Your Ultimate Guide to Sourcing Machine Manufacturing

Introduction: Navigating the Global Market for machine manufacturing

In today’s interconnected world, machine manufacturing stands as a cornerstone of industrial growth and innovation. As international B2B buyers from Africa, South America, the Middle East, and Europe navigate a dynamic market landscape, the demand for customized and specialized machinery has surged. This evolution is driven by the need for greater efficiency, enhanced product quality, and the ability to swiftly adapt to changing production requirements.

This guide offers a comprehensive resource designed to empower buyers with critical insights into the diverse types of machinery available, ranging from CNC-based systems to automated assembly solutions. It delves into the essential materials and technologies that fuel modern manufacturing processes, while also outlining proven strategies for quality assurance and supplier management.

Understanding the complexities of cost structures and market dynamics is vital for making informed decisions. Each region presents unique challenges—be it regulatory hurdles, logistical intricacies, or competitive pressures. By equipping buyers with detailed analyses, actionable strategies, and answers to frequently asked questions, this guide aims to facilitate effective sourcing decisions. Whether you’re looking to upgrade existing machinery or embark on a new production line, the insights provided will enable you to forge strong partnerships with reliable suppliers, ensuring your operations remain competitive in the global marketplace.

Understanding machine manufacturing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC-Based Custom Machines | High-precision computer-controlled fabrication with multiple axes | Aerospace, automotive, electronics, metalworking | Superior accuracy and flexibility; higher upfront investment, skilled operators needed |

| Automated Assembly Systems | Integration of robotics, conveyors, and sensors for tailored automation | Consumer goods, electronics, packaging, food & beverage | Boosts throughput and consistency; complex to design and maintain |

| Retrofit/Rebuild Solutions | Upgrading existing machines with modern controls and sensors | Heavy industry, automotive, energy, rail | Cost-effective modernization; depends on existing asset’s base condition |

| Material Handling Customizers | Equipment tailored for lifting, moving, or positioning products | Logistics, warehousing, construction, manufacturing | Improves safety and efficiency; design must match workflow precisely |

| Specialized Process Machines | Purpose-built for niche manufacturing steps | Niche sectors: paper, plastics, specialty goods | Enables unique output; less resale value, specific to single production need |

CNC-Based Custom Machines

CNC-based custom machines are essential for industries requiring high precision, such as aerospace and automotive. These machines utilize advanced computer controls to execute complex machining tasks with exceptional accuracy. When purchasing, B2B buyers should evaluate the machine’s compatibility with their materials, available precision levels, and the supplier’s aftersales support. While the initial investment may be high, the long-term benefits of improved product quality and operational efficiency are often worth the cost.

Automated Assembly Systems

Automated assembly systems leverage robotics and intelligent controls to enhance production efficiency in sectors like consumer goods and food processing. These systems allow for the automation of complex assembly lines, resulting in consistent output and reduced labor costs. Buyers should focus on suppliers that offer robust integration support and spare parts availability. Additionally, understanding the system’s scalability and the need for operator training is crucial to ensure a smooth transition and ongoing operational success.

Retrofit/Rebuild Solutions

Retrofit and rebuild solutions offer a cost-effective way to modernize aging machinery by integrating new technologies and controls. This option is particularly attractive for companies in heavy industries looking to maximize their existing assets. B2B buyers should assess the condition of their current machines and consider the potential return on investment from modernization efforts. Engaging with suppliers who specialize in retrofitting can lead to significant operational improvements without the need for new equipment purchases.

Material Handling Customizers

Material handling customizers focus on creating specialized equipment for the safe and efficient movement of products within a facility. These machines are critical for logistics and warehousing operations where workflow optimization is essential. Buyers must ensure that the custom designs align with their specific processes and safety standards. Investing in tailored solutions can lead to significant enhancements in productivity and safety, but careful planning is needed to avoid mismatches in design and operational needs.

