in Europe indicate compliance with safety and environmental requirements, while API standards are crucial in the oil and gas sector.

When sourcing from different regions, buyers should ensure that suppliers understand and comply with both local and international quality standards. Establishing clear communication regarding quality expectations and certifications from the outset can prevent misunderstandings and ensure product reliability.

In conclusion, understanding the intricacies of manufacturing processes and quality assurance in injection molding is vital for B2B buyers. By focusing on these aspects, companies can forge strong partnerships with suppliers that meet their production needs while adhering to the highest quality standards.

Related Video: Awesome Scene! Best Mass Production Factory Manufacturing Process

Comprehensive Cost and Pricing Analysis for injection molders Sourcing

Understanding the cost structure and pricing dynamics of injection molding is essential for international B2B buyers. This section delves into the various cost components, pricing influencers, and offers actionable tips for negotiating better deals, particularly for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The choice of materials significantly impacts costs. Engineering plastics and specialty resins tend to be more expensive than standard options. Eco-friendly materials, while beneficial for branding, may also come with a premium. Buyers should assess the balance between cost and material performance to optimize their selections.

-

Labor: Labor costs vary by region, with countries offering lower labor costs often attracting buyers. However, the trade-off may involve compromises in quality or lead times. It’s crucial to evaluate the skill level and experience of the workforce at the manufacturing site.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and administrative costs. A supplier’s location can influence these costs, as regions with higher operational expenses will reflect that in their pricing.

-

Tooling: Tooling is a significant upfront investment in injection molding. The complexity of the design and the type of materials used can affect tooling costs. Buyers should consider suppliers with in-house tooling capabilities to reduce lead times and costs associated with outsourcing this critical component.

-

Quality Control (QC): Rigorous QC processes are essential for maintaining high standards. Suppliers with advanced QC systems may charge more, but this investment can lead to reduced defects and long-term savings. Certifications like ISO can also indicate a supplier’s commitment to quality.

-

Logistics: Shipping costs and logistics management play a vital role, especially for international transactions. Incoterms can dictate responsibilities and costs associated with transportation, insurance, and customs clearance, affecting overall pricing.

-

Margin: Suppliers will typically include a margin that reflects their operational costs and desired profit. Understanding the industry standard margins can help buyers gauge the fairness of a quoted price.

Price Influencers

-

Volume/MOQ: Pricing is often tiered based on order volume. Higher volumes generally lead to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) that align with their production needs while maximizing cost efficiency.

-

Specifications/Customization: Highly customized products may incur additional costs due to the complexity of design and production. Buyers should clearly define specifications to avoid unexpected charges.

-

Quality and Certifications: Suppliers with recognized certifications may charge higher prices. However, these certifications often ensure a higher level of quality and compliance with industry standards, which can mitigate risks in the long run.

-

Supplier Factors: The reputation, experience, and capabilities of the supplier can influence pricing. A well-established supplier may command higher prices due to their reliability and proven track record.

-

Incoterms: Understanding different Incoterms is crucial for determining who is responsible for shipping costs, insurance, and customs duties. This knowledge can help buyers negotiate better terms and manage overall expenses.

Buyer Tips

-

Negotiate Effectively: Buyers should come prepared with market research and a clear understanding of their needs. Leverage volume commitments to negotiate better pricing and terms.

-

Focus on Total Cost of Ownership (TCO): Consider all costs associated with the product lifecycle, including maintenance, warranty, and potential rework. A lower initial price may not always equate to lower TCO.

-

Be Aware of Pricing Nuances: International buyers should understand how currency fluctuations, tariffs, and local economic conditions can affect pricing. Establishing relationships with multiple suppliers can provide leverage in negotiations.

-

Conduct Supplier Audits: Regularly assess suppliers’ capabilities and performance metrics to ensure alignment with quality and cost expectations. This proactive approach can lead to more strategic partnerships and better pricing agreements.

Disclaimer

Prices are indicative and can vary significantly based on numerous factors including region, supplier capabilities, and specific project requirements. Buyers should seek detailed quotations and conduct thorough due diligence to obtain accurate pricing information tailored to their needs.

Spotlight on Potential injection molders Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘injection molders’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for injection molders

Understanding the technical properties and terminology of injection molding is essential for B2B buyers. This knowledge not only aids in effective communication with suppliers but also ensures that the selected partners meet quality and performance expectations.

Key Technical Properties

-

Material Grade

– Definition: Refers to the specific type of plastic resin used in the injection molding process. Common grades include ABS, polycarbonate, and polypropylene.

– B2B Importance: Different grades offer varying properties such as strength, flexibility, and thermal resistance. Selecting the right material grade is crucial for ensuring product performance and compliance with industry standards. -

Tolerance

– Definition: The allowable variation in the dimensions of a molded part. Tolerances are expressed in units (e.g., millimeters) and dictate how much deviation from the specified dimensions is acceptable.

