Master Polyurethane Injection Molding: Your Ultimate B2B

Introduction: Navigating the Global Market for polyurethane injection molding

Polyurethane injection molding stands at the forefront of modern manufacturing, offering unparalleled versatility and performance across various industries. As a critical process for producing durable and lightweight components, it caters to sectors ranging from automotive to consumer goods, making it an essential consideration for international B2B buyers. This guide delves into the intricate world of polyurethane injection molding, providing comprehensive insights that empower informed sourcing decisions.

Understanding the nuances of different types of polyurethane materials, manufacturing processes, and quality control measures is vital for maximizing product performance and reducing costs. This guide covers a spectrum of topics, including the various polyurethane types used in injection molding, advanced manufacturing techniques, and strategies for selecting reliable suppliers. Additionally, it addresses frequently asked questions to clear common uncertainties that may arise during the sourcing process.

For B2B buyers in Africa, South America, the Middle East, and Europe, navigating this global market requires a well-rounded understanding of local and international dynamics. By leveraging the information presented in this guide, buyers will be equipped to make strategic decisions that enhance their competitive edge, ensuring they source high-quality polyurethane products that meet their specific needs. Whether you are looking to innovate or streamline your supply chain, this guide serves as a valuable resource for unlocking the full potential of polyurethane injection molding.

Understanding polyurethane injection molding Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Reaction Injection Molding (RIM) | Utilizes a chemical reaction to create polyurethane, allowing for complex shapes and larger parts. | Automotive parts, industrial equipment | Pros: High strength, lightweight. Cons: Longer cycle times. |

| Thermoplastic Polyurethane (TPU) | Flexible and elastic, combines properties of rubber and plastic, allowing for reprocessing. | Consumer goods, automotive, medical | Pros: Versatile, can be recycled. Cons: Limited heat resistance. |

| Long Fiber Injection (LFI) | Incorporates long fibers into the polyurethane matrix, enhancing strength and durability. | Structural components in vehicles, machinery | Pros: High impact resistance, lightweight. Cons: Higher material costs. |

| Structural Foam Molding | Involves injecting a gas into the polyurethane to create a foamed structure, reducing weight. | Packaging, furniture, automotive parts | Pros: Cost-effective for large parts. Cons: Limited surface finish quality. |

| Overmolding | Combines two different materials in a single process, often layering TPU over a rigid substrate. | Electronics, automotive, consumer products | Pros: Improved grip, aesthetic appeal. Cons: Complexity in design and tooling. |