Specialized Process Machines

Specialized process machines are designed for specific manufacturing tasks, catering to niche markets such as plastics and specialty goods. These machines provide unique outputs tailored to precise production requirements. B2B buyers should consider the limited resale value of these machines, as they are often suited to singular applications. It is vital to evaluate the long-term demand for the specialized products before investing, ensuring that the machinery aligns with broader business objectives and market trends.

Related Video: All Machine Learning Models Clearly Explained!

Key Industrial Applications of machine manufacturing

| Industry/Sector | Specific Application of Machine Manufacturing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Precision CNC Machining | Enhanced accuracy and reduced production waste | Supplier expertise in CNC technology and aftersales support; material compatibility |

| Food Processing | Automated Packaging Systems | Increased efficiency and consistency in packaging | Integration capabilities with existing systems; local support for maintenance |

| Energy | Custom Turbine Manufacturing | Improved energy efficiency and lower operational costs | Proven track record in energy sector; compliance with international standards |

| Consumer Electronics | Specialized Assembly Lines | Higher output quality and reduced labor costs | Scalability for future products; training for local workforce on new technology |

| Construction | Custom Material Handling Equipment | Enhanced safety and productivity on-site | Tailored design to specific workflows; reliability of local suppliers for spare parts |

Automotive

In the automotive sector, precision CNC machining is critical for producing complex components with tight tolerances, such as engine parts and transmission systems. This application addresses challenges related to quality control and waste reduction, ensuring that components meet stringent industry standards. International B2B buyers must prioritize suppliers with extensive CNC expertise and robust aftersales support, particularly in regions like Europe and South America, where compliance with local regulations is essential. Additionally, understanding material compatibility and the potential need for skilled operators is crucial for successful integration into existing production lines.

Food Processing

Automated packaging systems in the food processing industry significantly enhance efficiency and consistency. These systems automate tasks such as filling, sealing, and labeling, which helps to reduce labor costs and minimize human error. Buyers from Africa and the Middle East should consider the integration capabilities of these systems with their current operations and ensure that suppliers can provide local support and spare parts. Furthermore, the ability to quickly adapt to changing packaging requirements is vital, making flexibility a key consideration when sourcing these machines.

Energy

In the energy sector, custom turbine manufacturing plays a pivotal role in optimizing energy production and reducing operational costs. Tailored turbines can be designed for specific energy sources, such as wind or hydro, allowing for improved efficiency. For international buyers, especially in regions rich in natural resources, sourcing from suppliers with a proven track record in the energy sector is essential. Compliance with international standards and local regulations is crucial, as is the ability to provide ongoing maintenance and support.

Consumer Electronics

Specialized assembly lines are increasingly employed in the consumer electronics industry to enhance output quality and reduce labor costs. These systems automate the assembly process, ensuring consistency and precision in the production of devices like smartphones and tablets. Buyers should focus on suppliers that offer scalable solutions that can adapt to future product lines, as well as those that provide training for the local workforce on new technologies. This is particularly important for B2B buyers in regions like South America and Europe, where rapid technological advancements are common.

Construction

Custom material handling equipment is vital in the construction industry, where safety and productivity are paramount. Tailored solutions for lifting and moving heavy materials can significantly improve operational efficiency on job sites. When sourcing this type of equipment, buyers should ensure that the design is specifically matched to their workflows and that suppliers can provide reliable local support for spare parts and maintenance. Understanding the unique challenges faced in various regions, such as Africa and the Middle East, is crucial for selecting the right equipment that meets both safety and operational standards.

Related Video: The World’s Largest Bevel Gear CNC Machine- Modern Gear Production Line. Steel Wheel Manufacturing

Strategic Material Selection Guide for machine manufacturing

When selecting materials for machine manufacturing, international B2B buyers must consider various factors that impact product performance, cost, and suitability for specific applications. Here, we analyze four common materials used in machine manufacturing, highlighting their properties, advantages, disadvantages, and considerations for buyers from Africa, South America, the Middle East, and Europe.