– B2B Importance: Tight tolerances are essential for parts that must fit precisely within an assembly. Understanding tolerance requirements helps buyers select suppliers who can meet their precision needs, ultimately affecting product functionality and assembly efficiency. -

Cycle Time

– Definition: The total time required to complete one cycle of the injection molding process, from the injection of material to the ejection of the finished part.

– B2B Importance: Shorter cycle times can lead to increased production efficiency and lower costs. Buyers should inquire about cycle times to gauge a supplier’s capability to meet production demands and timelines. -

Surface Finish

– Definition: The texture and appearance of the surface of the molded part. Common finishes include glossy, matte, or textured.

– B2B Importance: The surface finish can significantly impact the aesthetic and functional properties of a product. It is vital for branding and user experience, so buyers must specify their finish requirements clearly. -

Shrinkage Rate

– Definition: The percentage decrease in size of a molded part as it cools and solidifies after being ejected from the mold.

– B2B Importance: Understanding the shrinkage rate is crucial for ensuring that parts maintain their intended dimensions and fit correctly in their applications. This knowledge helps in the design phase to avoid costly rework or production delays.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer. In injection molding, this refers to businesses that outsource part production to specialized molders.

– B2B Importance: Understanding OEM relationships can help buyers identify the right partners for production, ensuring that parts meet specific requirements for quality and performance. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– B2B Importance: Knowing the MOQ is essential for budgeting and inventory management. Buyers must assess whether the MOQ aligns with their production needs and financial capabilities. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products or services.

– B2B Importance: An RFQ allows buyers to gather competitive pricing and evaluate supplier capabilities. This process is crucial for making informed sourcing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of standardized terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers in international transactions.

– B2B Importance: Familiarity with Incoterms is vital for understanding shipping responsibilities, costs, and risks involved in international procurement, helping to avoid disputes and ensure smooth logistics. -

Lead Time

– Definition: The time taken from placing an order to the delivery of the finished product.

– B2B Importance: Understanding lead times is crucial for planning and managing production schedules. Buyers should prioritize suppliers who can meet their lead time requirements to ensure timely market entry.

By grasping these technical properties and trade terms, B2B buyers can enhance their sourcing strategies, improve supplier interactions, and ultimately achieve better outcomes in their injection molding projects.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the injection molders Sector

Market Overview & Key Trends

The injection molding sector is witnessing transformative changes driven by globalization, technological advancements, and evolving consumer demands. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for informed sourcing decisions.

Global Drivers:

The demand for injection molded products is increasing due to the rapid growth of industries such as automotive, consumer goods, and healthcare. Factors such as rising disposable incomes, urbanization, and technological innovations in manufacturing processes are propelling this growth. Additionally, the shift towards automation and Industry 4.0 is reshaping production capabilities, enhancing efficiency, and reducing lead times.

Emerging Trends:

1. Digitalization: The integration of IoT (Internet of Things) and AI (Artificial Intelligence) is revolutionizing the injection molding process. Smart manufacturing techniques enable real-time monitoring, predictive maintenance, and optimized production schedules, which are essential for maintaining competitive advantage.

2. Customization and Flexibility: As market demands shift towards personalized products, injection molders are increasingly adopting flexible manufacturing systems. This allows for quick adaptations in production lines to cater to diverse client needs without substantial downtime.

3. Cost Management: Buyers are focusing on total cost of ownership rather than just upfront costs. This shift emphasizes the importance of long-term partnerships with suppliers who offer value-added services, such as in-house tooling and design support.

For B2B buyers in emerging markets, understanding these trends not only aids in supplier selection but also enhances their strategic positioning in a competitive landscape.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a non-negotiable aspect of sourcing in the injection molding industry. As environmental concerns intensify, businesses are under pressure to adopt more sustainable practices in their supply chains. This includes sourcing from manufacturers that prioritize eco-friendly materials and processes.

Environmental Impact:

The injection molding process can have significant environmental implications, from energy consumption to waste generation. Buyers should seek suppliers who implement energy-efficient technologies and sustainable practices to minimize their carbon footprint.

Importance of Ethical Supply Chains:

Establishing an ethical supply chain is essential for maintaining brand integrity and meeting regulatory requirements. B2B buyers should conduct thorough due diligence to ensure their suppliers comply with environmental regulations and ethical labor practices.

Green Certifications and Materials:

Look for suppliers that have certifications such as ISO 14001 for environmental management or use materials like recycled plastics and bio-based resins. These certifications not only demonstrate a commitment to sustainability but can also enhance product appeal in environmentally conscious markets.

Incorporating sustainability into sourcing strategies not only mitigates risk but also aligns with the growing consumer preference for sustainable products, making it a strategic imperative for international buyers.

Brief Evolution/History

The injection molding industry has evolved significantly since its inception in the mid-20th century. Originally, injection molding was limited to simple plastic products, but advancements in technology have transformed it into a sophisticated manufacturing process capable of producing complex and high-precision components.

The introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems in the 1980s marked a turning point, enabling more intricate designs and faster production times. In recent years, the focus has shifted towards sustainability and automation, with a growing emphasis on environmentally friendly materials and smart manufacturing practices. This evolution reflects the industry’s responsiveness to market demands and technological advancements, positioning it as a critical component of modern manufacturing across various sectors.

Understanding this historical context can provide B2B buyers with insights into current capabilities and future trends, enhancing their sourcing strategies in the injection molding sector.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of injection molders

-

What key factors should I consider when vetting injection molding suppliers?

When vetting injection molding suppliers, prioritize their industry experience, market versatility, and relevant certifications. Look for suppliers that demonstrate a diverse portfolio, which indicates stability and adaptability to market changes. Additionally, ensure they have certifications that align with your industry standards (e.g., ISO, IATF) to guarantee compliance with quality management practices. Finally, review their engineering capabilities and quality control processes to assess their ability to meet your specific production needs. -

Can injection molders customize products according to my specifications?

Yes, many injection molders offer customization to meet specific design requirements. When discussing customization, provide detailed drawings, material specifications, and any functional requirements. A skilled molder will utilize advanced design methodologies, such as Design for Manufacturability (DfM), to optimize the manufacturing process. Engage in collaborative discussions during the design phase to ensure that your expectations are met and that the final product aligns with your vision. -

What are the typical minimum order quantities (MOQs) and lead times for injection molding projects?

Minimum order quantities (MOQs) can vary significantly based on the complexity of the part, materials used, and the specific molder’s capabilities. Generally, MOQs can range from a few hundred to thousands of units. Lead times for injection molding can also differ, often ranging from a few weeks to several months, depending on tooling requirements and production schedules. It is essential to communicate your project timelines with potential suppliers to find a suitable partner who can accommodate your needs.

Illustrative Image (Source: Google Search)

-

How do I ensure quality assurance and certifications from my injection molding partner?

To ensure quality assurance, request documentation of your supplier’s certifications and quality control processes. Key certifications to look for include ISO 9001 for general quality management and industry-specific certifications like ISO 13485 for medical devices. Ask about their quality control measures, including inspection protocols, testing methods, and compliance with international standards. Regular communication about quality expectations and periodic audits can further solidify your partnership. -

What logistical considerations should I be aware of when sourcing injection molders internationally?

When sourcing injection molders internationally, consider factors such as shipping times, customs regulations, and import duties. Collaborate with your supplier to establish a clear logistics plan that includes shipping methods, delivery timelines, and potential risks. Understanding local regulations in both your country and the supplier’s country is crucial to avoid delays. Additionally, consider the supplier’s location relative to your market to optimize shipping costs and time. -

How can disputes be effectively managed with injection molding suppliers?

Managing disputes with injection molding suppliers requires clear communication and well-defined contracts. Establish expectations regarding quality, timelines, and payment terms upfront. In the event of a dispute, address the issue promptly and professionally, focusing on collaborative problem-solving rather than confrontation. Including a dispute resolution clause in your contract, such as mediation or arbitration, can provide a structured approach to resolving conflicts while minimizing disruption to your production process. -

What role does technology play in the injection molding process?

Technology plays a crucial role in enhancing efficiency, precision, and innovation in injection molding. Advanced technologies such as computer-aided design (CAD), simulation software, and automated quality control systems improve design accuracy and production reliability. Suppliers utilizing state-of-the-art machinery can offer faster turnaround times and higher-quality outputs. When evaluating potential partners, inquire about their technological capabilities and how they leverage these tools to enhance their manufacturing processes.

- How can I assess the financial stability of an injection molding supplier?

Assessing the financial stability of an injection molding supplier involves reviewing their business history, client portfolio, and market reputation. Request financial statements, if possible, to understand their revenue trends and profitability. Additionally, consider their customer retention rate and the longevity of existing partnerships, as these factors can indicate reliability and stability. Engaging in direct conversations with the supplier about their business model and growth strategies can also provide insights into their financial health.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for injection molders

In the dynamic landscape of injection molding, strategic sourcing emerges as a cornerstone for success, particularly for international B2B buyers. Emphasizing the selection of the right partners can lead to enhanced product quality, cost efficiency, and timely market entry. By understanding the various types of injection molders—from in-house manufacturers to specialized high-precision molders—buyers can tailor their sourcing strategies to align with specific project needs.

Key takeaways include the importance of evaluating suppliers based on market versatility, certifications, and engineering support. Implementing a rigorous assessment process will not only mitigate risks but also foster long-term partnerships that drive innovation and efficiency. As global supply chains continue to evolve, staying ahead of technological advancements and industry standards will be crucial for maintaining competitive advantage.

Looking forward, international buyers from Africa, South America, the Middle East, and Europe should proactively engage with diverse injection molding partners to unlock new opportunities. Embrace the potential of strategic sourcing as a pathway to not only meet current demands but also to anticipate future trends in manufacturing. Start your journey today by identifying the right injection molding partners that align with your vision for sustainable growth and excellence.