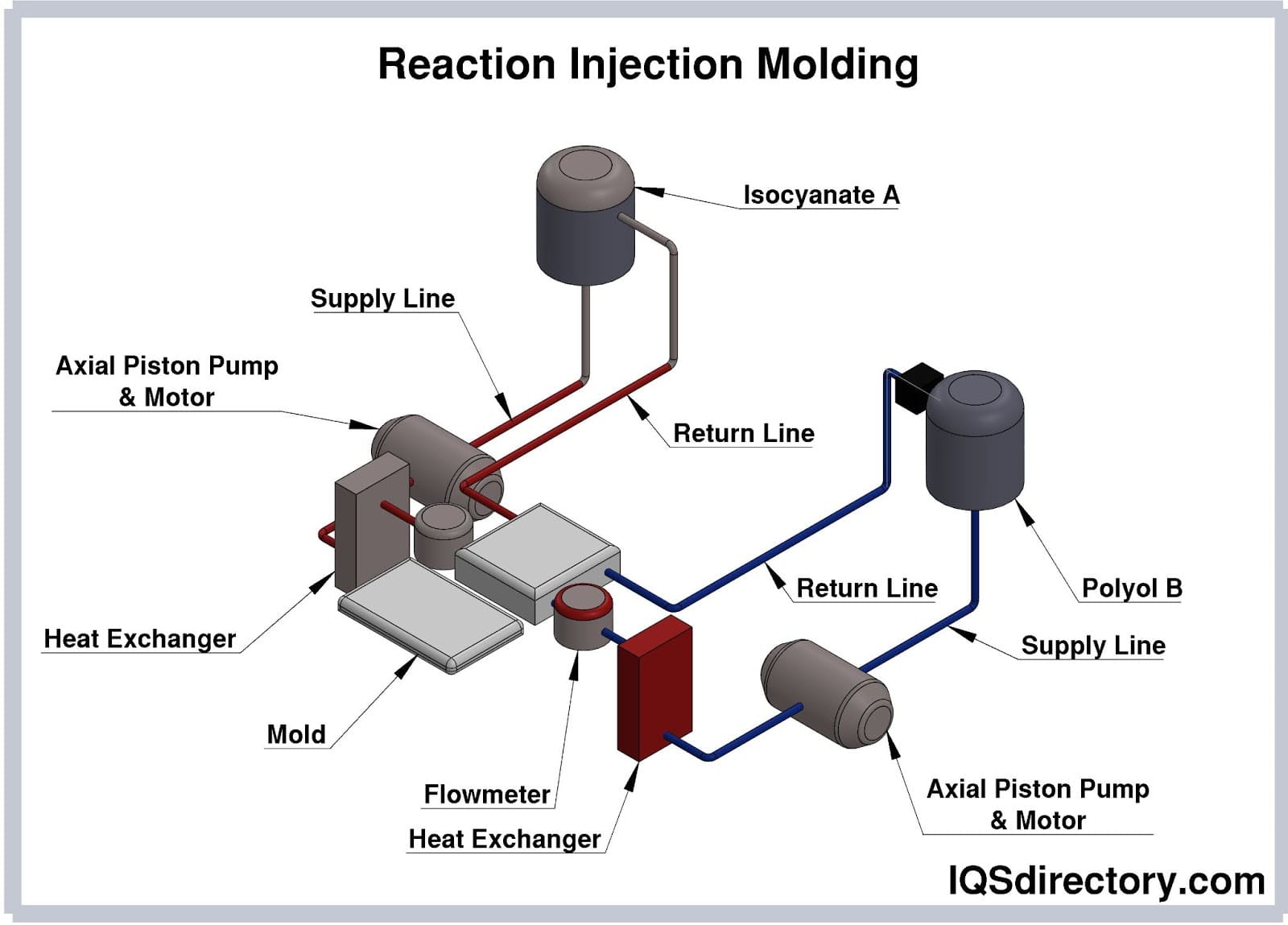

Reaction Injection Molding (RIM)

RIM involves a chemical reaction that occurs when two liquid components are mixed and injected into a mold. This method is particularly suitable for creating large, complex parts due to its ability to form intricate shapes. B2B buyers should consider RIM for applications in automotive parts and industrial equipment where high strength and lightweight components are essential. However, they should be prepared for longer cycle times compared to other methods, which may impact production schedules.

Thermoplastic Polyurethane (TPU)

TPU is a versatile material that combines the properties of rubber and plastic, making it ideal for various applications. It can be reprocessed, which adds to its sustainability appeal. Industries such as automotive, medical, and consumer goods benefit from TPU’s flexibility and chemical resistance. Buyers should note that while TPU offers excellent performance, it has limited heat resistance, which may affect its suitability for high-temperature applications.

Long Fiber Injection (LFI)

LFI technology enhances the mechanical properties of polyurethane by incorporating long fibers into the matrix. This results in components that are not only lightweight but also exhibit high impact resistance, making them ideal for structural applications in vehicles and machinery. B2B buyers should weigh the benefits of durability against the higher material costs associated with LFI, especially if the application demands robust performance.

Structural Foam Molding

Structural foam molding is a cost-effective solution for producing large parts by injecting a gas into the polyurethane mixture, creating a foamed structure. This method is commonly used in packaging, furniture, and automotive parts, where weight reduction is a priority. Buyers should be aware that while structural foam molding is economical, it may result in a lower surface finish quality, which could be a consideration for aesthetic applications.

Overmolding

Overmolding is a specialized technique that allows for the combination of two different materials in a single molding process. This is particularly useful for creating products that require enhanced grip or aesthetic appeal, such as in electronics and automotive components. While overmolding offers significant advantages, buyers should consider the complexity involved in design and tooling, which may increase production lead times and costs.