Steel

Key Properties: Steel is known for its high tensile strength, durability, and versatility. It can withstand high temperatures and pressures, making it suitable for a wide range of applications. Additionally, various grades of steel can offer varying levels of corrosion resistance.

Pros & Cons: Steel is durable and can be easily machined, welded, and formed. However, it can be heavy, which may increase shipping costs and complicate handling. The cost of steel can vary significantly based on the grade and treatment, with high-performance alloys being more expensive.

Impact on Application: Steel is commonly used in structural components, machine frames, and tooling due to its strength. Buyers must consider the specific media compatibility, especially in environments where corrosion resistance is critical.

Considerations for International Buyers: Compliance with international standards such as ASTM or DIN is essential. Buyers should also be aware of local regulations regarding steel sourcing and environmental impact, particularly in regions with strict sustainability mandates.

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity. It can be easily extruded and formed into complex shapes, making it ideal for various applications.

Pros & Cons: The primary advantage of aluminum is its weight, which reduces shipping costs and makes it easier to handle. However, it is generally less strong than steel and may not be suitable for high-stress applications. The cost of aluminum can also be higher than that of standard steel.

Impact on Application: Aluminum is widely used in automotive and aerospace applications where weight savings are crucial. Its corrosion resistance makes it suitable for outdoor applications and environments with moisture.

Considerations for International Buyers: Buyers should ensure that aluminum sourced meets relevant standards like JIS or ISO. Additionally, they should evaluate the availability of local suppliers to mitigate lead times and shipping costs.

Plastics

Key Properties: Plastics are lightweight, resistant to corrosion, and can be molded into complex shapes. They have varying temperature and pressure ratings depending on the type of plastic used.

Pros & Cons: Plastics are cost-effective and can reduce the weight of components significantly. However, they may not withstand high temperatures or mechanical stresses as well as metals, limiting their use in certain applications.

Impact on Application: Plastics are often used in components that require insulation or chemical resistance, such as housings and seals. Compatibility with specific media is crucial, especially in chemical processing applications.

Considerations for International Buyers: Buyers should be aware of the specific plastic grades required for their applications and ensure compliance with local regulations regarding plastic use and recycling. Understanding the environmental impact of plastic sourcing is also increasingly important.

Composites

Key Properties: Composite materials, such as carbon fiber or fiberglass, offer high strength-to-weight ratios and excellent corrosion resistance. They can be engineered for specific performance criteria, including thermal stability and electrical insulation.

Pros & Cons: Composites are exceptionally lightweight and can outperform metals in specific applications. However, they tend to be more expensive and require specialized manufacturing processes, which can complicate sourcing.

Impact on Application: Composites are ideal for high-performance applications in aerospace and automotive sectors. Their unique properties allow for innovative designs that traditional materials cannot achieve.

Considerations for International Buyers: Buyers must ensure that composites meet relevant industry standards and certifications. Additionally, they should consider the availability of local expertise in composite manufacturing to avoid long lead times.

| Material | Typical Use Case for machine manufacturing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, machine frames | High tensile strength | Heavy and can be costly | Medium |

| Aluminum | Automotive and aerospace components | Lightweight and corrosion-resistant | Less strong than steel | High |

| Plastics | Housings, seals, insulation components | Cost-effective and lightweight | Limited temperature resistance | Low |

| Composites | High-performance aerospace and automotive | High strength-to-weight ratio | Expensive and complex to manufacture | High |

In-depth Look: Manufacturing Processes and Quality Assurance for machine manufacturing

In the realm of machine manufacturing, understanding the manufacturing processes and quality assurance (QA) practices is crucial for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. This section explores the typical stages of manufacturing, key techniques employed, and the relevant quality assurance measures that ensure reliability and compliance with international standards.

Manufacturing Processes

Machine manufacturing typically involves several main stages, each crucial for producing high-quality machinery. These stages include:

-

Material Preparation

– Raw Material Selection: The initial step involves selecting appropriate raw materials, such as metals, plastics, or composites. Buyers should ensure that suppliers can provide materials that meet the required specifications and standards.

– Cutting and Shaping: Techniques like laser cutting, waterjet cutting, or machining are used to prepare materials into the desired shapes and sizes. Advanced CNC (Computer Numerical Control) machines enhance precision during this stage. -

Forming

– Processes: This stage involves transforming raw materials into usable forms through techniques such as forging, casting, or extrusion. Each method has its advantages depending on the material properties and desired characteristics.

– Importance of Precision: Ensuring precision in this stage is essential, as even minor errors can lead to significant quality issues later in the process. -

Assembly

– Integration of Components: After forming, the next step is the assembly of various components. This can involve manual assembly or automated systems depending on the complexity and volume of production.

– Testing During Assembly: Implementing in-process quality checks (IPQC) during assembly helps catch defects early, reducing the risk of larger issues in the final product. -

Finishing

– Surface Treatment: Techniques such as painting, coating, or polishing are applied to enhance the durability and appearance of the machine.

– Final Assembly and Inspection: Once finishing is complete, the machine undergoes final assembly, followed by thorough inspections to ensure it meets all specifications.

Quality Assurance

Quality assurance in machine manufacturing is vital to ensure that products meet both buyer expectations and regulatory standards. This process encompasses several key components:

-

International Standards

– ISO 9001: This standard focuses on quality management systems and is widely recognized globally. It helps organizations ensure they meet customer and regulatory requirements consistently.

– Industry-Specific Standards: Depending on the machine type, additional certifications may be necessary, such as CE marking for the European market or API standards for the oil and gas industry. -

Quality Control Checkpoints

– Incoming Quality Control (IQC): This initial inspection stage assesses the quality of incoming materials and components. Buyers should verify that suppliers have robust IQC processes in place.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early. Techniques such as statistical process control (SPC) can be employed here.

– Final Quality Control (FQC): The final inspection ensures that the finished product meets all specifications before delivery. This includes functional testing and visual inspections. -

Testing Methods

– Common Testing Techniques: These can include non-destructive testing (NDT), functional tests, and performance evaluations. Buyers should inquire about the specific tests conducted and their relevance to the intended use of the machinery.

– Documentation of Results: Suppliers should provide detailed reports of testing outcomes to ensure transparency and accountability.

Illustrative Image (Source: Google Search)

- Verifying Supplier Quality Control

– Audits: Conducting regular audits of suppliers can help buyers assess compliance with quality standards and operational practices. This is particularly important for international buyers to ensure adherence to their standards.

– Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their quality management processes and product reliability.

– Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s capabilities and product quality.

Regional Considerations for B2B Buyers

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, face unique challenges and considerations:

- Regulatory Compliance: Different regions have varying regulatory requirements. It’s essential for buyers to understand these regulations and ensure that suppliers can meet them.

- Cultural Nuances: Building strong relationships with suppliers is key. Understanding cultural differences can enhance communication and collaboration.

- Logistical Challenges: Buyers must consider the logistics of sourcing machinery, including shipping times, customs, and tariffs. This can impact overall costs and delivery schedules.

Conclusion

For international B2B buyers, a thorough understanding of the manufacturing processes and quality assurance practices is critical for successful sourcing of machine manufacturing. By focusing on material preparation, forming, assembly, and finishing stages, and implementing rigorous quality control measures, buyers can ensure they acquire reliable, high-quality machinery that meets their operational needs and regulatory requirements. Engaging in proactive supplier management, including audits and performance assessments, will further enhance the chances of successful partnerships in the global marketplace.

Related Video: Amazing factories | Manufacturing method and top 4 processes | Mass production process

Comprehensive Cost and Pricing Analysis for machine manufacturing Sourcing

Understanding the cost structure and pricing dynamics in machine manufacturing is essential for international B2B buyers. This analysis focuses on the various cost components involved, the factors influencing pricing, and actionable tips for effective negotiation and cost management.

Key Cost Components

-

Materials: The primary input in machine manufacturing, material costs can vary significantly based on quality, sourcing location, and market conditions. Common materials include metals, plastics, and composites, each with distinct price fluctuations driven by global supply and demand.