Related Video: Polyurethane injection molding- Custom Urethane Parts

Key Industrial Applications of polyurethane injection molding

| Industry/Sector | Specific Application of Polyurethane Injection Molding | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Bumpers and body panels | Lightweight yet durable components reduce vehicle weight and improve fuel efficiency. | Suppliers must ensure compliance with automotive safety standards and provide high-quality finishes. |

| Construction | Insulation panels for buildings | Enhanced thermal insulation properties lead to energy savings in heating and cooling. | Look for suppliers with experience in building materials and certifications for thermal performance. |

| Medical | Custom prosthetics and orthotics | Tailored solutions improve patient comfort and mobility, leading to better health outcomes. | Ensure materials meet medical-grade standards and have proven biocompatibility. |

| Consumer Goods | Durable casings for electronics | Provides protection against impacts and enhances product longevity, increasing customer satisfaction. | Suppliers should offer customizable designs and quick turnaround times for prototypes. |

| Industrial Equipment | Seals and gaskets for machinery | Improved durability reduces maintenance costs and downtime, enhancing overall productivity. | Prioritize suppliers who can deliver precision-engineered components and have a robust supply chain. |

Automotive Applications

Polyurethane injection molding is extensively used in the automotive sector for producing bumpers and body panels. These components benefit from polyurethane’s lightweight nature and durability, which contribute to overall vehicle weight reduction and improved fuel efficiency. Buyers in this sector should ensure that suppliers comply with automotive safety standards, as well as provide high-quality finishes that meet aesthetic and functional requirements.

Construction Applications

In the construction industry, polyurethane injection molding is employed to create insulation panels that enhance energy efficiency in buildings. These panels provide superior thermal insulation, leading to significant energy savings in heating and cooling. For international buyers, especially from regions with extreme weather, sourcing from suppliers with experience in building materials and relevant certifications is crucial to guarantee performance and compliance with local regulations.

Medical Applications

The medical field utilizes polyurethane injection molding for custom prosthetics and orthotics. This application allows for the creation of tailored solutions that enhance patient comfort and mobility, ultimately leading to improved health outcomes. Buyers should ensure that the materials used meet stringent medical-grade standards and demonstrate proven biocompatibility to avoid any adverse effects.

Consumer Goods Applications

Polyurethane injection molding is also applied in the production of durable casings for electronic devices. These casings protect against impacts while enhancing the longevity of products, which is essential for customer satisfaction. Buyers looking for suppliers in this sector should prioritize those who offer customizable designs and quick turnaround times for prototypes, ensuring that products meet market demands swiftly.

Industrial Equipment Applications

In the industrial equipment sector, polyurethane injection molding is critical for manufacturing seals and gaskets. These components offer improved durability, which significantly reduces maintenance costs and machinery downtime, thus enhancing overall productivity. International buyers should focus on sourcing from suppliers capable of delivering precision-engineered components, ensuring a robust supply chain to meet production schedules effectively.

Related Video: Thermoplastic Elastomer TPE & Polyurethane TPU Injection Molding | Poly Labs

Strategic Material Selection Guide for polyurethane injection molding

When selecting materials for polyurethane injection molding, international B2B buyers must consider various factors that can significantly impact the performance, cost, and suitability of the final products. Below is an analysis of four common materials used in polyurethane injection molding, focusing on their key properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Thermoplastic Polyurethane (TPU)

Key Properties:

TPU is known for its excellent elasticity, abrasion resistance, and chemical stability. It can withstand temperatures ranging from -40°C to 100°C, making it suitable for diverse applications.

Pros & Cons:

Pros: TPU offers high flexibility and durability, making it ideal for products that require repeated bending or stretching. It is also easy to process and can be recycled.

Cons: The material can be more expensive than traditional plastics, and its processing requires precise temperature control to avoid degradation.

Impact on Application:

TPU is widely used in automotive parts, medical devices, and consumer goods due to its compatibility with oils and greases, ensuring longevity in challenging environments.

Considerations for International Buyers:

Buyers should ensure compliance with local regulations regarding material safety and environmental impact. Standards such as ASTM D624 for tensile strength and ISO 10993 for biocompatibility are essential for medical applications.