-

Labor: Labor costs encompass direct and indirect expenses associated with skilled workers, machine operators, and engineers. Regions with higher labor costs may necessitate investments in automation or advanced manufacturing technologies to maintain competitiveness.

-

Manufacturing Overhead: This includes expenses not directly tied to production, such as utilities, facility maintenance, and administrative costs. Buyers should consider how supplier overheads may affect pricing, particularly in regions with varying operational costs.

-

Tooling: Custom tooling is often required for specialized machines. Tooling costs can be substantial and should be factored into the total cost of ownership. Buyers must assess whether to invest in reusable tooling or incur one-time costs for bespoke designs.

-

Quality Control (QC): Ensuring that machines meet specified standards incurs costs related to testing, inspections, and certifications. These costs can vary based on the complexity of the machine and the regulatory environment in the buyer’s region.

-

Logistics: Transportation and shipping costs are critical, especially for international buyers. Factors such as distance, mode of transport, and customs duties can substantially influence total costs.

-

Margin: Suppliers typically build a profit margin into their pricing, which can vary based on market competition, perceived value, and the supplier’s operational efficiency.

Price Influencers

Several factors can significantly impact pricing in machine manufacturing:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate for favorable pricing based on anticipated demand.

-

Specifications and Customization: Custom features and technical specifications can drive up costs. It’s essential for buyers to clearly define their requirements to avoid unexpected expenses.

-

Materials: Premium materials can enhance machine performance but will increase costs. Buyers should balance quality with budget constraints, considering the total cost of ownership.

-

Quality and Certifications: Machines that meet international quality standards often command higher prices. Buyers must decide on the trade-off between cost and compliance with quality benchmarks.

-

Supplier Factors: The supplier’s reputation, reliability, and location play a significant role in pricing. Buyers should conduct thorough due diligence to select suppliers that align with their quality and budget expectations.

-

Incoterms: Understanding shipping terms and responsibilities (e.g., FOB, CIF) is critical in international transactions. These terms affect logistics costs and risk allocation.

Buyer Tips for Cost Management

-

Effective Negotiation: Engage suppliers early in the procurement process to negotiate pricing based on volume commitments and long-term partnerships. Leverage competitive quotes to foster better terms.

-

Cost-Efficiency Analysis: Assess the total cost of ownership, including initial purchase price, maintenance, and operational costs. This holistic view helps in making informed sourcing decisions.

-

Local vs. Global Suppliers: Consider the benefits and drawbacks of sourcing locally versus internationally. Local suppliers may offer shorter lead times and lower shipping costs, while global suppliers might provide better pricing or specialized expertise.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and trade agreements that can influence pricing. Establishing contracts in stable currencies can mitigate risks associated with exchange rate volatility.

Disclaimer: Prices in machine manufacturing can fluctuate based on numerous factors, including market conditions and supplier capabilities. It is advisable to conduct regular market assessments to ensure accurate budgeting and sourcing strategies.

Spotlight on Potential machine manufacturing Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘machine manufacturing’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for machine manufacturing

In the realm of machine manufacturing, understanding key technical properties and trade terminology is crucial for international B2B buyers. This knowledge not only facilitates better communication with suppliers but also aids in making informed procurement decisions. Here’s a breakdown of essential specifications and terms that every buyer should be familiar with.

Critical Technical Properties

-

Material Grade

– Definition: This refers to the classification of materials based on their chemical composition and mechanical properties.

– Importance: Material grade affects durability, strength, and suitability for specific applications. For example, stainless steel grades differ in corrosion resistance, making certain grades more suitable for food processing machinery than others. Buyers must ensure that the materials used align with industry standards and application needs. -

Tolerance

– Definition: Tolerance specifies the allowable limits of variation in a physical dimension or measured value.

– Importance: In machine manufacturing, precise tolerances are critical for ensuring parts fit together correctly and function efficiently. For instance, a tolerance of ±0.01 mm might be essential in aerospace applications, where precision is paramount. Understanding tolerance levels helps buyers assess the quality and reliability of the machines they are procuring. -

Load Capacity

– Definition: This indicates the maximum weight or force that a machine or component can safely support or withstand.

– Importance: Knowing the load capacity is vital for ensuring that machines can handle the demands of specific tasks without risk of failure. This is particularly relevant in sectors like construction and logistics, where equipment is often subjected to heavy loads. Buyers should verify that the load capacities meet their operational requirements. -

Cycle Time

– Definition: Cycle time is the total time required to complete one cycle of operation, from start to finish.

– Importance: A shorter cycle time can lead to increased productivity and efficiency in manufacturing processes. Buyers should analyze cycle times when comparing different machines, as this can significantly impact overall operational costs and output rates. -

Energy Efficiency

– Definition: This refers to the amount of energy consumed by a machine to perform its intended task relative to its output.

– Importance: Energy-efficient machines reduce operational costs and minimize environmental impact. As sustainability becomes increasingly important in global markets, buyers should prioritize machines that offer energy efficiency ratings that align with their sustainability goals.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships is crucial for buyers as it determines the quality and compatibility of parts. Engaging with reputable OEMs ensures reliability and often provides better support for maintenance and replacement parts. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Buyers need to be aware of MOQs to effectively manage inventory and procurement costs. High MOQs can lead to excess stock, while low MOQs can offer flexibility but might incur higher per-unit costs. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products or services.

– Relevance: An RFQ is critical for obtaining competitive pricing and evaluating supplier capabilities. It serves as a basis for negotiation and helps buyers compare different offers systematically. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms is essential for understanding shipping costs, risks, and responsibilities. They help clarify who is responsible for transportation, insurance, and customs clearance, thereby reducing disputes. -

Lead Time

– Definition: The amount of time that passes from the initiation of a process until its completion, particularly in manufacturing and procurement.

– Relevance: Understanding lead times helps buyers plan their production schedules and inventory management effectively. Shorter lead times can enhance responsiveness to market demands, making it a key factor in supplier selection.

By grasping these technical properties and trade terms, international B2B buyers can enhance their sourcing strategies, improve negotiations, and ultimately ensure the procurement of machines that meet their operational needs and industry standards.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the machine manufacturing Sector