2. Polyester-based Polyurethane

Key Properties:

Polyester-based polyurethanes exhibit high mechanical strength and excellent abrasion resistance. They can operate effectively at temperatures up to 120°C.

Pros & Cons:

Pros: These materials offer superior durability and are resistant to wear and tear, making them suitable for heavy-duty applications.

Cons: They may have lower hydrolysis resistance compared to other types, which can limit their use in humid environments.

Impact on Application:

Ideal for industrial applications, polyester-based polyurethanes are commonly used in coatings, adhesives, and sealants where strength and durability are critical.

Considerations for International Buyers:

Buyers should be aware of the specific environmental regulations in their regions. Compliance with standards such as DIN EN 15534 for composite materials is important for ensuring product quality.

3. Polyether-based Polyurethane

Key Properties:

Polyether-based polyurethanes are known for their excellent flexibility and stability at low temperatures, with a service temperature range from -30°C to 80°C.

Pros & Cons:

Pros: They are highly resistant to hydrolysis and microbial attack, making them suitable for applications in wet environments.

Cons: They generally have lower mechanical strength compared to polyester-based variants, which may limit their use in high-stress applications.

Impact on Application:

These materials are often used in applications such as footwear, gaskets, and seals, where moisture resistance is crucial.

Considerations for International Buyers:

It’s important for buyers to verify compliance with relevant standards like JIS K 6853 for thermoplastic elastomers, particularly in regions with stringent product safety regulations.

4. Dicyclopentadiene (DCPD) Polyurethane

Key Properties:

DCPD polyurethane is characterized by its high thermal stability and excellent mechanical properties, suitable for temperatures up to 150°C.

Pros & Cons:

Pros: This material offers exceptional impact resistance and is ideal for structural applications.

Cons: The processing of DCPD can be complex and may require specialized equipment, leading to higher manufacturing costs.

Impact on Application:

DCPD is commonly utilized in automotive and aerospace applications, where high performance and durability are essential.

Considerations for International Buyers:

Buyers must consider the availability of processing technology in their regions and ensure compliance with international standards like ISO 9001 for quality management systems.

Summary Table

| Material | Typical Use Case for polyurethane injection molding | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic Polyurethane | Automotive parts, medical devices | High flexibility and durability | Higher processing costs | Medium |

| Polyester-based Polyurethane | Industrial coatings, adhesives | Superior durability and wear resistance | Lower hydrolysis resistance | Medium |

| Polyether-based Polyurethane | Footwear, gaskets, seals | Excellent moisture resistance | Lower mechanical strength | Low |

| Dicyclopentadiene Polyurethane | Automotive, aerospace components | Exceptional impact resistance | Complex processing requirements | High |

This guide provides a comprehensive overview of the materials available for polyurethane injection molding, enabling international B2B buyers to make informed decisions that align with their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane injection molding

Polyurethane injection molding is a sophisticated process that combines the versatility of polyurethane materials with advanced manufacturing techniques to produce high-quality parts. Understanding the manufacturing processes and quality assurance protocols is crucial for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This section will delve into the typical manufacturing stages, key techniques, and relevant quality control measures that can significantly impact the procurement decisions of international buyers.

Manufacturing Processes

The manufacturing process for polyurethane injection molding consists of several critical stages, each essential for ensuring the final product meets quality and performance standards.

1. Material Preparation

The first step involves preparing the polyurethane materials, which can include both thermosetting and thermoplastic variants. The preparation process typically involves:

- Material Selection: Choosing the appropriate type of polyurethane based on the desired properties (e.g., flexibility, durability).

- Pre-Mixing: Mixing the polyol and isocyanate components in precise ratios to achieve the desired chemical reaction and final material properties.

- Temperature Control: Ensuring materials are at the correct temperature to facilitate optimal flow and reaction during injection.

2. Forming

The actual molding process is where the mixed polyurethane is injected into a pre-heated mold. Key techniques in this stage include:

- Injection Molding: The most common method where the polyurethane mixture is injected into a mold cavity under high pressure.

- Reaction Injection Molding (RIM): A specialized process where the components react within the mold, allowing for complex shapes and structures.

- Multi-Shot Injection Molding: This technique allows for the injection of different materials or colors in a single cycle, enhancing product functionality and aesthetics.

3. Assembly

After forming, the components may require further assembly. This can involve:

- Mechanical Assembly: Attaching parts using screws, clips, or adhesives.

- In-Mold Assembly: Integrating additional components into the mold before the polyurethane sets, reducing assembly time and enhancing product integrity.

4. Finishing

The final stage involves finishing processes to enhance the product’s appearance and functionality. Common finishing techniques include:

- Surface Treatment: Applying coatings, paints, or textures to improve aesthetics and performance.

- Trimming and Cutting: Removing excess material or flash to ensure precise dimensions and a clean finish.

- Quality Checks: Conducting inspections at various stages to ensure compliance with specifications.

Quality Assurance

Quality assurance is paramount in the polyurethane injection molding process, particularly for international B2B buyers who must navigate varying standards and expectations across regions.

International Standards

Buyers should ensure that suppliers adhere to established international quality standards, such as:

- ISO 9001: This standard focuses on quality management systems and is crucial for ensuring consistent product quality.

- ISO 14001: Pertains to environmental management, important for companies looking to reduce their ecological footprint.

- Industry-Specific Certifications: Depending on the application, certifications such as CE (Conformité Européenne) for European markets or API (American Petroleum Institute) for oil and gas components may be relevant.

Quality Control Checkpoints

A robust quality control system typically involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Conducting checks during the manufacturing process to identify defects early and minimize waste.

- Final Quality Control (FQC): Performing comprehensive inspections of the finished products before they leave the facility.

Common Testing Methods

To verify product quality, various testing methods can be employed, including:

- Mechanical Testing: Assessing tensile strength, elongation, and hardness.

- Chemical Resistance Testing: Evaluating how the product performs against various chemicals.

- Thermal Testing: Determining the material’s behavior under temperature fluctuations.

Verifying Supplier Quality Control

International buyers must conduct due diligence to verify a supplier’s quality control practices. Here are several strategies to consider:

- Supplier Audits: Regular audits can help assess compliance with quality standards and operational practices. Consider both initial and periodic audits.

- Quality Reports: Request detailed quality reports and documentation to understand the supplier’s quality management processes and outcomes.

- Third-Party Inspections: Engage independent third-party inspection services to validate the supplier’s claims and ensure adherence to quality standards.

Quality Control Nuances for International Buyers

Navigating the complexities of quality control in international transactions can be challenging. Here are a few considerations:

- Cultural Differences: Be aware that quality expectations and practices may vary across regions. For example, European buyers may have stricter compliance standards compared to those in other regions.

- Communication: Establish clear lines of communication with suppliers to discuss quality requirements and expectations. Language barriers can lead to misunderstandings, so consider using technical specifications and visual aids.

- Regulatory Compliance: Ensure that the products comply with local regulations in your market, which may differ significantly from the supplier’s country.

In summary, understanding the manufacturing processes and quality assurance measures associated with polyurethane injection molding is essential for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and rigorous quality control protocols, buyers can make informed decisions that enhance their supply chain efficiency and product reliability.

Related Video: Detailed Process of Injection Molding | PCBWay Factory

Comprehensive Cost and Pricing Analysis for polyurethane injection molding Sourcing

When sourcing polyurethane injection molding, understanding the cost structure and pricing dynamics is essential for making informed purchasing decisions. This analysis will explore key cost components, price influencers, and provide actionable tips for international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The cost of polyurethane raw materials can vary significantly based on type (thermoplastic vs. thermosetting), quality, and market fluctuations. Polyether and polyester-based polyurethanes are common, with each offering different mechanical properties and price points. Buyers should consider sourcing from multiple suppliers to mitigate price volatility.

-

Labor: Labor costs can vary based on geographic location and the complexity of the molding process. Regions with higher labor costs might have advanced skill sets but could also lead to increased overall costs. Understanding local labor markets is crucial for accurate budgeting.

-

Manufacturing Overhead: This includes utilities, facility costs, and administrative expenses. Overhead is often a fixed cost that can affect pricing. Buyers should inquire about how these costs are allocated in the pricing structure.