Market Overview & Key Trends

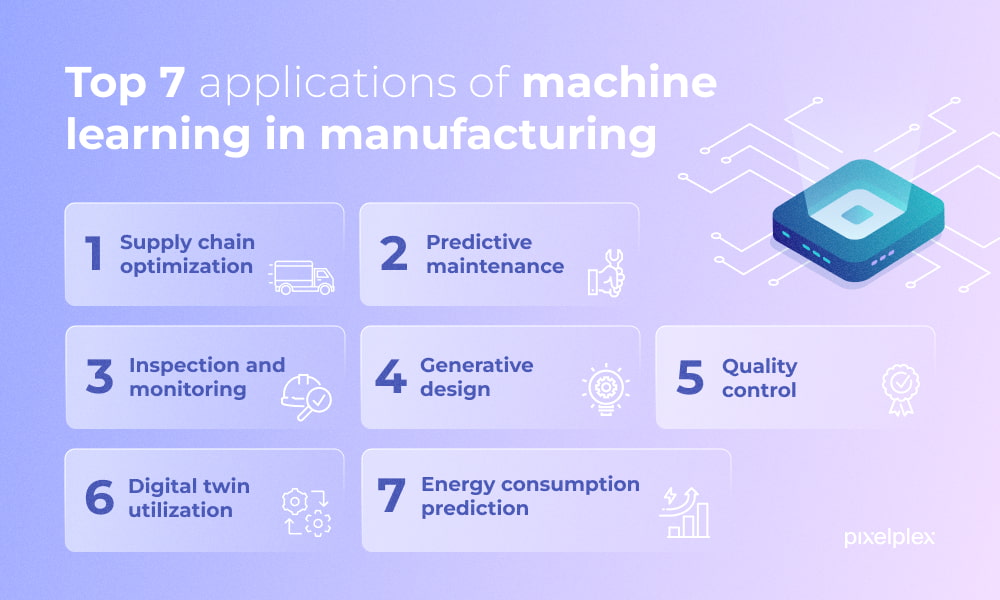

The machine manufacturing sector is witnessing transformative changes driven by globalization, technological advancements, and shifting consumer demands. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly focused on sourcing customizable and specialized machines to enhance operational efficiency and product quality. Key trends shaping the market include the rise of Industry 4.0 technologies, such as IoT and AI, which facilitate real-time monitoring and predictive maintenance, allowing manufacturers to optimize production processes.

Another significant trend is the increasing demand for automation in manufacturing. Automated solutions not only improve productivity but also reduce labor costs and minimize human error. Buyers should pay attention to suppliers offering integrated systems that combine robotics with traditional manufacturing processes, enabling a seamless transition to automation.

Additionally, sustainability is becoming a crucial consideration in sourcing decisions. Buyers are now prioritizing suppliers who adopt environmentally friendly practices and materials. This shift is partly driven by regulatory pressures and consumer expectations for corporate social responsibility. As a result, companies that can demonstrate their commitment to sustainable practices are likely to gain a competitive edge in the marketplace.

Illustrative Image (Source: Google Search)

Lastly, the ongoing disruptions in global supply chains, exacerbated by geopolitical tensions and the COVID-19 pandemic, have prompted buyers to diversify their supplier base. This strategy not only mitigates risks but also opens up opportunities to engage with local suppliers who can offer faster lead times and reduced transportation costs.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer an optional add-on but a fundamental aspect of the machine manufacturing sector. International buyers are increasingly aware of the environmental impact of their sourcing choices. The demand for eco-friendly materials and practices is growing, with many organizations seeking to reduce their carbon footprint throughout the supply chain.

Ethical sourcing is equally important. Buyers should evaluate their suppliers not only on the quality and cost of their products but also on their commitment to ethical labor practices and environmental stewardship. Engaging with suppliers that hold certifications such as ISO 14001 (Environmental Management) or FSC (Forest Stewardship Council) can provide assurance that materials are sourced responsibly.

Incorporating sustainability into procurement strategies can lead to long-term cost savings and enhanced brand reputation. Buyers can look for suppliers who utilize recycled materials or implement energy-efficient manufacturing processes. Furthermore, transparency in the supply chain is becoming essential; buyers should demand visibility into where and how materials are sourced to ensure compliance with ethical standards.

Brief Evolution/History

The machine manufacturing sector has evolved significantly over the past century. Initially dominated by manual labor and simple mechanical processes, the industry underwent a major transformation with the advent of the assembly line in the early 20th century. This innovation drastically improved production efficiency and set the stage for mass manufacturing.

As technology progressed, the introduction of computer numerical control (CNC) machines revolutionized precision manufacturing in the late 20th century. This shift allowed for greater customization and accuracy, catering to the diverse needs of B2B buyers across various industries.

Today, the sector stands at the crossroads of traditional manufacturing and digital transformation. The integration of smart technologies and a focus on sustainability are driving the next phase of evolution, making it essential for international buyers to adapt their sourcing strategies accordingly. Understanding this historical context helps buyers appreciate the continuous innovations that shape their procurement decisions.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of machine manufacturing

-

How can I effectively vet suppliers for custom machine manufacturing?

To vet suppliers, start by reviewing their industry experience and expertise in custom machine manufacturing. Request references from previous clients and check their track record in delivering similar projects. Look for certifications that demonstrate adherence to international quality standards, such as ISO 9001. Additionally, consider conducting on-site visits or virtual audits to assess their production capabilities and quality control processes firsthand. Utilizing platforms like Alibaba or ThomasNet can also help in finding credible suppliers with verified ratings. -

What customization options should I consider when sourcing machines?