-

Tooling: Tooling costs can be substantial, particularly for custom molds. Initial investments in tooling can range from a few thousand to tens of thousands of dollars, depending on the complexity and size of the mold. Buyers should evaluate the tooling amortization period to understand its impact on pricing.

-

Quality Control (QC): Implementing robust QC processes can add to costs but is essential for ensuring product reliability and compliance with industry standards. Certifications (e.g., ISO, ASTM) can further influence costs.

-

Logistics: Transportation and shipping costs can vary widely based on distance, shipping method, and Incoterms. Understanding the logistics involved in sourcing from different regions is vital, as it directly affects the total landed cost.

-

Margin: Supplier margins can vary based on market positioning, competition, and service offerings. It is essential for buyers to assess the value proposition offered by suppliers beyond just price.

Price Influencers

-

Volume/MOQ: The minimum order quantity (MOQ) can significantly influence pricing. Larger volumes typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to optimize pricing.

-

Specifications/Customization: Custom designs or specific material requirements can increase costs. Buyers should clearly define specifications to avoid unexpected price increases.

-

Material Quality/Certifications: Higher quality materials or specialized certifications can lead to increased costs. Buyers should assess whether the benefits justify the additional expense.

-

Supplier Factors: Supplier reputation, reliability, and service levels can influence pricing. Long-term partnerships may yield better terms and pricing stability.

-

Incoterms: Understanding the implications of Incoterms on shipping responsibilities and costs is crucial for accurate budgeting. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect total costs.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing and terms. Leverage potential future business to negotiate better rates, especially if you can commit to larger volumes.

-

Cost-Efficiency: Conduct a total cost of ownership (TCO) analysis that includes all cost components, not just the initial price. This approach will help identify the most cost-effective suppliers.

-

Pricing Nuances for International Buyers: When sourcing from different regions, be aware of currency fluctuations, trade tariffs, and import duties that could affect overall costs. Buyers should factor in these elements into their cost calculations.

-

Research and Benchmarking: Gather market intelligence to benchmark prices and services across different suppliers. This will provide leverage in negotiations and help identify competitive pricing.

Disclaimer

Pricing for polyurethane injection molding can fluctuate based on market conditions, supplier capabilities, and specific project requirements. Buyers should obtain detailed quotes and consider all cost components before making sourcing decisions.

Spotlight on Potential polyurethane injection molding Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘polyurethane injection molding’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for polyurethane injection molding

Key Technical Properties in Polyurethane Injection Molding

Understanding the essential technical properties of polyurethane injection molding is crucial for B2B buyers to make informed decisions. Here are several critical specifications to consider:

-

Material Grade

– Material grades specify the quality and performance characteristics of polyurethane used in the injection molding process. Common grades include thermoplastic polyurethane (TPU) and thermosetting polyurethane. Selecting the right grade is vital for meeting specific application requirements, such as durability, flexibility, and resistance to environmental factors. -

Tolerance

– Tolerance refers to the allowable variation in dimensions during manufacturing. In polyurethane injection molding, tight tolerances (e.g., ±0.1 mm) are often essential for components that must fit precisely in assemblies. Understanding tolerance requirements helps ensure product compatibility and reduces the risk of costly rework or waste. -

Hardness

– Measured on the Shore durometer scale, hardness indicates the material’s resistance to indentation. Polyurethanes can range from soft, flexible materials (Shore A) to rigid, hard materials (Shore D). Buyers should choose hardness levels that align with the end-use application, as this affects performance characteristics like wear resistance and flexibility. -

Viscosity

– Viscosity is the measure of a fluid’s resistance to flow. In injection molding, the viscosity of the polyurethane material impacts the ease of processing and the quality of the final product. Lower viscosity materials can fill molds more easily, reducing defects and ensuring uniformity in complex shapes. -

Chemical Resistance

– This property determines how well polyurethane can withstand exposure to various chemicals. For industries like automotive or medical, where parts may encounter oils, solvents, or cleaning agents, understanding chemical resistance is vital to ensure product longevity and performance. -

Thermal Stability

– Thermal stability indicates how well a material can maintain its properties under varying temperature conditions. This is especially important for applications that involve exposure to heat or cold. Buyers should ensure the selected polyurethane can withstand the thermal conditions of its intended environment.

Common Trade Terminology

Familiarity with industry jargon is essential for effective communication and negotiation. Here are several key terms relevant to polyurethane injection molding:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of polyurethane injection molding, understanding the role of OEMs can help buyers identify reliable suppliers who can meet specific production needs. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This is a critical consideration for international buyers, as it can affect inventory management and cost efficiency. Knowing the MOQ can help buyers plan their orders to meet production demands without overcommitting. -

RFQ (Request for Quotation)

– An RFQ is a document used to invite suppliers to bid on specific products or services. It typically includes detailed specifications and quantities. For B2B buyers, issuing RFQs can streamline the procurement process and facilitate comparison of supplier offerings. -

Incoterms (International Commercial Terms)

– Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for managing logistics and shipping costs effectively. Common Incoterms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). -

Lead Time

– Lead time is the amount of time between the initiation of a process and its completion. In injection molding, this includes the time required for tooling, production, and delivery. Buyers should assess lead times when planning projects to ensure timely availability of components. -

Injection Cycle Time

– This term refers to the time it takes to complete one cycle of the injection molding process, from injection to cooling and ejection of the molded part. Understanding cycle times can help buyers estimate production efficiency and plan their manufacturing schedules accordingly.

By grasping these technical properties and trade terms, B2B buyers can enhance their purchasing strategies, ensuring they select the right materials and suppliers for their polyurethane injection molding needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the polyurethane injection molding Sector

Market Overview & Key Trends

The global polyurethane injection molding market is experiencing robust growth driven by various factors, including rising demand across sectors such as automotive, construction, and consumer goods. Technological advancements in injection molding processes, such as Reaction Injection Molding (RIM) and Long Fiber Injection (LFI), are enhancing production efficiency and product quality. These technologies enable manufacturers to produce complex geometries with lightweight and durable materials, making them ideal for applications requiring high performance.

Emerging trends in B2B sourcing are significantly influenced by digital transformation. The adoption of Industry 4.0 technologies, including IoT and AI, is optimizing supply chain management, enabling real-time tracking, predictive maintenance, and enhanced decision-making. B2B buyers in regions like Africa and South America should leverage these technologies to streamline procurement processes and reduce lead times.

Additionally, sustainability is becoming a critical consideration for international buyers. The increasing regulatory pressure and consumer demand for eco-friendly products are driving manufacturers to explore bio-based polyurethanes and recyclable materials. This shift not only aligns with global sustainability goals but also opens new market opportunities for buyers prioritizing environmentally responsible sourcing.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

The environmental impact of polyurethane production, particularly in terms of carbon emissions and resource consumption, is prompting a shift towards sustainable practices within the industry. B2B buyers must prioritize suppliers that demonstrate a commitment to ethical sourcing and sustainable manufacturing processes. This includes assessing the lifecycle of materials, energy consumption during production, and waste management practices.

Green certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) can serve as benchmarks for evaluating potential suppliers. Furthermore, the use of recycled or bio-based polyurethanes can significantly reduce the environmental footprint of products. Buyers are encouraged to establish partnerships with manufacturers that invest in sustainable technologies and practices, as this not only enhances their corporate social responsibility profile but also positions them favorably in a market that increasingly values sustainability.

Brief Evolution/History

The polyurethane injection molding industry has evolved significantly since its inception in the mid-20th century. Initially dominated by traditional plastics, the introduction of polyurethane materials revolutionized manufacturing due to their versatility, durability, and lightweight properties.

The development of advanced molding techniques, such as RIM and TPU injection molding, has further expanded the application scope of polyurethanes, making them integral to industries ranging from automotive to healthcare. Today, the focus is shifting towards integrating sustainability and technology into production processes, reflecting broader market trends that prioritize environmental responsibility and innovation.

This evolution underscores the importance for international B2B buyers to stay informed about industry advancements and sustainability practices, ensuring that their sourcing strategies align with both market demands and ethical standards.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane injection molding

-

How do I vet suppliers for polyurethane injection molding?