Customization options vary widely based on the machine type and its intended application. Key considerations include the machine’s size, materials, and specific features such as automation capabilities or software integration. Discuss your production needs in detail with potential suppliers to explore how they can tailor their machines to fit your operations. Ensure that any custom features align with your production goals and regulatory requirements in your region, as this can impact both functionality and compliance. -

What are typical minimum order quantities (MOQ) and lead times for custom machines?

MOQs for custom machines can vary significantly depending on the supplier and the complexity of the machine. Some suppliers may require a minimum of one unit, while others might have higher thresholds, especially for specialized equipment. Lead times typically range from a few weeks to several months, influenced by factors such as the machine’s complexity, customization level, and the supplier’s production capacity. Always clarify these details upfront to align your procurement timeline with your production schedules. -

How do payment terms generally work in international B2B machine sourcing?

Payment terms can vary, but common practices include deposits ranging from 20% to 50% upfront, with the balance due upon completion or before shipping. Some suppliers may offer financing options or letter of credit arrangements to facilitate international transactions. It’s essential to negotiate clear payment terms upfront and ensure they align with your cash flow and budgeting strategies. Be wary of suppliers who request full payment upfront, as this can be a red flag regarding their reliability. -

What quality assurance measures should I ask suppliers about?

Inquire about the supplier’s quality assurance (QA) processes, including their testing protocols and inspection methods. Look for suppliers who utilize standardized QA systems and can provide documentation such as certificates of compliance or inspection reports. Ask about their approach to handling defects and their procedures for addressing quality issues post-delivery. Establishing clear quality expectations in your contract can help mitigate risks associated with receiving subpar machinery. -

What certifications should I look for when sourcing machinery internationally?

Key certifications to look for include ISO 9001 for quality management systems, CE marking for compliance with European health and safety standards, and UL certification for safety in electrical equipment. Depending on your industry, additional certifications may be required, such as FDA compliance for food processing equipment. Verify that the supplier can provide documentation for these certifications and ensure they are relevant to the markets you operate in, as this can affect your import/export processes. -

What are best practices for managing logistics when importing machines?

Effective logistics management starts with understanding the shipping options available for your machinery, such as container shipping or air freight. Work closely with your supplier to determine the best shipping method based on cost, urgency, and machine size. Ensure that all necessary customs documentation is in order to avoid delays at the border. Consider partnering with a logistics provider experienced in handling heavy machinery to streamline the import process and mitigate potential risks. -

How can I handle disputes with suppliers in international transactions?

To handle disputes effectively, establish clear terms and conditions in your contract, including conflict resolution procedures. Maintain open lines of communication with your supplier to address issues as they arise. If a dispute escalates, consider mediation or arbitration as a means to resolve the issue amicably. Document all communications and agreements related to the dispute, as this can be vital in any formal proceedings. Familiarize yourself with international trade laws that may apply to your transaction to better navigate potential conflicts.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for machine manufacturing

In today’s competitive landscape, strategic sourcing is paramount for international B2B buyers in the machine manufacturing sector. By prioritizing customization and aligning sourcing strategies with operational goals, businesses can enhance product quality, optimize efficiency, and respond adeptly to changing market demands. Buyers should focus on building strong relationships with reliable suppliers, leveraging data-driven insights to evaluate performance, and ensuring compliance with local regulations, especially in diverse regions such as Africa, South America, the Middle East, and Europe.

Key Takeaways:

- Customization is Key: Tailor-made machines significantly improve operational outcomes and product quality.

- Supplier Relationships Matter: Establishing robust partnerships with suppliers fosters reliability and consistency.

- Cost Management: Analyzing total procurement costs, including logistics and quality assurance, is essential for sustainable growth.

As we look to the future, the machine manufacturing landscape will continue to evolve, with increasing emphasis on sustainability and technological advancements. International B2B buyers are encouraged to embrace these changes proactively, ensuring they are well-positioned to capitalize on emerging opportunities. Take the next step in your sourcing journey—evaluate your current strategies and explore new partnerships that can drive your business forward in this dynamic market.