When vetting suppliers, focus on their experience, certifications, and past projects. Request samples of previous work to assess quality and ensure they align with your specifications. It’s also beneficial to check references and customer testimonials. Utilize platforms like Alibaba or ThomasNet for supplier ratings and reviews. Additionally, consider their production capabilities and technology used, ensuring they can meet your specific needs in terms of volume and complexity. -

Can suppliers customize polyurethane products to meet my specifications?

Yes, most reputable suppliers can customize polyurethane products based on your requirements. Communicate your specifications clearly, including dimensions, hardness, color, and application. Discussing design modifications early in the process can prevent misunderstandings later. Ensure the supplier has experience in the specific type of customization you need, as this will enhance the likelihood of achieving the desired outcome. -

What are the typical minimum order quantities (MOQs) and lead times?

Minimum order quantities (MOQs) vary by supplier, but they typically range from 500 to 5,000 units depending on the product complexity and material costs. Lead times also differ, often spanning from 4 to 12 weeks. For international buyers, consider potential delays due to customs or shipping. It’s advisable to negotiate MOQs and lead times upfront to align with your production schedule and inventory needs. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary significantly between suppliers. Common methods include advance payment, letter of credit, or payment upon delivery. For international transactions, be cautious of currency fluctuations and transaction fees. Negotiate terms that provide security for both parties; for instance, consider a 30% deposit with the balance due upon shipment. Ensure that all payment agreements are documented to avoid disputes later. -

What quality assurance processes should suppliers have in place?

A reliable supplier should implement stringent quality assurance (QA) processes throughout production. Ask about their QA certifications, such as ISO 9001, and their testing methods for finished products. Regular audits and inspections should be part of their process. Inquire about their ability to provide documentation, such as certificates of compliance or test reports, to ensure the products meet your standards.

Illustrative Image (Source: Google Search)

-

How do logistics and shipping work for international orders?

Logistics for international orders involve multiple steps, including customs clearance, freight forwarding, and local delivery. Work with suppliers who have experience in international shipping and can assist with documentation and compliance. It’s crucial to discuss shipping terms upfront—Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact costs and responsibilities. Consider potential tariffs or duties that may apply in your country. -

What should I do if there’s a dispute with a supplier?

In case of a dispute, the first step is to communicate directly with the supplier to resolve the issue amicably. Document all interactions and agreements to provide clarity. If direct negotiations fail, refer to the contract for dispute resolution clauses, which may include mediation or arbitration. It’s advisable to have a legal expert familiar with international trade laws to guide you through the process and protect your interests. -

What certifications should I look for in polyurethane injection molded products?

Certifications can vary based on industry and application, but common ones include ISO 9001 for quality management and ISO 14001 for environmental management. For specific applications, such as automotive or medical, look for compliance with industry standards like ASTM or FDA approvals. Request documentation from suppliers to verify these certifications, ensuring that the products meet the necessary safety and quality standards required in your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for polyurethane injection molding

In the rapidly evolving landscape of polyurethane injection molding, strategic sourcing has emerged as a critical factor for international B2B buyers. By leveraging the unique properties of polyurethane materials, businesses can achieve superior product performance, cost efficiency, and market differentiation. It is imperative for buyers to engage with suppliers who demonstrate a commitment to quality, innovation, and sustainability, particularly in regions such as Africa, South America, the Middle East, and Europe.

Key Takeaways:

– Prioritize Supplier Relationships: Establishing strong partnerships with manufacturers can lead to improved supply chain resilience and access to advanced technologies.

– Invest in R&D: Collaborating with suppliers on research and development can yield tailored solutions that meet specific industry demands.

– Focus on Sustainability: As global markets shift towards environmentally friendly practices, sourcing sustainable materials will not only enhance brand reputation but also comply with regulatory standards.

Looking ahead, the demand for polyurethane injection molding is set to rise, driven by advancements in materials technology and manufacturing processes. B2B buyers are encouraged to stay ahead of the curve by exploring innovative applications and forming strategic alliances that will drive growth in this dynamic sector. Embrace the potential of polyurethane injection molding to elevate your product offerings and strengthen your competitive edge in the global marketplace.